Bilanciai 813775 User manual

MANUAL CODE:

813775

CLIENT

YEAR OF MANUFACTURE:

2023

WEIGHING PLATFORM

PMA

USE AND WARNING

INSTRUCTIONS

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

EDITION: 08/2023 - REVISION: 01

2

WEIGHING PLATFORM –PMA

INTRODUCTION

All rights reserved.

No part of this publication may be reproduced, distributed, translated into other languages, or

transmitted by any electronic or mechanical means, including photocopying, recording, or any other

storage and retrieval systems, for purposes other than the User’s exclusive personal use, without the

Manufacturer’s express written approval.

PUBLISHER’S NOTE

This documentation is intended for trained technicians.

Some information easily deduced from reading the texts and examining the drawings may not be further

specified.

The Publisher is not responsible for the information and data in this manual.

All information contained in this manual is provided, checked and approved through verification by the

Manufacturer. Campogalliano (MO) - 41011 - Via S.Ferrari, 16

Tel. +39 059.893611

info@coopbilanciai.it - www.coopbilanciai.com

GENERAL REMARKS

All instructions described in this manual must be observed.

The Manufacturer recommends regular maintenance operations to keep the machine in top condition.

Closely train the personnel responsible for the machine's operations, both for its use and for maintenance

and monitoring of compliance with the operating procedures and all the safety rules indicated in this

manual.

INFORMATION

The manufacturer is not liable for damage to property or persons caused by failure to

comply with the instructions in this manual.

COPYRIGHT

© 2023 Soc. Coop. Bilanciai Campogalliano

3

Use and warning manual

CONTENTS

1. IDENTIFICATION................................................................................................5

1.1 MANUFACTURER IDENTIFICATION ............................................................................................................... 5

1.2 MACHINE IDENTIFICATION.............................................................................................................................. 5

1.3 IDENTIFICATION PLATE..................................................................................................................................... 6

1.4 CONTENT OF THE EU DECLARATION OF CONFORMITY...................................................................... 8

1.5 REFERENCE DIRECTIVES.................................................................................................................................... 9

2. PRELIMINARY INFORMATION .......................................................................10

2.1 RECIPIENTS...........................................................................................................................................................10

2.2 SUPPLY AND STORAGE....................................................................................................................................10

2.3 UPDATES ...............................................................................................................................................................10

2.4 LANGUAGE...........................................................................................................................................................10

2.5 GLOSSARY ............................................................................................................................................................ 11

2.6 OPERATOR QUALIFICATIONS........................................................................................................................13

2.7 SAFETY MESSAGES USED WITHIN THE MANUAL....................................................................................15

2.8 PERSONAL PROTECTIVE EQUIPMENT.........................................................................................................16

2.9 WARRANTY ..........................................................................................................................................................17

3. SAFETY DEVICES ...........................................................................................18

3.1 NOISE .....................................................................................................................................................................18

3.2 VIBRATIONS .........................................................................................................................................................18

3.3 ELECTROMAGNETIC COMPATIBILITY..........................................................................................................18

3.4 RESIDUAL RISKS ..................................................................................................................................................19

4. INSTRUMENT DESCRIPTION.........................................................................20

4.1 INTENDED USE...................................................................................................................................................20

4.2 REASONABLY FORESEEABLE MISUSE.........................................................................................................20

4.3 OBLIGATIONS AND PROHIBITIONS .............................................................................................................21

4.3.1 USERS’ OBLIGATIONS 21

4.3.2 OBLIGATIONS OF OPERATING PERSONNEL (OPERATORS / MAINTENANCE PERSONNEL /

TECHNICIANS) 21

4.3.3 PROHIBITIONS OF OPERATING PERSONNEL (OPERATORS/MAINTENANCE/TECHNICIANS)

22

4.4 TECHNICAL DATA .............................................................................................................................................23

4

WEIGHING PLATFORM –PMA

4.4.1 OVERALL DIMENSIONS 24

4.5 MAIN COMPONENTS ......................................................................................................................................27

