Binsfeld TorqueTrak Revolution User manual

TorqueTrak Revolution

Torque and Power

Monitoring System

User’s Guide

866001-9_J

- 1 -

Table of Contents

System Overview 2

System Components 3

Controls and Connections Overview 4

Controls and Connections 5

Power Input 5

Torque Output Signal 6

Torque Signal Calibration Controls 7

Power Output Signal 10

Power Signal Calibration Controls 11

Speed (RPM) and Direction Output Signals 14

System Status Indicator Lights 16

Transmitter Status Indicator Light 17

Installation Procedure 18

Set Up Procedure 21

Appendix A: Revolution Specifications 25

Appendix B: Torque Calibration Calculations 27

Appendix C: Error Codes & Troubleshooting 29

Appendix D: Strain Gage Application 32

Warranty and Service Information 37

- 2 -

System Overview

The TorqueTrak Revolution is a single channel, non-contact,

inductively-powered system designed to provide continuous

torque, speed (rpm), power, and direction of rotation data from a

rotating shaft. The system consists of two primary components:

the Rotating Shaft Collar with integral Transmitter Module and

the Master Control Unit with stationary Power Ring.

The TorqueTrak Revolution features:

➢four simultaneous data signals: torque, speed, power

and direction

➢user adjustable scaling for torque and shaft power

➢digital design inherently immune to electrical noise

➢non-contact inductive power and data transfer eliminates

wear surface for long life without signal degradation

➢does not require shaft modification or machine

disassembly to install

➢fully encapsulated rotating electronics with status

indicator light on the transmitter

➢switchable low pass filter

➢remote shunt system calibration

➢self diagnosis with error mode indicator lights

➢offset and gain settings stored in non-volatile memory

➢high resolution data (14 bit)

The TorqueTrak Revolution is a rugged precision instrument

designed for applications where ongoing measurement of torque

and/or power on a rotating shaft is required.

