Operation Switch

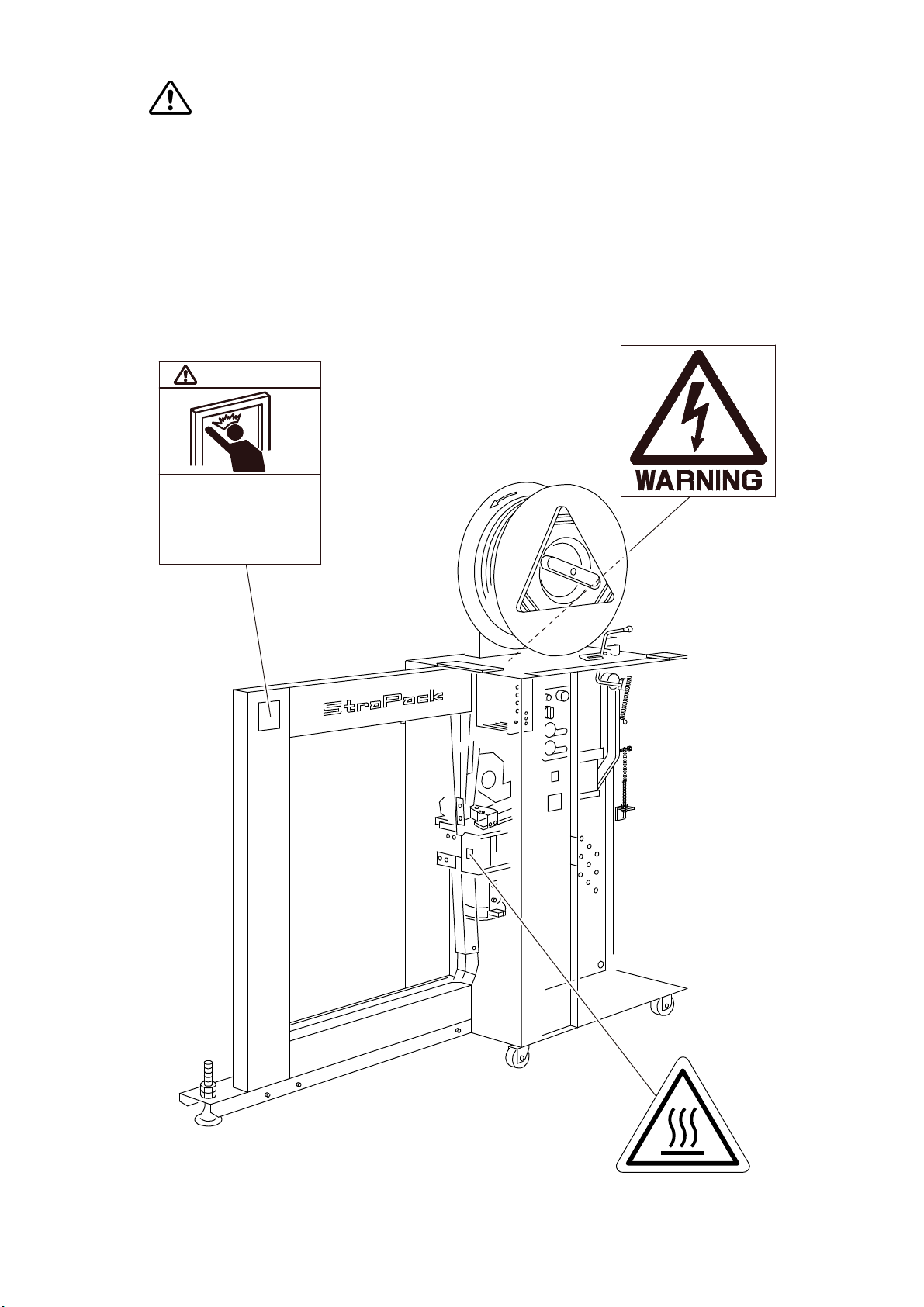

CAUTION

For the safety, Front Door is fixed with bolt.Turn OFF the Main Switch① when

it is opened.

Main Switch

Turning this switch on will supply the power to the machine.

O

eration Read

Switch and Power Indicator Lam

When the Power supply switch is turned on, the Power Indicator Lamp will

flash slowly. After the Heater Plates reaches operating temperature and

is ready to begin packaging, the lamp will flash quickly (Approximately

25 seconds after turning the machine on). Press the Operation Ready Switch

once, so that the lamp will change from flashing to a steady light.

While this indicator is blinking, the machine will not start a packaging operation,

even if you press the start button.

When the coil of strapping is completely exhausted, the Power Indicator Lamp

will start to flash slowly and the machine will come to a standstill automatically.

Remove the remaining strap from the Pool Box and mount a new coil of

strapping on the machine (refer to: How to thread the strapping material).

Tension Ad

ust Dial (T3)

The Tension Adjust Dial controls the strap tension. Although this model

has an adjustable tension stroke of 0 - 150 mm, the dial scale runs from 0

(minimum) to 10 (maximum), for the operator's convenience (for 5/6 mm

strapping, the tension stroke is 0 - 90 mm). Using this dial, set a suitable

strap tension according to the size of the package.

Start Switch

This step will initiate the strapping cycle. When the Start Switch is pressed,

one strapping operation cycle will start.

If no strapping operation takes place for 3 minutes, the Sealing Motor will

be shut off by an energy-saving circuit. To restart the Sealing Motor

turning, press the Start Switch. If a strapping cycle is not initiated, press

the switch again or, hold it down in order to activate The Sealing Motor and

start a strapping cycle at the same time.

Sto

Switch

Use the stop switch in emergency or whenever you want to stop the

strapping cycle before it is complete. When pressed, the Stop Switch will

lock. This switch will bring the machine to a complete and immediate stop.

However, unlike the Power Supply Switch, the Stop Switch does not

disconnect the Heater. Therefore, the operator can resume strapping at

any time without waiting for heater element to warm up again.

To resume operation, twist to release lock on the Stop Switch and press

the Operation Ready switch to re-start rotation of the sealing motor. The

lamp inside the Operation Ready Switch will change from flashing to a steady

light. Then the machine will be ready for strapping again. when the machine

will not be used for a period of time, Press this switch for added safety.

-7-