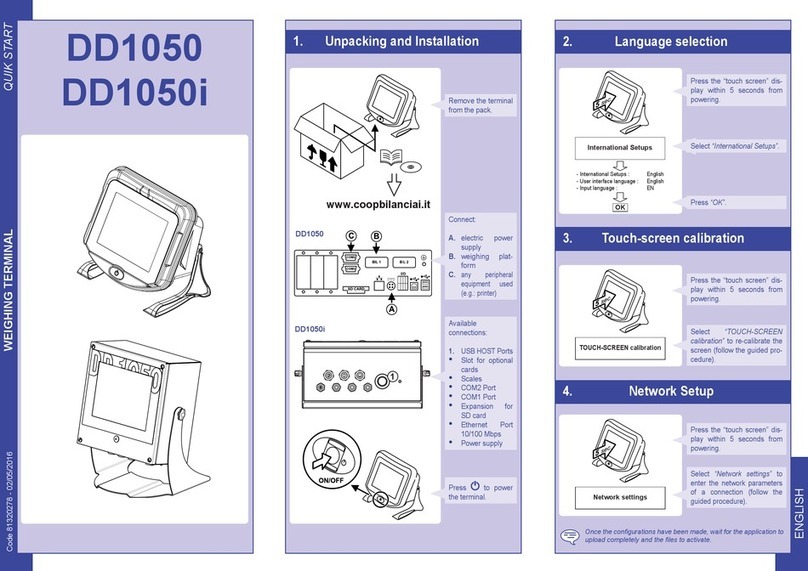

4.6 INSTRUMENT DESCRIPTION..........................................................................................................................29

4.7WORK PROCESS DESCRIPTION....................................................................................................................30

4.8 OPTIONAL ACCESSORIES...............................................................................................................................30

5. TRANSPORT AND COMMISSIONING ............................................................32

5.1 PACKAGING ........................................................................................................................................................32

5.1.1 UNIT AND WEIGHT DIVISION TABLE 32

5.1.2 PACKAGING REMOVAL 33

5.2 TRANSPORT AND HANDLING ......................................................................................................................34

5.2.1 LIFTING AND HANDLING OPERATIONS 34

5.3 INSTALLATION AND COMMISSIONING.....................................................................................................36

5.3.1 SET-UPS TO BE PROVIDED BY THE CUSTOMER 36

5.3.2 PERMITTED ENVIRONMENTAL CONDITIONS 36

5.3.3 INSTALLATION PLACE 37

5.3.4 INSTALLATION AND LEVELLING 37

5.4 CONNECTIONS..................................................................................................................................................43

5.4.1 ELECTRICAL CONNECTION 43

6. CONTROLS AND USE .....................................................................................45

6.1 OPERATIONAL PROCEDURES .......................................................................................................................46

6.1.1 PRELIMINARY CHECKS 46

6.1.2 WORK PROCEDURE 46

6.1.3 SWITCHING OFF THE INSTRUMENT 46

7. MAINTENANCE ................................................................................................47

7.1 PLACING THE INSTRUMENT IN MAINTENANCE MODE.......................................................................49

7.2 ROUTINE MAINTENANCE...............................................................................................................................50

7.2.1 CLEANING 51

7.3 EXTRAORDINARY MAINTENANCE...............................................................................................................52

8. DECOMMISSIONING AND DISPOSAL ...........................................................53

8.1 DECOMMISSIONING ........................................................................................................................................53

8.2 DISPOSAL.............................................................................................................................................................54

9. ANNEXES .........................................................................................................55

9.1 LIST OF ANNEXES..............................................................................................................................................55

5

Use and warning manual

1.IDENTIFICATION

1.1 MANUFACTURER IDENTIFICATION

MANUFACTURER

Soc. Coop. Bilanciai Campogalliano

ADDRESS

Via S. Ferrari 16 - 41011 Campogalliano (MO)

