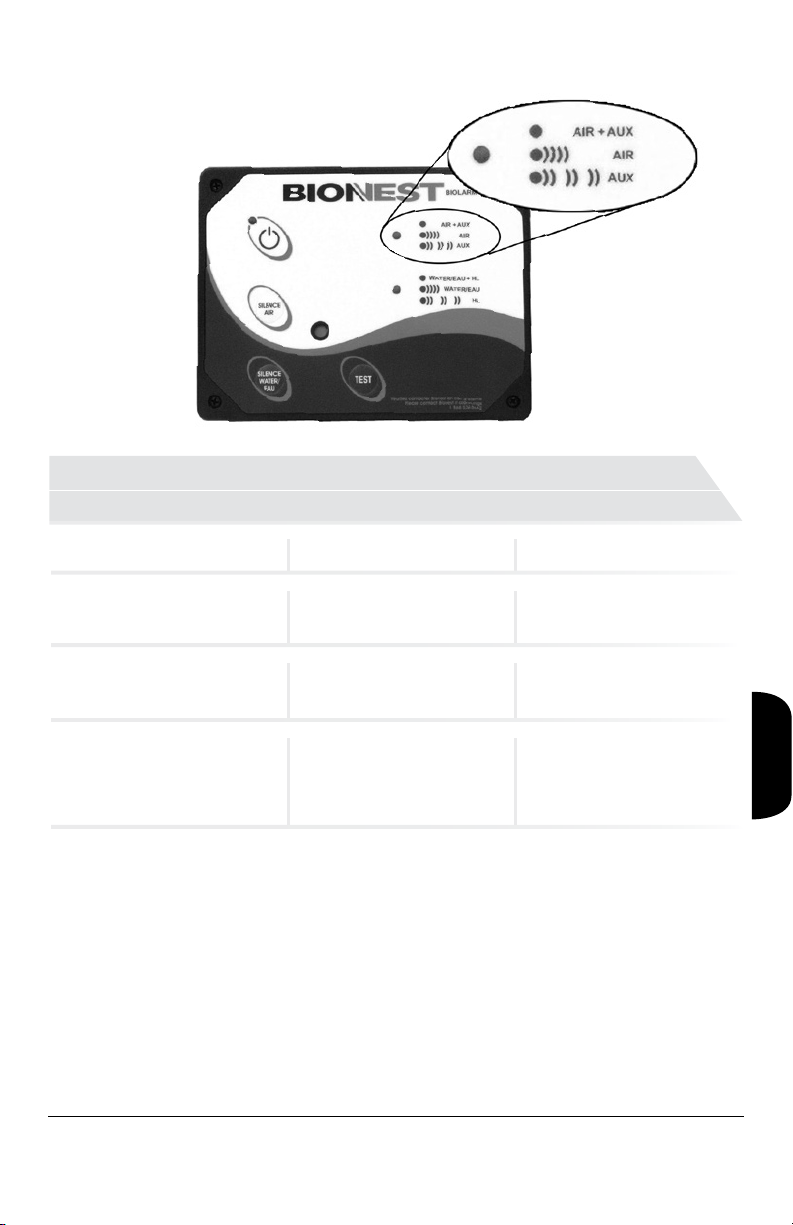

Bionest SA-3 User manual

Other manuals for SA-3

1

This manual suits for next models

5

Other Bionest Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Suchy Mips

Suchy Mips BENS G4 manual

Judo

Judo PROFIMAT JPF-A Series Installation and operating instructions

Oase

Oase BioSmart 18000 operating instructions

Danfoss

