Bin Master VF-90 User manual

1

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

Operating Instructions

Vibrating level switch for

powders relay (DPDT)

VF-90

VIBRATING FORK

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

2

2

Contents

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

Contents

1 About this document ............................................................................................................... 4

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety ......................................................................................................................... 5

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 Safety label on the instrument .......................................................................................... 6

2.6 Conformity........................................................................................................................ 6

2.7 SIL conformity .................................................................................................................. 6

2.8 Installation and operation in the USA and Canada ........................................................... 6

2.9 Safety instructions for Ex areas ........................................................................................ 6

2.10 Environmental instructions ............................................................................................... 6

3 Product description ................................................................................................................. 7

3.1 Conguration.................................................................................................................... 7

3.2 Principle of operation........................................................................................................ 7

3.3 Adjustment ....................................................................................................................... 8

3.4 Storage and transport....................................................................................................... 8

4 Mounting................................................................................................................................. 10

4.1 General instructions ....................................................................................................... 10

4.2 Mounting instructions ..................................................................................................... 11

5 Connecting to power supply................................................................................................. 15

5.1 Preparing the connection ............................................................................................... 15

5.2 Connection procedure.................................................................................................... 16

5.3 Wiring plan, single chamber housing.............................................................................. 16

6 Setup ....................................................................................................................................... 19

6.1 General information........................................................................................................ 19

6.2 Adjustment elements...................................................................................................... 19

6.3 Function table................................................................................................................. 20

7 Maintenanceandfaultrectication...................................................................................... 22

7.1 Maintenance .................................................................................................................. 22

7.2 Rectify faults................................................................................................................... 22

7.3 Exchanging the electronics module................................................................................ 23

7.4 How to proceed if a repair is necessary.......................................................................... 24

8 Dismount................................................................................................................................. 26

8.1 Dismounting steps.......................................................................................................... 26

8.2 Disposal ......................................................................................................................... 26

9 Supplement ............................................................................................................................ 27

9.1 Technical data ................................................................................................................ 27

9.2 Dimensions .................................................................................................................... 30

9.3 Industrial property rights................................................................................................. 32

9.4 Trademark ...................................................................................................................... 32

3

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

3

Contents

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

Safety instructions for Ex areas:

Ta ke noteoftheExspecicsafetyinstructionsforExapplications.

These instructions are attached as documents to each instrument

with Ex approval and are part of the operating instructions.

Editing status: 2022-09-15

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

4

4

1 About this document

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

1 About this document

1.1 Function

This instruction provides all the information you need for mounting,

connection and setup as well as important instructions for mainte-

nance,faultrectication,theexchangeofpartsandthesafetyofthe

user. Please read this information before putting the instrument into

operation and keep this manual accessible in the immediate vicinity

of the device.

1.2 Target group

This operating instructions manual is directed to trained personnel.

Thecontentsofthismanualmustbemadeavailabletothequalied

personnel and implemented.

1.3 Symbols used

Document ID

This symbol on the front page of this instruction refers to the Docu-

ment ID. By entering the Document ID on www.vega.com you will

reach the document download.

Information, note, tip: This symbol indicates helpful additional infor-

mation and tips for successful work.

Note: This symbol indicates notes to prevent failures, malfunctions,

damage to devices or plants.

Caution: Non-observance of the information marked with this symbol

may result in personal injury.

Warning: Non-observance of the information marked with this symbol

may result in serious or fatal personal injury.

Danger: Non-observance of the information marked with this symbol

results in serious or fatal personal injury.

Ex applications

This symbol indicates special instructions for Ex applications.

• List

The dot set in front indicates a list with no implied sequence.

1 Sequence of actions

Numbers set in front indicate successive steps in a procedure.

Disposal

This symbol indicates special instructions for disposal.

5

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

5

2 For your safety

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

2 For your safety

2.1 Authorised personnel

All operations described in this documentation must be carried out

onlybytrained,qualiedpersonnelauthorisedbytheplantoperator.

During work on and with the device, the required personal protective

equipment must always be worn.

2.2 Appropriate use

The VEGAWAVE 61 is a sensor for point level detection.

Yo u cannddetailedinformationabouttheareaofapplicationin

chapter " Product description".

Operational reliability is ensured only if the instrument is properly

usedaccordingtothespecicationsintheoperatinginstructions

manual as well as possible supplementary instructions.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbi-

traryconversionsormodicationsareexplicitlyforbidden.

2.3 Warning about incorrect use

Inappropriate or incorrect use of this product can give rise to applica-

tion-specichazards,e.g.vesseloverllthroughincorrectmounting

or adjustment. Damage to property and persons or environmental

contamination can result. Also, the protective characteristics of the

instrument can be impaired.