- 3 -

System Components

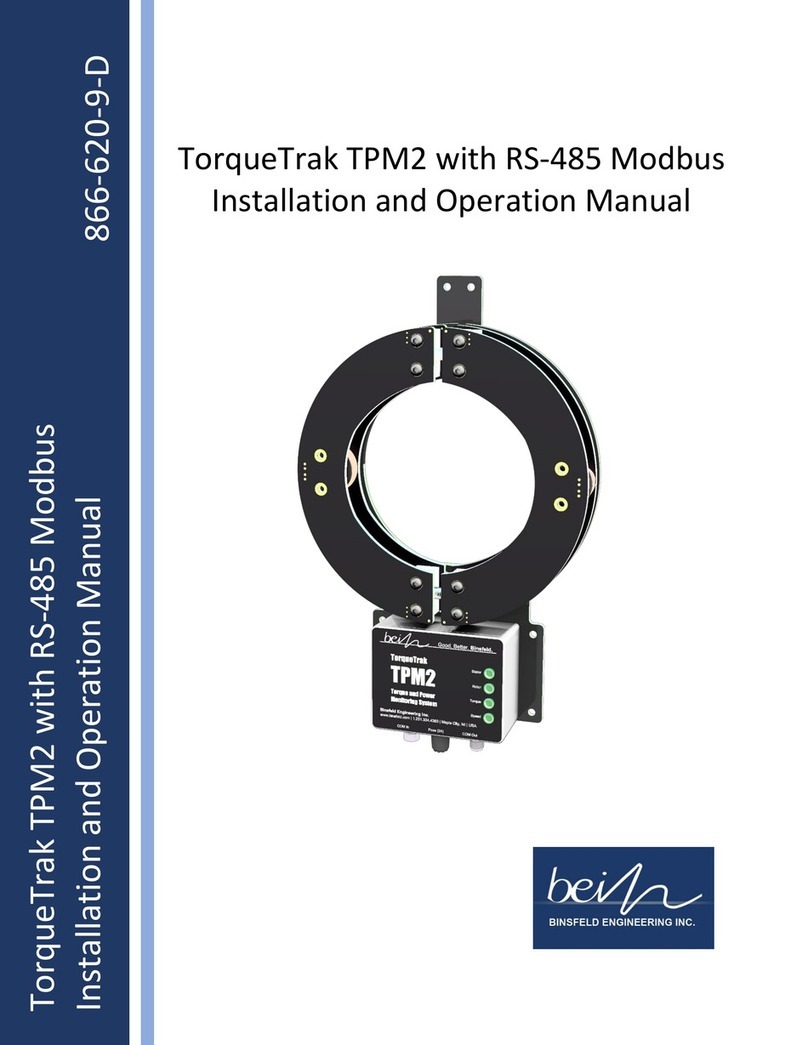

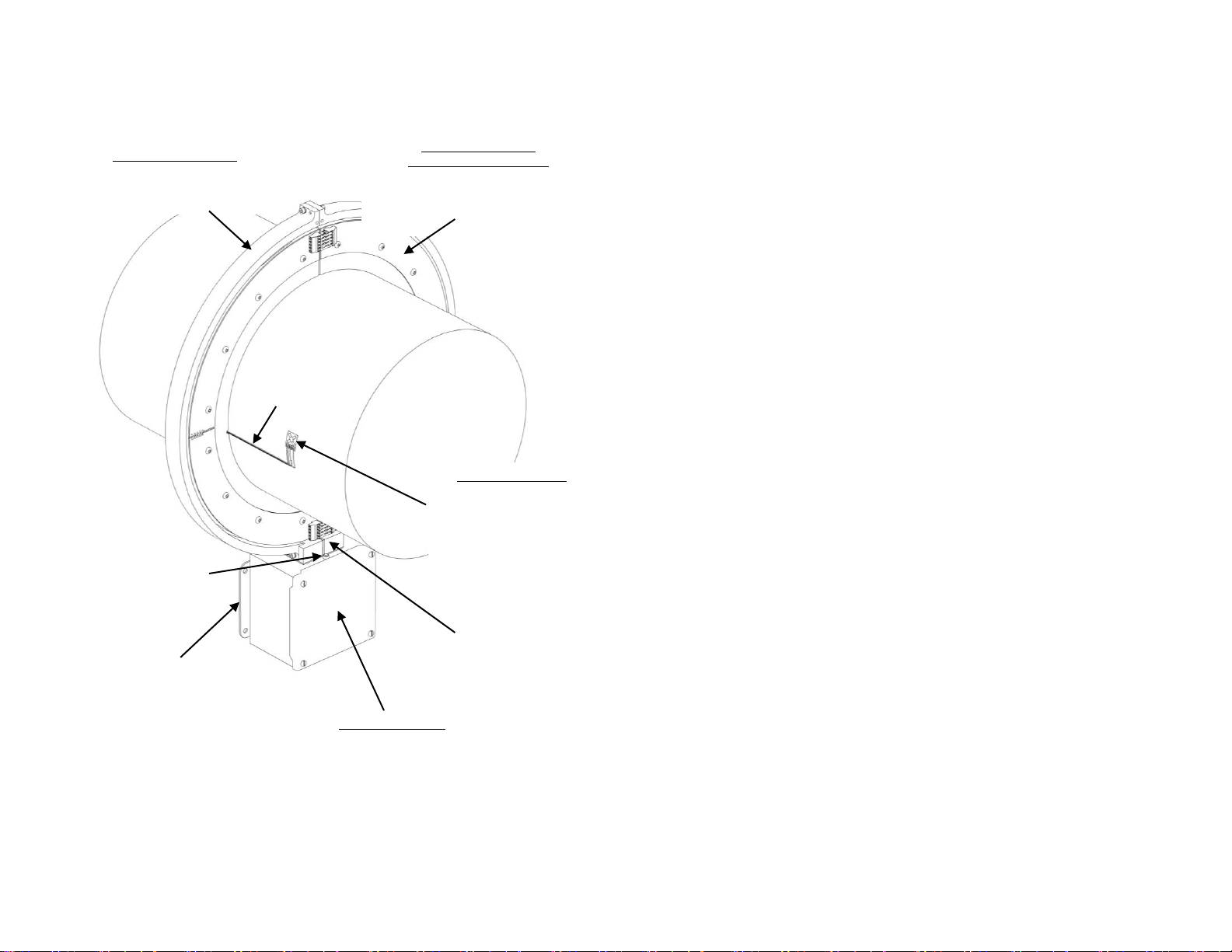

Figure 1 –Revolution System Components

Strain Gage Sensor

(Glued to shaft; not

included but ordered as

an accessory)

Converts mechanical

torque to electrical signal

which is transmitted from

the Rotating Collar to the

Stationary Power Ring.

Stationary Power Ring

Sends power to the Rotating

Collar and receives data signal

from the Rotating Collar

Rotating Shaft Collar

(with Transmitter Module)

Clamps to shaft with bolts provided.

Houses Transmitter Module which

converts strain gage signal to digital

code.

Master Control Unit

Provides power signal to Power Ring.

Processes digital data signal from

transmitter to produce four 4-20mA output

signals corresponding to torque, speed

(RPM), shaft power and direction of

rotation.

Mounting Flange

Lead wires from

collar for sensor

connection

(shaft)

Mounting Block with

speed sensor

Main System

Status Indicator

Light

- 4 -

Controls and Connections Overview

Power Config Switches

1 = Pos FS power

2 = Neg FS power

1&2 = Zero power

3 = Set zero power to 4mA

4 = Reverse signal polarity

5 = Power once/revolution

6 = ON for <10 RPM

7 = Off Off On On

8 = Off On Off On

Filter: 1000 12 1.5 0.1Hz

Note: When Torque

Configuration Switches 1

and 2 are ON

simultaneously, the system

simulates a zero input

signal from the transmitter

(nominally generates a 12

mA output).

Torque Config Switches

1 = Pos FS torque

2 = Neg FS torque

1&2 = Zero torque

3 = Set zero torque to 4mA

4 = Reverse signal polarity

5 = Bypass user calibration

6 = Not used.

7 = Off Off On On

8 = Off On Off On

Filter: 1000 12 1.5 0.1Hz

System Calibration

“EN” to enable

Offset/Gain switches.

“SAVE” to store.

Gain (Scale)

Adjustment

System Status Indicators

Stator: ON = Input power level okay

Rotor: ON = Collar power okay, no errors

Data: ON = No data transmission errors

Range:ON = Sensor input out of range

RPM: Flashes 6 times per revolution

(NOT USED)

Signal Output Terminals

1 = Torque Output HI (+I)

2 = Torque Output LO (-I)

3 = Power Output HI (+I)

4 = Power Output LO (-I)

5 = Speed Output HI (+I)

6 = Speed Output LO (-I)

7 = Direction Output HI (+I)

8 = Direction Output LO (-I)

Power Scaling (RPM Factor) Switches

Set (RPM Factor) switches to:

RPM Factor = PFS x C / TFS

PFS = Full Scale Power (hp or kW)

TFS = Full Scale Torque (ft-lb or N-m)

C = 5252 (ft-lb,hp) or 9550 (N-m,kW)

Main Power Switch

Offset (Zero)

Adjustment

Shunt

Calibration

Switch

CAUTION!

