Bioquell ProteQ User manual

©Bioquell UK Ltd (2020). All rights reserved.

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Bioquell UK Ltd

52 Royce Close

West Portway

Andover

Hampshire SP10 3TS

T:

F:

E:

W:

+44 (0)1264 835 835

+44 (0)1264 835 836

info@bioquell.com

www.bioquell.com

Hydrogen Peroxide Vapour Decontamination

Suite

USER MANUAL

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 2 of 58

REV

Description

Date

C.R.No

Orig

Chkd

Apprd

3

Update to spec, US distance measurer & user

access

8th May 2019

CR3852

ORC

PM

REP

4

Addition of Flexi adaptor and Active directory

20 Feb 2020

CR4063

ORC

PM

REP

5

Addition of FDA requirement and new DoC

29 Oct 20

XXXXX

ORC

XX

XX

Bioquell designs, manufactures and supplies as a service a broad range of bio-

decontamination solutions for:

•rooms

•systems and processes

•laboratory equipment

•biomedical equipment

For further information and contact details refer to website www.bioquell.com

Hydrogen peroxide vapour is potentially dangerous if used incorrectly. It is essential that

the safety and operating instructions described in this manual are observed.

These are the Original Instructions

The Bioquell ProteQ is only to be used by personnel who have been trained by

Bioquell or their agents on its safe use. If the equipment is used in a manner not

specified by the manufacturer, the protection provided by the equipment may be

impaired.

United States of America only:

•The Bioquell Technology system hasbeen authorized by the United States Food

Drug and Administration (FDA) todecontaminate compatible N95 respirators

under an Emergency Use Authorization (EUA).

•The Bioquell Technology System has neither been cleared or approved by FDA, but

has been authorized for emergency use by FDA under an EUA for the

decontamination of compatible N95 respirators for single-user reuse by HCP to

prevent exposure to SARS-CoV-2 and other pathogenic biological airborne

particulates;

•The emergency use of the Bioquell Technology System is authorized only for the

duration of the declaration that circumstances exist justifying the authorization of

the emergency use of medical devices during the COVID-19 outbreak, under

Section 564(b)(1) of the Federal Food, Drug, and Cosmetic Act, 21 U.S.C. §

360bbb-3(b)(1), unless the declaration is terminated or authorization is revoked

sooner.

Report Adverse events, including problems with test performance or results, to MedWatch by submitting the

online FDA Form 3500 (https://www.accessdata.fda.gov/scripts/medwatch/index.cfm?action=reporting.home) or

