Bio-Art Smart User manual

Smart

S E A L I N G M A C H I N E

i n t e l l i g e n t s o l u t i o n s

INSTRUCTIONS

MANUAL

INDEX

1- Introduction .....................................................................................1

2- Package Content.............................................................................1

3- Installation .......................................................................................1

4- Instructions for use..........................................................................2

5- Problems and solutions...................................................................3

6- Maintenance and Cleaning .............................................................3

7- Technical specifications ..................................................................4

8- Symbology ......................................................................................4

9- Warranty term and technical assistance .........................................4

10 - Authorized representative in Europe............................................4

1 - INTRODUCTION

2 - PACKAGE CONTENT

3 - INSTALLATION

Modern and practical, the Bio-Art Smart Sealer has armored resistance and PTC (Positive

Temperature Coefficient) heating technology for the effective sealing of Surgical Grade Paper. It

works with paper width up to 300mm, with 12mm sealing and has sliding cutter guillotine for both

directions.

Smart Sealing (1 unit).

Instructions manual (1 unit)

- The Smart sealer is manufactured for 127 or 220VAC voltages not having a bivolt switching system,

and must be connected to a power line with grounding and bipolar protection devices. Before

connecting the power cable to the mains, observe the correct voltage of your Sealing Machine: 127

or 220 volts.

- Do not install the Smart Sealer in the same outlet where other appliances, machines or equipment

are already installed.

- Install the Smart Sealer in a ventilated place on a flat, moisture-free base with a height of around

90cm in order to facilitate its handling.

- Since the Smart Sealer does not have paper roll support, the back of the machine must be free to

accommodate the rollers. 1

2

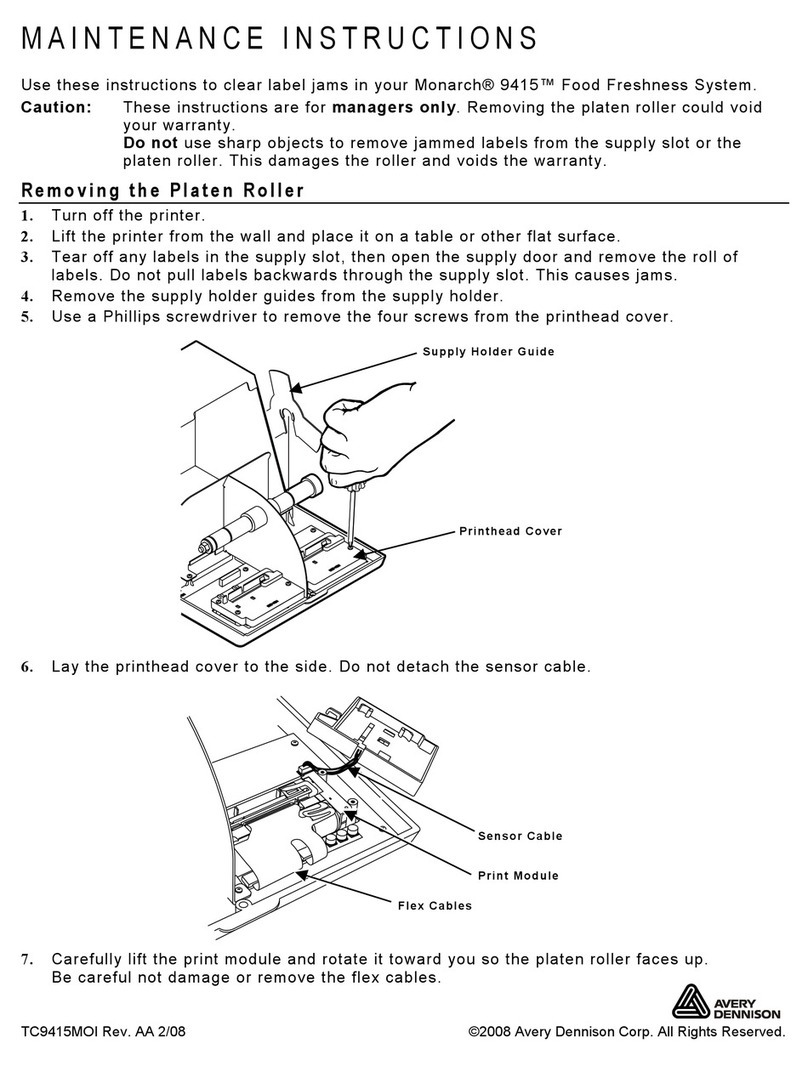

Figure 1 Figure 2

4 - USE INSTRUCTIONS

145

2 3

6 7

1- Turn on the Smart Sealer by turning the switch (06) on the back. The LED will flash indicating the

time for heating the sealing unit (~ 3 minutes);