Power Input

1 = +Pos/HI

2 = Chassis

3 = -Neg/LO

Rev A

- 5 -

Controls and Connections

Power Input

The Master Control Unit operates on 11-16 VDC (standard) or

115VAC or 230VAC (optional). Power connections are made via

a removable three-position screw terminal block as shown

below.

WARNING: Supply voltage (up to 230VAC) is live in the

Master Control Unit even when the Main Power switch

is off! Use caution when accessing internal controls.

Figure 2 - Power Input Controls and Connections

Main Power Switch

Fuses

One fuse is connected to high

side power, one fuse is

connected to low side power.

Power Input Connector Block

DC Power AC Power

Terminal 1: +Pos High

Terminal 2: Chassis Gnd Chassis Gnd

Terminal 3: -Neg Low

115VAC/230VAC Switch

(only available with VAC Option)

Slide to the left for 115VAC power.

Slide to the right for 230VAC power.

- 6 -

Torque Output Signal

The 4-20mA torque output signal is accessed from a removable

eight-position screw terminal block on the upper-most board in

the Master Control Unit. Torque signal calibration controls,

including gain and offset adjustments, are described below.

Figure 3 - Torque Output Controls and Connections

Torque Signal Configuration Switches

Used to set data signal options, e.g.

activating low pass filter or reversing

signal polarity. See details below.

Torque Signal Output Terminals

Terminal 1 = Shaft Torque Output Current Loop (+I)

Terminal 2 = Shaft Torque Output Current Loop Return (Common)

User Calibration Enable Switch

ENabled (right) position: Calibration is enabled (gain and offset adjustments

are active and will affect the torque output signal)

SAVE (left) position: Calibration is saved (gain and offset settings are stored

in memory and adjustment switches are disabled)

User Calibration Offset Adjustment

(Zero Reference Adjustment)

Push DEC switch to decrease torque

output signal offset. Push INC switch to

increase torque output signal offset.

User Calibration Gain Adjustment

(Scale Adjustment)

Push DEC switch to decrease torque

output signal gain. Push INC switch to

increase torque output signal gain.

Remote Shunt Calibration Switch

Used to place a precision “shunt”

resistor across one arm of the full-

bridge strain gage sensor simulating

50% full scale torque.

- 7 -

Torque Signal Calibration Controls

The Revolution System offers several features for fine-tuning the

torque output signal to suit the user’s application. The primary

controls are for adjusting the offset (zero) and gain (scale) of the

system. Other operations include activating the remote shunt

calibration and changing the default zero output signal from

12 mA to 4 mA. All of the controls are described here.

User Calibration Enable –Used to enable the User Calibration

Gain and Offset Adjustments. Specifically, when this switch is in

the EN (enable) position,the GAIN and OFFSET INC (increment)

and DEC (decrement) pushbutton switches are active. (See

description below.) When switched to the SAVE position, the

current offset and gain adjustments are stored in memory and

the GAIN and OFFSET adjustment switches are disabled.

User Calibration Offset Adjustment –Used to manually adjust

the offset (zero reference point) of the torque output signal.

When User Calibration is enabled (see description above),

pressing the OFFSET INC button will increase the offset thus

changing the nominal 12 mA zero reference to a higher value.

Conversely, pressing the DEC button will decrease the offset

thus changing the nominal 12 mA zero reference to a lower

value. The nominal zero reference output of 12 mA can be set to

any output level from 0 –24 mA. Note: Changing the offset

(zero reference) of the torque output signal does not affect the

gain (scale factor) of the torque output signal.

To change the zero reference value from 12 mA to 4

mA (i.e. change the zero-to-positive full scale output

range from 12-20 mA to 4-20 mA) activate Torque

Signal Configuration Switch #3 as described below.

User Calibration Gain Adjustment –Used to manually adjust

the gain (scale factor) for the torque output signal. When User

Calibration is enabled (see description above), pressing the

GAIN INC button will increase the torque signal gain.

Conversely, pressing the DEC button will decrease the torque

signal gain. The torque signal gain can be adjusted to any level

from 25% (¼x) to 400% (4x). Note: Changing the gain (scale

factor) of the torque output signal may affect the offset (zero

reference) of the torque output signal.

- 8 -

Remote Shunt Calibration Switch –Used to verify system

operation without directly accessing the strain gage. When

switched to the ON position, a fixed precision resistance (inside

the Transmitter Module) is applied across one arm of the strain

gage bridge simulating strain that produces a torque signal

output corresponding to 50% of Full Scale in the positive

direction at factory default settings (16mA for 12mA zero torque,

12mA for 4mA zero torque). In the OFF position, the resistance

is removed from the sensor. Note: The System Status Indicator

light flashes (and the internal “Rotor” light flashes) when the

Remote Shunt is applied.

Torque Signal Configuration Switches –Used to set specific

torque signal parameters as listed here. The ON position for

each switch is upwards (towards the Power Ring).