by calling 1-800-FDA-1088

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 3 of 58

CONTENTS

1 SAFETY .................................................................................................. 4

1.1 Warning Labels .................................................................................. 7

2 UNPACKING INSTRUCTIONS ................................................................. 8

3 VAPOUR BIO-DECONTAMINATION PROCESS .........................................9

3.1 Process Sequence............................................................................... 9

3.1.1 Conditioning Phase ...................................................................................9

3.1.2 Gassing Phase ..........................................................................................9

3.1.3 Dwell Phase .............................................................................................9

3.1.4 Aeration Phase .........................................................................................9

4 PROTEQ DESCRIPTION ........................................................................ 11

4.1 Main Module Features & Connections .................................................. 11

4.1.1 Base Unit...............................................................................................11

4.1.2 Lectern.................................................................................................. 12

4.1.3 Aeration Unit (Optional)...........................................................................12

4.2 Hydrogen Peroxide Supply................................................................. 13

5 MOVING THE PROTEQ.......................................................................... 13

6 EQUIPMENT SET-UP ............................................................................ 14

6.1 Setting-up the ProteQ ....................................................................... 14

6.2 Measuring the room.......................................................................... 15

7 LOADING HYDROGEN PEROXIDE BOTTLES .......................................... 16

7.1 Bottle Indicators............................................................................... 16

7.2 Installing Hydrogen Peroxide Bottles................................................... 17

7.3 Fitting Insert for 950ml Bottle ............................................................ 19

7.4 Flexi Adaptor ................................................................................... 19

8 OPERATION ......................................................................................... 20

8.1 Running a Cycle ............................................................................... 20

8.2 Viewing Cycle Variables (Sensor units only) ......................................... 23

8.3 Aeration Only Cycle .......................................................................... 24

8.4 Printed Report.................................................................................. 24

8.5 Log OFF .......................................................................................... 25

8.6 Process Stop.................................................................................... 25

9 LOADING AN EXISTING PRE-PROGRAMMED CYCLE ............................. 26

10 CREATING A NEW CYCLE ................................................................... 27

11 SYSTEM ADMINISTRATION ............................................................... 29

11.1 System Information ........................................................................ 29

11.2 Time Zone, Daylight Saving and Region ............................................ 29

11.3 Date and Time ............................................................................... 29

11.4 Manage Users and Passwords........................................................... 29

11.4.1 Adding New Users .................................................................................30

11.4.2 Changing Access Level...........................................................................31

11.4.3 Deleting Users ...................................................................................... 31

11.4.4 Changing Password ...............................................................................31

11.4.5 Backing-up User and password data........................................................31

11.5 Network Administrator Functions ...................................................... 32

11.6 Audit Trail (Option) ......................................................................... 32

11.7 Data logging out of Cycle................................................................. 32

12 PACKING-UP...................................................................................... 33

13 OPERATING THE WIRELESS NETWORK (PAIRING)............................ 34

13.1 Changing the Wireless Network Colour .............................................. 34

13.2 Pairing a Lectern to a ProteQ Base Unit ............................................. 34

13.3 Joining Aeration units to the network ................................................ 35

13.4 Using the Wireless Repeater............................................................. 36

14 ROUTINE MAINTENANCE ................................................................... 37

14.1 User Routine Maintenance ............................................................... 37

14.1.1 Changing the Printer Paper ....................................................................37

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 4 of 58

14.1.2 Cleaning ..............................................................................................37

14.1.3 Hydrogen Peroxide Liquid.......................................................................38

14.2 Scheduled Maintenance ................................................................... 38

15 TROUBLE SHOOTING ......................................................................... 39

15.1 Software Cycle Interlocks ................................................................ 39

15.2 Warnings & Alarms ......................................................................... 40

15.3 Fault Finding .................................................................................. 47

16 SPECIFICATION................................................................................. 48

17 HAND HELD LOW LEVEL HYDROGEN PEROXIDE SENSOR ................... 50

18 DISTANCE MEASUREMENT DEVICE (OPTIONAL)................................ 51

19 PARTS LIST ....................................................................................... 52

19.1 Consumables ................................................................................. 52

19.2 Replacement Parts .......................................................................... 52

20 SCREEN NAVIGATION........................................................................ 53

21 DECLARATION OF CONFORMITY........................................................ 55

22 DEFAULT PASSWORDS ...................................................................... 56

1SAFETY

Safety instructions that must be observed when operating the Bioquell ProteQ

hydrogen peroxide system or handling the hydrogen peroxide bottles are listed

below.

Danger and Warning signs are used where there is potential hazard to

personnel.

The mandatory symbol is used to describe other safety precautions that

must be followed before operating the equipment.

HANDLING HYDROGEN PEROXIDE

Always wear gloves, long sleeves and eye protection when handling

Hydrogen Peroxide.

Exposure to HYDROGEN PEROXIDE LIQUID can cause burns and

blistering to the skin and tissue damage to the eyes. HYDROGEN

PEROXIDE VAPOUR can cause irritation to eyes, nose, throat, lungs and

skin, breathing difficulties and coughing.

IN ALL CASES SEEK MEDICAL ADVICE.

ACTION TO BE TAKEN ON EXPOSURE TO HYDROGEN PEROXIDE

EYES

Irrigate with sterile water for at least 10 minutes.

LUNGS

Remove casualty immediately to fresh air, rest and keep warm.

