BIO UV BIO-UV Series User manual

Gamme_Piscine_Monolampe_(Anglais_SansChimie).doc, version A, edition du 24/11/2011 Copyright BIO-UV

Marque, Modèles et Brevets déposés – Modèles exclusifs Page 1/ 1

UV10 UV20 UV30 UV40

Company BIO-UV SA

ZAC La Petite Camargue

34400 LUNEL - France

Phone: +33 (0)4 99 133 911

www.bio-uv.com Email : export@bio-uv.com

BIO

-

UV range

for Swimming pools and Spas

INSTALLATION AND USER MANUAL

Gamme_Piscine_Monolampe_(Anglais_SansChimie).doc, version A, edition du 24/11/2011 Copyright BIO-UV

Marque, Modèles et Brevets déposés – Modèles exclusifs Page 2/ 2

CERTIFICAT DE CONFORMITE

CERTIFICATE OF CONFORMITY

Ce certificat confirme que tous les appareils conçus et fabriqués par la

société BIO-UV SA depuis le 01/06/2000 sont conformes a toutes les

directives CEE particulièrement en matière de directives C.E.M et

Electriques.

This certificate confirm that all products manufactured by BIO-UV SA for sale after

June 2000 will comply with the requirements of all relevant EEC directives.

Specifically these include the E.M.C directive.

Benoît GILLMANN

Chairman and Managing Director of BIO-UV

Company BIO-UV SA

ZAC La Petite Camargue

34400 LUNEL - France

Phone: +33 (0)4 99 133 911

www.bio-uv.com Email : [email protected]m

Gamme_Piscine_Monolampe_(Anglais_SansChimie).doc, version A, edition du 24/11/2011 Copyright BIO-UV

Marque, Modèles et Brevets déposés – Modèles exclusifs Page 3/ 3

We thank you for choosing a BIO-UV ultraviolet water treatment system.

Our equipment has been designed to offer you operational reliability in total confidence

for many years.

CONTENTS

Page

Safety Warning 4

Exploded view 5

Dimensions 6

Standard installation 7

Electrical Connections 8

Wiring Diagram 10

Maintenance 11

Guarantees 12

DESCRIPTION UV 10 UV 20 UV 30 UV 40

Maximum pressure in Use 3 Bar 3 Bar 3 Bar 3 Bar

Maximum flow rate (m

3

/h)

(after pressure losses) 7 12 20 25

EXPOSITION TIME / secondes 2,8” 2,6” 2,3‘‘ 2,1‘‘

PERFORMANCE In millijoules at the actual flow

rates recommended above.

(mandatory standard for drinking water: 25mj)

30 mJ 30 mJ 30 mJ 30 mJ

BALLAST 1 1 1 1

LAMP (nomber and power) 1 x 33 W 1 x 55 W 1 x 87 W 1 x 105 W

SERVICE LIFE of LAMPS 13 000 h 13 000 h 13 000 h 13 000 h

OVERALL HEIGHT in cm 42,6 69,6 94,2 119,6

DIAMETER of the UV CHAMBERS in cm 15,4 15,4 15,4 15,4

WEIGHT POIDS (without water) kg 4,3 6 8 9,4

INPUT/OUTPUT (diameter in mm)

with Unions supplied 50 50 63 75

The BIO-UV equipment is ready to be installed.

No intervention is required inside the equipment.

A simplified quick assembly procedure is provided.

Gamme_Piscine_Monolampe_(Anglais_SansChimie).doc, version A, edition du 24/11/2011 Copyright BIO-UV

Marque, Modèles et Brevets déposés – Modèles exclusifs Page 4/ 4

Safety Warning

NEVER LOOK AT THE ULTRAVIOLET LAMP WHEN LIT WITHOUT USING PROTECTIVE

GOGGLES AS IT COULD CAUSE SEVERE INJURIES, BURNS OR EVEN BLINDNESS.

NEVER UNDO THE STAINLESS STEEL TIGHTENING NUT WITH THE FILTRATION

RUNNING, AS THE QUARTZ SLEEVE COULD BE EXPELLED FROM ITS HOLDER AT

SPEED AND INJURE YOU

Before attempting to access the connection terminals, all power supplies should be

disconnected. If the cable is damaged, it must be replaced by a cable or special assembly

available from the after-sales service.