2- Slide the blade car (4) to one end of its guide rail;

3- Wait for the LED to change from flashing to steady light, indicating that the Sealing Machine is

ready for use;

4- Insert the paper from the back of the Sealer with the plastic front up to the desired length. Then

compress the paper by pressing the top cover (1) with the palm of the hand in the region shown in

figure 03, and hold the paper for 6 seconds, at which time the LED light will change to alert that the

sealing has been completed;

5- Whenever necessary to cut the paper, still with the top cover (01) pressed down, slide the blade

carriage (04) to the other end;

6- Release the compression of the top cover (01) for its spring return in the initial position, being ready

for the next sealing.

1 - Upper compression cover;

2 - Sealing Base;

3 - Electrical resistance;

4 - Car of blades for cutting paper;

5 - Power cable;

6 - Switch on and off;

7 - Protection fuse housing

COMPRESS IN THIS

REGION TO SEAL THE

PAPER

PAPER ENTRY

Note:

1 - The blade car (4) of the sealing cuts the paper slidingly in both directions by sliding on both sides of

the top cover (1). The cutting operation must be performed after sealing and always with the paper

pressed by the top cover (1);

2 - If the top cover (1) is pressed before the initial heating time of 03 minutes, the led will show an alert

because the temperature of the electrical resistance is not yet ready for use;

3 - After being turned on through the switch (6), if the top cover (1) is not pressed in a time interval of 60

minutes, it will automatically be turned off as a safety measure. Even when turned off, the Sealer will be

energized and the led will emit small flashes of light. In order for the Sealing Machine to warm up again

and to re-operate, it is necessary to turn on the switch again (6).

3

5 - PROBLEMS AND SOLUTIONS

6 - MAINTENANCE AND CLEANING

PROBLEM POSSIBLE CAUSE SOLUTIONS

The sealer does not turn on

when the switch is turned on,

light Indicator (led) remains off.

Power failure in the

sealing

Poor sealing time

Residues clogging the

welding unit.

Power failure in the

sealing

Excessive heating of the

sealing system

compartment.

Poor sealing

Paper burns and/or plastic melts

during sealing.

Excessive heating of the sealing

system compartment.

Power failure in the sealing

During the sealing, do not release the compression of the

top cover before 06 seconds, wait for the LED warning.

Check for possible obstructions through the paper entry

window, and gently remove using a plastic spatula.

Release the compression of the top cover after 06 seconds

and after the LED alert.

Disconnect the sealing machine for a cooling interval and

then return. The Smart sealer should be installed in a

ventilated room.

BLOCKED SCREW FROM

THE BLADE CAR

1 - To clean the Sealer, use only a soft dry cloth and do not use solvents, detergents or chemicals;

2- Do not use metal or sharp objects to clean any part of the Smart Sealer;

3- No maintenance on the Smart Sealer must be performed by the user, always use an authorized service

center.

6.1- Replacing the fuse.

1 - Disconnect the power cable from the wall outlet before replacing the fuse;

2- Insert a small screwdriver into the hole in the fuse holder drawer (07) located on the underside of the

product, by forcing it outward and pull the fuse holder drawer;

3- Note the existence of two fuses, which the fuse located more internally in the drawer should be replaced

by the spare fuse, located just behind;

4- Return the fuse drawer until it fits into place;

5- Return the power cable to the wall outlet and switch on the machine to check its correct operation.

Attention

- If the fuse is experiencing a problem again, contact the Authorized Techincal Assistance;

- Always keep a good spare fuse in the fuse holder drawer, and only use a standard 05x2Omm 6A/250V

fuse.

6.2- Replacing the paper cutting blades.

