BINDTEC YL-420 User manual

YL-420(S)

USER MANUAL

CONTENTS

1. Safety Features Overview and Precaution

2. Product Introduction and Accessories

3. Part Names and Functions

4. Band Installation

4-1) How to feed the band for 420(30)(50)

4-2) How to feed the band for 420S

5. Operation

5-1) How to change Standby Time before Banding

5-2) Banding Regardless of Sensor Detecting an Object

6. Sheet Replacement

6-1) Life expectancy of Heater Sheet

6-2) How to check the Condition of Sheet

7. Failed Band Removal

8. Checking before Troubleshooting

9. Extra Functions

9-1) Band Removal in case of Jam

9-2) Banding Black or Transparent Objects

9-3) Banding Soft Object

10. Specifications

Product Warranty

1

Safety Features Overview and Precaution

For your safety

Please read this user manual carefully

before operating the banding machine.

Maintenance requirements

1. Make sure that the power is supplied. Voltage fluctuation must be kept at a

minimum.

2. High temperature and humidity or any other environmental conditions may

render the unit nonoperational as the band may get jammed around the roller

and so on.

3. Please clean the unit often. In particular, it is important to keep the sensor part

and upper cover clean using dry and soft fabrics.

4. Warranty will be void if the unit is tampered with or disassembled by anyone

other than the designated service personnel.

5. Touching the heater when the unit is in operation or within 10 min of the

machine’s shutdown may cause burns and injuries.

6. Ensure that the power is off after using the unit.

* Don’t lift the arch when moving the machine.