Italy

CONTACTS

Tel. +39 059 893611

Fax +39 059 527079

info@coopbilanciai.it

www.coopbilanciai.com

1.2 MACHINE IDENTIFICATION

NAME

WEIGHING PLATFORM

MODEL

PMA

SERIAL NUMBER

YEAR OF MANUFACTURE

2023

6

WEIGHING PLATFORM –PMA

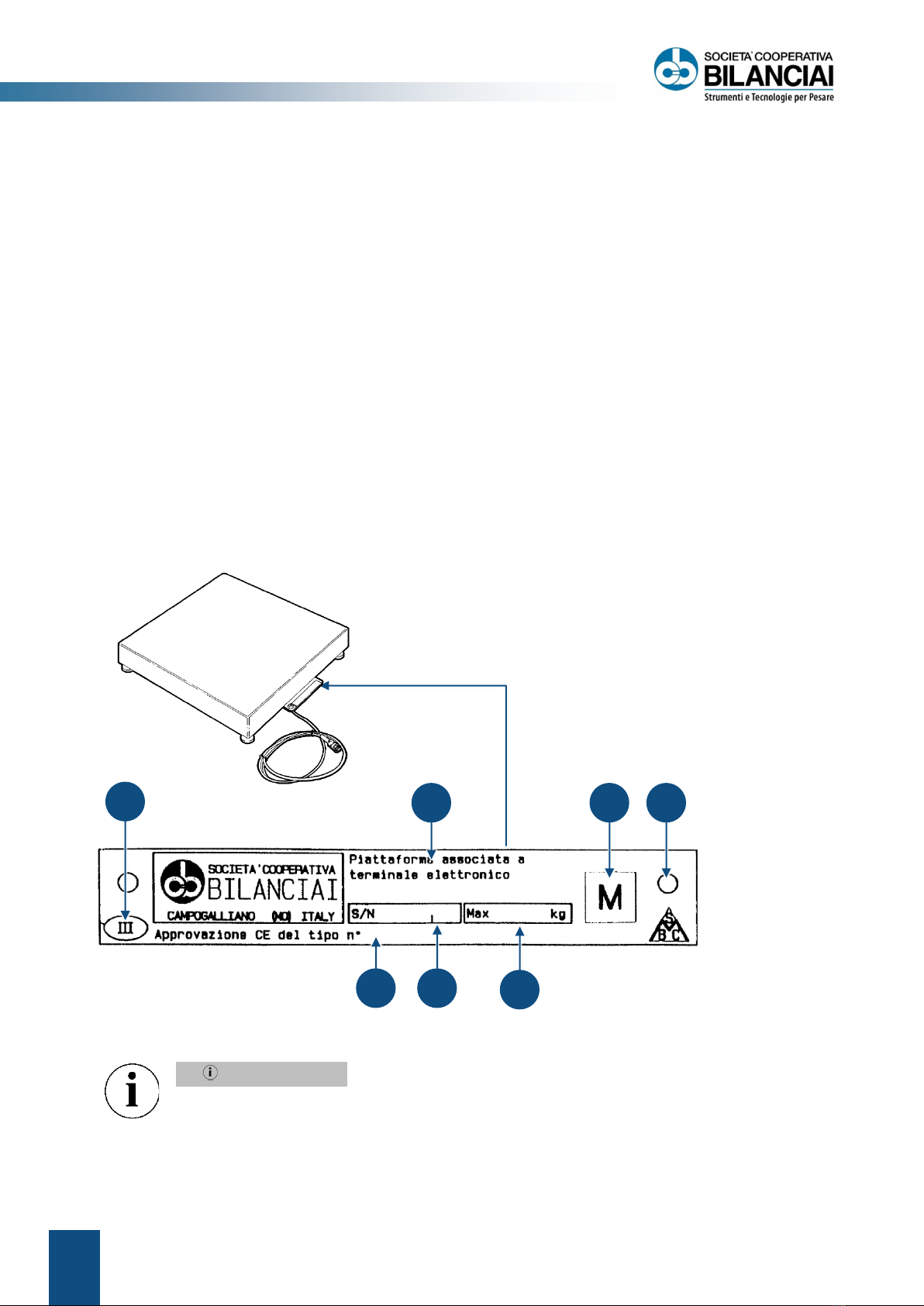

1.3 IDENTIFICATION PLATE

The instrument is equipped with an identification plate.

The identification plate is positioned as shown in the figure below.

The instrument's identification details can be found on the identification plate.

1. Instrument precision class.

2. Model of the terminal associated with the platform.

3. Serial number (S/N).

4. Maximum capacity or full scale of the instrument.

5. CE approval certificate number.

6. Marking of conformity M (where applicable):

M on green background = instrument subject to metrological control.

No marking = instrument not subject to metrological control.

7. Stamps or labels.

INFORMATION

Do not remove the identification plate or replace it with other plates.

The customer must inform the manufacturer if the plate is damaged or removed, for

accidental reasons.

1

2

6

7

4

3

5

7

Use and warning manual

8

WEIGHING PLATFORM –PMA

1.4 CONTENT OF THE EU DECLARATION OF CONFORMITY

9

Use and warning manual

1.5 REFERENCE DIRECTIVES

The instrument supplied by the manufacturer complies with Directive 2014/31/EU EEC.