For your safety as an installer and/or user:

1. Read all the instructions in this manual before switching on the

BIO-UV sterilizer

2. WHEN REPLACING THE LAMPS AND/OR DURING THE ANNUAL CLEANING OF QUARTZ

SLEEVES, CHECK THAT THE ELECTRICAL PART IS IN PLACE AND CORRECTLY SECURED

BEFORE SWITCHING ON THE STERILIZER.

3. CHECK THAT THE NUT, WASHER AND O-RING (16-15-14) ARE CORRECTLY POSITIONED,

OTHERWISE THE QUARTZ SLEEVES COULD BE EXPELLED FROM THEIR HOLDER AT SPEED

AND INJURE YOU.

4. In order to avoid electrical short-circuits, never submerge electrical wires or the BIO-UV sterilizer

in the pool water or any other liquid

5. Disconnect the BIO-UV sterilizer before all maintenance and cleaning operations

6. Allow the ultraviolet lamps to cool before handling

7. DO not touch the ultraviolet lamps with bare hands. It would leave dirt on the

lamps which would reduce their service life. If you touch them, clean them

using methylated spirits or spirit vinegar

8. Do not operate the BIO-UV sterilizer if the power supply lead is damaged

9. Do not re-start the system without first checking that the electrical part and the sterilizer’s upper

unit are correctly back in place

10. Do not use the BIO-UV sterilizer for any other purpose than that for which it was designed

Gamme_Piscine_Monolampe_(Anglais_SansChimie).doc, version A, edition du 24/11/2011 Copyright BIO-UV

Marque, Modèles et Brevets déposés – Modèles exclusifs Page 5/ 5

Sterilizer – Exploded view

REACTOR UV 10

REP

Ref PMI Description

3 JTS003934 Quartz_Guide

5 PIE001949 Switch

6 BAL001422 Ballast_lw20eb65

7 QUA000016

Quartz sleeve_d25x594mm

8 LPE000003 UV Lamp

9 JTS000100 O-ring Ø25x5

10 PIE000659 Washer

11 USI000018 Nut

12 ELE000001 Socket

13 ELE000311 Carter_174x249x100

14 ELE000817

Lamp operating indicator

with LED

15

ACC000967

Grounding lug

REACTOR UV 20

REP

Ref PMI Description

3 JTS003934 Quartz_Guide

5 PIE001949 Switch

6 BAL000025 Ballast_lw20eb65

7 QUA000017

Quartz sleeve_d25x594mm

8 LPE000004 UV Lamp

9 JTS000100 O-ring Ø25x5

10 PIE000659 Washer

11 USI000018 Nut

12 ELE000001 Socket

13 ELE000311 Carter_174x249x100

14 ELE000817

Lamp operating indicator

with LED

15

ACC000967

Grounding l

ug

REACTOR UV 30

REP

Ref PMI Description

3 JTS003934 Quartz_Guide

5 PIE001949 Switch

6 BAL000026 Ballast_lw20eb65

7 QUA000018

Quartz sleeve_d25x594mm

8 LPE000005 UV Lamp

9 JTS000100 O-ring Ø25x5

10 PIE000659 Washer

11 USI000018 Nut

12 ELE000001 Socket

13 ELE000311 Carter_174x249x100

14 ELE000817

Lamp operating indicator

with LED

15

ACC000967

Grounding lug

REACTOR UV 40

REP

Ref PMI Description

3 JTS003934 Quartz_Guide

5 PIE001949 Switch

6 BAL000026 Ballast_lw20eb65

7 QUA000019

Quartz sleeve_d25x594mm

8 LPE000006 UV Lamp

9 JTS000100 O-ring Ø25x5

10 PIE000659 Washer

11 USI000018 Nut

12 ELE000001 Socket

13 ELE000311 Carter_174x249x100

14 ELE000817

Lamp operating indicator

with LED

15

ACC000967

Grounding lug

Gamme_Piscine_Monolampe_(Anglais_SansChimie).doc, version A, edition du 24/11/2011 Copyright BIO-UV

