Biobase BOV-V30F User manual

Forced Air Drying Oven

BOV-V30/45/65/125/230/625F

User Manual

BIOBASE GROUP

Version 2020.07

1

Preface

Thank you for purchasing BIOBASE Drying Oven.

Using object

This manual is intended for the laboratory technologists operating this instrument. Before using the

product, please carefully read this manual. Keep this manual in a safe place for easy reference. If you

do not follow the precautions described in this manual, we will not guarantee the maintenance.

Statement

Jinan Biobase Biotech Co., Ltd (hereinafter referred to as "Biobase") has the final interpretation of

this manual.

The Company shall be responsible for the safety, reliability and performance of the product only if

all of the following requirements happened:

1.Assembly operations, expansion, re-adjustment, improvement and repair by the Company

recognized professionals.

2.All repairs involving replacement parts and supporting the use of accessories, supplies are original

of the Company (original) or approved by the Company.

3.The related electrical equipment is according to national standards and the use of the manual

requirements.

4.Product operation is carried out according to the instruction manual.

Disclaimer

Biobase shall not be liable for any equipment failure or damage, or for any direct or indirect damage

that may occur during the use of the equipment.

1.Malfunction or damage due to violation of the instructions, precautions, and intended use of this

manual.

2.Malfunction or damage caused by repair or alteration of the other company.

3.Malfunction or damage caused by use instruments of other company at the same time.

4.Malfunction or damage caused by operating environment not corresponding to the specified

operating environment (power conditions, installation environment, etc).

5.Malfunction or damage caused by natural disasters such as earthquakes and floods.

6.Malfunction or damage caused by the company unaware of the movement or transfer (transport)

after installation.

2

Content

Preface.................................................................................................................................................... 1

1. Installation and Operating Conditions................................................................................................3

2. Product Structure................................................................................................................................3

3. Technical Parameters..........................................................................................................................4

4. Control Panel...................................................................................................................................... 5

5. Instructions of Operation....................................................................................................................6

6. Wiring Diagram.................................................................................................................................. 9

7. Trouble Shooting................................................................................................................................ 9

8. Warranty........................................................................................................................................... 10

3

1. Installation and Operating Conditions

1.1. This equipment should be placed in a room with good ventilation, shading, and cool conditions.

The equipment and walls must be more than 10 cm away. Do not place flammable or explosive

materials around it.

1.2. When the equipment is used for the first time, there may be slight fumes and odors due to spray

and rust-proof coating. This does not affect the use, it will disappear after one or two uses. Therefore,

it is best to open the doors and windows for a while when using for the first time.

1.3. The power box should be in accordance with the specified voltage and be reliably grounded to

ensure safe use.

1.4. Do not place excessively indoor objects. Space for air convection must be allowed to facilitate

hot air circulation and discharge of humid exhaust gas.

1.5. When the door is opened or the item is put in for a long time, the temperature setting should be

lowered or the power switch should be turned off for 5 to 10 minutes (depending on the length of the

door opening time) to reduce the occurrence of temperature and avoid unnecessary loss.

1.6. In order to maintain the appearance of the equipment, please do not use acid or alkali and other

corrosive materials to wipe the surface, the box can be cleaned regularly with a dry cloth.

1.7. The fuse box of the equipment is equipped with a fuse. If the equipment is not energized, first

check whether the fuse tube is in good condition. Please cut off the power when checking and

replacing the fuse tube. And replace the same type of fuse tube.

1.8. The oven doesn’t have explosion-proof function, do not put flammable and explosive substances

in.

1.9. Please turn off the power after using.

2. Product Structure

2.1. External material: cold-rolled steel with anti-bacteria powder coating.

2.2. Stainless steel inner chamber, round angle structure, adjustable shelves.

2.3. Double-layer glass observation window, adjustable airtight buckle lock.

2.4. PID microprocessor intelligent temperature controller.

2.5. Over-temperature protection.

2.6. Optional independent temperature protector

4

3. Technical Parameters

Model

BOV-V30F

BOV-V45F

BOV-V65F

BOV-V125

F

BOV-V230

F

BOV-V625F

Capacity

30L

45L

65L

125L

230L

625L

Temp. Range

RT+5~300℃

Temp. Precision

0.1℃

Temp.