The manufacturer places the instrument on the market with:

CE Marking

EU Declaration of Conformity

Document drawn up according to point 1-A of annex II of the

"Machinery Directive" 2006/42/EC

Instruction manual

Documentation drawn up as provided for in point 1.7.4 of the

“Machinery Directive” 2006/42/EC

The machine is designed according to the following Directives:

2014/31/EU

Non-automatic weighing instruments directive

2014/30/EU

Electromagnetic Compatibility Directive

2014/35/EU

Low Voltage Directive

The machine is designed according to the following Harmonised standards:

EN45501:2015

Metrological aspects of non-automatic weighing instruments

EN 60950-1:2006

Information Technology Equipment

EN 61000-6-3:2007

Generic standards - Emission for Residential, Commercial and

Light Industrial

EN 61000-6-4:2007

Emission for industrial environments.

10

WEIGHING PLATFORM –PMA

2. PRELIMINARY INFORMATION

2.1 RECIPIENTS

The manual is intended for operators in charge of using and managing the instrument throughout

its service life.

The manual contains topics that refer to the correct and safe use of the instrument.

The manual is an integral part of the instrument and must accompany it whenever it is relocated or resold.

The user must keep the manual intact for reference throughout the life of the instrument.

2.2 SUPPLY AND STORAGE

The manual is provided in both hard and soft copies.

Additional documentation is provided as an annex to this manual.

The annexed additional documentation is an integral part of this manual.

The same recommendations/prescriptions as in this manual apply to the annexed additional

documentation.

The manual must be kept with the instrument for easy reference by the operator.

The manual is an integral part for safety purposes and must therefore:

•Be kept intact. A copy of the manual should be requested immediately if it is lost or damaged.

•Follow the machine until demolition even in the case of transfer, sale, leasing, rental, etc...

2.3 UPDATES

The Manufacturer is responsible for revising and updating the manual if the instrument requires functional

modifications or replacements.

The Manufacturer is responsible for delivering the updated manual to the User.

The User must only provide up-to-date versions of the manual at the point of use of the instrument.

2.4 LANGUAGE

The instrument's original instructions are written in Italian.

Any translations into additional languages shall be done from the original instructions.

11

Use and warning manual

2.5 GLOSSARY

The following table explains the terms and abbreviations used in this manual:

TERM

DEFINITION

ATEX

Derived from the words ATmosphèresand EXplosibles.

This is the conventional name for two European Union (EU) directives:

•2014/34/EU for the regulation of equipment intended for use in

hazardous areas.

•99/92/EC for the safety and health of workers in explosive

atmospheres or potentially explosive environments.

FAILURE

Fault of various kinds preventing the normal operation of a machine, plant,

etc.....

DAMAGE

Any negative consequence resulting from the occurrence of the

hazardous event.

P.P.E.

The term Personal Protective Equipment (PPE) means any piece of

equipment designed to be worn and held by the worker so as to protect

him or her against one or more risks liable to be a threat to the safety or

health during work, as well as any additional item or accessory designed

for that purpose.

FAULT

Element totally deprived of the normal possibilities of performing a

required function.

INSTRUMENT

Complete measuring chain (platform + electronic terminal).

MALFUNCTION

Faulty or inadequate functioning of a machine or its element in performing

a certain function.

PROTECTIVE

MEASURE

Measure intended to achieve risk reduction, implemented:

•By the design engineer (intrinsically safe design, additional

protections and protective measures, information for use).

•By the user (organisation: safe work procedures, supervision, work

permits; provision and use of additional means of protection; use of

personal protective equipment; training).

HAZARD

Potential source of harm that, if not avoided, poses a risk to the safety and

health of exposed persons.

EXPOSED PERSON

Any person wholly or partially in a danger zone.

PREVENTION

The set of provisions or measures that are also necessary according to the

particular nature of the work, experience and technique, in order to avoid

risks or reduce the probability of their occurrence.

12

WEIGHING PLATFORM –PMA

TERM

DEFINITION

PROTECTION

Defence against what could cause harm. Element that interposes itself

between who may suffer harm and what may cause it due to hazards that

cannot be reasonably eliminated or risks that cannot be sufficiently

reduced during design.

We distinguish between:

•The active protection that the operators themselves must activate

(emergency stops for example) and/or wear (PPE).

•Passive protection that intervenes even without human command.

GUARD

Physical barrier designed as part of the machine to provide protection.