Marque, Modèles et Brevets déposés – Modèles exclusifs Page 6/ 6

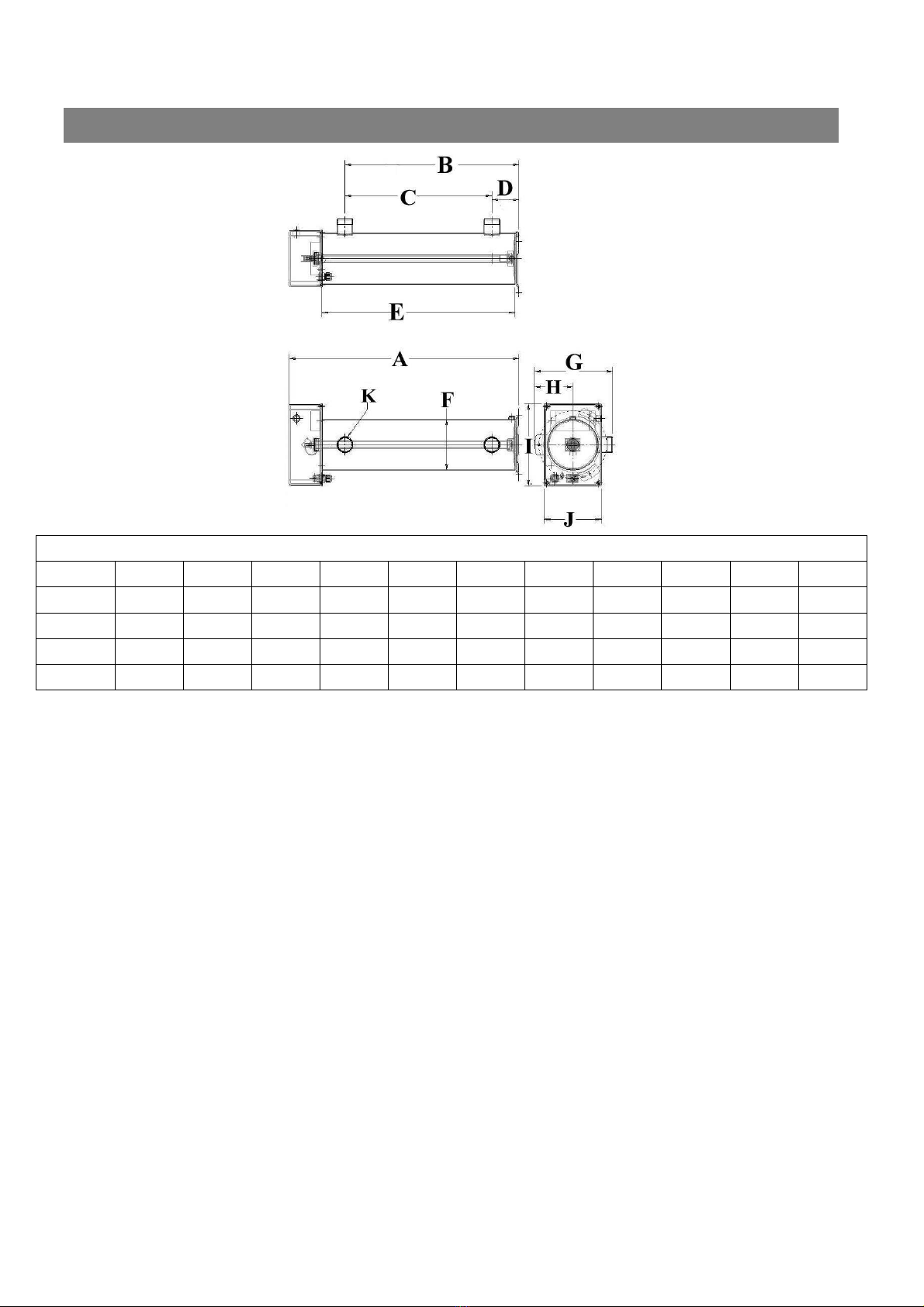

Dimensions

DIMENSIONS in mm (excepted K)

Model

A B C D E F G H I J K

UV 10

426 275,5 2133 62,5 313 154 223 108 249 174 1"1/2

UV 20

696 545,5 483 62,5 583 154 223 108 249 174 1"1/2

UV 30

942 771.5 689 82,5 829 154 228 113 249 174 2"

UV 40

1196

1025,5

943 82,5 1083 154 233 118 249 174 2"1/2

Gamme_Piscine_Monolampe_(Anglais_SansChimie).doc, version A, edition du 24/11/2011 Copyright BIO-UV