Fluctuation

±0.5℃

Ambient Temp.

5~40℃

Timing Range

1~9999min

Shelves No.

2 pcs

3 pcs

Power

Consumption

800W

1200W

1600W

2300W

3000W

5000W

Power Supply

220V±10%, 50/60Hz

380V/50HZ

Internal

Size(W*D*H)

mm

310*310*31

0

350*350*35

0

400*360*45

0

500*450*55

0

600*500*75

0

660*760*125

0

External

Size(W*D*H)

mm

460*510*69

5

500*550*73

5

540*550*84

0

636*680*91

5

730*670*12

20

895*925*183

0

Packing Size

(W*D*H) mm

550*570*76

5

620*585*80

0

640*640*90

5

730*720*10

00

900*800*13

50

1000*1080*2

000

Gross

Weight(kg)

51

56

61

71

105

160

5

4. Control Panel

1. Measured value display 6. Shift key,

2. Setting value display 7. Addend key

3. Alarm 2 indicator 8. Reduction key

4. Alarm 1 indicator 9. Main control output indicator

5. Set key 10. Auto tuning indicator

6

5. Instructions of Operation

The upper row of digital tubes displays the measured temperature, and the lower row displays the set

temperature

Press the SET key shortly, the temperature setting state will be entered

The parameters can be corrected by the▼, ▲ keys, press the SET key to enter the time setting state

Adjust time by After the▼, ▲ keys, after confirm, return to normal display screen.

AT (temperature auto tuning)

7

It need to re-adjust the temperature if the temperature fluctuations is more than 5 degrees, or can’t

meet the requirements of the temperature.

For example:

After setting the required temperature of 100 degrees, press the button 5 seconds, AT indicator

is on, then enter the auto tuning state. Can’t open the door or pump, can’t reset, can’t shut off the

power in this process. The meter will automatically calculate the heating rate. AT indicator will be off

after 30 mins. the instrument will control the temperature according to new program and in order to

achieve high precision temperature control.

Parameter list:

Code

Value range

Function

Factory value

SP

SPL~SPH

Temperature setting

Random

ST

0~9999min

Time setting

0

press set key over 5 seconds

Lock

0~9999

Parameter lock

0

SC

-50.0~+50.0℃

Process value biasing

0℃

SCK

0.700~1.300

Process value sloping

1.000

Lock: ××××(But ask the manufacturer for)

P

0.1~50.0℃

Proportional Band

5.0℃

I

1~400

Integral Time

40s

d

0~100

Derivative Time

10s

T

1~200

Control Period

20s(2s)

AL1

-20~+20℃

alarm value

5℃

ET

0~2

Function option the regular time

2

dP

0~1

Point changing

1

PT

1~30min

Print gap time

1min

Addr

0~32

This machine mail address

0

Pr

1~100

Upper limit constant temperature

power percentages

20%

SPL

Measuring range

lower limit ~SPH

Temperature setting value lower

limit

Measuring range lower

limit

SPH

SPL~ Measuring

range upper limit

Temperature setting value upper

limit

Measuring range upper

limit

Description:

1) Through press or < key, revise parameters rapidly,The necessaries being over affirms

modification according to set key, Otherwise invalidate. Think that Lock is 0, Only when SC/

SCK is parametric may revise; Think that Lock is XXXX,Except SC /SCK, all parameters may

revise.

2) SC is process value biasing, SCK is process value sloping. May amend the measurement error

that cause from sensor to other arouses. Be in appearance when not having been amended

(SC=0;SCK=1.000), While zero position error of appearance is bigger may adjust SC,SC=

Standard value -Measure value; While full degree error of appearance is bigger may adjust

8

SCK,SCK= Standard value / Measure value.

3) P for setting proportional band. When take place regular oscillation of controlled temperature, the

proportional band should be increased and if controlled temperature drifts irregularly we ought to

decrease the proportional band.