Switch Function when switch is ON:

1 Simulates a positive full scale torque input signal from

the transmitter (nominally generates 20 mA output)

2 Simulates a negative full scale torque input signal from

the transmitter (nominally generates 4 mA output)

1&2 Simulates a zero input signal from the transmitter

(nominally generates a 12 mA output)

3 Full Scale Torque Output Range:

4-20mA with dipswitch #3 ON (up), 4mA zero

12±8mA with dipswitch #3 OFF (down), 12mA zero

4 Reverses the polarity of the torque signal

5 System bypasses the user calibration settings (i.e.

manual gain and offset adjustments are ignored)

6 (Not used)

To restore the factory offset and gain settings:

a) Slide SAVE-CAL-ENable switch to “EN” position

b) Activate dipswitch #5 of Torque Signal

Configuration panel, “Bypass User Calibration”

c) Slide SAVE-CAL-ENable switch to “SAVE” position

d) Deactivate dipswitch #5 of Torque Signal

Configuration panel.

(See Torque Configuration Switch details below.)

- 9 -

7&8 Used to set frequency response of torque signal (i.e.

select cut-off frequency for low pass filter) as follows:

Switch 7 Switch 8 Cut-off Frequency

Off Off 1000 Hz

Off On 12 Hz

On Off 1.5 Hz

On On 0.1 Hz

Factory Default: All switches in the OFF position.

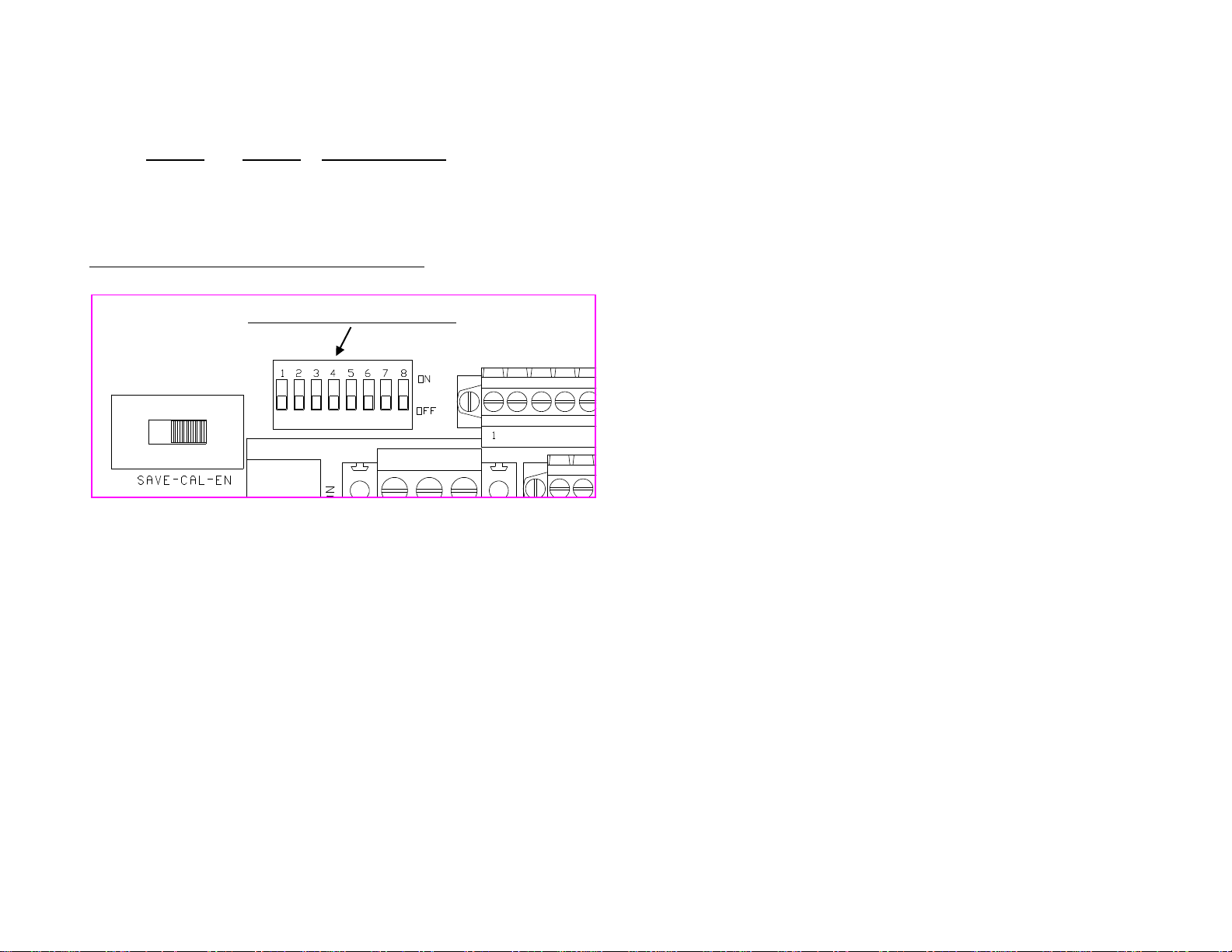

Figure 4 - Torque Signal Configuration Switches

Torque Signal Configuration Switches

- 10 -

Power Output Signal

The 4-20 mA shaft power output signal is accessed from a

removable eight-position screw terminal block on the upper-most

board in the Master Control Unit. Power signal scaling and

configuration switches are described below.