2.4 General safety instructions

This is a state-of-the-art instrument complying with all prevailing

regulations and directives. The instrument must only be operated in a

technicallyawlessandreliablecondition.Theoperatorisresponsi-

ble for the trouble-free operation of the instrument.When measuring

aggressive or corrosive media that can cause a dangerous situation

if the instrument malfunctions, the operator has to implement suitable

measures to make sure the instrument is functioning properly.

The safety instructions in this operating instructions manual, the na-

tional installation standards as well as the valid safety regulations and

accident prevention rules must be observed by the user.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbi-

traryconversionsormodicationsareexplicitlyforbidden.Forsafety

reasons,onlytheaccessoryspeciedbythemanufacturermustbe

used.

To avoid any danger, the safety approval markings and safety tips on

the device must also be observed.

The VF-90 is a sensor for point level detection.

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

6

6

2 For your safety

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

2.5 Safety label on the instrument

The safety approval markings and safety tips on the device must be

observed.

2.6 Conformity

The device complies with the legal requirements of the applicable

country-specicdirectivesortechnicalregulations.Weconrmcon-

formity with the corresponding labelling.

The corresponding conformity declarations can be found on our

homepage.

2.7 SIL conformity

VEGAWAVE 61 meets the requirements to the functional safety ac-

cording to IEC 61508. Further information is available in the Safety

Manual " VEGAWAVE series 60".

2.8 Installation and operation in the USA and

Canada

This information is only valid for USA and Canada. Hence the follow-

ing text is only available in the English language.

Installations in the US shall comply with the relevant requirements of

the National Electrical Code (ANSI/NFPA 70).

Installations in Canada shall comply with the relevant requirements of

the Canadian Electrical Code.

2.9 Safety instructions for Ex areas

For applications in explosion-proof areas (Ex), only devices with cor-

respondingExapprovalmaybeused.ObservetheEx-specicsafety

instructions.These are an integral part of the operating instructions

and are enclosed with every device with Ex approval.

2.10 Environmental instructions

Protection of the environment is one of our most important duties.

That is why we have introduced an environment management system

with the goal of continuously improving company environmental pro-

tection.Theenvironmentmanagementsystemiscertiedaccording

to DIN EN ISO 14001.

Pleasehelpusfullthisobligationbyobservingtheenvironmental

instructions in this manual:

• Chapter " Packaging, transport and storage"

• Chapter " Disposal"