2

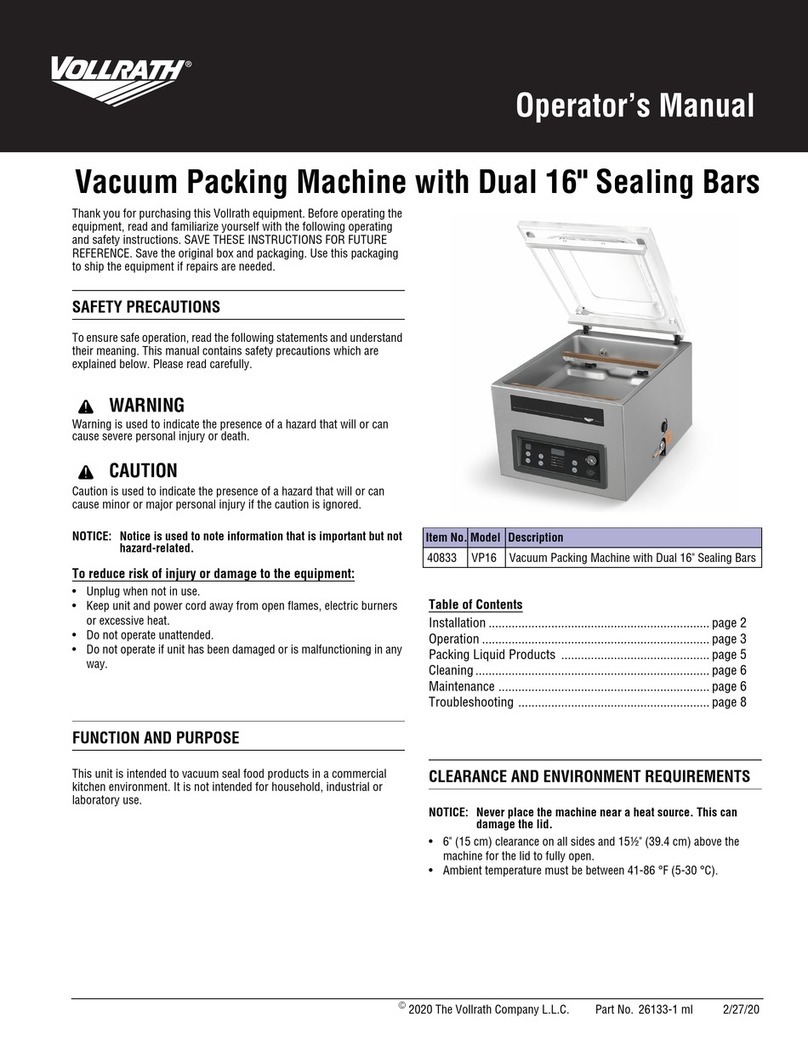

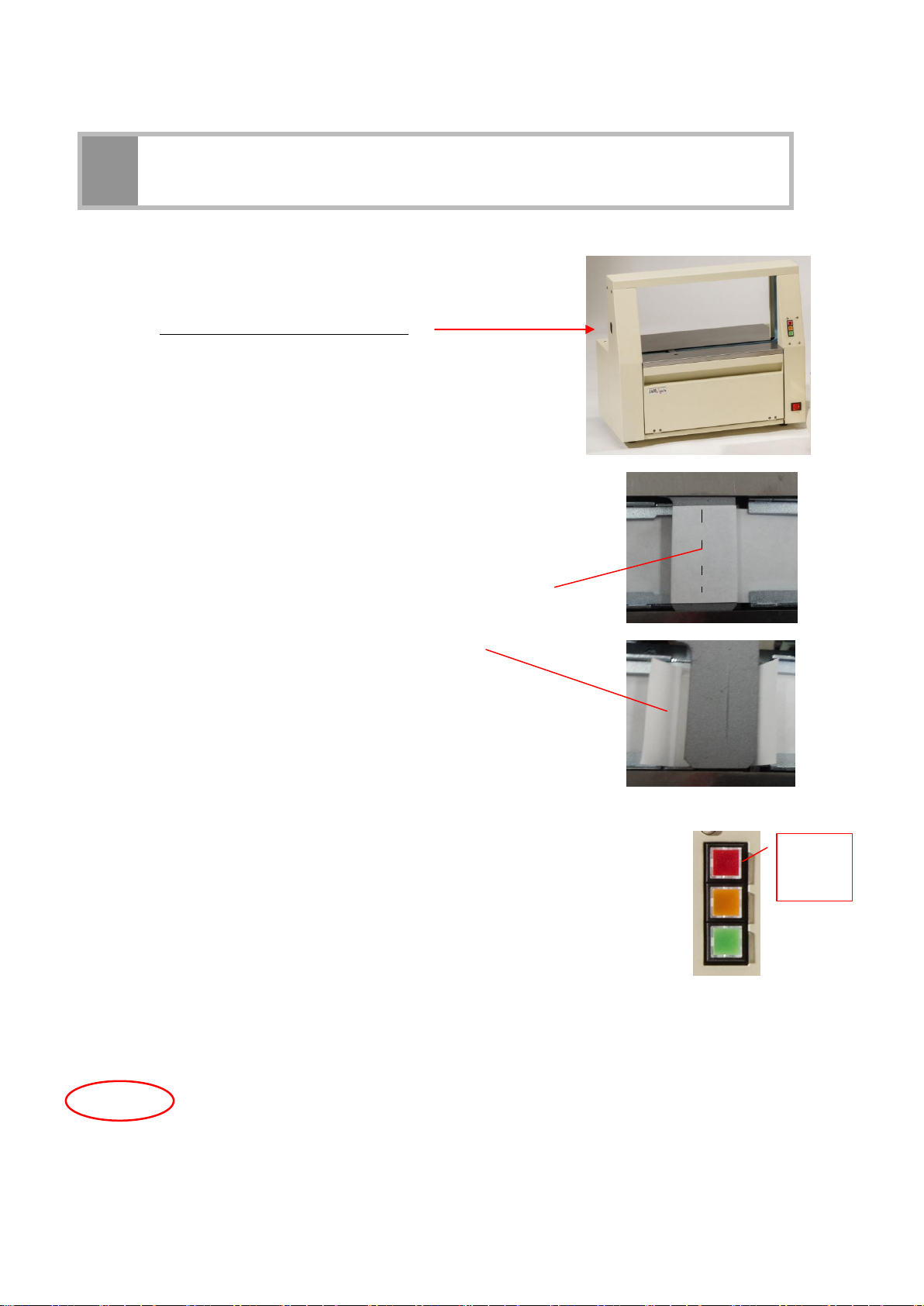

Product Introduction and Accessories

Automatic banding machine with paper/film YL-420(30)(50),420S

*Easy installation for easy relocation

* Korea’s first rail banding machine

* Compatible of paper and film bands

* Banding without warming up

* Banding without any odor and harmful substances

[Accessories]

Manual: 1 copy

Band: 1 roll

Guide: 1 set

Heater Sheet: 3 pcs

Tool: 1 pc

Power Cable: 1 pc

YL-420(30)

YL-420(50)

YL-420S

3

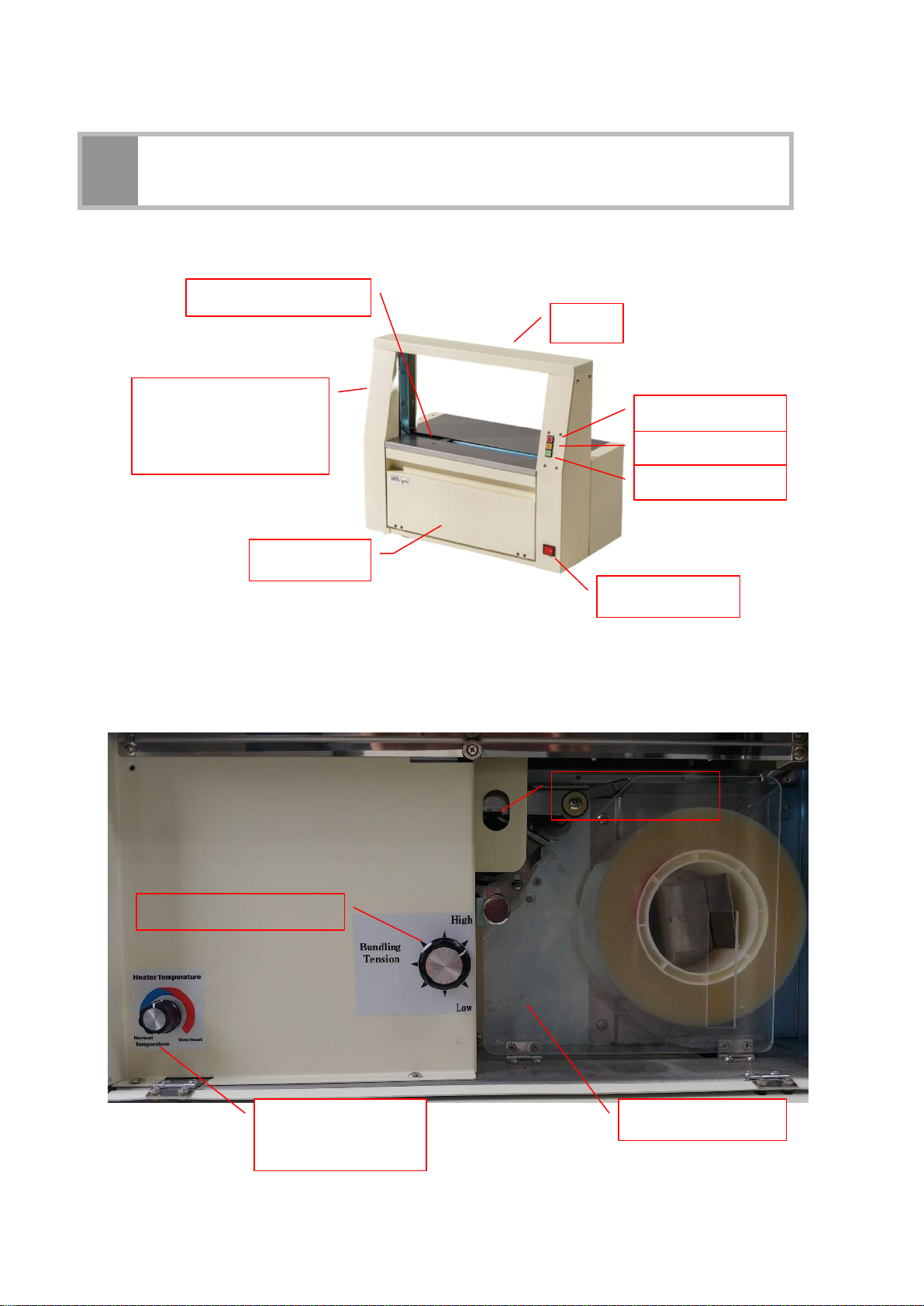

Part Names and Functions

Arch

2. Feed Button

3. Auto Button

4. Start Button

1. Power Switch

5. Object Sensor

9. Rail

Opening/Closing

Lever

7. Tension Control Knob

Band Reel Cover

6. Temperature

Control Knob

8. Band Set Lever

Front Cover

1. Power Switch

Turn the power ON or OFF.

2. Feed Button

The band is fed to the rail when the red button is pressed.

The RED LED lights up when the band is normally set.

Otherwise, the RED LED blinks.

3. Auto Button

The ORANGE LED lights up, and the auto mode is enabled when the button

is pressed. The ORANGE LED turns off, and manual mode is enabled when it is

pressed again. The machine works in auto banding when the sensor detects

any object in auto mode.

4. Start Button

The GREEN LED lights up, and manual mode is enabled when the power is

turned ON.

5. Object Sensor

It detects an object that is put on the machine for banding, and then the

GREEN LED blinks.

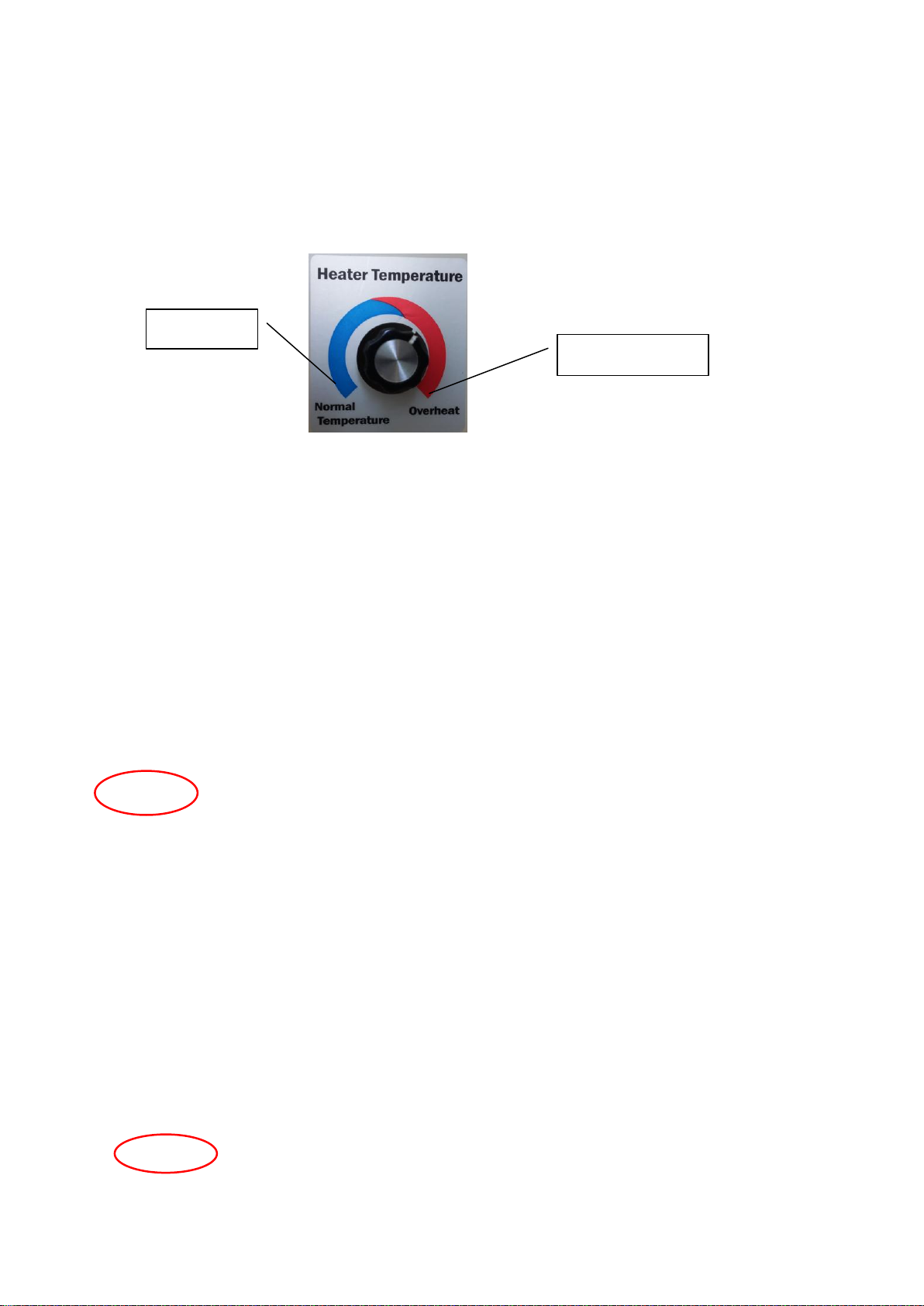

6. Temperature Control Knob

This control knob is used to adjust the heater temperature

for banding.

The heater temperature rises when the control knob

is turned clockwise.

7. Tension Control Knob

This control knob is used to adjust

banding tension, which increases

when the control knob is turned clockwise.

8. Band Set Lever

This lever is used to set the band. Raise the lever, insert the band, and press

the feed button to transfer it to the rail.