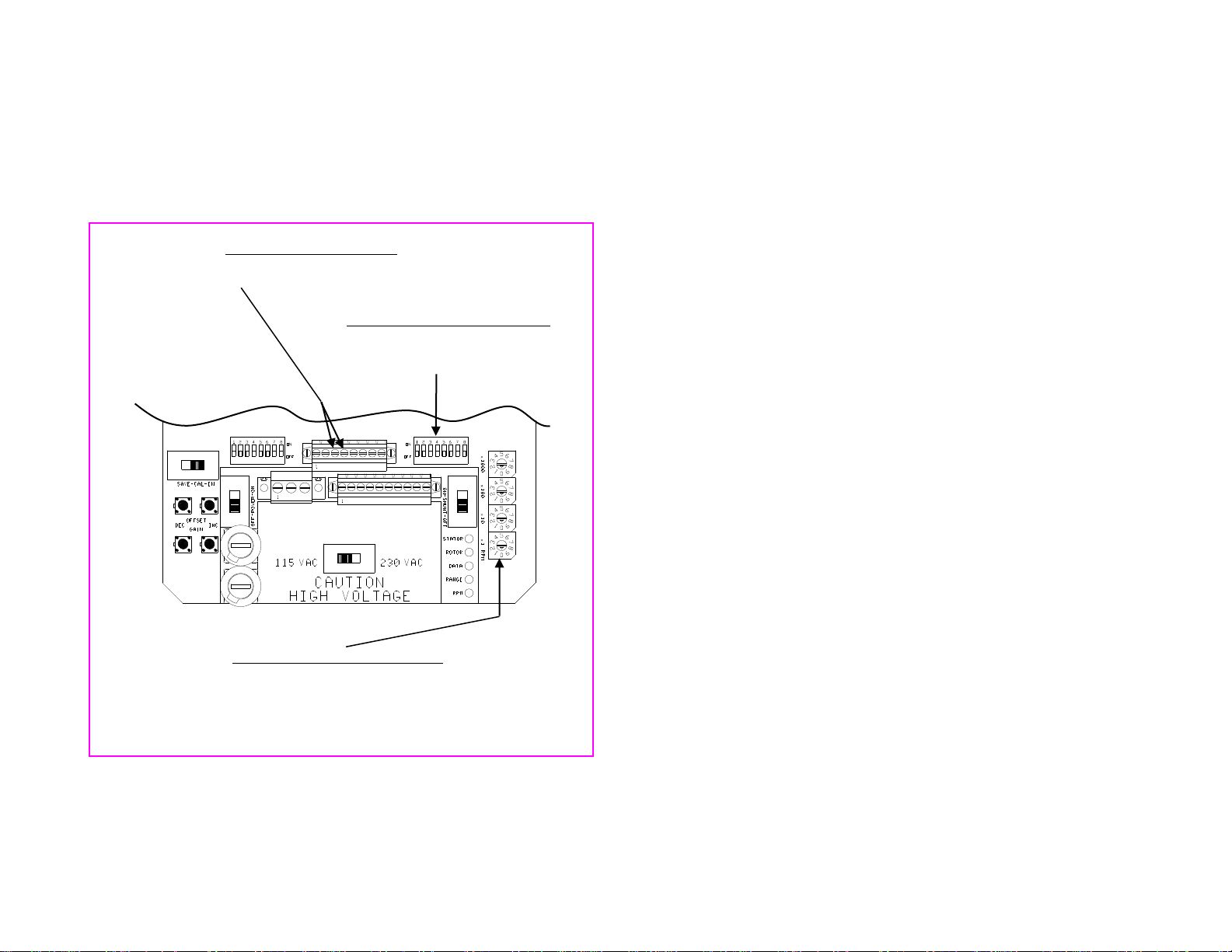

Figure 5 - Power Output Controls and Connections

Power Signal Configuration Switches

Used to set data signal options, e.g.

activating low pass filter or reversing signal

polarity. See table below for details.

Power Signal Output Terminals

Terminal 3 = Power Output Current Loop (+I)

Terminal 4 = Power Output Current Loop Return (Common)

Power Scaling (RPM Factor) Switches

Use these rotary switches to set the scale factor relating the torque signal to

the shaft power signal according to the equation:

PFS x Constant / TFS = RPM Factor.

See details below and in Set Up Procedure.

- 11 -

Power Signal Calibration Controls

The Revolution System offers several features for fine-tuning the

power output signal including adjusting the full scale value and

selecting the frequency response. The power scaling and

configuration controls are described here.

The only offset (zero reference) adjustment for the

power signal is via switch #3 in the Power Signal

Configuration Switch panel. (See details below). If

Power Configuration switch #3 is not activated a power

output signal of 12 mA will always indicate zero power

and zero power will always correspond to zero torque

and/or zero RPM.

Power Scaling (RPM Factor) Switches –Used to set the full

scale range for the power output signal (as described in the Set

Up Procedure). There are four rotary switches corresponding to

thousands (x1000), hundreds (x100), tens (x10) and units (x1).

The switches are set by using a small screwdriver to turn the dial

indicator to the desired digit and then cycling system power.

Note: System must be turned OFF then ON (using Main Power

Switch) to register new RPM factor switch settings!

For example, if the calculated RPM Factor is 1490 then the

switches would be set as follows:

x1000 -position 1

x100 -position 4

x10 -position 9

x1 -position 0

IMPORTANT: Power supply to the TorqueTrak Revolution must

be cycled Off, then back On, to make effective any changes to

the RPM Factor switch setting.