SKIN

Drench with water, remove clothing.

MOUTH

Rinse thoroughly with water and give plenty to drink.

SAFETY OBSERVANCE IS ESSENTIAL WHEN USING THIS EQUIPMENT.

READ THIS SECTION CAREFULLY BEFORE USING THE EQUIPMENT.

Only personnel who have been trained by Bioquell or their agents on the

safe use of the ProteQ should operate it.

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 5 of 58

HYDROGEN PEROXIDE VAPOUR IS HAZARDOUS

-Ensure that the enclosure to be gassed is sealed to prevent hydrogen

peroxide vapour escaping.

-Ensure that any possible points of entry are sealed, locked where

possible and warning signs displayed if appropriate.

-Ensure area to be gassed is free of any humans, animals and plants.

SPILLAGES

Mop up with plenty of water and run to waste, diluting at least 20:1.

POWER CONNECTION OF THE EQUIPMENT

Ensure the Bioquell ProteQ system modules are connected to

appropriately rated circuits which have an earth.

COMMUNICATION CONNECTIONS

If more than one system is in operation on a site, ensure each system is

on a separate network. This can be identified by the colour of the

wireless indicator, otherwise operational interference may occur

DURING A CYCLE

-Do not enter the area being bio-decontaminated

-A suitable portable H2O2detector should be used throughout the

cycle to monitor concentrations outside the area.

-If leak is detected, leak sealing and evacuation procedures should be

followed.

AT THE END OF AERATION

Before re-entering the area check that the vapour concentration is at, or

below, the countries Occupational Exposure Limit (OEL) (Long-term

exposure limit is 1ppm and short-term is 2ppm in the UK). In USA: the

Permitted Exposure Limit (PEL) has a Threshold Limit Value (TLV) of

1ppm for eight hours exposure a day.

IF THE CYCLE ABORTS DURING GASSING OR AERATION

-Check that the vapour concentration is at, or below, the OEL before

entering the enclosure

-If above the OEL, run further aeration cycles in accordance with

these instructions until the safe concentration level is reached.

EXTERNAL DISCHARGE OF VAPOUR

If a fixed ventilation system is used to exhaust, it must not allow

leakage of hydrogen peroxide vapours within the building. When the

HVAC is started, check that the room does not become heavily

pressurised, as this could cause the room sealing to become

compromised.

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 6 of 58

WARNING – EQUIPMENT DAMAGE

Operate only when located on a flat surface, and engage the brakes on

the ProteQ unit. Always remove Aeration units from the ProteQ base

unit, if present, before running a cycle.

Place the aeration units onto the floor in the correct position, do not drop

or throw to the ground. Carry units, do not move by kicking or dragging

along the floor

Do not use the aeration units as a step this will damage the equipment

BEFORE MOVING EQUIPMENT after cycle is complete always disconnect

power cables. Put away all equipment in the ProteQ base unit.

Repairs, maintenance or adjustments to the Bioquell ProteQ generator

must only be made by trained Bioquell personnel or their agents.

The equipment must be serviced in accordance with the Maintenance

Schedule to maintain safe performance.

DANGER – PERSONAL INJURY HAZARD

The ProteQ can weigh up to 86Kg (190 lbs), the lectern alone 9Kg (20 lbs)

and the aeration units weigh 10Kg (22 lbs). Appropriate lifting procedures

should be followed. Do not lift multiple aeration units.

When moving the ProteQ use the handles on either side of the bottle

module. Two aeration units can be transported in the ProteQ, any further

units should be transported using a suitable trolley and securing method.

The user should not open access panels. This should only be for Bioquell

trained service engineers.

When moving the ProteQ with bottles containing liquid ensure the bottle

engagement plunger is locked in its down position.

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 7 of 58

1.1 Warning Labels

ProteQ warning labels and their meaning

ELECTRICAL INJURY

HAZARD

Only trained personnel

should be accessing the

internal PCB area.

