EN

77-3026-R1.22 / 16

Binks reserves the right to modify equipment specification without prior notice.

EC Declaration of Conformity

Manuf. By: Finishing Brands

195 Internationale Blvd.

Glendale Heights, IL 60139

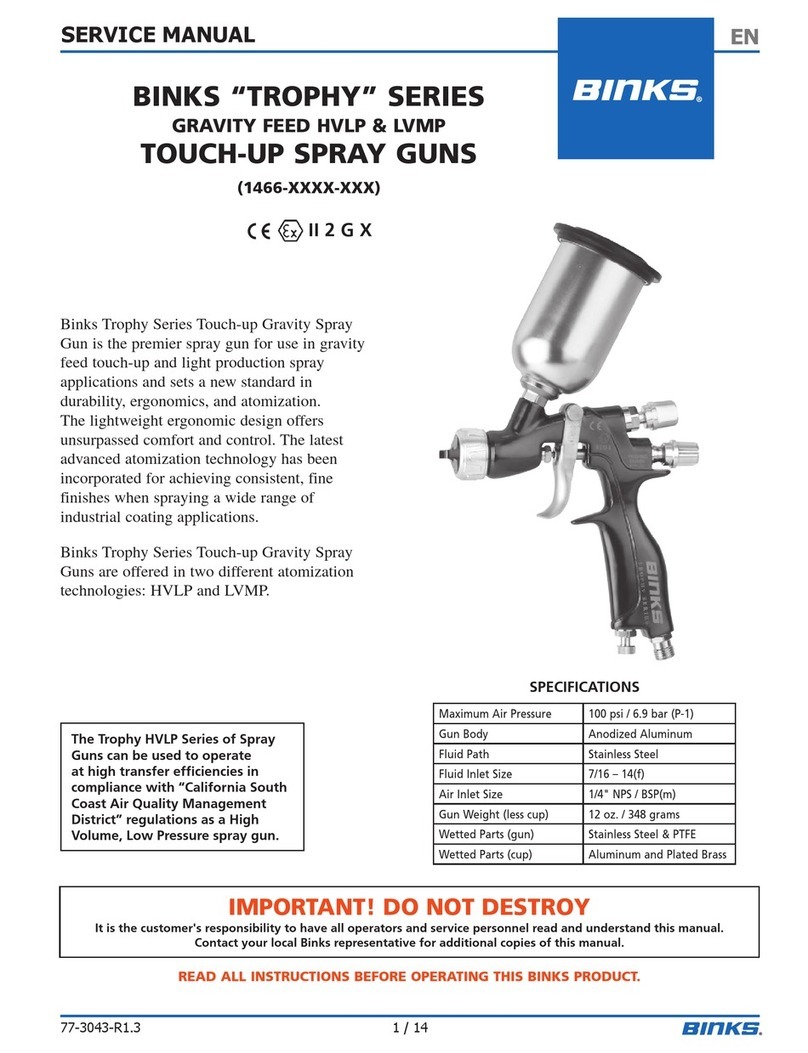

Type/Series: Handheld Spray Guns

Model: Binks “Trophy” Series

The equipment to which this document relates is in conformance with the following standards or other normative references:

BS EN IS0 12100:2010 and BS EN 1953:1998 + A1:2009 and thereby conform to the protection requirements of Council

Directive 2006/42/EC relating to Machinery Safety Directive, and;

BS EN 13463-1:2009, Council Directive 94/9/EC relating to Equipment and Protective Systems for use in Potentially Explosive

Atmospheres, protection level II 2 G X.

Approved By: _____________________________ Date: ______________

Binks

Marvin Burns August 1, 2013

WARNING

!

In this part sheet, the words WARNING, CAUTION and NOTE are used to emphasize important safety information as follows:

!

CAUTION

Hazards or unsafe practices which could

result in minor personal injury, product

or property damage.

!

WARNING

Hazards or unsafe practices which could

result in severe personal injury, death or

substantial property damage.

NOTE

Important installation, operation or

maintenance information.

Read the following warnings before using this equipment.

FOR FURTHER SAFETY INFORMATION REGARDING BINKS AND DEVILBISS EQUIPMENT,

SEE THE GENERAL EQUIPMENT SAFETY BOOKLET (77-5300).

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PROVIDE THIS INFORMATION TO THE OPERATOR OF THE EQUIPMENT.

READ THE MANUAL

Before operating finishing equipment, read and understand all

safety, operation and maintenance information provided in the

operation manual.

WEAR SAFETY GLASSES

Failure to wear safety glasses with side shields could result in

serious eye injury or blindness.

DE-ENERGIZE, DEPRESSURIZE, DISCONNECT AND LOCK OUT ALL

POWER SOURCES DURING MAINTENANCE

Failure to De-energize, disconnect and lock out all power

supplies before performing equipment maintenance could cause

serious injury or death.

OPERATOR TRAINING

All personnel must be trained before operating finishing

equipment.

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture,

malfunction, or start unexpectedly and result in serious injury.

KEEP EQUIPMENT GUARDS IN PLACE

Do not operate the equipment if the safety devices have been

removed.

PROJECTILE HAZARD

You may be injured by venting liquids or gases that are released

under pressure, or flying debris.

PINCH POINT HAZARD

Moving parts can crush and cut. Pinch points are basically any

areas where there are moving parts.

INSPECT THE EQUIPMENT DAILY

Inspect the equipment for worn or broken parts on a daily basis.

Do not operate the equipment if you are uncertain about its

condition.

NEVER MODIFY THE EQUIPMENT

Do not modify the equipment unless the manufacturer provides

written approval.

KNOW WHERE AND HOW TO SHUT OFF THE EQUIPMENT IN CASE

OF AN EMERGENCY

PRESSURE RELIEF PROCEDURE

Always follow the pressure relief procedure in the equipment

instruction manual.

NOISE HAZARD

You may be injured by loud noise. Hearing protection may be

required when using this equipment.

STATIC CHARGE

Fluid may develop a static charge that must be dissipated through

proper grounding of the equipment, objects to be sprayed and all

other electrically conductive objects in the dispensing area. Improper

grounding or sparks can cause a hazardous condition and result in

fire, explosion or electric shock and other serious injury.

PROP 65 WARNING

WARNING: This product contains chemicals known to the

State of California to cause cancer and birth defects or other

reproductive harm.

FIRE AND EXPLOSION HAZARD

Never use 1,1,1-trichloroethane, methylene chloride, other

halogenated hydrocarbon solvents or fluids containing such solvents

in equipment with aluminum wetted parts. Such use could result in

a serious chemical reaction, with the possibility of explosion. Consult

your fluid suppliers to ensure that the fluids being used are

compatible with aluminum parts.