Note: The power signal gain (sensitivity) is dependent

upon and proportional to the torque gain.

Power Signal Configuration Switches –Used to set specific

power signal parameters as listed here. Note: The ON position

for each switch is upwards (towards the Power Ring).

- 12 -

Switch Function when switch is ON (Factory Default: All OFF):

1 Generates positive full scale power output signal (20mA)

2 Generates negative full scale power output signal (4 mA)

1&2 Generates zero power output signal (12 mA)

3 Full Scale Power Output Range:

4-20mA with dipswitch #3 ON (up)

12±8mA with dipswitch #3 OFF (down)

4 Reverses the polarity of the power signal

5 Updates power output signal once per shaft revolution

6 Normally OFF. ON for very low speed shafts (<10 RPM)

7&8 Used to set frequency response of power signal (i.e. select cut-

off frequency for low pass filter) as follows:

Switch 7 Switch 8 Cut-off Frequency

Off Off 1000 Hz

Off On 12 Hz

On Off 1.5 Hz

On On 0.1 Hz

Figure 6 - Power Signal Scaling and Configuration Switches

Power Scaling (RPM Factor)

Switches

Power Signal Configuration

Switches

- 13 -

When switch #3 is activated the output signal at zero power

changes from 12 mA to 4 mA and simultaneously the signal gain

is doubled.

When Switch #5 is OFF, the power output signal is calculated

and updated 6 times per shaft revolution (i.e. whenever the RPM

sensor is triggered). When Switch #5 is ON, the power output

signal is calculated and updated only once per shaft revolution

thereby averaging the power data over a complete revolution.

Switch #6 is used when the shaft speed is very low (less than 10

RPM). When Switch #6 is ON the system adds a delay between

the time the RPM sensor is triggered and the time the power

output signal is allowed to indicate zero power. This feature

prevents a slowly rotating shaft from erroneously generating a

zero power data signal.

- 14 -

Speed (RPM) and Direction Output Signals

The 5 or 19mA speed (RPM) and direction output signals are

accessed from a removable eight-position screw terminal block

on the upper-most board in the Master Control Unit as described

below.

Figure 7 - Speed and Direction Output Connections

The speed (RPM) output signal is a pulse train that is nominally

5 mA or 19 mA (depending on shaft direction) which pulses to

the alternate current level at the following rate:

RPM

FPULSE = ------------

10

FPULSE = Frequency of the pulse train in Hertz

RPM = Shaft revolutions/minute

Direction Signal Output Terminals

Terminal 7 = Direction of Rotation Output Current Loop (+I)

Terminal 8 = Direction of Rotation Output Current Loop Return (Common)

Speed (RPM) Signal Output Terminals

Terminal 5 = Speed Output Current Loop (+I)

Terminal 6 = Speed Output Current Loop Return (Common)

- 15 -

When viewed from the front of the Master Control Unit with the

coil board on the Rotating Collar in view a clockwise rotation

produces a speed signal that is nominally 19 mA with 5 mA

pulses. Conversely a counterclockwise rotation produces a

speed signal that is nominally 5 mA with 19 mA pulses.

Six magnets in the Rotating Collar trigger the pickup sensor in

the Mounting Block on top of the Master Control Unit to generate

the speed signal.

The direction signal is a simple binary indicator, 5 mA when the

shaft rotates in one direction and 19 mA when it rotates in the

other direction.

Clockwise Shaft Rotation:

Direction signal:19 mA, constant

Speed signal: 19 mA, pulsing to 5 mA at the rate of 6 pulses

per revolution

Counterclockwise Shaft Rotation:

Direction signal:5 mA, constant

Speed signal: 5 mA, pulsing to 19 mA at the rate of 6 pulses

per revolution

NOTE: The maximum load resistance of any one of the

TorqueTrak Revolution output current loops is 500 ohms. This

means the system can drive the 4-20 mA output signal into

resistances of 0 to 500 ohms. To calculate the distance the

signal can travel, add the input resistance of the device you plan

to “drive” plus the resistance of the wire length. As long as the

total resistance is less than 500 ohms, the TorqueTrak

Revolution output signal will drive the device.

- 16 -

System Status Indicator Lights

There is one Main System Status Indicator light located outside

the Master Control Unit at the base of the Power Ring and five

secondary system status indicator lights inside the unit. See

Appendix C: Error Codes & Troubleshooting for indicator details.

Figure 8 - System Status Indicators

Secondary System Status Indicators

Stator (Green) = On solid if input power level is in range

Rotor (Green) = On solid if collar power is in range and no data errors

Data (Green) = On solid if no data transmission errors

Range (Red) = Off if sensor input signal is within range

RPM (Green) = At slow shaft speeds used to verify operation of RPM

sensor. LED flashes as magnets trigger pickup sensor.

(See Appendix C for more details.)