WEAR PROTECTIVE

GLOVES

Wear protective clothing

when handling hydrogen

peroxide bottles.

WEAR EYE

PROTECTION

Wear protective eye

protection when handling

hydrogen peroxide bottles.

READ MANUAL

Read manual prior to

operation of the

equipment

Consumable H2O2warning label and its meaning

CHEMICAL INJURY

HAZARD

Contents harmful.

CHEMICAL INJURY

HAZARD

Hydrogen peroxide liquid

is harmful and is an

oxidizing agent

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 8 of 58

Aeration unit warning label and its meanings

DO NOT STAND HERE Do not stand on the

aeration unit

ELECTRICAL INJURY

HAZARD

Only trained personnel

should be accessing the

internal PCB/power supply

area.

2UNPACKING INSTRUCTIONS

This ProteQ is supplied in one large box on a pallet:

1. Cut the retaining straps and remove the lid from the box.

2. Remove the small boxes containing the hand held instruments.

3. Remove the large outer sleeve by lifting it up and over the unit.

4. Lower the ramp.

5. Carefully cut open the silver bag.

6. Carefully, with two people, wheel out the ProteQ down the ramp.

Charge the hand held low level H2O2sensor as soon as it is unpacked, if

supplied. The sensor, charger and information booklet are contained in

separate small white boxes; see Section 17 of the manual on sensor

charging.

WARNING: Two people are required to safely remove the system

from the pallet.

WARNING: The ProteQ module weighs 87kg (192lbs). Appropriate

lifting procedures should be followed.

