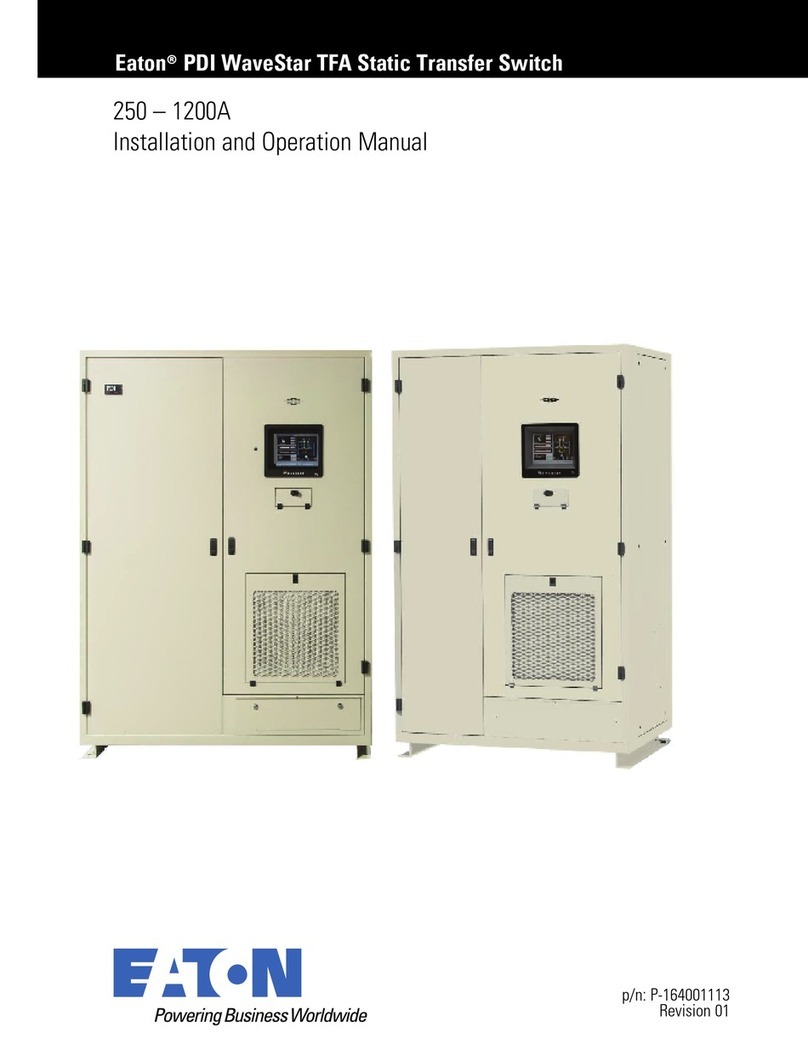

1.0 INTRODUCTION

Throughout this manual there are a number

of HAZARD WARNINGS that must be read

and adhered to in order to prevent possible

personal injury and/or damage to the equipment.

Three signal words "DANGER", "WARNING",

and "CAUTION" are used to indicate the

severity of the hazard, and are preceded by

the safety alert symbol .

Denotes the most serious hazard,

and is used when serious injury or

death WILL result from misuse or

failure to follow specific instructions.

When serious injury or death

MAY result from misuse or failure to

follow specific instructions.

When injury or product/equipment

damage may result from misuse or

failure to follow specific instructions.

It is the responsibility and the duty of all

personnel involved in the installation, opera-

tion and maintenance of the equiment on

which this device is used to fully understand

the , and

procedures by which hazards are to be

avoided.

1.1 Description

1.1.1 The Airflex Model DBB brakes were

designed for heavy duty industrial

applications where spring set (power off)

braking is required.

1.1.2 All Airflex DBB brakes are supplied with long

wearing, NON-ASBESTOS friction material.

1.1.3 The spring housing (16) piston and cylinder

(19) are Nituff®coated, which is Teflon pene-

trated hard coat anodizing. The friction disc

assembly (101) is made out of steel and is

specially nitrided with a quench-polish-

quench system. The release springs (34) are

made from stainless steel and have flexible

polyurethane coating. The exposed cast sur-

faces are painted with multiple coats of

corrosion resistant paint. Bronze bushings

are provided in the reaction plate and pres-

sure plates to facilitate axial movement. The

clamp tubes (12) are made from aluminum-

bronze which provides high resistance to

wear and corrosion.

1.1.4 The rugged construction ensures long,

trouble free service. The corrosion protection

provided with these units will help prevent

premature failure when using in marine

environments. The iron components are

painted with a marine,two coat, epoxy coat-

ing. All other components are either coated

or manufactured with corrosion resistant

alloys.

1.2 How it Works

1.2.1 Referring to Figure 1, the gear (28) is

mounted on the shaft which is to be stopped

and the brake assembly is attached to the

machine frame or a reaction bracket. As air

pressure is applied through the ports in the

cylinder (19), the cylinder and pressure plate

(13), which are attached to each other with

screws (20), flat washers (17) and spacer

tubes (27), move away from the mounting

flange (1), which is connected to the

machine frame or reaction bracket. The

pressure plate compresses the springs (22)

against the stationary spring housing (16)

and the clamp force is removed from the

friction disc assembly (7) which rides on the

gear. The shaft is then free to rotate. As air

pressure is exhausted, the springs force the

pressure plate toward the mounting flange,

clamping the friction disc assembly between

the two members. On dual disc models, an

additional friction disc assembly and a

reaction plate (30) are clamped between the

pressure plate and mounting flange.

DBB8104 PDFformat 2© Copyright Eaton Corp., 1998. All rights reserved.

(Revised:January,1998)