Main System

Status Indicator

Red light is on solid if no

system errors are present

- 17 -

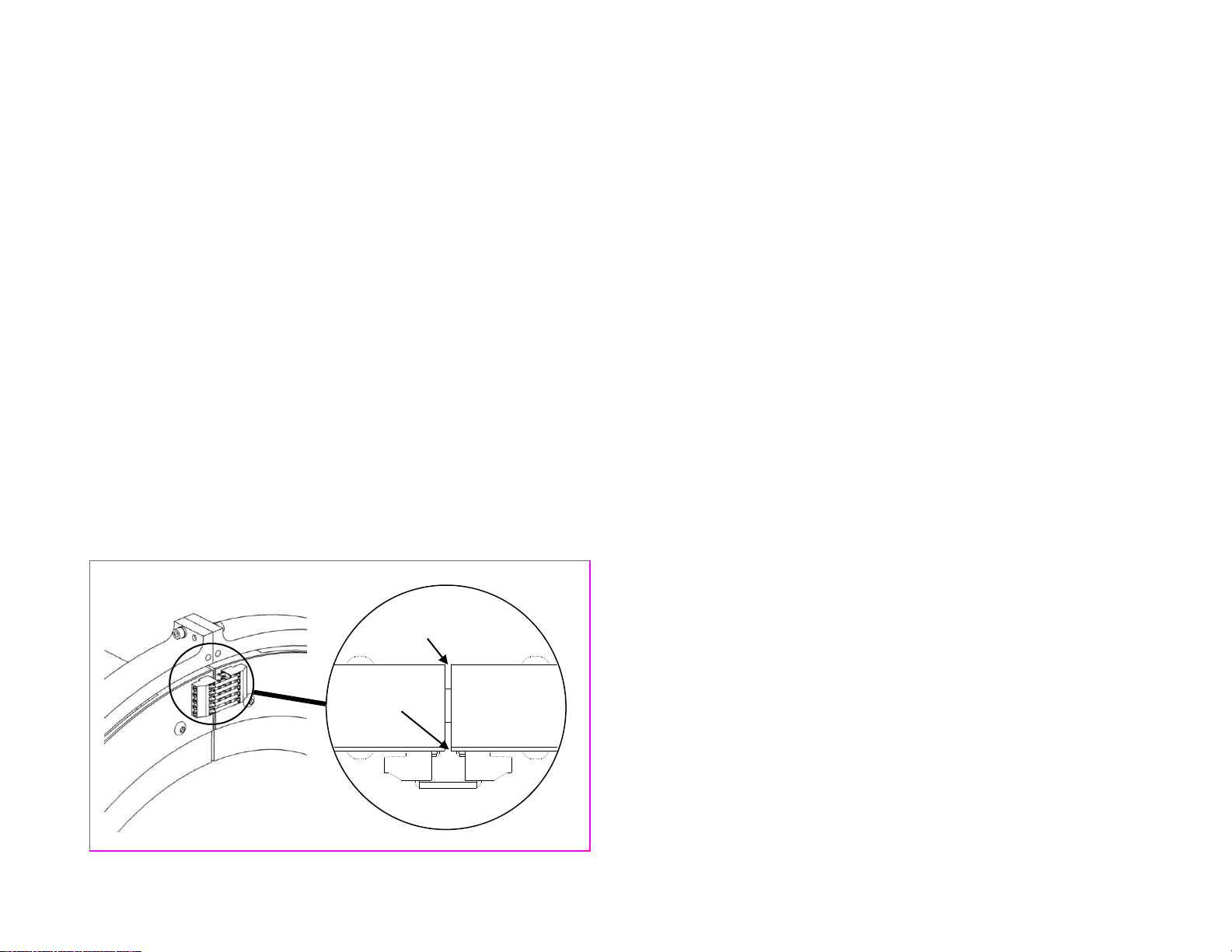

Transmitter Status Indicator Light

The green light embedded in the cover of the transmitter module

(located on the back side of the Rotating Collar) is the

Transmitter Status Indicator Light.

Figure: Transmitter Status Indicator Light

When the Transmitter Status Indicator Light is on solid, the

transmitter module is receiving sufficient power from the rotating

coil and is sending out viable digital data.

This indicator is most useful when troubleshooting an error mode

(refer to Appendix C). When the error mode is “weak inductive

link” (i.e., Main System Status light is flashing fast, Stator light is

on solid, Rotor and Data lights are off or blinking) and the

Transmitter Status Indicator is on, it means that the transmitter is

still receiving enough power to send data, but the data signal

being sent to the MCU is not being received. If the light is off,

this may indicate that insufficient power is being supplied to the

transmitter or that the transmitter module has failed. In either

case, follow the corrective actions outlined in Appendix C.

Transmitter

Status Indicator

Light

- 18 -

Installation Procedure

1. If not already installed, attach strain gage(s) (or other

sensors) to shaft being measured. (See Appendix D: Strain

Gage Application for simplified instructions.)

2. For 4-piece Rotating Collars and Power Rings, pre-assemble

half-sections using hardware and instructions provided.

Make sure 4-piece collar sections are assembled in the

correct order, otherwise speed and power sensing

features will not function properly.

3. Apply anti-seize compound (provided) to threads of collar

bolts. Assemble collar on shaft adjacent to gage with ribbon

cable from collar leading towards gage. (Refer to Figure 1

on page 3 or Figure 10 on page 20.) Install opposing collar

bolts from opposite directions to maintain balance. Tighten

alternate bolts evenly until gap between collar halves is .100”

(2.5mm) at all junctions. (See Figure 9 below.)

CAUTION: Before proceeding make sure bolts

are tight enough to prevent loosening while

rotating but not so tight that the boards attached

to the Rotating Collar are interfering with each

other.