The VF-90 meets the requirements to the functional safey ac-

7

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

7

3 Product description

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

3 Product description

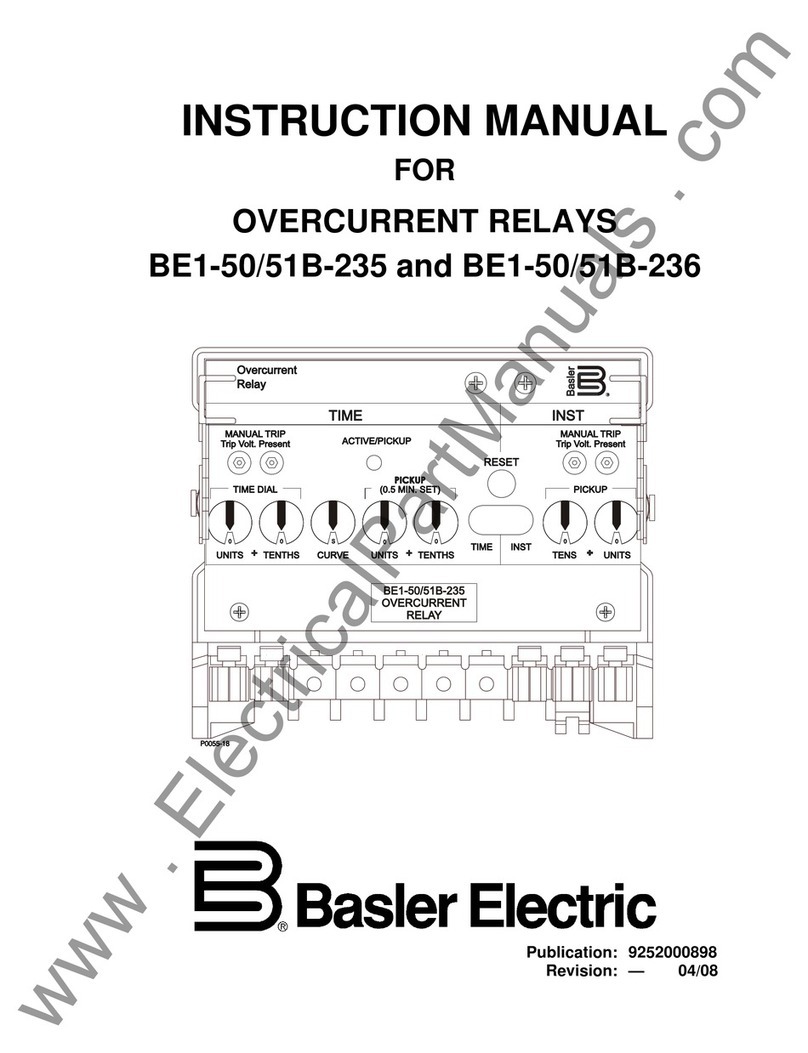

3.1 Conguration

The scope of delivery encompasses:

• VEGAWAVE 61 point level switch

• Documentation

– This operating instructions manual

– Safety Manual " Functional safety (SIL)" (optional)

– Supplementary instructions manual " Plug connector for level

sensors" (optional)

– Ex-specic"Safety instructions" (with Ex versions)

– Ifnecessary,furthercerticates

The VEGAWAVE 61 consists of the components:

• Housing lid

• Housing with electronics

• Processttingwithtuningfork

1

2

3

Fig. 1: VEGAWAVE 61 with plastic housing

1 Housing lid

2 Housing with electronics

3 Processtting

Thetypelabelcontainsthemostimportantdataforidenticationand

use of the instrument:

• Article number

• Serial number

• Technical data

• Article numbers, documentation

• SILidentication(withSILratingexworks)

With the serial number, you can access the delivery data of the instru-

ment via " www.vega.com", " Search".Yo u canndtheserialnumber

on the inside of the instrument as well as on the type label on the

outside.

3.2 Principle of operation

VEGAWAVE 61 is a point level sensor with tuning fork for point level

detection.

Scope of delivery

Constituent parts

Type label

Application area

The VF-90 point level switch

Fig. 1: VF-90 with plastic housing

The VF-90

The VF-90 consists of the components:

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

8

8

3 Product description

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

It is designed for industrial use in all areas of process technology and

is preferably used for bulk solids.

Typicalapplicationsareoverllanddryrunprotection.Thankstoits

simple and robust measuring system, VEGAWAVE 61 is virtually unaf-

fected by the chemical and physical properties of the bulk solid.

It also works when subjected to strong external vibrations or changing

products.

Solid detection in water

If VEGAWAVE 61 was ordered for solids detection in water, the tuning

fork is set to the density of water. In air or when immersed in water

(density: 1 g/cm³/0.036 lbs/in), VEGAWAVE 61 signals "uncovered".

Only when the vibrating element is also covered with solids (e.g.

sand, sludge, gravel etc.) will the sensor signal "covered".

Function monitoring

The electronics module of VEGAWAVE 61 continuously monitors the

following criteria:

• Correct vibrating frequency

• Linebreaktothepiezodrive

If one of the stated malfunctions is detected or in case of voltage sup-

ply,theelectronicstakesonadenedswitchingstatus,i.e.therelay

deenergises (safe state).

Thetuningforkispiezoelectricallyenergisedandvibratesatits

mechanicalresonancefrequencyofapprox.150Hz.Whenthetuning

fork is submerged in the product, the vibration amplitude changes.

This change is detected by the integrated electronics module and

converted into a switching command.

VEGAWAVE 61 is a compact instrument, i.e. it can be operated with-

out external evaluation system.The integrated electronics evaluates

the level signal and outputs a switching signal. With this switching

signal, a connected device can be operated directly (e.g. a warning

system, a pump etc.).

Thedataforpowersupplyarespeciedinchapter"Technical data".

3.3 Adjustment

Ontheelectronicsmoduleyouwillndthefollowingdisplayand

adjustment elements:

• Signal lamp for indication of the switching condition (green/red)

• Potentiometer for adaptation to the product density

• Mode switch for selecting the switching condition (min./max.)

3.4 Storage and transport

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

based on ISO 4180.

Functional principle

Voltage supply

Packaging

The VF-90

the VF-90 is virtually unaf-.

If the VF-90 was ordered for solids detection in water, the tuning

the VF-90 signals “uncovered”.

the VF-90 continuously monitors the

9

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

9

3 Product description

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

The packaging of standard instruments consists of environment-

friendly, recyclable carton material. The sensing element is additional-

ly protected with a cardboard cover. For special versions, PE foam or

PE foil is also used. Please dispose of the packaging material through

specialised recycling companies.

