Biocontrol CL-10 Plus User manual

CL-10 Plus

User Manual

CL-10 Plus – User Manual 2 / 75 ECPUS vers 0.2 eng

Index

I

In

nd

de

ex

x_

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

_2

2

1

1.

.

I

In

nt

tr

ro

od

du

uc

ct

ti

io

on

n_

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

_4

4

2

2.

.

I

In

ns

st

ta

al

ll

la

at

ti

io

on

n_

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

_5

5

2.1 . Unpacking and checking. _______________________________________________________________5

2.2 . PC system Configuration._______________________________________________________________5

2.3. System Installation.____________________________________________________________________6

2.3.1

Installation Requirements._________________________________________________________6

2.3.2

Mains voltage setting. ____________________________________________________________6

2.3.3

Connection cables. _______________________________________________________________6

2.3.4

Software Installation and configuration______________________________________________7

2.3.5

Hydraulic connections. ____________________________________________________________9

2.3.6

Internal & peristaltic pump tubing’s _______________________________________________10

2.4.

CL-10 Plus switching on. _____________________________________________________________11

2.5.

Instrument Stabilisation._____________________________________________________________11

2.5.1

Materials.______________________________________________________________________11

2.5.2

Peristaltic starter tube sealing control._____________________________________________11

2.5.3

Electrodes regeneration. _________________________________________________________12

2.5.4

Standby mode (Rest)_____________________________________________________________12

2.6. Instrument stabilisation with wash solution_______________________________________________13

2.6.1

Instrument preparation (Milk application).__________________________________________13

2.6.2

Instrument preparation (Wine application). _________________________________________13

2.6.3

Starting and calibrating __________________________________________________________14

2.7.

End of working session. ______________________________________________________________14

2.8.

Changing of application within the same working session._________________________________15

3

3.

.

T

Th

he

e

I

In

ns

st

tr

ru

um

me

en

nt

t_

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

_1

16

6

3.1

The principle_______________________________________________________________________16

3.2

The Measuring System. ______________________________________________________________16

3.2.1

Instrument layout. ______________________________________________________________16

3.2.2

Titration curve and Buffer Power measurement. _____________________________________17

3.2.3

END POINT measurement. ________________________________________________________20

3.2.4

KINETIC measurement (KIN). ______________________________________________________26

3.2.5

FIXED TIME measurement. ________________________________________________________29

4

4.

.

T

Th

he

e

C

CL

L-

-1

10

0

P

Pl

lu

us

s

P

Pr

ro

og

gr

ra

am

m_

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

_3

32

2

4.1. Menu and commands. _________________________________________________________________32

4.2.

FILE Menu . ________________________________________________________________________34

4.2.1

Select method __________________________________________________________________34

4.2.2

Create a new method ____________________________________________________________35

4.2.3

Edit method____________________________________________________________________35

4.2.4

Add method for Measure unit change; Biochemical Chemistry Application________________39

4.2.5

Clear graph ____________________________________________________________________41

4.2.6

Print graph_____________________________________________________________________41

4.2.7

Method name___________________________________________________________________41

4.3.

START UP Menu . ___________________________________________________________________42

4.3.1

Prime Enzyme or F2._____________________________________________________________42

4.3.2

Clean or F3. ____________________________________________________________________43

4.3.3

START UP parameters. ___________________________________________________________43

4.3.4

Run Start up procedure or F4._____________________________________________________43

4.4.

ROUTINE Menu._____________________________________________________________________45

4.4.1

Sample (GO icon or F5). __________________________________________________________45

4.4.2

Blank (B icon or F6). _____________________________________________________________46

4.4.3

Calibrate (C icon or F7).__________________________________________________________46

CL-10 Plus – User Manual 3 / 75 ECPUS vers 0.2 eng

4.4.4

Stop Measure. __________________________________________________________________46

4.5.

WOKLIST Menu _____________________________________________________________________47

4.5.1

Print Worklist __________________________________________________________________47

4.5.2

Edit Worklist ___________________________________________________________________48

4.5.3

Erase Worklist __________________________________________________________________48

4.5.4

Export Worklist _________________________________________________________________48

4.6.

SERVICE Menu ._____________________________________________________________________51

4.6.1

Auto increment SAMPLE ID. _______________________________________________________51

4.6.2

Enter rest mode.________________________________________________________________51

4.6.3

Instrument parameters (Access password: default).___________________________________51

4.6.4

Calibrate Temperature. __________________________________________________________53

4.6.5

Communication parameters. ______________________________________________________53

4.6.6

Print Technical Report. __________________________________________________________53

4.6.7

Terminal Emulation _____________________________________________________________54

4.6.8

Electrodes Test 1 and 2.__________________________________________________________56

5

5.

.