Marque, Modèles et Brevets déposés – Modèles exclusifs Page 7/ 7

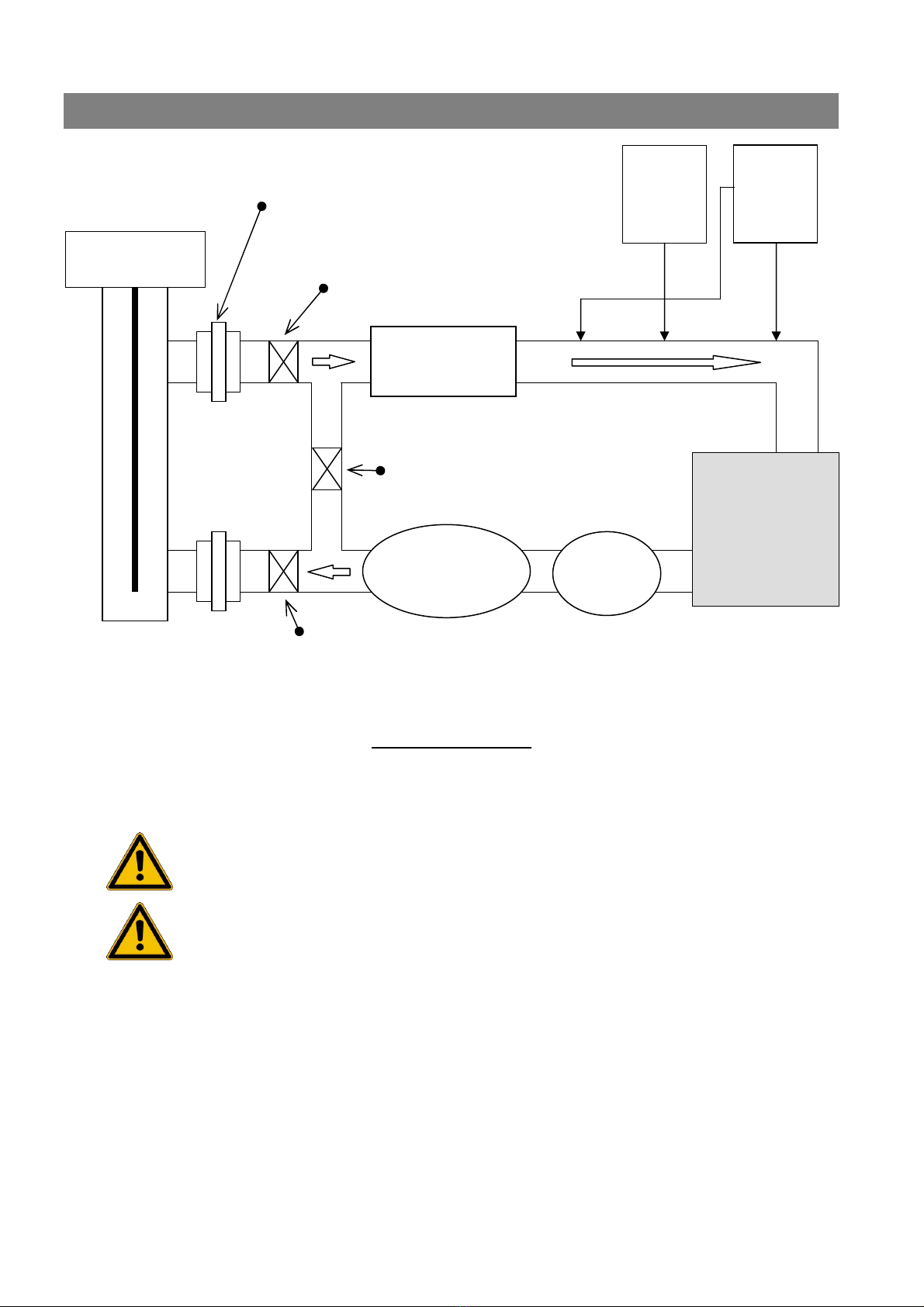

Standard Installation

RECOMMANDATIONS

Install the BIO-UV equipment in the equipment room, respecting the 0.1 and 2 safety areas around the

volume in accordance with the current installation rules (NF C15100)

Unless the equipment is dismantled in order to change the lamps and clean the quartz sleeves,

leave enough room to remove the lamps – the AVAILABLE HEIGHT in the equipment

room must be DOUBLE the total size of the equipment

The BIO-UV equipment must be installed on the discharges after the filter and before the

heater (where applicable).

The equipment’s water inlet should preferably be at the bottom and, thus, its outlet to the pool at the top.

(If necessary it can be positioned horizontally).