Transport must be carried out in due consideration of the notes on the

transport packaging. Nonobservance of these instructions can cause

damage to the device.

The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or con-

cealed defects must be appropriately dealt with.

Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

• Not in the open

• Dry and dust free

• Not exposed to corrosive media

• Protected against solar radiation

• Avoiding mechanical shock and vibration

• Storage and transport temperature see chapter " Supplement -

Technical data - Ambient conditions"

• Relative moisture 20 … 85 %

With instrument weights of more than 18 kg (39.68 lbs) suitable and

approved equipment must be used for lifting and carrying.

Transport

Transport inspection

Storage

Storage and transport

temperature

Lifting and carrying

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

10

10

4 Mounting

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

4 Mounting

4.1 General instructions

Note:

For safety reasons, the instrument must only be operated within the

permissibleprocessconditions.Yo u cannddetailedinformationon

the process conditions in chapter " Technical data" of the operating

instructions or on the type label.

Hence make sure before mounting that all parts of the instrument ex-

posed to the process are suitable for the existing process conditions.

These are mainly:

• Active measuring component

• Processtting

• Process seal

Process conditions in particular are:

• Process pressure

• Process temperature

• Chemical properties of the medium

• Abrasionandmechanicalinuences

The instrument is suitable for standard and extended ambient condi-

tions acc. to DIN/EN/IEC/ANSI/ISA/UL/CSA 61010-1. It can be used

indoors as well as outdoors.

In general, VEGAWAVE 61 can be installed in any position.The instru-

ment only has to be mounted in such a way that the vibrating element

is at the height of the desired switching point.

Use the recommended cables (see chapter " Connecting to power

supply") and tighten the cable gland.

You can give your instrument additional protection against moisture

penetration by leading the connection cable downward in front of the

cablegland.Rainandcondensationwatercanthusdraino.This

applies mainly to outdoor mounting as well as installation in areas

where high humidity is expected (e.g. through cleaning processes) or

on cooled or heated vessels.

To maintain the housing protection, make sure that the housing lid is

closed during operation and locked, if necessary.

Process conditions

Suitability for the ambient

conditions

Switching point

Moisture

the VF-90

In general, the VF-90 can be installed in any position. The instru-

11

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

11

4 Mounting

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

Fig. 2: Measures against moisture ingress

Do not hold VEGAWAVE 61 on the vibrating element. Especially with

angeandtubeversions,thesensorcanbedamagedbytheweight

of the instrument.

Remove the protective cover just before mounting.

Theprocessttingmustbesealedifthereisgaugeorlowpressure

in the vessel. Before use, check if the sealing material is resistant

against the measured product and the process temperature.

Themax.permissiblepressureisspeciedinchapter"Technical

data" or on the type label of the sensor.

The vibrating level switch is a measuring instrument and must be

treated accordingly. Bending the vibrating element will destroy the

instrument.

Warning:

The housing must not be used to screw the instrument in! Applying

tightening force can damage internal parts of the housing.

Use the hexagon above the thread for screwing in.

Metric threads

In the case of instrument housings with metric thread, the cable

glands are screwed in at the factory. They are sealed with plastic

plugs as transport protection.

You have to remove these plugs before electrical connection.

NPT thread

In the case of instrument housings with self-sealing NPT threads, it is

not possible to have the cable entries screwed in at the factory. The

free openings for the cable glands are therefore covered with red dust

protection caps as transport protection.

Prior to setup you have to replace these protective caps with ap-

proved cable glands or close the openings with suitable blind plugs.

4.2 Mounting instructions

The vibrating element should protrude into the vessel to avoid

buildup.Forthatreason,avoidusingmountingbossesforanges

Transport

Pressure/Vacuum

Handling

Cable entries - NPT

thread

Cable glands

Nozzle

the VF-90

Do not hold the VF-90 on the vibrating element. Especially with

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

12

12

4 Mounting

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

andscrewedttings.Thisappliesparticularlytousewithadhesive

products.

Mount the instrument in such a way that the tuning fork does not

protrudedirectlyintothellingstream.

20°

a. b.

Fig. 3: Horizontal installation

a Protective sheet

b Concave protective sheet for abrasive solids

If such an installation location should be necessary, mount a suitable

protective sheet above or in front of the vibrating element, see illustra-

tion "a").

In abrasive solids, mounting according to illustration "b" has proven.

A spout forms in the concave protective sheet preventing wear of the

protective sheet.

To achieve a very precise switching point, you can install VEGAWAVE

61horizontally.However,iftheswitchingpointcanhaveatoleranceof

a few centimeters, we recommend mounting VEGAWAVE 61 approx.