M

Ma

ai

in

nt

te

en

na

an

nc

ce

e

a

an

nd

d

P

Pr

re

es

se

er

rv

va

at

ti

io

on

n_

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

_5

57

7

5.1

Weekly Maintenance_________________________________________________________________57

5.2

Routine Maintenance ________________________________________________________________57

5.3.

Maintenance – rapid guide____________________________________________________________58

5.4.

Enzyme Contamination in the reference electrode _______________________________________59

5.5

CL10 preparation for a period of halt (over 2 weeks). ____________________________________61

5.6

Instrument Reactivation _____________________________________________________________61

6

6.

.

T

Tr

ro

ou

ub

bl

le

e

S

Sh

ho

oo

ot

ti

in

ng

g.

._

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

_6

63

3

6.1.

Electrical Section. __________________________________________________________________63

6.1.1

Instrument does not switch on.____________________________________________________63

6.1.2

Pumps do not operate when the instrument is on.____________________________________63

6.1.3

The analytical unit does not accept commands from the program. ______________________64

6.2. Fluidic Section._______________________________________________________________________65

6.2.1

The Mixer does not fill-in or empty.________________________________________________65

6.2.2

Liquid spills out from the mixing chamber.__________________________________________65

6.2.3

Absence of signal during the measurement. _________________________________________66

6.2.4

Unstable Measurements ._________________________________________________________66

6.3

Electrodes. ________________________________________________________________________66

6.3.1

Control of electrodes performances________________________________________________66

6.3.2

Electrodes replacement. _________________________________________________________68

6.4.

CL-10 Plus troubleshooting – rapid guide________________________________________________71

7

7.

.

T

TH

HE

E

P

PI

IP

PE

ET

TT

TE

E,

,

c

ch

ha

ar

ra

ac

ct

te

er

ri

is

st

ti

ic

cs

s,

,

u

us

se

e

a

an

nd

d

m

ma

ai

in

nt

te

en

na

an

nc

ce

e.

._

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

__

_7

73

3

7.1

Materials. _________________________________________________________________________73

7.2

Using the Microman Pipette.__________________________________________________________73

7.2.1

How to Mount the Piston. ________________________________________________________73

7.2.2

How to mount the capillary. ______________________________________________________73

7.3

Pipetting.__________________________________________________________________________74

7.3.1

Aspiration._____________________________________________________________________74

7.3.2

Dispensing._____________________________________________________________________74

7.3.3

Simultaneous ejection of the piston and capillary. ___________________________________74

7.4

Pipette Specifications._______________________________________________________________74

7.5

How to Inject The Sample. ___________________________________________________________75

CL-10 Plus – User Manual 4 / 75 ECPUS vers 0.2 eng

CL-10 Plus

1. Introduction

CL-10 Plus instrument is an automatic multi-parametric analyser, working in differential-pH

technique for chemical analyses in various type of matrices, from food industry to clinical

applications.

Technique characteristics are:

-Operative simplicity on different matrices, also particularly difficult ones.

-Versatility:

oexecutes the tests using few (from 5 to 1000) µL sample.

oin short time (from 15 seconds to 3 minutes).

-Promptness of response of tests made on unstable matrices.

-Use of dedicated and ready to use reagents, of 4-6 months shelf life

Products of common use are listed hereafter, in order to make the reading of the present

manual easier.

These products will be often mentioned, when required for routine procedures, maintenance

and repair.

