1-3

1.1 ACCESSORIES

1.1.1 Battery

Use only original Fromm batteries N5.4349 (Li-Ion).

1.1.2 Battery chargers

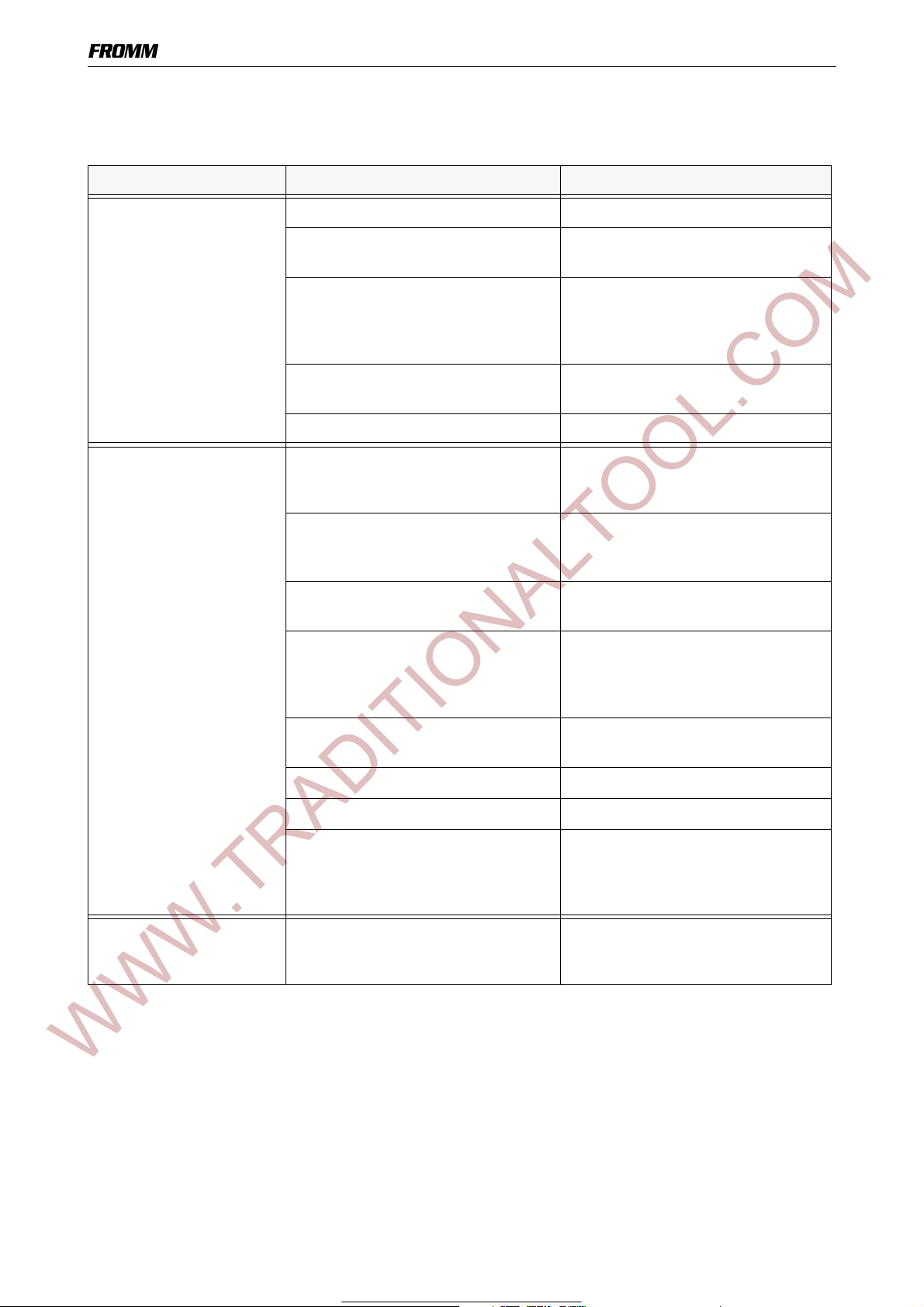

The battery charger must be ordered separately according to the table mentioned below.

(..) = an adaptor N52.2102 is required.

1.1.3 Battery tester

Information to the Battery tester you will get by FROMM System GmbH.

(see 1.10 SERVICE ADDRESS)

1.1.4 Memory reader for circuit board

To read the memory information of the tools circuit board the reader N7.5154 can be ordered.

With this the following data could be read:

• software version

• date of software

• strapping cycles

• calibration current

1.1.5 Fan

In order to avoid overheating of the motor we recommend at environmental temperatures above 40°C / 104°F

using the optional fan P32.0228.

(see 1.4.7 Assembly information)

1.2 TECHNICAL DETAILS

1.2.1 Strap tension

The tension force values mentioned in the operation manual (250-2600N) are not achievable with each strap.

They depend on following factors:

• Hardness of the package,

the maximum tension force values are achievable with hard packages.

• Elongation and creep properties of the plastic strap,

the maximum tension force values are achievable by using plastic straps with a low elongation.

• Surface quality of the plastic strap,

the maximum tension force values are achievable with waxed and embossed straps.

• Strap width, strap thickness,

the maximum tension force values are achievable with thick and wide straps.

Item-No. Voltage / frequency Admitted for country

N5.4443 220 - 240V / 50 - 60Hz A, B, BG, BIH, BOL, BR, BY, CH, CL, CZ, D, DK, DZ, E, EAS, EST,

ET, F, FIN, GE, GR, H, HK, HR, I, IL, IND, IR, IRQ, IS, JOR, KSA,

KWT, L, LAR, LT, LV, MA, MC, MK, MOC, N, NL, P, PK, PE, PL, PRC,

PY, RA, RCH, RI, RL, RO, ROK, ROU, RP, RUS, S, SK, SLO, SYR,

THA, TN, TR, UA, (UAE), YU, YV, (BRN), (BRU), (CY), (EAK), (EAT),

(GB), (IRL), (M), (MAL), (OM), (SGP), (Y), (Z), (ZA), (ZW)

N5.4447 120V / 50 - 60Hz BR, C, CDN, CO, CR, DOM, EC, GCA, J, JA, KSA, LB, MEX, NIC,

PA, Puerto Rico, RC, RP, USA, YV

N5.4445 220 - 240V / 50 - 60Hz AUS, NZ

For Parts & Service 1-877-862-6699