9. Rail Opening/Closing Lever

Press or release this lever to open or close the rail respectively.

Open the rail you can remove the band when jammed.

4

Band Installation

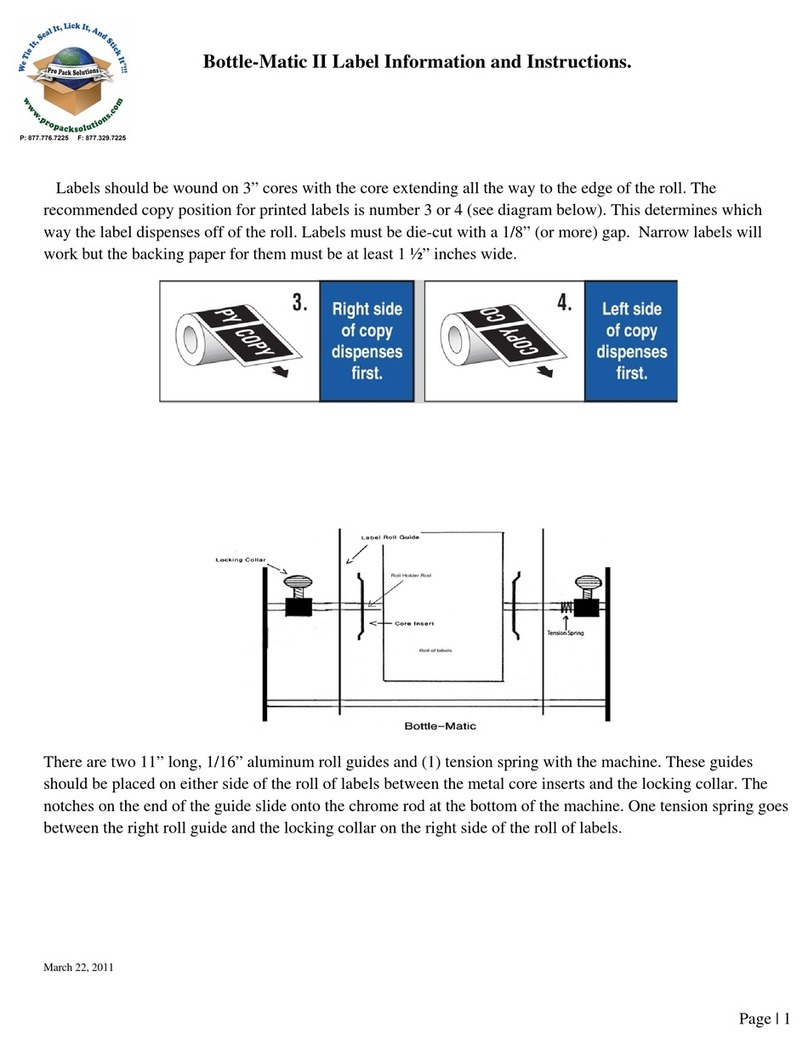

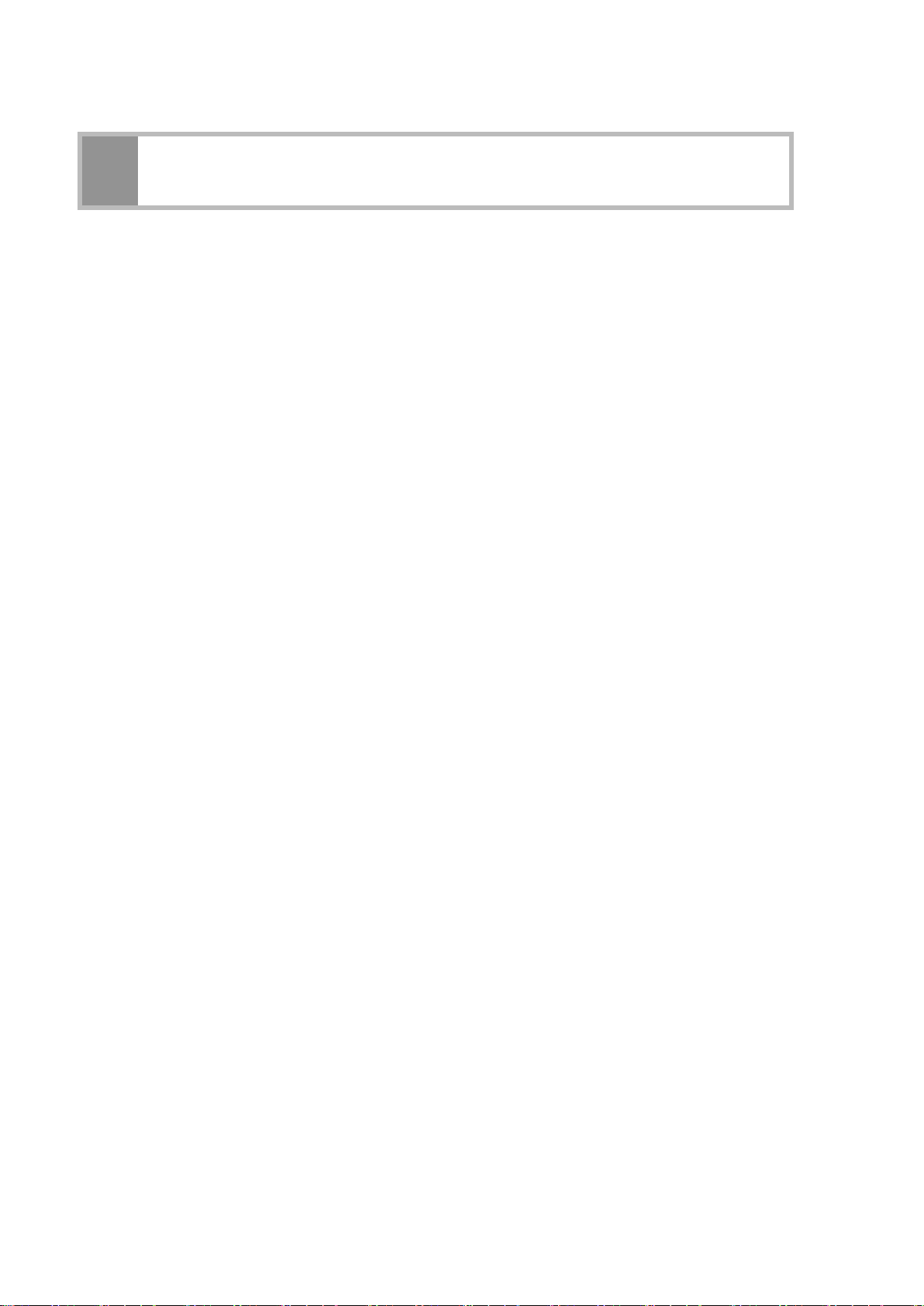

4-1) How to feed the band for 420(30)(50)

1) Check the condition of the band.

Cut off the end of the new band with scissors if it is roughly cut, wrinkled, or

contaminated, as such poor conditions may cause a jam.

2) Pull the front cover and band reel cover to open them.

3) Set the band such that the reel rotates clockwise to feed the band, as shown in

the following figures.

4) Raise the band set lever, and then insert the band between the rollers.

5) Close the band reel and front covers.