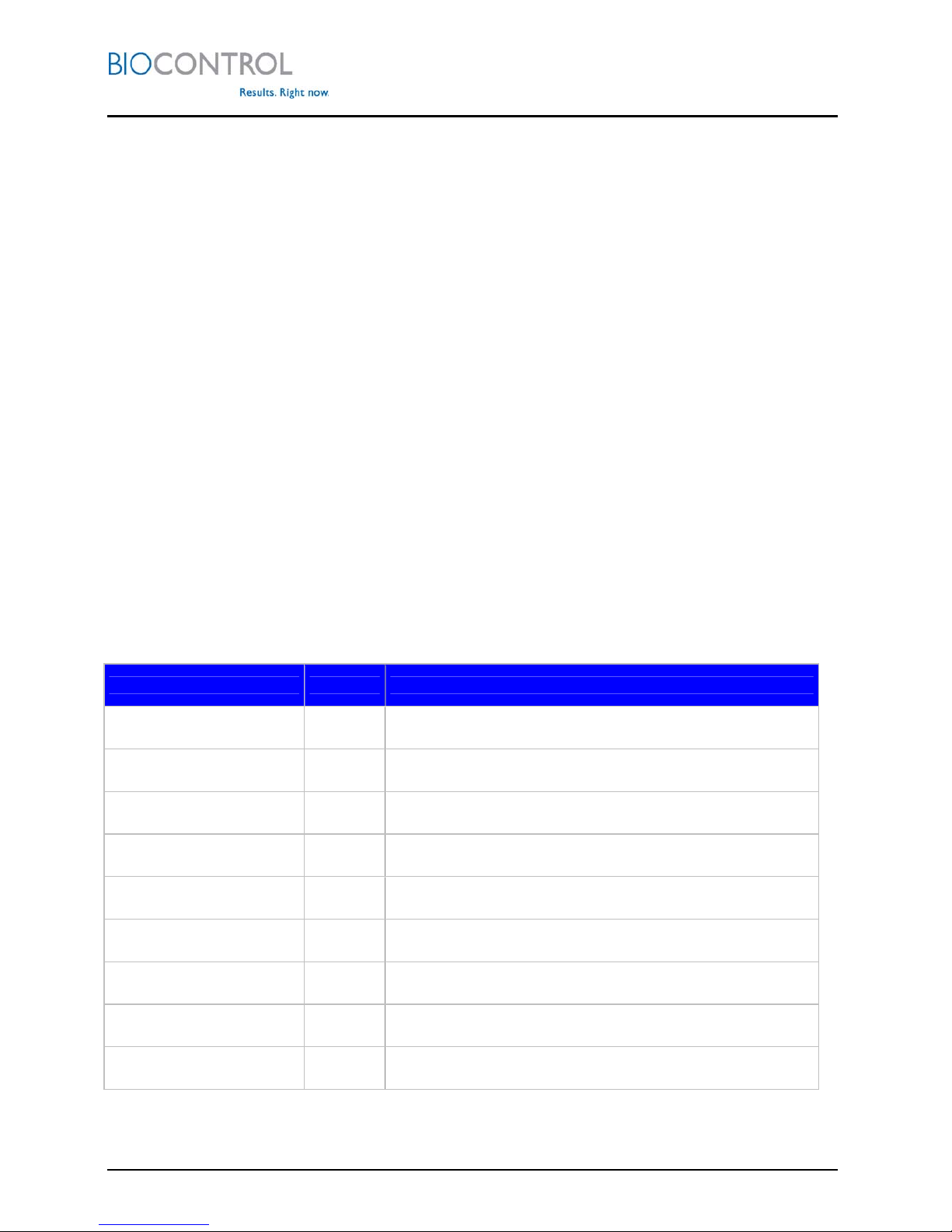

Product Code Use

Polif Solution GEN718 wash solution, to be used with all Milk and Wine applications

Wash Kit GEN698 wash solution, to be used with all Clinical Chemistry applications, but not

with G6PD

Wash Kit GEN699 wash solution, to be used with G6PD Clinical Chemistry application

Diluent Buffer GEN644 to be used with Wine applications (when described in the specific

package insert)

Combi Clean GEN674 to be used with Wine Combi Test and pH/Acidity kits

Microman M25 micro-pipette GEN102 to be used with all applications, except Wine Combi Test and pH/Acidity

Electrodes test GEN603 Used to check electrodes performances, regardless the application field

(see§4.6.8)

Regenerating Solution GEN518 Used for the Maintenance §5

Strong Regenerating Solution GEN613 Used for the maintenance §5

CL-10 Plus – User Manual 5 / 75 ECPUS vers 0.2 eng

2. Installation

The CL10 Plus instrument consists of a thermo stable measuring block which contains two

capillary glass electrodes, a mixing chamber, two groups of peristaltic pumps, a differential

amplifier and a microprocessor which calculates the analyte concentration or enzyme activity

in the sample, and controls all the functions of the instrument.

CL-10 Plus is delivered with the fluidics empty (free from liquid) and dry and with the

peristaltic pumps unhooked (see § 5.5 figure; the detail of the pump tubing’s).

The procedure for the electrodes reactivation and stabilisation takes from 2 to 24 hours (see

§ 2.5.3).

2.1 . Unpacking and checking.

Check the list of content:

1. Instrument CL10 Plus

2. power 230 VAC (110 VAC) - 12 VDC

3. power cable

4. serial cable CL10-PC

5. Plastic bottles ( Kartel type) for the buffer and/or standby solution and for the waste

(2x250 ml)

6. Set pump tubing’s (Art. No. SSP112 or SPP112+SPP113)

7. CL-10 Plus Software on CD-ROM and relative Licence

8. CL-10 Plus Operator Manual

9. CL10 Plus Testing Certificate

Instrument Serial Number:

The serial number is located on the back of the instrument; it is the same number

written on the CL-10 Plus Testing Certificate .

2.2 . PC system Configuration.

•Pentium PC at 175 MHz or superior

•Microsoft Windows 95/98/2000/Me/XP

•RAM 32 MB or superior

•6 MB available on the Hard Disk

•floppy disk 3,5”

•Monitor Super VGA with 256 colours

•Video card with 800x 600 pixel

•CD-ROM 4x or superior

•COM1 RS232 9 pin or USB* port

•If USB port is used USB-RS232 converter is required.

(recommended: Targus Replicator type. PA070)

Table of contents

Other Biocontrol Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual