Triton Systems ©

5

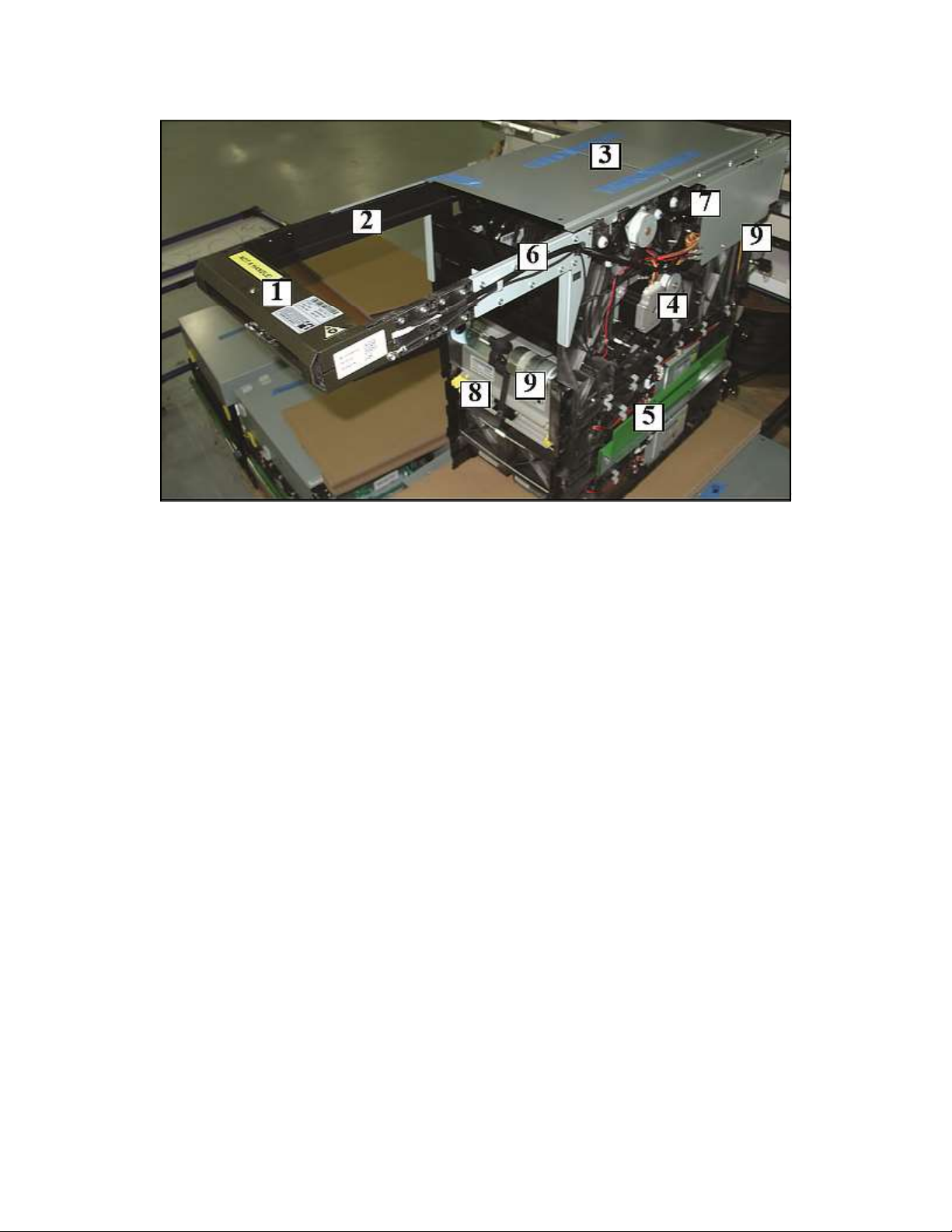

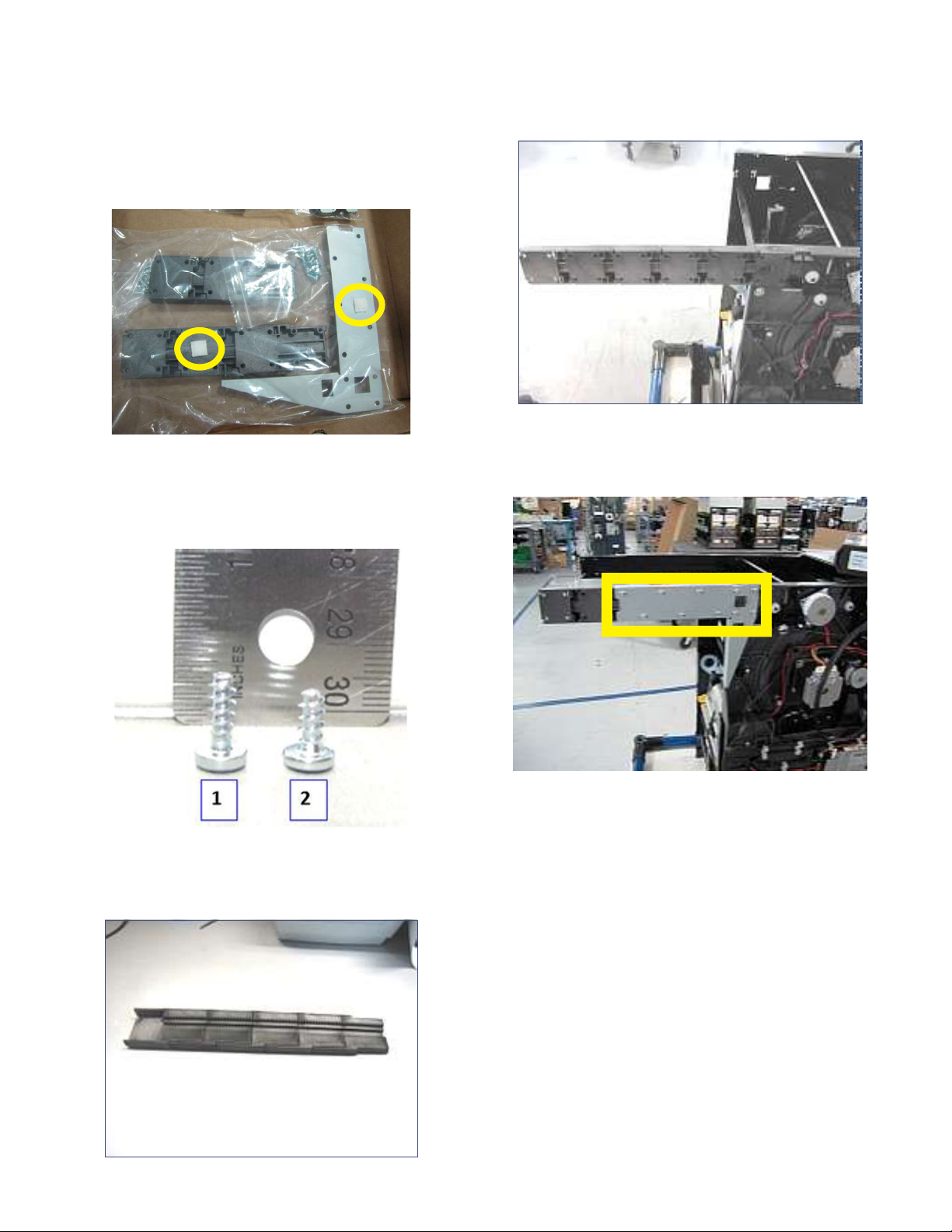

1. Do not remove the inner box. Use the inner and

outer boxes for repackaging and shipping. Save all

packing material for re-use in return shipment, the

four (4) corner cushions, (Figure 2A), green air

llers, and the cardboard tray (Figure 2B).

Figure 2A Figure 2B

Caution

e BOU with cable is connected to the NMD100

chassis. Do not damage the cable in the process of

removing the BOU and the dispenser from the box.