The unions provided for ease of fitting and dismantling are supplied with either a 50 mm (UV10 & 20),

63 mm (UV30) or 75 mm diameter (UV40).

If a bypass is used for the heating, the BIO-UV equipment should be installed before the bypass

Using clamping collars (50, 63 or 75 mm diameter

)

secure the REMANENT and pH liquid injectors and pH

analysis probe in the correct order, see diagram above.

BIO

-

UV

DOSING

PUMP

INJECTION

BIO

-

UV

pH

REGULAT

OR

BY

-

PASS

VALVE

BY

-

PASS

VALVE

BY

-

PASS

VALVE

Ø50 ou 63 ou 75

UNION

pH

PROBE

HEATING

FILTRE

SWIMMIN

G POOL

PUMP

BIO-UV

Gamme_Piscine_Monolampe_(Anglais_SansChimie).doc, version A, edition du 24/11/2011 Copyright BIO-UV

Marque, Modèles et Brevets déposés – Modèles exclusifs Page 8/ 8

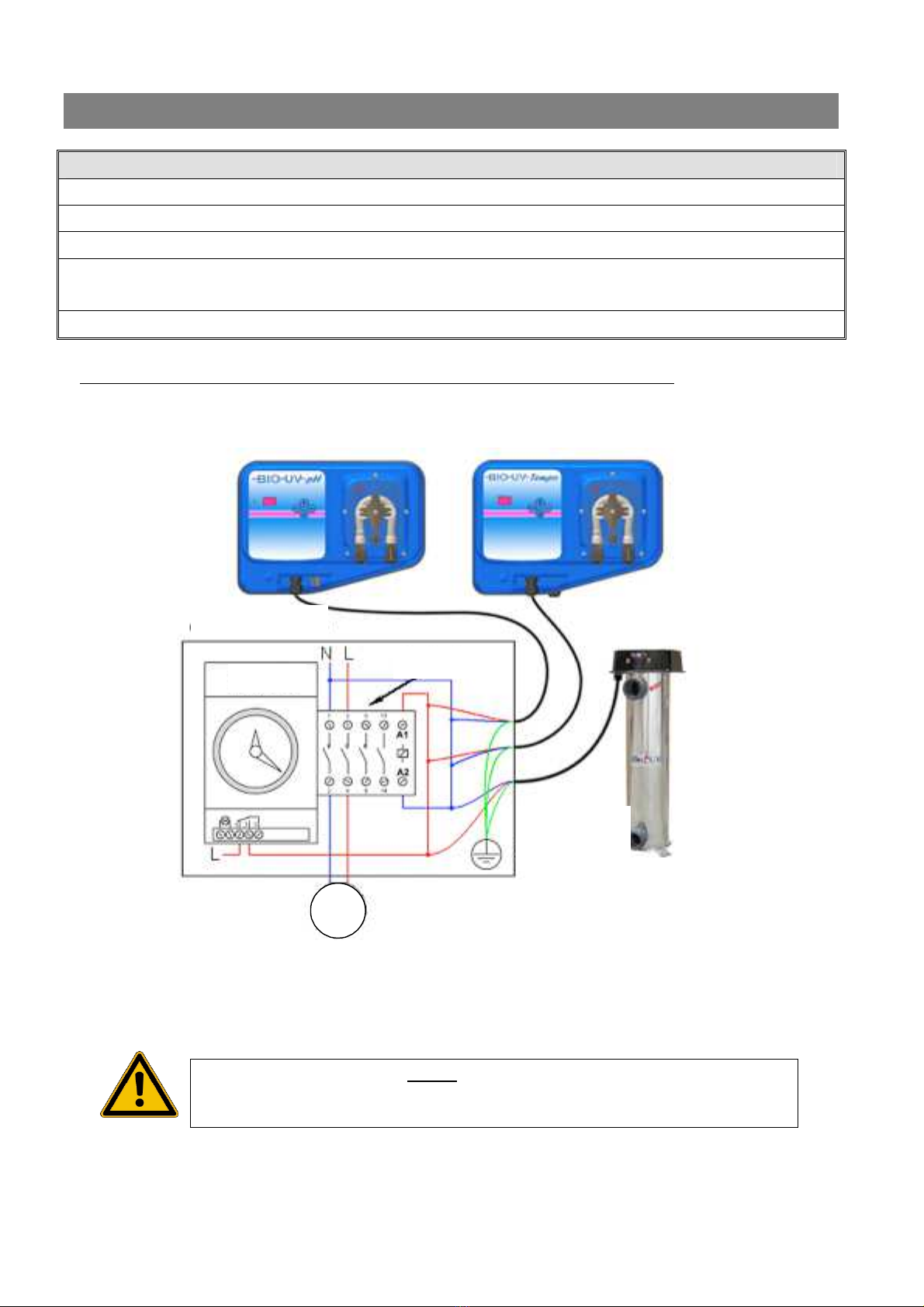

ELECTRICAL CONNECTIONS

IMPORTANT

The connections must be made by a qualified technician.