20° inclined to the vessel bottom to avoid buildup.

Filling opening

Horizontal mounting the VF-90

the VF-90

the VF-90 approx.

13

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

13

4 Mounting

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

20°

Fig. 4: Horizontal mounting

IfVEGAWAVE61ismountedinthellingstream,unwantedfalse

measurement signals can be generated. For this reason, mount

VEGAWAVE 61 at a position in the vessel where no disturbances, e.g.

fromllingopenings,agitators,etc.,canoccur.

To make sure the tuning fork of VEGAWAVE 61 generates as little

resistanceaspossibletoproductow,mountthesensorsothatthe

surfaces are parallel to the product movement.

1

2

Fig. 5: Flow orientation of the tuning fork

1 Marking with screwed version

2 Directionofow

Incaseofhorizontalmountinginadhesiveproducts,thesurfacesof

the tuning fork should be vertical in order to reduce buildup on the

tuningfork.Onthescrewedversionyouwillndamarkingonthe

hexagon.With this, you can check the position of the tuning fork when

Inowingmedium

Productow

Adhesive products

the VF-90

the VF-90

the VF-90

If the VF-90 is mounted in the lling stream, unwanted false

the VF-90 at a position in the vessel where no disturbances, e.g.

To make sure the tuning fork of the VF-90 generates as little

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

14

14

4 Mounting

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

screwing it in.When the hexagon touches the seal, the thread can still

beturnedbyapprox.halfaturn.Thisissucienttoreachtherecom-

mended installation position.

Inthecaseofangeversions,theforkisalignedwiththeangeholes.

1

Fig. 6: Horizontal installation - marking

1 Marking on top with screwed version

In applications such as grit chambers or settling basins for coarse

sediments, the vibrating element must be protected against damage

withasuitablebae.

Thisbaemustbemanufacturedbyyou.

> 125 mm

(> 5")

> 120 mm

(> 4.7")

Fig.7:Baeforprotectionagainstmechanicaldamage

Baeprotectionagainst

falling rocks

15

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

15

5 Connecting to power supply

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

5 Connecting to power supply

5.1 Preparing the connection

Always keep in mind the following safety instructions:

Warning:

Connect only in the complete absence of line voltage.

• The electrical connection must only be carried out by trained,

qualiedpersonnelauthorisedbytheplantoperator.

• Alwaysswitchopowersupply,beforeconnectingordisconnect-

ing the instrument.

Note:

Install a disconnecting device for the instrument which is easy to

access.The disconnecting device must be marked for the instrument

(IEC/EN 61010).

Inhazardousareasyoumusttakenoteoftherespectiveregulations,

conformityandtypeapprovalcerticatesofthesensorsandpower

supply units.

Connect the voltage supply according to the connection diagrams.

The electronics module with relay output is designed in protection

class I. To maintain this protection class, it is absolutely necessary

that the earth conductor be connected to the inner earth conductor

terminal. Keep the general installation regulations in mind. Take note

ofthecorrespondinginstallationregulationsforhazardousareaswith

Ex applications.

Thedataforpowersupplyarespeciedinchapter"Technical data".

The instrument is connected with standard three-wire cable without

shielding. If electromagnetic interference is expected which is above

the test values of EN 61326 for industrial areas, shielded cable should

be used.

Make sure that the cable used has the required temperature resist-

anceandresafetyformax.occurringambienttemperature

Use cable with round cross-section. A cable outer diameter of

5…9mm(0.2…0.35in)ensuresthesealeectofthecablegland.

Ifyouareusingcablewithadierentdiameterorcross-section,

exchange the seal or use a suitable cable gland.

Inhazardousareas,useonlyapprovedcableconnectionsforVEGA-

WAVE 61.

Take note of the corresponding installation regulations for Ex applica-

tions.

Cover all housing openings conforming to standard according to

EN 60079-1.

Note safety instructions

Take note of safety

instructions for Ex

applications

Voltage supply

Connection cable

Connection cable

for Ex applications

the VF-90.

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

16

16

5 Connecting to power supply

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

5.2 Connection procedure

With Ex instruments, the housing cover may only be opened if there is

no explosive atmosphere present.