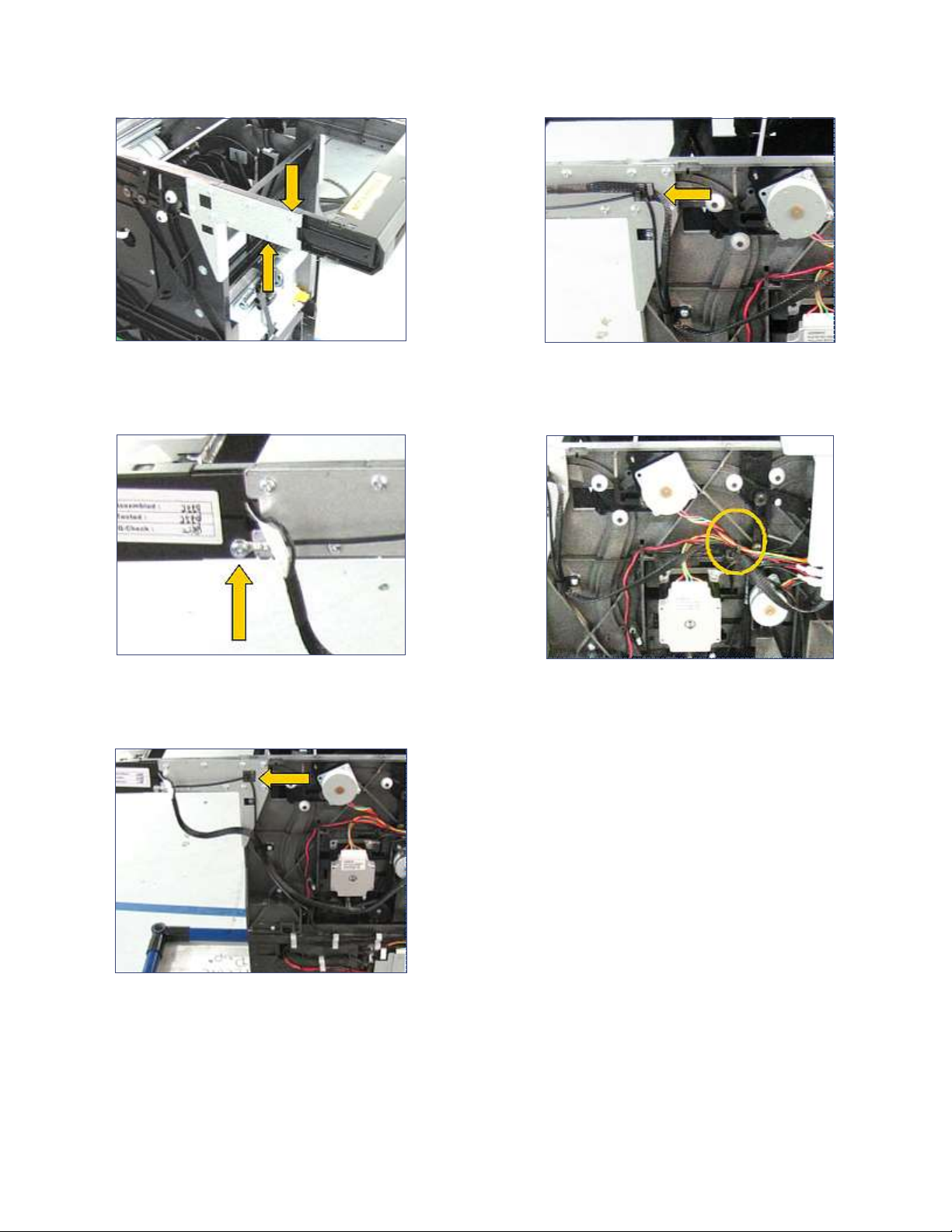

2. (Figure 3A), remove the extension kit (Yellow ar-

row) and set aside. Hold the BOU with the (STOP)

label out of the way until ready to li the dispenser

from the box.

Figure 3A

3. Remove and set aside the packing foam from the

top and sides of the dispenser. All returns must be

received with original packing material.

4. Remove the top cover with the internal foam label.

No fasteners hold the cover in place, (Figure 3B).