A 30mA differential circuit breaker must be present and a fuse or a circuit breaker must be installed.

The power supply must correspond to that shown on the label on the side of the equipment.

The power supplied to the pH regulator must be servo-controlled by the filtration.

(See wiring diagram below).

Before making the connections, switch off the power supplies.

1°/ General case : you have a contactor with a coil supplied with 220-240Vac :

Connect the UV reactor to the filtration unit as shown below:

• Connect the UV reactor to the contactor coil.

•Check that the fuse or circuit breaker is appropriate for the power of all the connected

equipment.

The UV reactor must never be connected to the same terminal

strip as the filtration pump(s) and/or to the boosters in your

system.

Filtration

Timer

contactor

Earth

= Green/

Yellow

L = Li

ve = Brown (220

-

240Vac)

N = Neutral = Blue

Pump

…

Gamme_Piscine_Monolampe_(Anglais_SansChimie).doc, version A, edition du 24/11/2011 Copyright BIO-UV

Marque, Modèles et Brevets déposés – Modèles exclusifs Page 9/ 9

2°/ Particular case : you have a contactor with a coil not supplied with 220-240Vac :

• Take a relay (not provided) which must :

-have the same tension on its coil as on the contactor coil,

-allow at least 5 amperes on its contacts.

• Connect the UV reactor with the adviced relay as shown on the drawing below:

•Check that the fuse or circuit breaker is appropriate for the power of all the

connected equipment.

The UV reactor must never be connected to the same terminal

strip as the filtration pump(s) and/or to the boosters in your

system.

Earth

= Green/

Yellow

L = Live = Brown (220-240Vac)

N = Neutral = Blue

Pump

…

Filtration

Relay

Timer

Gamme_Piscine_Monolampe_(Anglais_SansChimie).doc, version A, edition du 24/11/2011 Copyright BIO-UV

Marque, Modèles et Brevets déposés – Modèles exclusifs Page 10/ 10

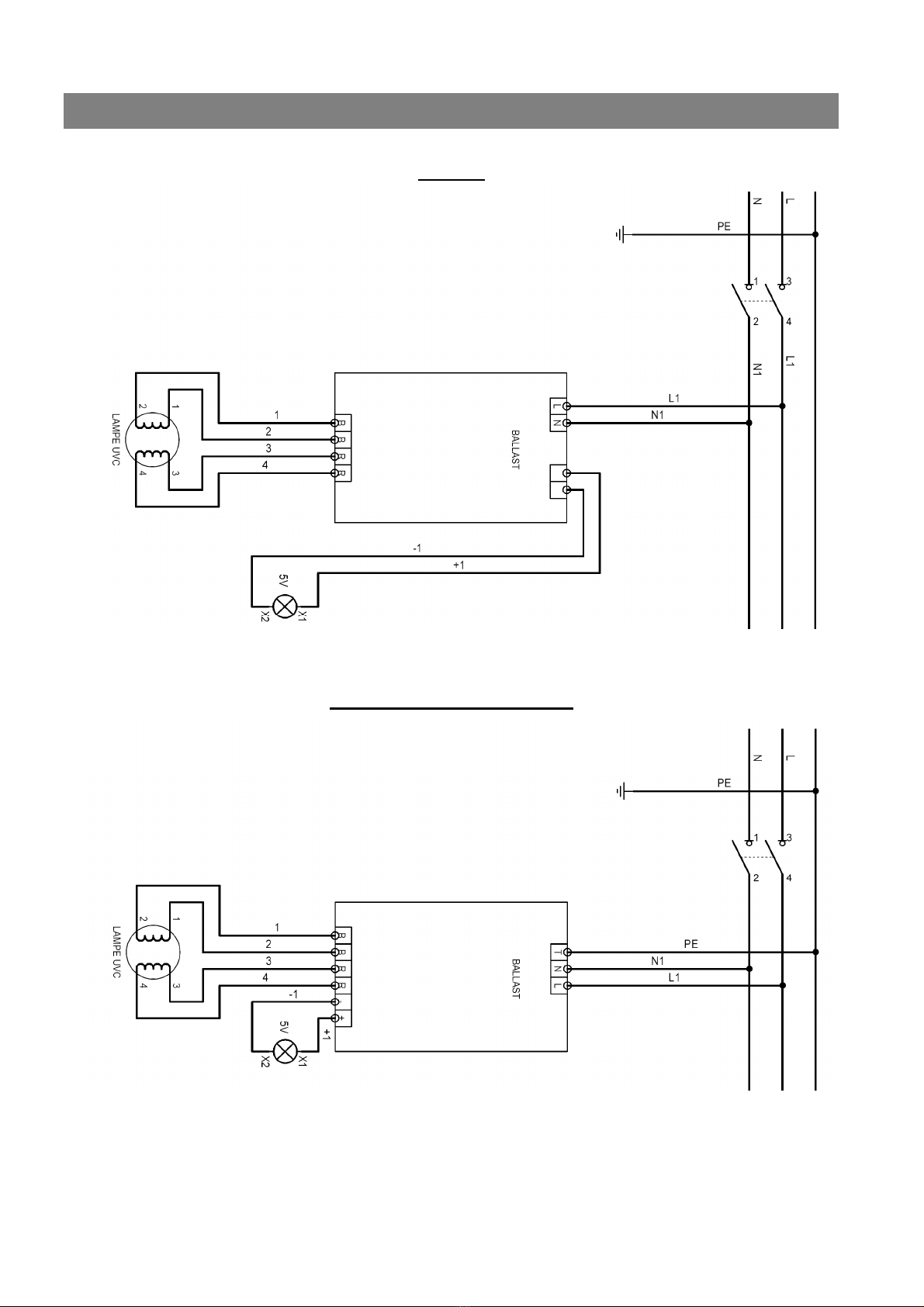

WIRING DIAGRAM

UV 10

UV 20 – UV 30 – UV40

N = Neutral / L = Live / PE = Earth

OPERATING

INDICATOR

LIGHT

I ON/OFF SWITCH

OPERATING

INDICATOR

LIGHT

ON/OFF SWITCH

Gamme_Piscine_Monolampe_(Anglais_SansChimie).doc, version A, edition du 24/11/2011 Copyright BIO-UV

Marque, Modèles et Brevets déposés – Modèles exclusifs Page 11/ 11

Maintenance

(See exploded view on p6-7)

The ultraviolet lamps are d

esigned to last for 13,000

hours or be switched on 1,000 times, i.e. approximately 2

years for a seasonal outdoor pool, or 1 year for an indoor

pool operating 24 hours a day.

In order to prevent premature wear, it is recommended

that they be switched on (i.e. 1 filtration cycle) once a

day which will also preserve the filtration pump.

Changing the lamp:

Changing the lamp: Changing the lamp:

Changing the lamp:

It is essential to work with the

lamp off and the filtration

stopped.

Whether the equipment is installed vertically or

horizontally, check that there is sufficient space to

remove the lamp in the equipment room.

Disassembly (see part numbers on the diagram on

page 7-8)

- Remove the unit (22).

- Take hold of the 4-pin connector (21) and gently pull

the lamp upwards rotating it.

- As soon as the lamp is a few centimetres out,

remove the connector, take hold of the ceramic base and

disengage the lamp from the quartz sleeve keeping it

correctly in the axis.

- Carry out the operation with care.

Do not drop the lamp in the quartz

sleeve as it could break and damage

the quartz.

Re-assembly

- Take hold of the new lamp, avoiding touching it with

bare fingers outside the upper and lower ceramic bases

(if you do touch it, clean it with a soft cloth using

methylated spirits).

- Engage the lamp in the quartz sleeve, keeping it

correctly in the axis, inside the equipment.

- Having engaged it ¾ of the way in, connect up the

lamp using the connector (21) on the lamp’s 4 pins,

making sure you get it the right way round (locating pin).

Do not force it.

- Engage the lamp fully inside the quartz sleeve.

- Refit the unit (22).

Cleaning the quartz sleeve:

Cleaning the quartz sleeve:Cleaning the quartz sleeve:

Cleaning the quartz sleeve:

Every year you must check that the quartz sleeve has not

become opaque due to scale deposits. It should be

completely transparent so as not to reduce the amount of UV

radiation passing through it.

- Stop the filtration and work with the lamps off.

- Close all the valves on the installation.

Dismantling the quartz sleeve

Dismantling the quartz sleeve Dismantling the quartz sleeve

Dismantling the quartz sleeve

WARNING: they are not guaranteed

against breakage.

-

Remove the lamp (see previous paragraph).

- Place it on a soft surface where it cannot get broken.

- Undo the stainless steel nut by hand (16)

- Remove the plastic washer (15),

- Insert your thumb or a finger into the sleeve, and gently

slide it until the O-ring (14) disengages from its housing.

- Take hold of the quartz sleeve in order to fully extract it

from the equipment ensuring that it remains aligned with

the equipment’s axis.

If the sleeve is clean and completely transparent: reassemble

it in accordance with the instructions below.

If whitish calcium deposits are present, you must clean it. This

is done using spirit vinegar or acid and a soft cloth. The quartz

must not be scratched as this would change the

ultraviolet radiation qualities.

Re

ReRe

Re-

---assembling the quartz sleeve:

assembling the quartz sleeve:assembling the quartz sleeve:

assembling the quartz sleeve:

- Carefully insert the sleeve in the equipment, keeping it

aligned with the equipment’s axis.

- Using your finger inside the sleeve, position the

quartz in its holder at the bottom of the equipment. The

quartz should protrude slightly (by the thickness of the O-

ring), it should not fall right to the bottom. If the quartz

is correctly positioned in the holder, when it is pressed it

feels springy (pneumatic effect).

- Position the O-ring (14) around the sleeve having

moistened it beforehand. Push it fully into its housing

using your nail (do not use any tools).

- Place the plastic washer (15) inside the stainless steel

thread.

- Retighten the stainless steel nut (16) by hand,

tightening normally.

- Refit the lamp (see previous paragraph).

- Refit the unit (22).

- Reconnect.

Gamme_Piscine_Monolampe_(Anglais_SansChimie).doc, version A, edition du 24/11/2011 Copyright BIO-UV

Marque, Modèles et Brevets déposés – Modèles exclusifs Page 12/ 12

Guarantees

The guarantee for the BIO-UV equipment range applies as follows:

-

5 years

for the stainless steel reactor (materials and weld)

other than in the case of use in a highly corrosive environment (brackish or very salty environment, e.g.:

seawater),

-

2 years

for all other components, except for the UV lamp (13 000 hours, depending on the number of

switchings on/off)

The electrical components are not guaranteed against over-voltages or lightning damage.

Warning! The quartz sleeves and lamps are not guaranteed against

breakage.

- Any defective parts should be returned, giving details of the type and serial number of the equipment, to

BIO-UV who will replace it after technical survey.

- Postage costs will be shared between the retailer and BIO-UV.

- The guarantee comes into force on the day the equipment is installed: this date shall be communicated to

BIO-UV by returning the completed guarantee validation (see next page) by mail or fax.

Warning:

If the guarantee validation is not returned within 3 months of the equipment

being purchased, BIO-UV will assume that the guarantee’s effective date is the month and

year of its manufacture.

In the event that the equipment is not installed in accordance with the installation instructions and

user manuals, BIO-UV will not accept any responsibility and the guarantees will be null and void.

Conclusion

The BIO-UV system produces unequalled water quality, comfort and peace of mind.

Simple to use, and with reduced maintenance and after-sales service, in order to optimise

its reliability.

This physical water treatment, using UV-C radiation, offers an environmentally friendly

concept with no chemical residue toxic for either humans or nature

.

The BIO-UV team is at your disposal

Company BIO-UV SA

ZAC La Petite Camargue

34400 LUNEL France

Phone: +33 (0)4 99 133 911

www.bio-uv.com Email : [email protected]m

This manual suits for next models

4

Table of contents

Popular Swimming Pool Vacuum manuals by other brands

Bestway

Bestway Flowclear 58216 owner's manual

Astrapool

Astrapool AspiD Installation and maintenance manual

Maytronics

Maytronics 8180090 User instructions

Zodiac

Zodiac Super G+ owner's manual

Pentair

Pentair kreepy krauly kruiser Installation and user guide

Polaris

Polaris 3900 Sport Instructions for installation and use