Proceed as follows:

1. Unscrew the housing lid

2. Loosen compression nut of the cable gland and remove blind

plug

3. Remove approx. 10 cm (4 in) of the cable mantle, strip approx.

1 cm (0.4 in) of insulation from the ends of the individual wires

4. Insert the cable into the sensor through the cable entry

5. Lift the opening levers of the terminals with a screwdriver (see

following illustration)

Fig. 8: Connection steps 5 and 6

6. Insert the wire ends into the open terminals according to the wir-

ing plan

7. Press down the opening levers of the terminals, you will hear the

terminal spring closing

8. Check the hold of the wires in the terminals by lightly pulling on

them

9. Tighten the compression nut of the cable entry gland. The seal

ring must completely encircle the cable

10. If necessary, carry out a fresh adjustment

11. Screw the housing lid back on

Theelectricalconnectionisnished.

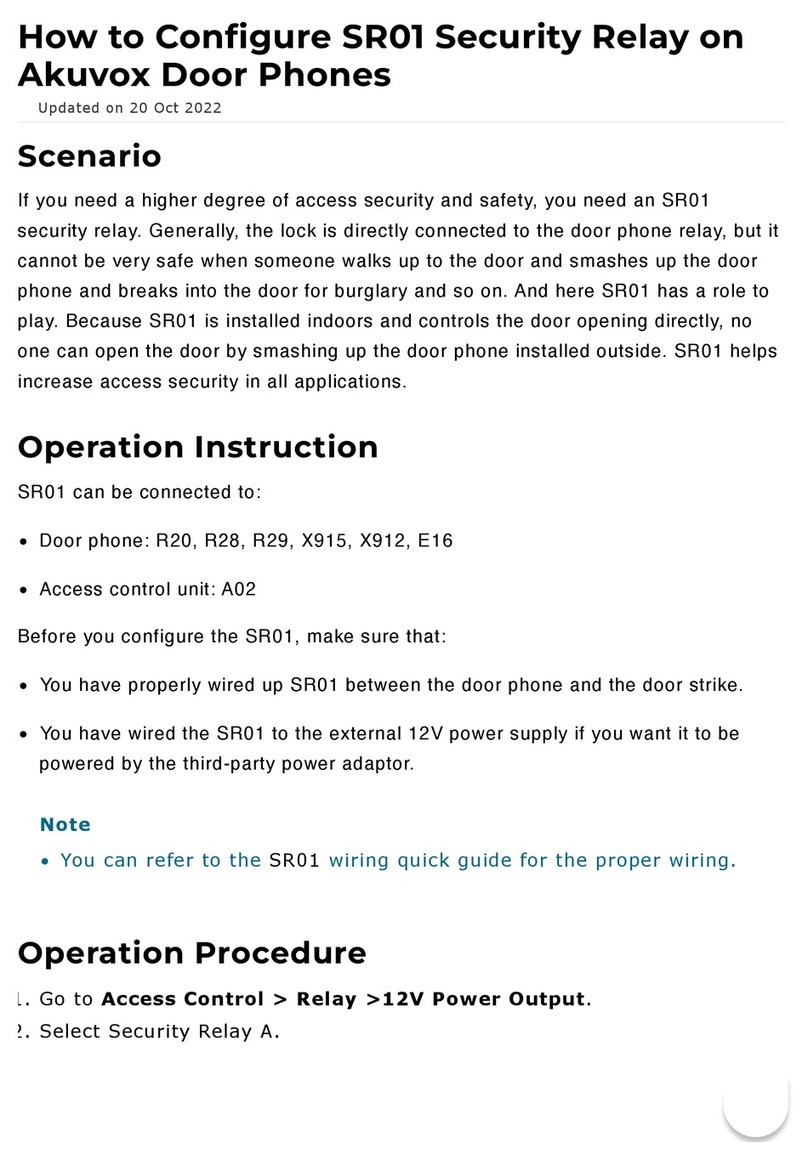

5.3 Wiring plan, single chamber housing

The following illustrations apply to the non-Ex as well as to the Ex-d

version.

17

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

17

5 Connecting to power supply

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

1 2

4

3

5

5

55

Fig. 9: Material versions, single chamber housing

1 Plastic (not with Ex d)

2 Aluminium

3 Stainless steel (not with Ex d)

4 Stainless steel, electropolished (not with Ex d)

5 Filter element for pressure compensation (not with Ex d)

We recommend connecting VEGAWAVE 61 in such a way that the

switching circuit is open when there is a level signal, line break or

failure (safe state).

The relays are always shown in non-operative condition.

3

2 1

Fig. 10: Wiring plan

1 Relay output

2 Relay output

3 Voltage supply

If inductive loads or stronger currents are switched through, the gold

plating on the relay contact surface will be permanently damaged.

The contact is then no longer suitable for switching low-voltage

circuits.