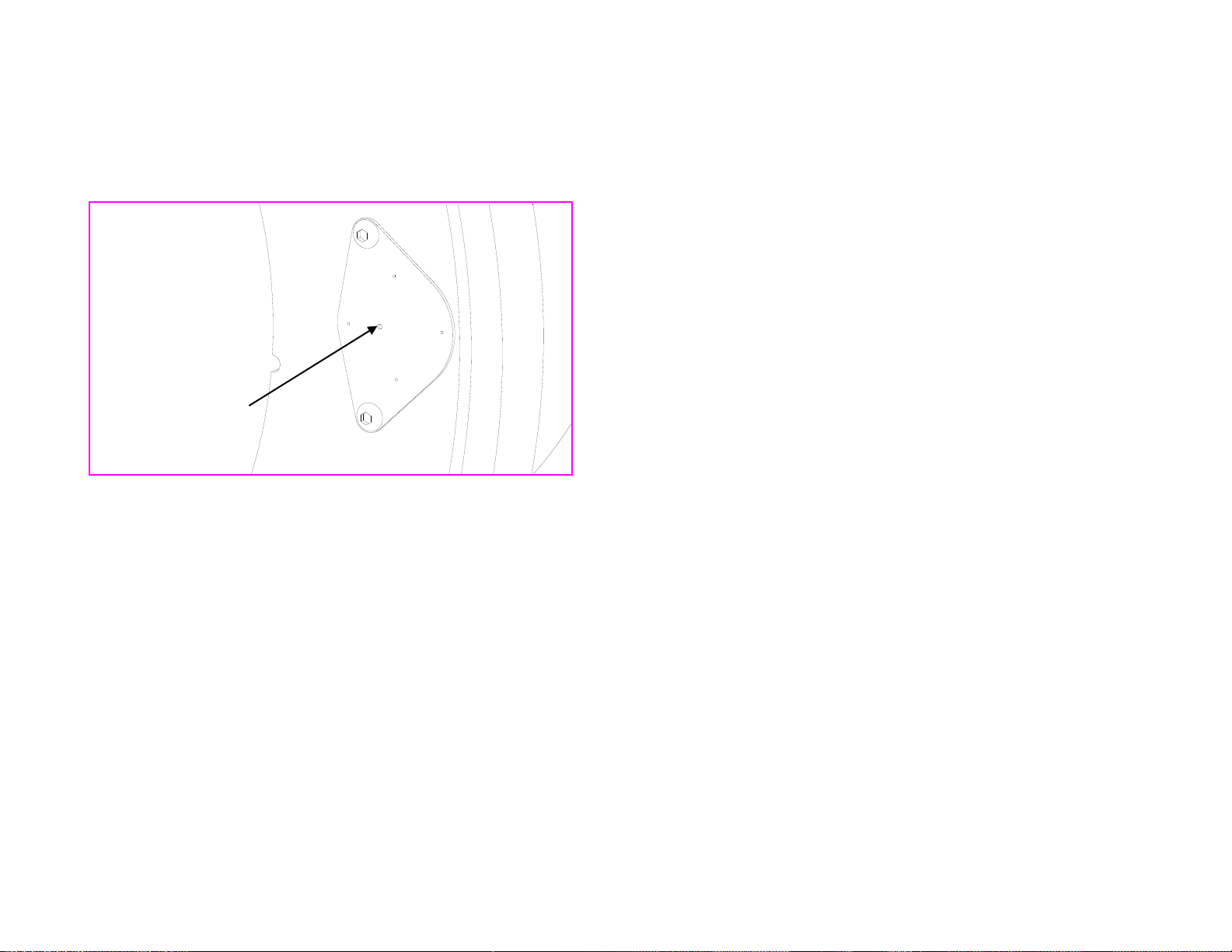

Figure 9 - Correct Collar Gap Spacing

jumper wire

0.100” (2.5 mm)

0.020” (0.5 mm)

- 19 -

4. After collar is bolted on the shaft, place jumper wires

(provided) in the screw terminal connectors at each collar

junction as shown in Figure 9 and tighten securely.

5. Assemble one half of Power Ring to Master Control Unit

using hardware provided. Position Master Control Unit with

half-ring around shaft and assemble second half of Power

Ring.

6. Securely mount Master Control Unit to machine or mounting

plate (not provided) so that the Rotating Collar is centered

within the Power Ring. (Refer to Figure 1 on page 3 or

Figure 10 on page 20.) For larger systems, use the Support

Brackets provided to stabilize and support the Power Ring

with additional braces.

7. Remove cover from Master Control Unit. Install cable clamps

or conduit connectors (not provided) in holes in bottom of

box. Route data signal wires from process control or

recording equipment through clamps or connectors then

connect to corresponding screw terminals (black connector)

inside unit. Note: Wiring holes must be sealed accordingly

to prevent contamination in the enclosure.

8. Route electrical power wires through clamps or connectors

then connect to corresponding electrical power terminals

(green connector) inside unit.

NOTE: Steps 9-11 outline verification of system

operation. A star bridge has been pre-wired to

the Revolution transmitter for this purpose.

Completing the verification will greatly reduce

troubleshooting effort if a system error exists.

9. Slide main power switch to ON. After 10 seconds, verify that

Main System Status light is on solid, indicating successful

data transmission. If Main System Status light is flashing,

see Appendix C: Error Codes & Troubleshooting.

10. Connect an amp meter (not provided) to the Torque Signal

Output Terminals (1 & 2) inside MCU. Measure the Torque

Signal (mA). Reading should be approximately 12 mA.

Other manuals for TorqueTrak Revolution

1

Table of contents

Other Binsfeld Measuring Instrument manuals