Remove the 3 pieces of BCU retaining foam from

**Note**

Before proceeding, follow these steps to properly unpack the contents and prepare for assembly of the Bundle

Output Unit extension and its attachment to the NMD 100 dispenser. Save all packing materials for use in

returning unit.

the unit, (Figure 3C). Set aside with the other

foams for reshipment.

Figure 3B Figure 3C

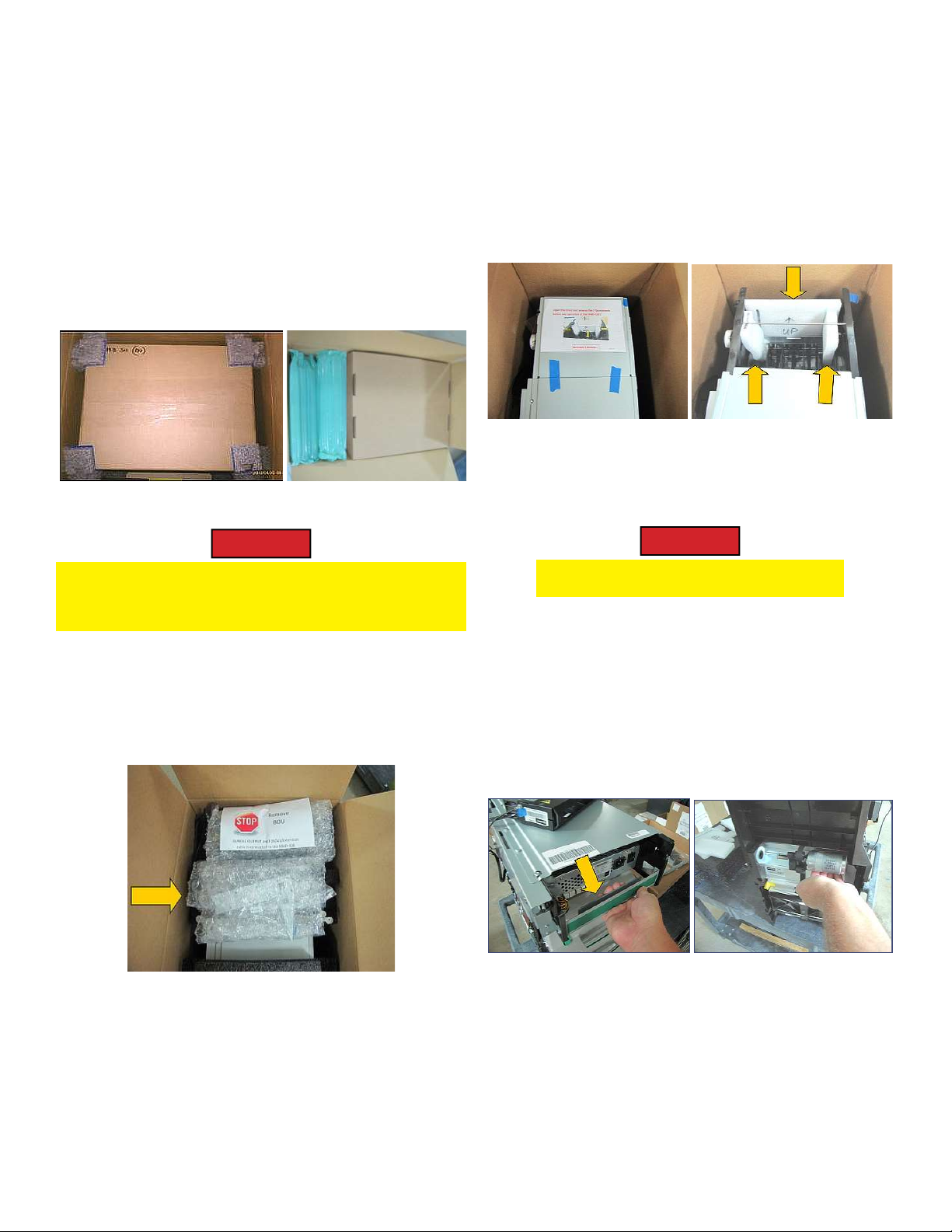