4) I for setting the integral time. When the system takes place regular oscillation ought to I for

setting proportional band. When take place regular oscillation of controlled temperature, the

proportional band should be increased and if controlled temperature drifts irregularly we ought to

decrease the proportional band. ncrease integral time and if the system controlled can not remove

the static deviation in a long time ought to decrease the integral time.

5) D for setting the derivative time. Increasing the derivative time can decrease the overshoot of the

system.

6) T is Control Period, Relay output ≮20s,SSR and thyristor output≮3s continuous output,1s.

7) AL1 is alarm value 1, Measure value giving an alarm after deflecting setting value ∣AL1∣℃,

AL1 is set up giving an alarm for being to reach the end point at 0,

Upper limit alarm for AL>0,

low Limit alarm for AL<0.

8) At the regular time function option parameter ET is 0,No regular time function,Time sets up a

menu concealing;ET is 1 or 2,Demonstrate time setting up menu ST. If ST is 0, Do not mind

time then, ET is 1, After the electricity on the instrument, Reckon by time beginning, ET is 2,

While the temperature reaches setting value start timing. Adopt countdown way at the regular

time, Begin to reckon by time,

the upper row displays the Remain in time value,

Reckon by time

being over, the upper row displays STOP,

Run stoppage,

Export a cutoff, Have intermittent buzz

sound prompting at the same time, Push down any key but noise reduction. After press start/stop

key over 3 seconds, Can start or stop procedure work.

9) dP is that the temperature is sure to change option , dP is 0 , temperature display has no point,

dP is 1 , temperature display has point.

10) Pr is Upper limit constant temperature power percentages, Generally, The function big or

preserving heat if systematic power allocation is prejudiced is very good, Pr value responds to

small, Can prevent from rushing the temperature; Whereas Pr value responds to then big, Can

improve litre of temperature speed. One system is different generally in different setting up under

the temperature from P , I , D parameter that adjust reaches, Suggest setting up temperature

adjusting parameter being able to reflect system inertia nearby in the room temperature, But be

used for the high temperature litre of temperature is possibly slower time end, Effect adjusting Pr

value now being ok to make system can reach very good controlling within entire range.