FIXED GUARD

A guard held in place (i.e. closed) either permanently (welded) or by

fastening systems (screws, bolts, etc.) that make it impossible to

remove/open without the use of tools (spanners, screwdrivers or Allen

keys). Easy-to-remove fastening systems (e.g. plastic knobs) are not

permitted.

MOBILE GUARD

A guard mechanically connected to the machine structure (e.g. with

hinges or guides) that can be opened without the use of tools.

RISK

Combination of the probability of an injury occurring and the severity of

that injury.

RESIDUAL RISK

Risk that remains after protective and preventive measures have been

taken.

INTENDED USE

Using a machine in accordance with the information provided in the

instruction manual.

REASONABLY

FORESEEABLE MISUSE

Using a machine in a way not foreseen by the design engineer, but which

may result from easily predictable human behaviour.

CONNECTOR

Plug or socket for connecting the terminal to the external equipment.

DIVISION

Appreciable minimum weight variation.

FULL SCALE

This is the maximum weighing capacity of the instrument, which does not

necessarily coincide with the max. structural capacity of the weighing

platform.

IP..

This indicates the protection rating for casings and enclosures containing

electrical or electronic components.

Penetration of solid foreign bodies (the first digit) and penetration of

liquids (the second digit).

13

Use and warning manual

2.6 OPERATOR QUALIFICATIONS

The table below shows the skills and qualifications of the operators assigned to the various tasks:

JOB DESCRIPTION

DEFINITION

OPERATOR

User personnel, trained and able to:

•Use the tool for production purposes, for the activities for which it was

built and supplied.

•Perform all the operations necessary for the efficient operation of the

machine and for their own safety or that of any collaborators.

If in doubt, the operator must report any anomaly to his/her superior.

NOTE: The operator is not allowed to perform any maintenance.

MANUFACTURER'S

TECHNICIAN

Technician qualified by the manufacturer and/or its distributor for complex

operations, because aware of the production cycle of the instrument.

This person intervenes in accordance with the user’s requests.

His/Her skills are mechanical.

CONDUCTOR OF

LIFTING EQUIPMENT

Qualified technician able to safely drive and manoeuvre lifting equipment

and handle loads lifted with it.

MECHANICAL

MAINTENANCE

TECHNICIAN

Qualified technician capable of:

•Carrying out preventive/corrective maintenance on all mechanical

parts of the instrument subject to maintenance or repair.

•Accessing all parts of the instrument for visual analysis, status checks,

adjustments and calibrations.

•Using the instrument like the operator.

•Working on mechanical parts for adjustments, maintenance and

repairs.

•Reading pneumatic, hydraulic and hydraulic diagrams, technical

drawings and parts lists.

•Operating the instrument with reduced safeties (only when strictly

necessary).

•Giving the operator instructions on how to use the tool properly for

production purposes.

NOTE: The mechanical maintenance technician is not qualified to work on

live electrical installations.

14

WEIGHING PLATFORM –PMA

JOB DESCRIPTION

DEFINITION

ELECTRICAL

MAINTENANCE

TECHNICIAN

Qualified technician capable of:

•Carrying out preventive/corrective maintenance on all electrical parts

of the instrument subject to maintenance or repair.

•Operating in the presence of voltage inside electrical panels, junction

boxes, control equipment etc. (only if he/she is a qualified person -

PEI).

•Accessing all parts of the instrument for visual analysis, status checks,

adjustments and calibrations.

•Using the instrument like the operator.

•Working on adjustments and electrical systems for maintenance,

repair and replacement of worn parts.

•Reading circuit diagrams and verifying the correct functional cycle.

•Giving the operator instructions on how to use the tool properly for

production purposes.

NOTE: The electrical maintenance technician does not perform software

programming of systems such as PLCs (logic or safety) and cannot change

system passwords.

The qualifications shown in the table on this page necessarily fall within the “trained person” category.

JOB DESCRIPTION

DEFINITION

Trained person

A person who has been informed, instructed and trained in the job, and is

acquainted with any dangers resulting from misuse.

The person is also aware of the importance of safety devices, accident-

prevention regulations and safe working conditions.

15

Use and warning manual

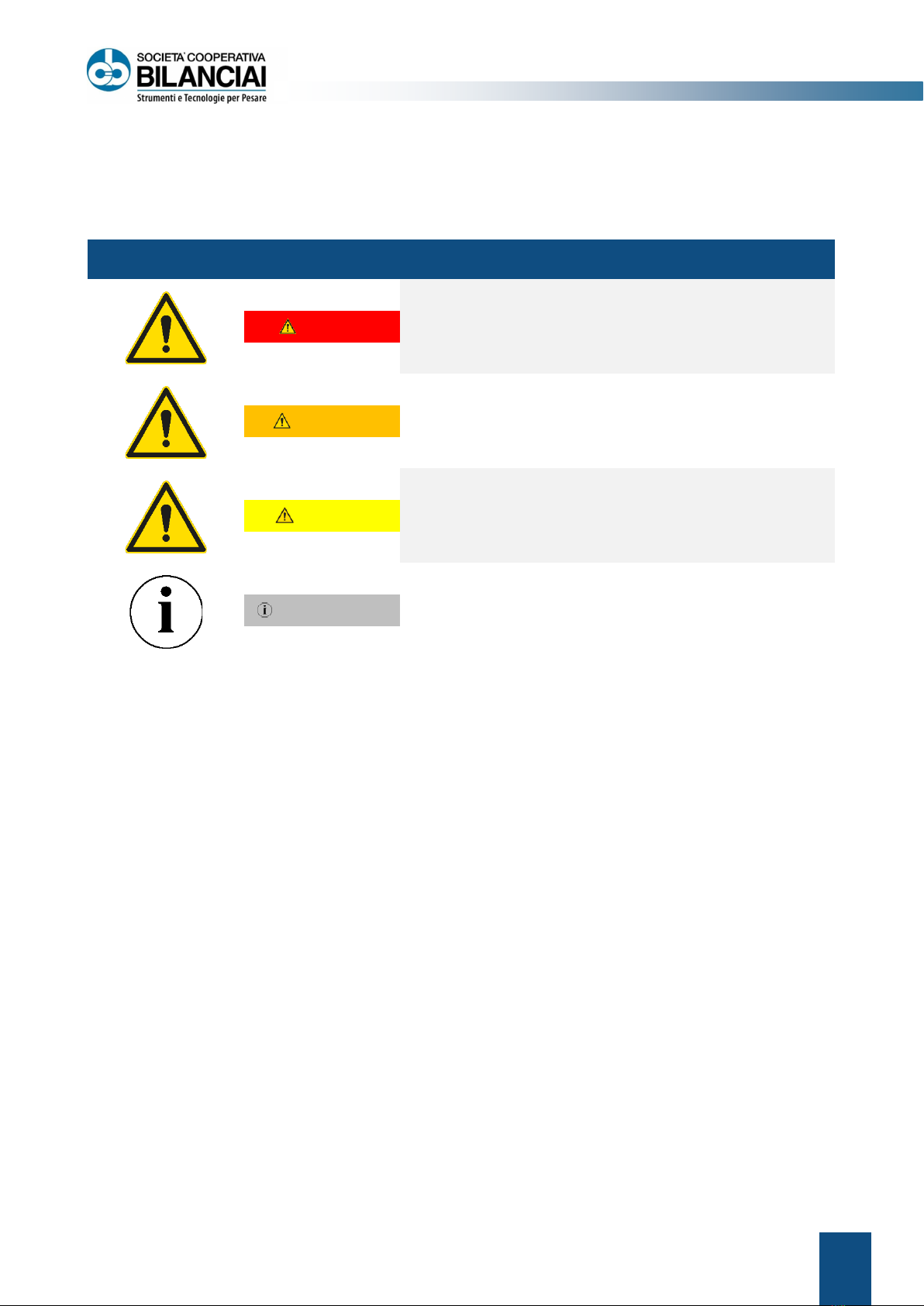

2.7 SAFETY MESSAGES USED WITHIN THE MANUAL

Safety messages in the manual are used to emphasise important information.

The following table describes the safety messages used:

SYMBOL

MESSAGE

DEFINITION

Instruction referring to an imminently hazardous situation

which, if not avoided, will cause instantaneous death or

serious or permanent damage to health.

DANGER

Instruction referring to a potentially hazardous situation

which, if not avoided, may result in death or serious harm

to health.

WARNING

Instruction referring to a potentially risky situation which, if

not avoided, could cause minor damage relating to the

safety of a machine.

CAUTION

Instruction referring to adopting the conduct necessary to

deal with practices not related to physical injury.

INFORMATION

16

WEIGHING PLATFORM –PMA

2.8 PERSONAL PROTECTIVE EQUIPMENT

Personnel working near the instrument must comply with the general accident prevention regulations

and use the personal protective equipment (PPE) required for each individual operation.