Danfoss IPS 8 user guide

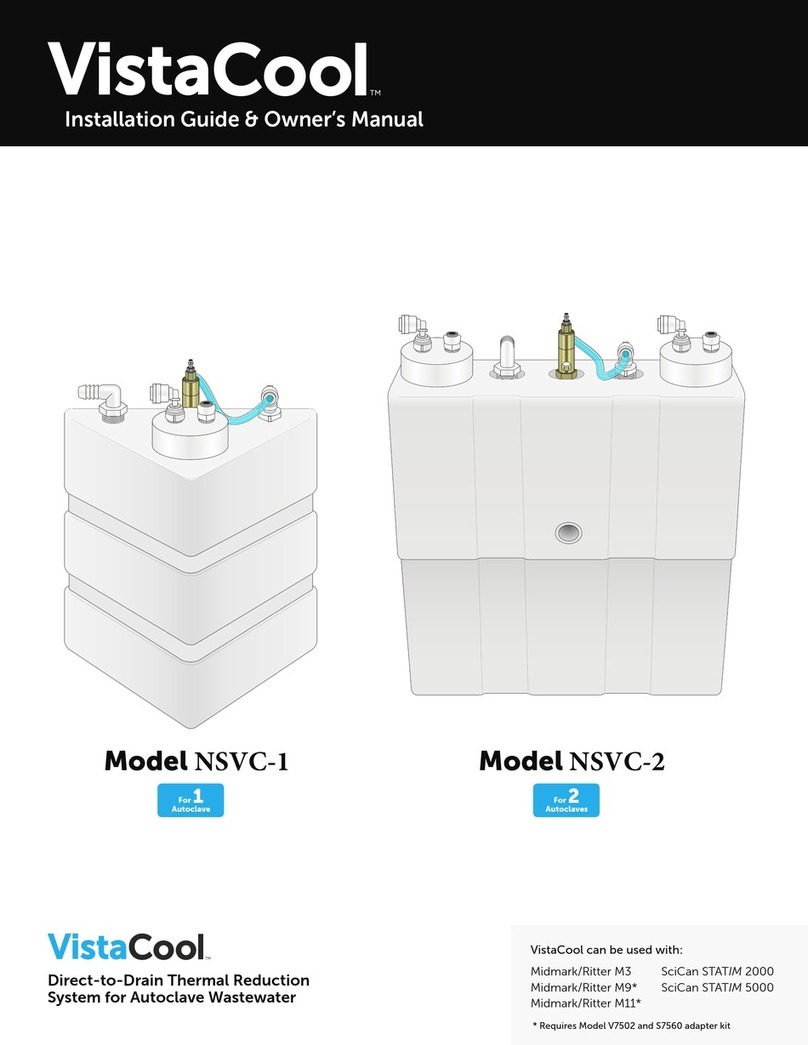

Duraline Systems

Duraline Systems Vistacool NSVC-1 Installation guide & owner's manual

KENT

KENT 112011 instruction manual

Lifesaver

Lifesaver LIBERTY user manual

Gardena

Gardena FFP 5000 UVC operating instructions

AMI

AMI Ultimate Mineral RO HD-81UM Instruction handbook for installation, operation and maintenance