9

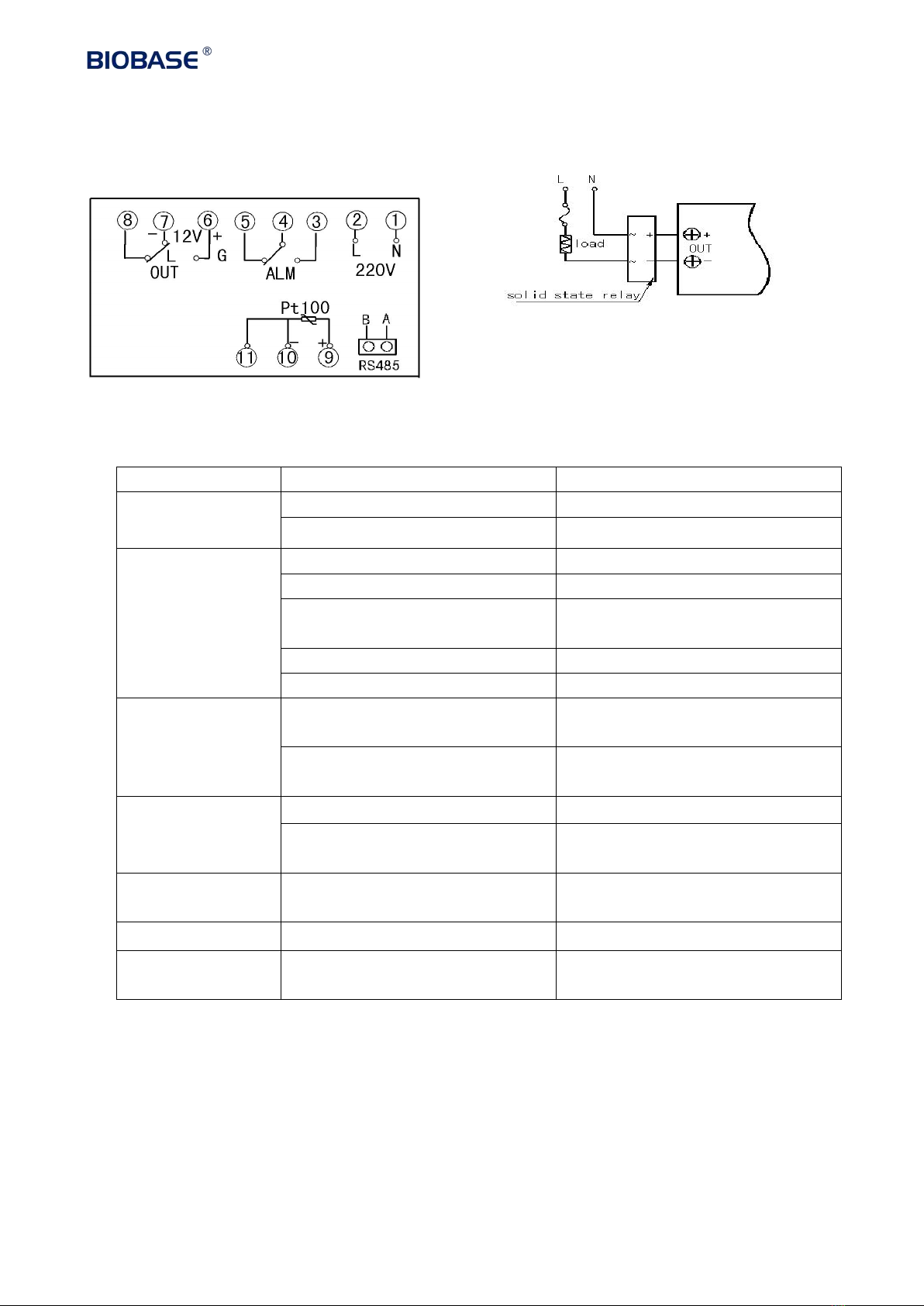

6. Wiring Diagram

7. Trouble Shooting

Common failures and Solutions:

Phenomena

Causation

Treatment Method

No power supply

a. poor plug contact or line broke

a. Connect the plug and line.

b. Fuse protector is broken.

b. Change the fuse protector.

No temperature

rising inside

container

a. Low setting temperature

a. Readjust and set temperature

b. Heater is broken.

b. Change the heater

c. Temp. controller is broken

c. Change the temperature

controller

d. Temp. sensor is loose.

d. Screw up the sensor nut.

e. Temp. sensor is broken

e. Change the temperature sensor.

No temperature

rising alarm

a. Set temp. of Detached tem.

limiter is low

a. Readjust the temperature 30℃

above setting temperature.

b. Detached temp. limiter sensor

is broken.

b. Change the detached temperature

limiter sensor

Temperature cannot

reach the setting

point.

a. Exhaust port is fully opened

a. Shut off the exhaust port.

b. The container is overfilled, no

hot air convection.

b. Decrease amount of sample to

improve convection condition.

The fan doesn’t

work.

The fan motor is broken

Stop work and check electric

capacity and motor

Displaying-------

The sensor is broken

Change the sensor

Display STOP

Time-up

Press the program key for 3s to

start

10

8. Warranty

8.1. Warranty is 12 months from EX-factory date (excluding consumable accessories).

8.2. Biobase would not be liable for any repair of damage caused by improper operation.

8.3. If the warranty has been expired, Biobase would still responsible for repair with relative charges.

8.4. Biobase would provide necessary technical data for maintenance companies or personnel trained

by Biobase engineers.

11

BIOBASE GROUP

2# building, No.9 Gangxing Road, High-tech Zone, Jinan City, Shandong Province,

China

Tel: +86-531-81219803/01

Fax: +86-531-81219804

Inquiry: [email protected]m

Complaints: custom[email protected]

Web: www.biobase.cc/www.meihuatrade.com / www.biobase.com

Other manuals for BOV-V30F

1

This manual suits for next models

5

Table of contents