The following table shows the P.P.E. that may be required for the different procedures:

SYMBOL

DESCRIPTION

Duty to use protective or insulating gloves.

Duty to wear safety glasses.

Duty to wear safety shoes.

Duty to wear protective clothing.

Duty to wear a protective helmet.

The clothing of personnel authorised to work with the instrument must comply with the essential safety

requirements defined by EU Reg. 2016/425 and the laws in force in the country where the instrument is

installed and used.

17

Use and warning manual

2.9 WARRANTY

INFORMATION

The full warranty clauses are incorporated in the sales contract.

Contact the Manufacturer for warranty information if in doubt.

18

WEIGHING PLATFORM –PMA

3. SAFETY DEVICES

3.1 NOISE

The noise exposure level of personnel is less than 80 dB, during the instrument's operating cycles.

The actual noise level of the instrument during operation at the site of use is different from the measured

value.

The noise level is influenced by:

•Type and characteristics of the site of use.

•Other adjacent running machines.

INFORMATION

The User must apply preventive and protective measures in relation to noise, in

accordance with the legislation of the country where the instrument is installed and

used.

3.2 VIBRATIONS

The vibrations produced by the instrument are not hazardous to the health of the operators.

CAUTION

Excessive vibration can only be caused by a mechanical fault, which must be reported

and rectified immediately, so as not to jeopardise the safety of the instrument and

the operators.

3.3 ELECTROMAGNETIC COMPATIBILITY

The supplied instrument contains electronic components that are affected by conducted and radiated

emissions and subject to Electromagnetic Compatibility regulations.

Emission values are within regulatory requirements through the use of:

•Components complying with the Electromagnetic Compatibility Directive.

•Suitable connections.

•Filters where needed.

Therefore, the machine complies with the Electromagnetic Compatibility Directive (EMC).

INFORMATION

The efficiency of the solutions adopted on the instrument may be compromised in

case of improperly performed maintenance or replacement of electrical parts.

19

Use and warning manual

3.4 RESIDUAL RISKS

The instrument is designed to ensure the essential safety requirements for the operator.

Safety was integrated into the design and construction of the instrument as far as possible.

However, there are still risks that operators must be protected from, especially when during:

•Transport and installation.

•Normal operation.

•Adjustment and fine-tuning.

•Maintenance and cleaning.

•Disassembly and dismantling.

The following table describes the residual risks when working with the instrument:

RISK

DESCRIPTION AND RISK REDUCTION MEASURES

RISK OF DUST

INHALATION

Dust inhalation, which can occur when cleaning the machine.

The user shall:

•Analyse the risks that could occur during handling and installation. The analyses made on the

handling of the instrument and its components were carried out only in view of the characteristics

of the instrument.

•Raise awareness and train personnel using the instrument on the risks arising from the

workplace.

20

WEIGHING PLATFORM –PMA

4. INSTRUMENT DESCRIPTION

4.1 INTENDED USE

The instrument is designed to be used for the following purposes:

OPERATION

ALLOWED

NOT ALLOWED

ENVIRONMENT OF

USE

Non-automatic

weighing of:

Pallets with features

listed under Technical

Data.

Any other use and/or

product other than

permitted.

Industrial

The tool is created to:

•meet the specific needs mentioned in the sales contract.

•be used according to the instructions and limits of use given in this manual.

The instrument is designed and built to work safely if:

•It is used within the limits stated in the contract and in this manual.

•The procedures in this instruction manual are followed.

•Routine maintenance is performed as recommended.

•Extraordinary maintenance is promptly performed in case of need.

•Safety devices are used correctly.

INFORMATION

Any other use is only allowed if expressly authorised by the Manufacturer.

4.2 REASONABLY FORESEEABLE MISUSE

Reasonably foreseeable misuse is listed below:

•Using the machine to obtain production values higher than the prescribed limits.

•Using the instrument as a support point.

•Using transport and handling systems other than those indicated in this manual.

•Using the instrument if it has not been installed in accordance with this manual.

•Using the machine other than as envisaged under “Intended use”.

Any use of the instrument other than intended is to be considered improper use and must be authorised

in advance in writing by the manufacturer.

INFORMATION

The manufacturer accepts no liability in the event of improper use of the instrument.

Table of contents

Other Bilanciai Scale manuals