Housing overview

Wiring plan

Connection to a PLC

the VF-90

We recommend connecting the VF-90 in such a way that the

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

18

18

5 Connecting to power supply

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

Inductive loads also result from the connection to a PLC input or

output and/or in combination with long cables. It is imperative that you

take measures to extinguish sparks to protect the relay contact (e.g. Z

diode) or use an electronic version with transistor output.

19

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

19

6 Setup

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

6 Setup

6.1 General information

Theguresinbracketsrefertothefollowingillustrations.

Ontheelectronicsmoduleyouwillndthefollowingdisplayand

adjustment elements:

• Potentiometer for adjustment of the density range (1)

• DIL switch for mode adjustment - min./max. (2)

• Signal lamp (5)

Note:

As a rule, always set the mode with mode switch (2) before starting

the setup of VEGAWAVE 61. The switching output will change if you

set the mode switch (2) afterwards.This could possibly trigger other

connected instruments or devices.

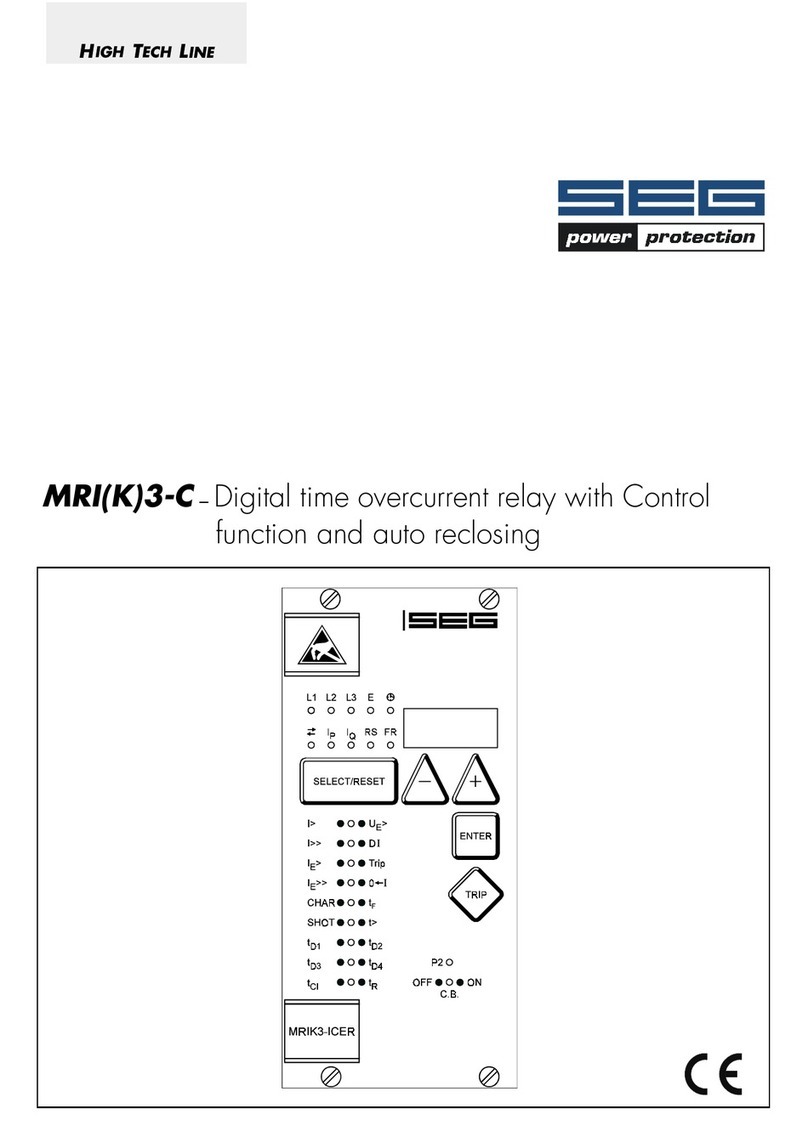

6.2 Adjustment elements

3

4

5

1

2

Fig. 11: Electronics and connection compartment - relay output

1 Potentiometer for adjustment of the density range

2 DIL switch for mode adjustment

3 Ground terminal

4 Connection terminals

5 Control lamp

With the potentiometer you can adapt the switching point to the solid.

Itisalreadypresetandmustonlybemodiedinspecialcases.

By default, the potentiometer of VEGAWAVE 61 is set to the right stop

(> 0.02 g/cm³ or 0.0008 lbs/in³). In case of very light-weight solids,

turn the potentiometer to the left stop (> 0.008 g/cm³ or 0.0003 lbs/

in³).VEGAWAVE 61 will thus be more sensitive and can detect light-

weight solids more reliably.