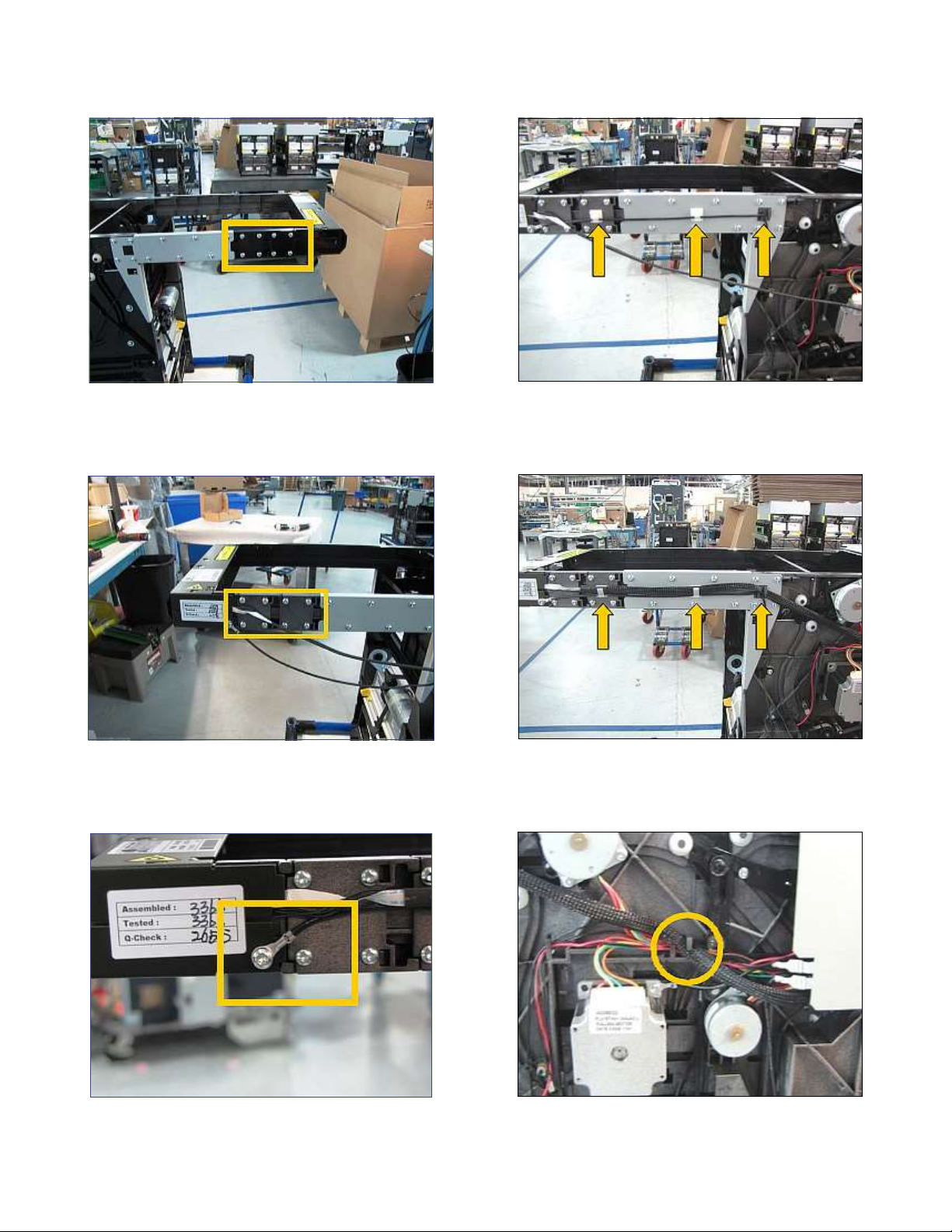

5. Rest the BOU on top of the dispenser, (Figure 4A).

Caution

e NMD100 is a two-person li .

6. Li handles will not be shipped with the unit. To

remove the unit, reach in front and grip the upper

dispenser bracket, (Figure 4A). Reach behind the

unit and grip the main motor housing, (Figure

4B). Li the dispenser straight up, then out of the

inner box. Place the unit on a sturdy work table to

complete the assembly.