Everpure

Everpure MRS-100 Quick start guides

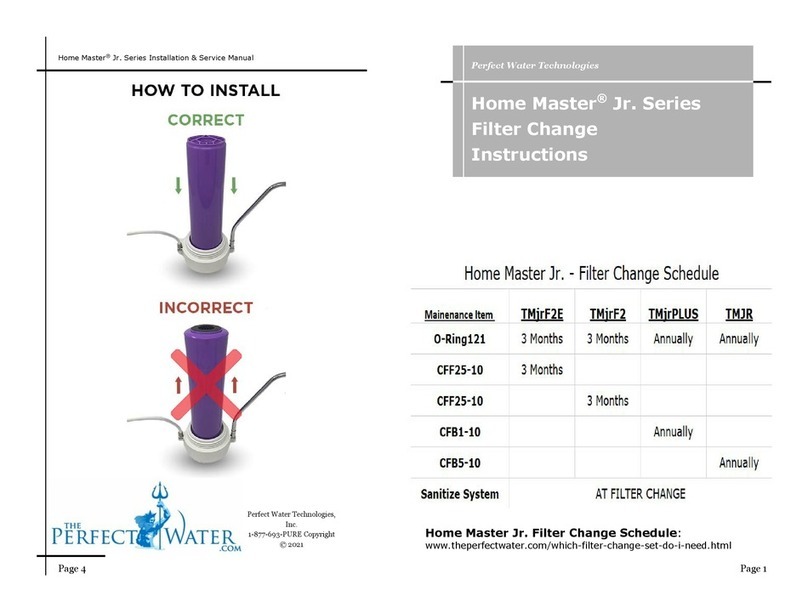

Perfect Water Technologies

Perfect Water Technologies Home Master Jr. Series instructions

Omcan

Omcan OF-CN-0023 instruction manual

Oase

Oase FiltoClear Series operating instructions

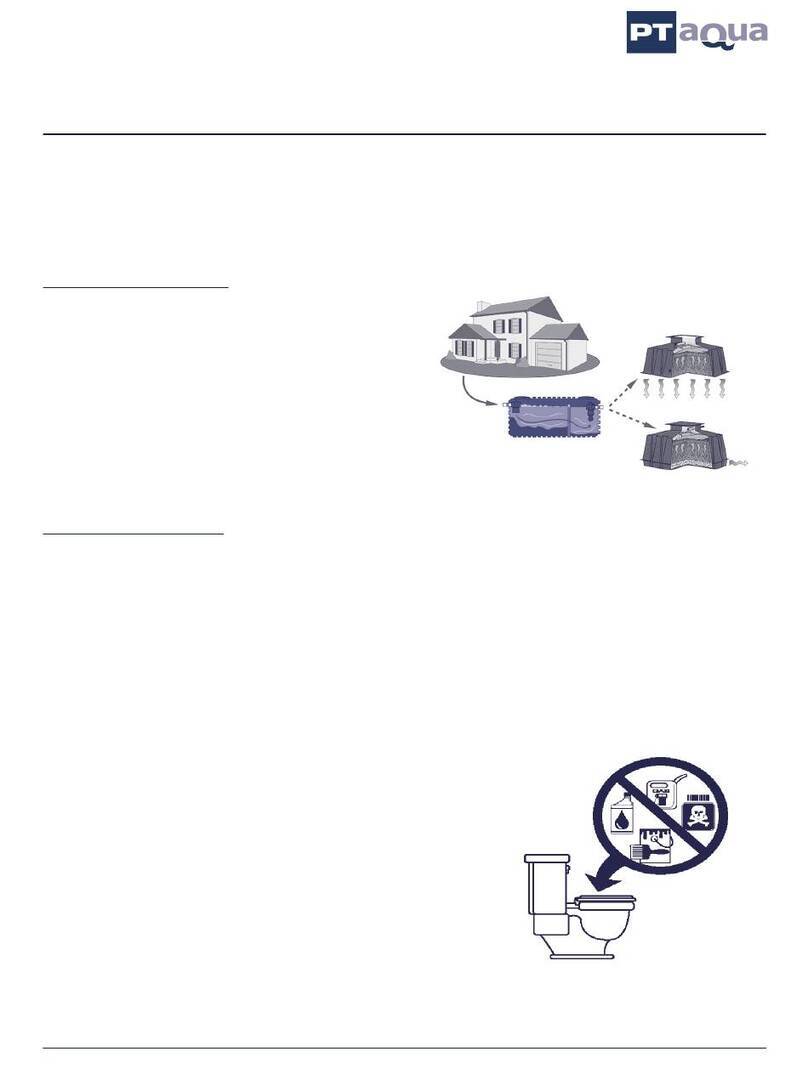

Premier Tech Aqua

Premier Tech Aqua Ecoflo ST-500 owner's manual

Philips

Philips HD3802 user manual

UV Pure Technologies

UV Pure Technologies Hallett 1000 maintenance

Vestergaard

Vestergaard LifeStraw PEAK Series user manual

Ultra Reef

Ultra Reef UCS-140 instruction manual