6) Turn ON the power using the power switch, and press the feed button.

The FEED BUTTON LED lights up when the feed motor runs, and the band is

set.

- If the end of the band becomes damaged, it may have been installed

incorrectly. As such, cut off the end using scissors.

- Make sure to close the band reel cover.

- Pay attention as the adhesive on the start and end of the band roll may cause

a jam and damage the machine.

Caution

band’s direction

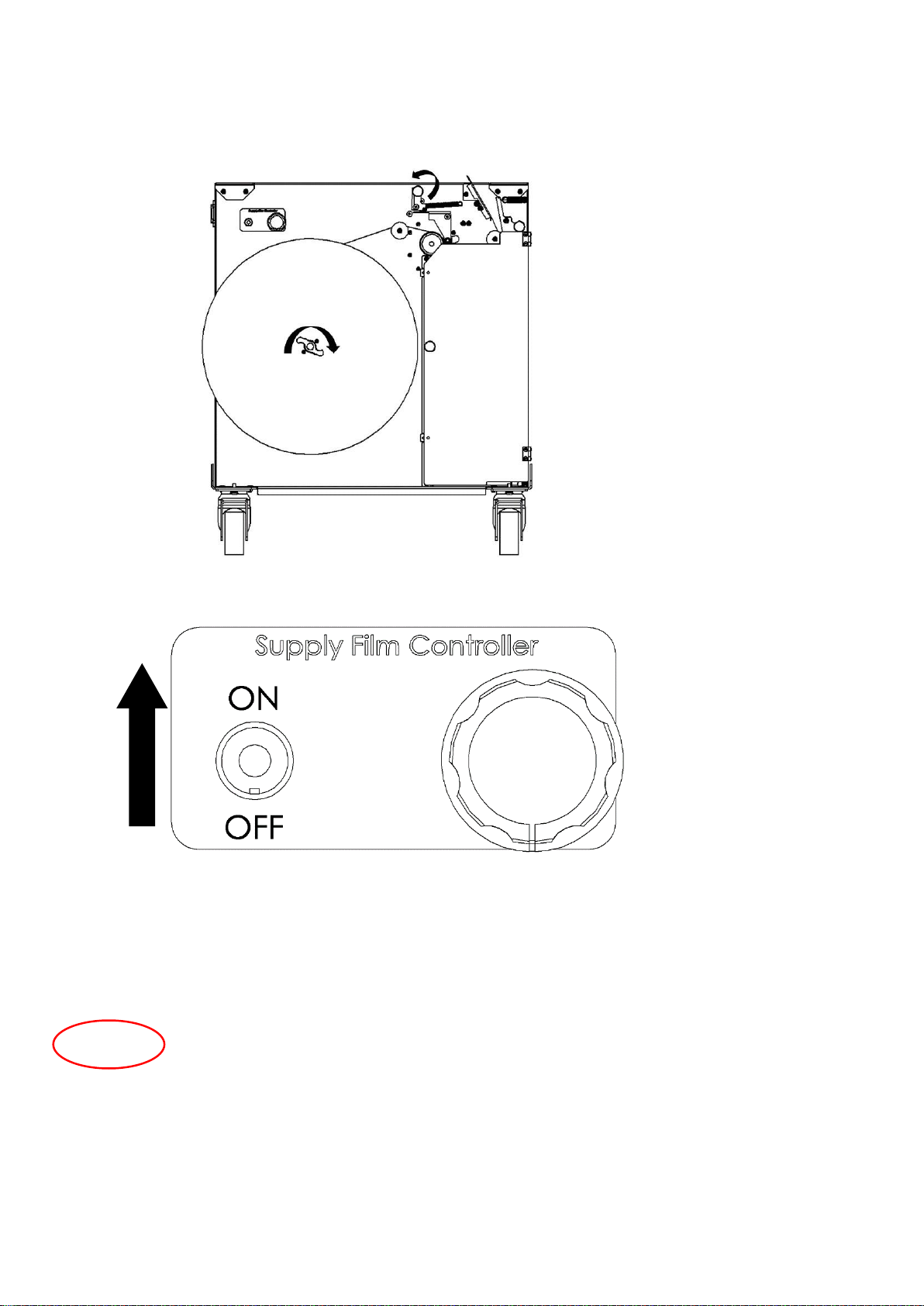

4-2) How to feed the band for 420S

1) Check the condition of the band.

Cut off the end of the new band with scissors if it is roughly cut, wrinkled, or

contaminated, as such poor conditions may cause a jam.

2) Turn the toggle switch to OFF.

3) Open the band reel cover and front cover.

4) Turn the band feed lever to widen the gap between the rollers.

5) Insert the band so that the feeding rotation

direction of the band is clockwise as shown

in the figure.

6) While holding the band anti-skid lever

with your hand, insert the band in order

and release the band anti-slip lever again.

(If the band is inserted normally, the band

will rise from the bottom of YL-420 on top.)

7) Close the band feed lever, the band cover, and the front cover.

8) After turning the toggle switch to ON, supply the band.

9) When the band supply is complete, insert the band from ‘6)’ into the YL-420

and press the feed button. At this time, the feed motor rotates and the band is

accurately seated on the rail.

- If the end of the band becomes damaged, it may have been installed

incorrectly. As such, cut off the end using scissors.

- Make sure to close the band reel cover.

- Pay attention as the adhesive on the start and end of the band roll may cause

a jam and damage the machine.

Caution

5

Operation

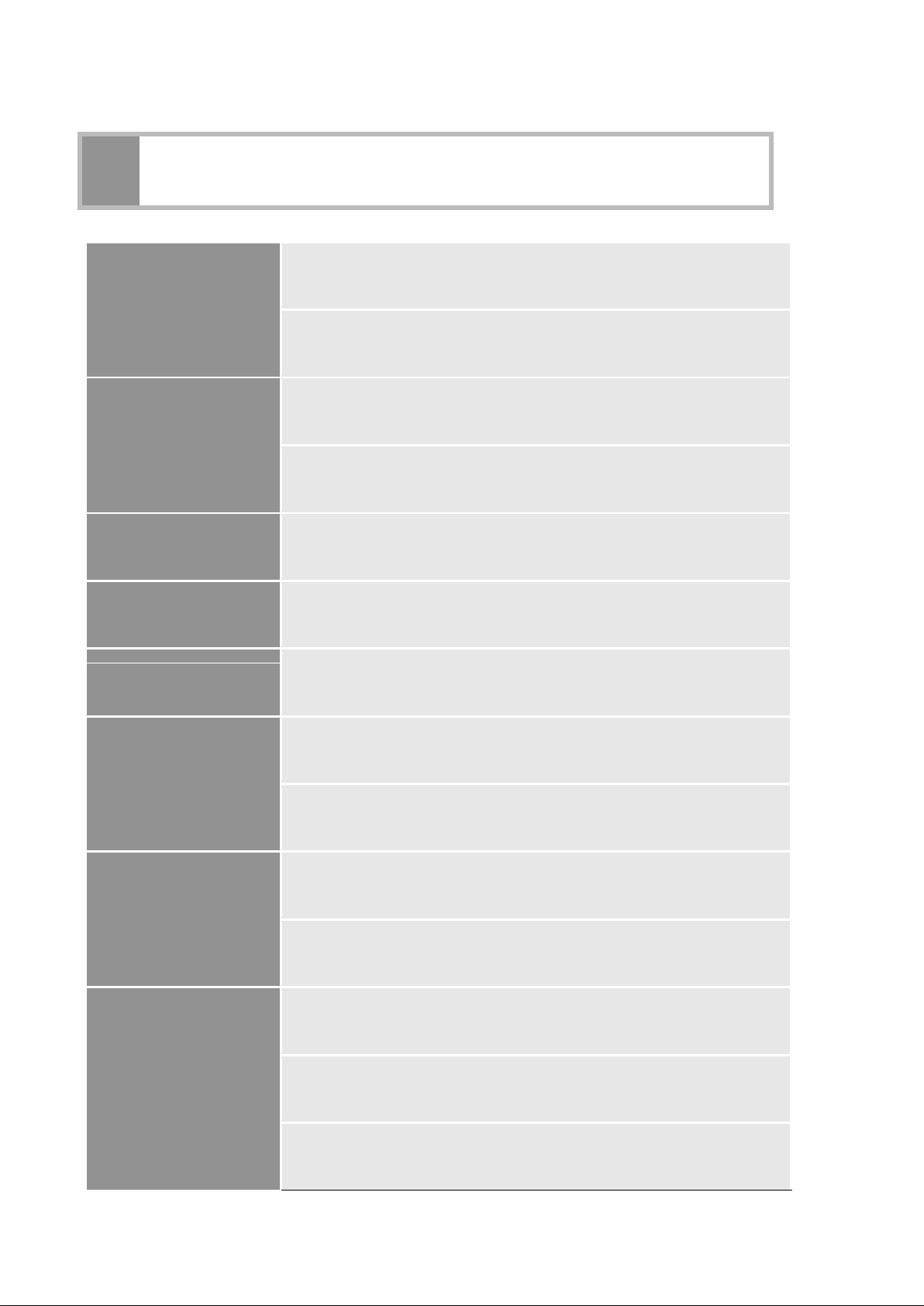

1) Turn ON the power using the power switch.

2) Check whether the FEED BUTTON LED and

START BUTTON LED are lit.

3) Auto Mode: Press the Auto Button

to turn on the ORANGE LED. Then, put an object on

the object sensor to allow the machine to start

banding automatically.

4) Manual Mode: Turn on the ORANGE LED.

Put an object on the object sensor, and press

the Start Button while holding the object.

5) Take out the object when the banding is completed.

- Pay attention as banding may unintentionally start in auto mode. As such,

disable auto mode, or turn off the power switch when the machine is not in

use.

- Make sure to put the object on the sensor for banding.

For banding without putting an object or banding an undetectable object,

refer to “5-2) Banding Regardless of Sensor Detecting an Object”.

Caution

Auto Button

Power

Feed Button

Start Button

5-1) How to change Standby Time before Banding

You can adjust the time to start banding after the sensor detects an object in auto

mode using the heater temperature control knob.

Turn OFF the power switch →Press the feed button →Turn ON the power switch

→The buzzer rings twice →Turn the feed button OFF →Control using the

heater temperature control knob →Turn OFF the power switch →Setting of

standby time is completed

Return the heater temperature control knob to its original position as

follows:

Turn ON the power switch →Set the original heater temperature →Ready to

start banding with the changed time

※Factory default = 0.5 sec

The standby time function is only available in auto mode.

5-2) Banding Regardless of Sensor Detecting an Object

The object sensor can be disabled for special objects or user convenience (e.g., black or

transparent objects).

Turn OFF the power switch →Press the start button →Turn ON the power switch

→Long buzzer sound rings once →Turn the start button OFF →Setting for

banding regardless of the sensor detecting an object is completed

Turn the power OFF, and then turn it ON again after 2–3 s to enable the setting.

This function is only available in manual mode.

Caution

Caution

Max 1.0 sec

Min 0.0 sec

6

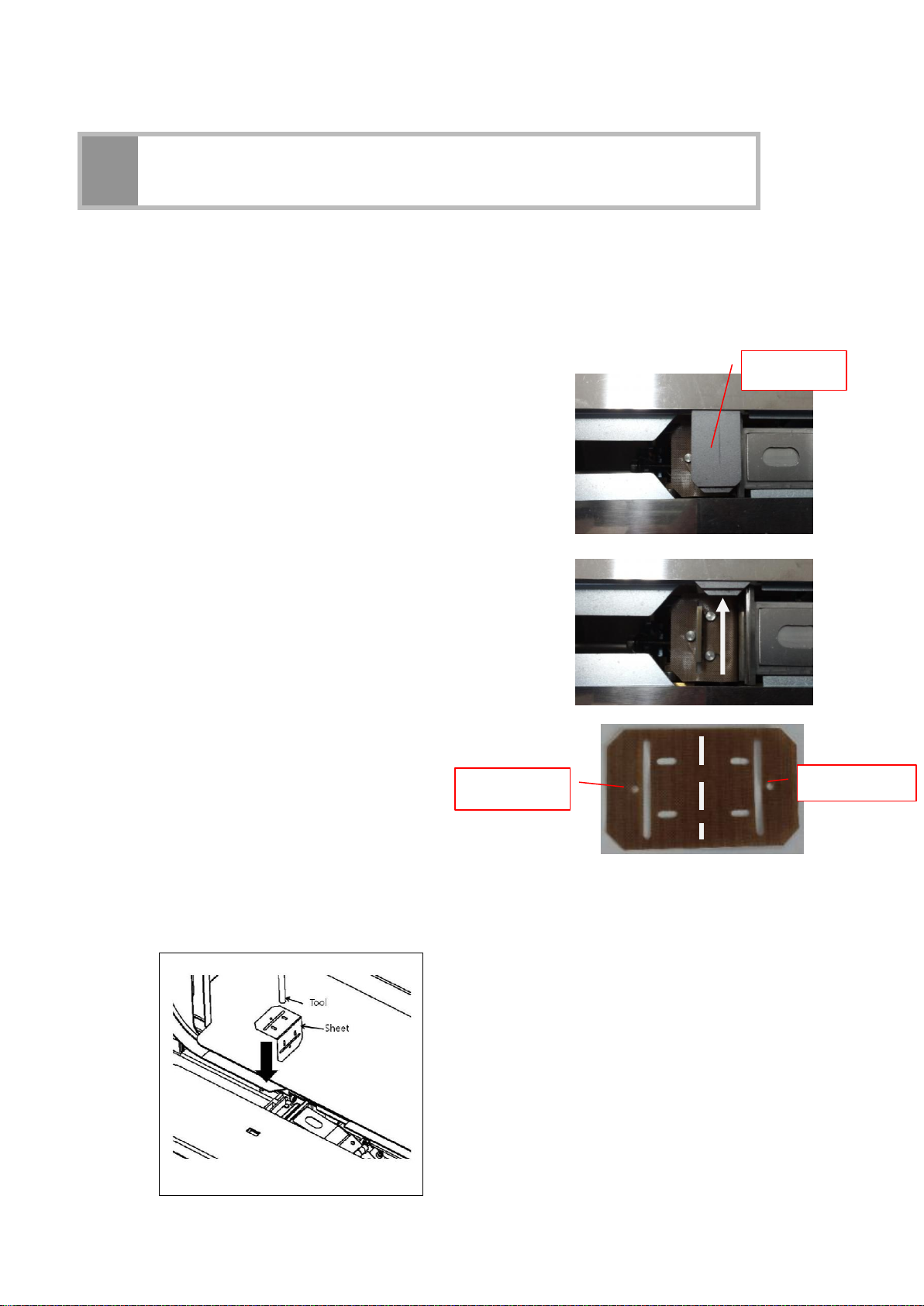

Sheet Replacement

1) Take out the installed band.

2) Turn OFF the power switch →Turn ON the power switch while pressing the

feed and auto buttons together →Check if both FEED BUTTON LED and

AUTO BUTTON LED are blinking →Release the feed and auto buttons

3) Operate the machine by repeatedly pressing the

feed button for a short period until the hold plate

is positioned, as shown in the figure.

4) Turn OFF the power switch.

5) Push the hold plate backward to make the entire

sheet visible.

6) Remove the sheet using tweezers.

7) The sheet has a symmetrical shape

and can be used twice.

8) Insert the right side of the new sheet between the cutter and heater head, and

then fix the sheet with the three pins using the supplied tool.

Hold plate

Second time

First time

9) Turn ON the power by pressing the power switch.

10) Press the start button, and the rail and hold plate will return to their initial

positions.

6-1) Life expectancy of Heater Sheet

Check the condition of the heater sheet before starting the banding operation.

The sheet has expired if its color has changed to black, and it would need to be

replaced with a new one.

The sheet may be torn if the banding operation continues without replacing the

old sheet and could make the surface of the deposited portion opaque when the

band is bound. This may result in jams or shortening of the heater’s life.

6-2) How to check the Condition of Sheet

Replace the heater sheet with a new one if the

color of the heater section changes to black,

as shown in the figure on the right.

To replace the sheet, refer to “6. Sheet Replacement”.

①Power

switch

Spa

cer

7

Failed Band Removal

When the rail is jammed with the band:

1) Turn OFF the power switch.

2) Press the rail opening/closing lever

to open the rail.

3) Cut the band around the hold plate using scissors.

4) Turn the band roll counterclockwise to completely

remove the band.

5) Set the band according to “4. Band Installation”.

When the band is wound around the hold plate:

1) Turn OFF the power switch.

2) Cut the band that is wound around the hold plate,

as shown in the figure.

3) Pull the left end of the band to remove it.

4) Turn ON the power switch.

5) Press the feed button to feed the band

if the band is incorrectly set in the rail.

* The band is incorrectly set if the FEED BUTTON LED is blinking.

As such, take action as follows:

- If the band is fed well after pressing the feed button again:

Do the banding 2–3 times to ensure that the machine works

normally as the cut end of the band may become rough or wrinkled.

- If it does not work even after pressing the feed button again:

Open the front and band reel covers, cut the band (around the band set lever),

and remove it while pressing and holding the rail opening/closing lever.

When the power is ON, do not put your hand in the rail or hold plate.

Pay attention during auto mode because the machine may start operating

once a part of your body is detected.

Caution

Feed

Button

8

Checking before Troubleshooting

Check the following if the machine cannot operate or the operation is not smooth:

1) If the START BUTTON LED is OFF:

*Check if the power cord is plugged.

*Check if the power switch is turned OFF.

→Plug the power cord, and turn ON the power switch.

2) If the FEED BUTTON LED is blinking:

*Check if the band is fed.

*Check if the band is fed well to the hold plate.

→Press the feed button to set the band to its initial position.

3) If the banding is not performed even if an object is put on the object sensor in

auto mode:

*Check if the banding is set to start regardless of the sensor detecting an object.

→Turn OFF the power switch, and then turn it ON.

4) If the START BUTTON LED is blinking (manual) or banding is performed

automatically (auto) without any object:

*Check if the sensor is dirty.

→Turn OFF the power switch, and then clean the object sensor.

5) If the band cannot be cut:

→Ask for A/S as the cutter is expired.

6) If the deposition is weak:

*Check if the heater temperature is too low.

→Increase the heater temperature by turning the heater temperature control knob

clockwise.

*Check if the band roll is set in the opposite direction.

→Set it correctly according to “4. Band Installation”.

7) If the deposition is weak even though the temperature is raised using the

temperature control knob:

*Check the heater sheet.

→Replace the heater sheet according to the replacement method.

*Ask for A/S as the heater is expired.

8) If the deposited portion is scorched or odors (fumes) are generated at the

deposition: →Lower the temperature as the heater temperature is too high.

9

Extra Functions

The following functions operate when each button is pressed and held:

9-1) Band Removal in case of Jam

Feed Button (Red): Used to remove the band in a jam

-Press and hold the feed button.

-The cam motor will rotate, retracting the hold plate slide (this state will be

maintained).

-Remove the jammed band.

-Press (do not hold) the feed button once again to return the slide to its

original position.

-Re-feeding the band is allowed to prepare for banding.

9-2) Banding Black or Transparent Objects

Auto Button(Yellow)): Used to enter or exit the “Banding regardless of sensor

detecting an object” mode

-Press and hold the auto button.

-The buzzer will ring twice to confirm that the object sensor has been

deactivated.

-If the machine is currently in auto mode, it will automatically switch back to

manual mode.

-This mode will remain even after the machine has been turned OFF and ON.

9-1) Feed Button

9-2) Auto Button

9-3) Start Button

-Press and hold the auto button once again to exit. Then, the buzzer will ring

once to confirm that the mode has been deactivated.

9-3) Banding Soft Object

Start Button(Green): Used to enter or exit the “After banding, the slide moves

forward and feeds if no object is sensed” mode

-Press and hold the start button.

-The buzzer will ring thrice to confirm that the slide has retracted.

-Soft object banding is used to prevent the slide from getting stuck between

the band when banding objects with unstable shapes.

-This mode will remain even after the machine has been turned OFF and ON.

-Press and hold the start button once again to exit. Then, the buzzer will ring

once to confirm that the mode has been deactivated.

Functions 2 and 3 cannot be used at the same time.

The machine will only function using the last command inputted

when both commands are entered.

Caution

10

Specifications

Banding Speed

420(30): 26 cycles/min

420(50): 24 cycles/min

Banding Size

Min: 30 (W) ×10 (H) mm

Max: 400 (W) ×200 (H) mm

Power Supply

AC 110/220 V, 50/60 Hz

Power Consumption

250 W

Tension

0.5~4 kg

Band Width

420(30): paper/film 30 mm

420(50): paper/film 50 mm

Dimensions

560 (W) ×300 (D) ×490 (H) mm

Stand : 600(W) x 510(D) x 660(H)mm

Weight

420(30): 35 kg

420(50): 39 kg

Stand: 28 kg

Product Warranty

BINDTEC Co., Ltd. warrants that it will repair and replace parts under the

following terms if any defects in the material or workmanship of the machine

occur within 12 months from the day of purchase by the user.

A purchase receipt or other evidence for the date of purchase must be shown to

receive warranty services.

Warranty terms

This warranty is valid only while and if the product is used and handled in a

normal and reasonable manner following the User Manual and installation

instructions.

Paid services

*Please read the User Manual carefully, as you will be charged for any services

requested except for product malfunctions guaranteed under the warranty.

*The product is not covered by warranty if damages or defects have occurred

because of:

- Customer misuse or unauthorized tampering or repairs;

- Use of parts other than those designated by BINDTEC Co., Ltd; or

- An act of God or the expiration of the normal service lives of any

expendable parts.

Model

Applicable

Band

Date of

Purchase

Serial No.

Purchased At

This manual suits for next models

3

Table of contents

Other BINDTEC Packaging Equipment manuals