To replace the car blades, it is not necessary to disassemble the Sealer, follow the procedures below:

1 - Disconnect the power cable from (7) the wall outlet

2- Position the blade car (4) totally to the left;

3- Using a Philips screwdriver remove the locking screw shown in the figure below to release the carriage;

4- Carefully pull the blade car (4) upwards, if necessary, relieve its tweezer effect with the help of a plastic

spatula;

5- With the carriage blades (4) out of the top cover (1), replace the blades with care;

6- Insert the blade carriage (4) into the upper cover housing (1) until you feel a clik, observe the correct

side of the car's introduction, orienting yourself by reading the inscription (CUT) engraved on the exposed

face of the car;

7- With the car positioned to the left side, replace the carriage locking screw with the Philips screwdriver;

Warning; Never move the carriage to cut the paper without the locking screw being replaced. It can cause

serious accidents.

4

7 - TECHNICAL SPECIFICATIONS

8 - SYMBOLOGY

9- WARRANTY TERM AND TECHNICAL ASSISTANCE

10 - AUTHORIZED REPRESENTATIVE IN EUROPE

BIO-ART EQUIPAMENTOS ODONTOLÓGICOS LTDA.

Obelis s.a.

Boulevard Général Wahis 53 - 1030 Brussels, BELGIUM

Tel: +(32) 2.732.59.54 - Fax: +(32) 2.732.60.03

E-mail: [email protected]

8

Power voltage ................................................ 127 or 220VAC 50/60Hz

Manufacturer Data

Maximum stacking

Work power .................................................... 300 W*- (*PTC Positive Temperature Coefficient)

Weld width...................................................... 12 mm

Initial warm-up time ........................................ 3 minutes

Welding time................................................... 6 seconds

Weld Length ................................................... 300mm (max)

Machine dimensions (WxDxH) ....................... 450 x 140 x 85 mm.

Package dimensions (WxDxH)....................... 480 x 175 x 110mm.

Smart sealer weight without packaging.......... 1.30 Kg

Smart sealer weight with packaging............... 2.10 Kg

See Instructions for

Use

Attention!

Series number

Attention

Hot Surface

Model code

Keep the place dry

Authorized

representative in Europe

This side up

Manufacturing Date

Fragile

BIO-ART Equipamentos Odontológicos Ltda., Provides a one (1) year warranty for this product from

the date of purchase. This warranty covers all and any manufacturing defect, being provided by repair

of the equipment that is conditioned to the following requirements:

• That the product has been used correctly, according to the instructions described in the instruction

manual;

• The claim is accompanied by the purchase invoice and registered within the warranty period,

followed by a report describing the defect and serial number of the product;

• The product is used, transported and stored with care;

• The cost of transportation (round trip) is paid by the customer;

Warranty limitations:

• Natural wear of parts;

• Misuse, falls or accidents;

• Inadequate transportation;

• Repair by unauthorized persons;

• Use in disregard to the characteristics and purposes of the product;

• Wear due to exposure to adverse conditions (humidity, cold and intense heat);

• Damage due to lack of cleaning or maintenance with improper products

If in doubt, consult the manufacturer:

Rua Teotônio Vilela, 120 - Jardim Tangará - CEP 13568-000 - São Carlos - SP - Brazil

Tel. +55 (16) 3371-6502 - Fax +55 (16) 3372-5953 - www.bioart.com.br

CNPJ 58.538.372/0001-56- State Enr. 637.034.447.113

Rev: CMAN2082 a - Fev/2018

Tel.+55 (16) 3371-6502 - Fax+55 (16) 3372-5953

www.bioart.com.br

Teotônio Vilela, 120 - Jd. Tangará - CEP 13568-000 - São Carlos - SP - Brasil Rua

i n t e l l i g e n t s o l u t i o n s

Table of contents

Popular Food Saver manuals by other brands

Raychem

Raychem E-150 installation instructions

3M

3M 3M-Matic 7000r-I Instructions and parts list

Guzzanti

Guzzanti GZ-305 instruction manual

cuisinecraft

cuisinecraft CV300 user manual

Prestige medical

Prestige medical Pouch Sealer Instructions for use

nVent RAYCHEM

nVent RAYCHEM CS-100 installation instructions