Figure 4A Figure 4B

7. Examine the BOU, parts kit, and the dispenser’s

outside and inside areas for cracks or damages

caused by shipping. Inspect wiring connections.

Ensure note quali er doors (Figure 1) are snapped

closed.

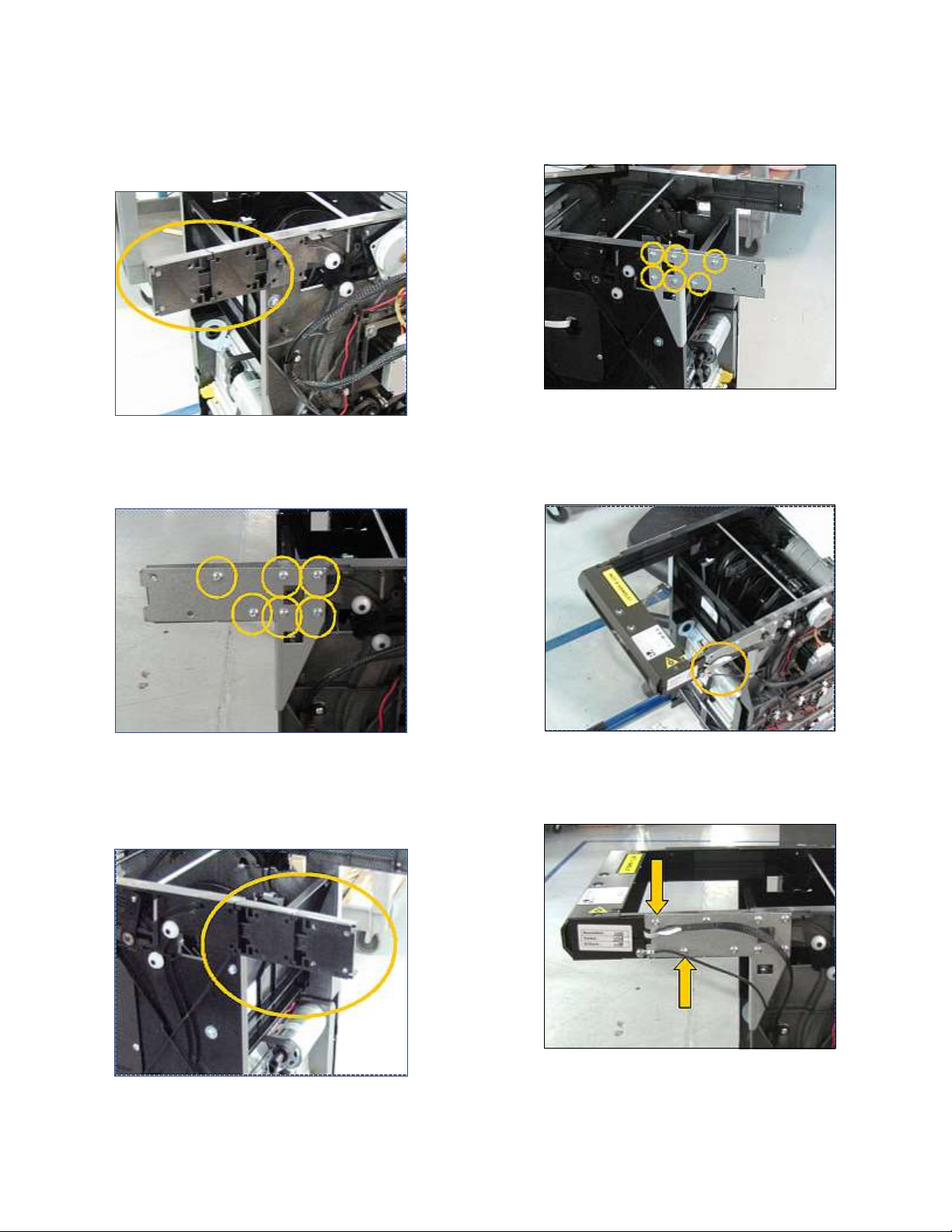

8. See instructions for installing a 5” or 10” extension

assembly below.