Function/Conguration

Electronics and connec-

tion compartment

Adjustment of the density

range (1)

the VF-90

the VF-90

the VF-90

the setup of the VF-90. The switching output will change if you

By default, the potentiometer of the VF-90 is set to the right stop

The VF-90 will thus be more sensitive and can detect light-

VF-90 Vibrating Rod | 925-0376 | ©2023 BinMaster all rights reserved

20

20

6 Setup

VEGAWAVE 61 • Relay (DPDT)

32247-EN-221012

For instruments detecting solids in water, these settings are not ap-

plicable.The density range is preset and must not be changed.

With the mode setting (min./max.) you can change the switching

condition of the relay.You can set the required mode according to the

" Function table"(max.-max.detectionoroverowprotection,min.-

min. detection or dry run protection).

We recommend connecting according to the idle current principle

(relaycontactdeenergizeswhentheswitchingpointisreached),

because the relay always takes on the same (safe) state if a failure is

detected.

Control lamp for indication of the switching status

• green=relayenergized

• red=relaydeenergized

• red(ashing)=failure

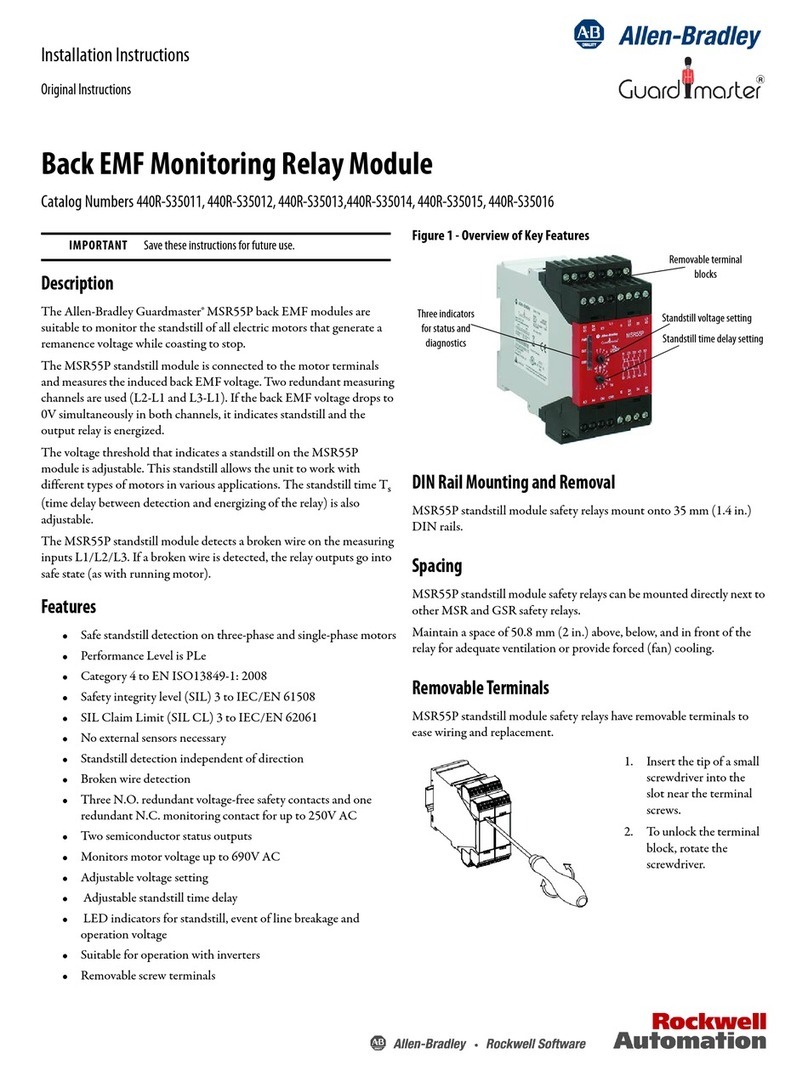

6.3 Function table

The following table provides an overview of the switching conditions

depending on the set mode and the level.

Level Switching status Control lamp

Mode max.

Overowprotection 53 4

(8)(6) (7)

Relayenergized Green

Mode max.

Overowprotection 53 4

(8)(6) (7)

Relaydeenergized Red

Mode min.

Dry run protection 53 4

(8)(6) (7)

Relayenergized Green

Mode min.

Dry run protection 53 4

(8)(6) (7)

Relaydeenergized Red

Failure of the supply volt-

age

(min./max. mode)

any

53 4

(8)(6) (7)

Relaydeenergized

Mode adjustment (2)

Signal lamp (5)

Other manuals for VF-90

1

Table of contents