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 9 of 58

3VAPOUR BIO-DECONTAMINATION PROCESS

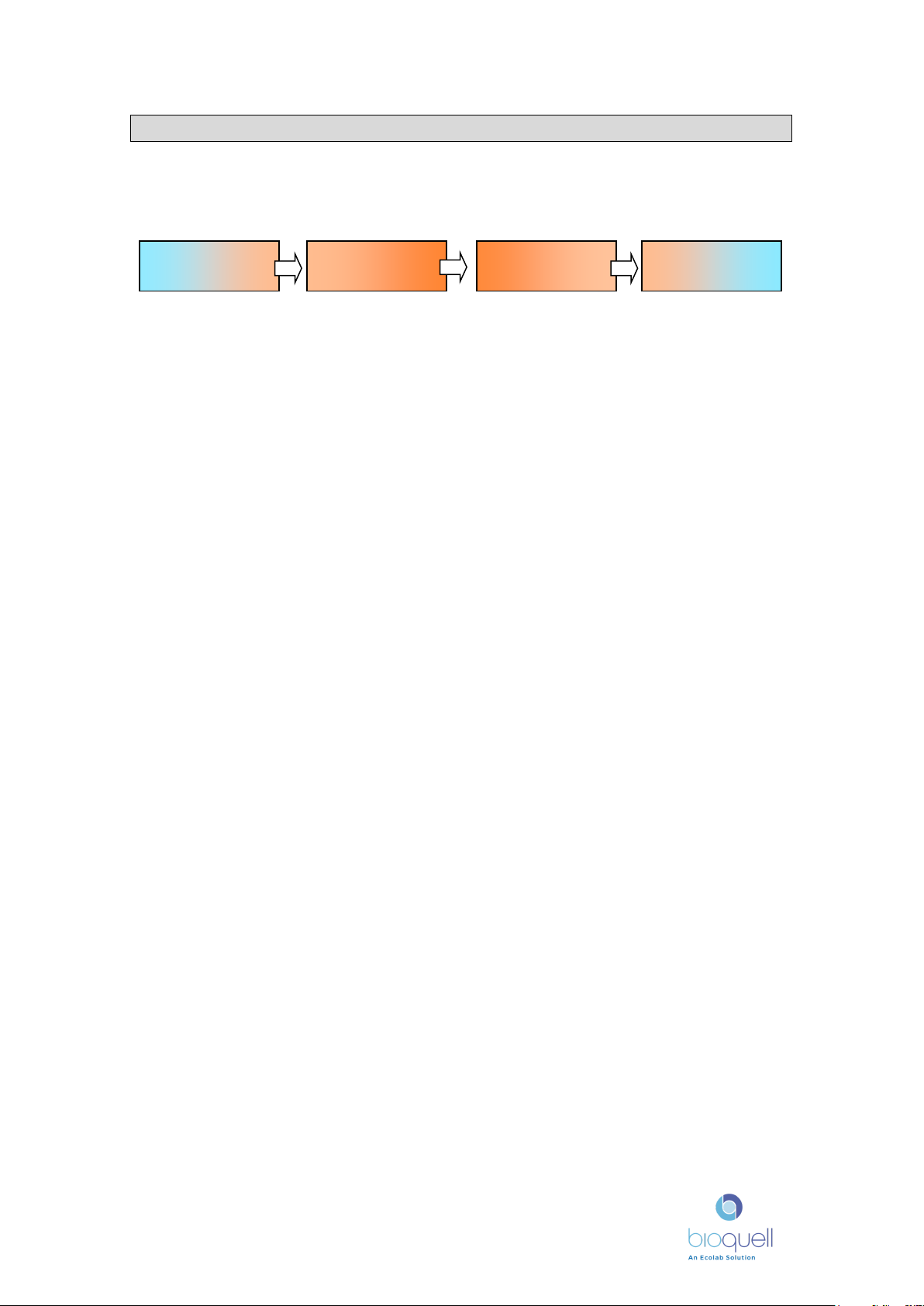

3.1 Process Sequence

The room bio-decontamination process consists of the following stages:

The ProteQ is designed to carry out the conditioning, gassing and dwell phases of

the bio-decontamination cycle. The aeration phase is performed by the lower

aeration part of the Base unit and optional aeration unit(s). Control and

monitoring of the process is performed outside the area using the lectern. The

Base unit, optional aeration units and lectern communicate with each other

wirelessly.

3.1.1 Conditioning Phase

When the system starts conditioning, the air and vaporizer heaters warm-up and

control to their set points ready for the next stage of the cycle.

During conditioning both the vaporizer and distribution fans operate, ensuring

that the hydrogen peroxide outlets reach a stable operating temperature.

Immediately after conditioning, the dosing pump is primed with hydrogen

peroxide liquid.

3.1.2 Gassing Phase

Liquid from a bottle is pumped onto the vaporizer heaters. Air then passes around

the heaters where it picks up the H2O2vapour for distribution.

The air circulation system has been designed to distribute the hot vapour evenly

throughout the room being bio-decontaminated. This system consists of fans,

which draw air from the top of the unit and blow it out of the four vents at high

velocity. An additional, internal flow path, from the distribution head down to the

base of the unit, ensures the inside of the unit is also bio-decontaminated.

There are two types of cycle parameters that can be programmed by the

operator. The first is a parametric cycle where the amount of H2O2to be used is

automatically calculated from the room volume and by the unit’s internal

instrumentation and control algorithm. The alternative is a fixed pre-validated

timed cycle.

3.1.3 Dwell Phase

The dwell phase allows the vapour to evenly distribute within the room and for

the condensation contact time to be prolonged.

3.1.4 Aeration Phase

CONDITIONING

GASSING

DWELL

AERATION

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 10 of 58

The Base unit has an aerator on the lower half. In addition up to 6 optional

aeration units can be used, two of which can be transported in the ProteQ. The

building’s HVAC system can also be used to aerate. The aerators contain a

catalyst, which converts the hydrogen peroxide (H2O2) vapour to water vapour

and oxygen. This phase continues until the hydrogen peroxide concentration

reaches 1ppm, when it should be checked with the hand held low level sensor.

Note: It is against US federal law to use a biocide in a manner inconsistent

with its labelling. Refer to and comply with Bioquell Hydrogen Peroxide

sterilant labelling.

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 11 of 58

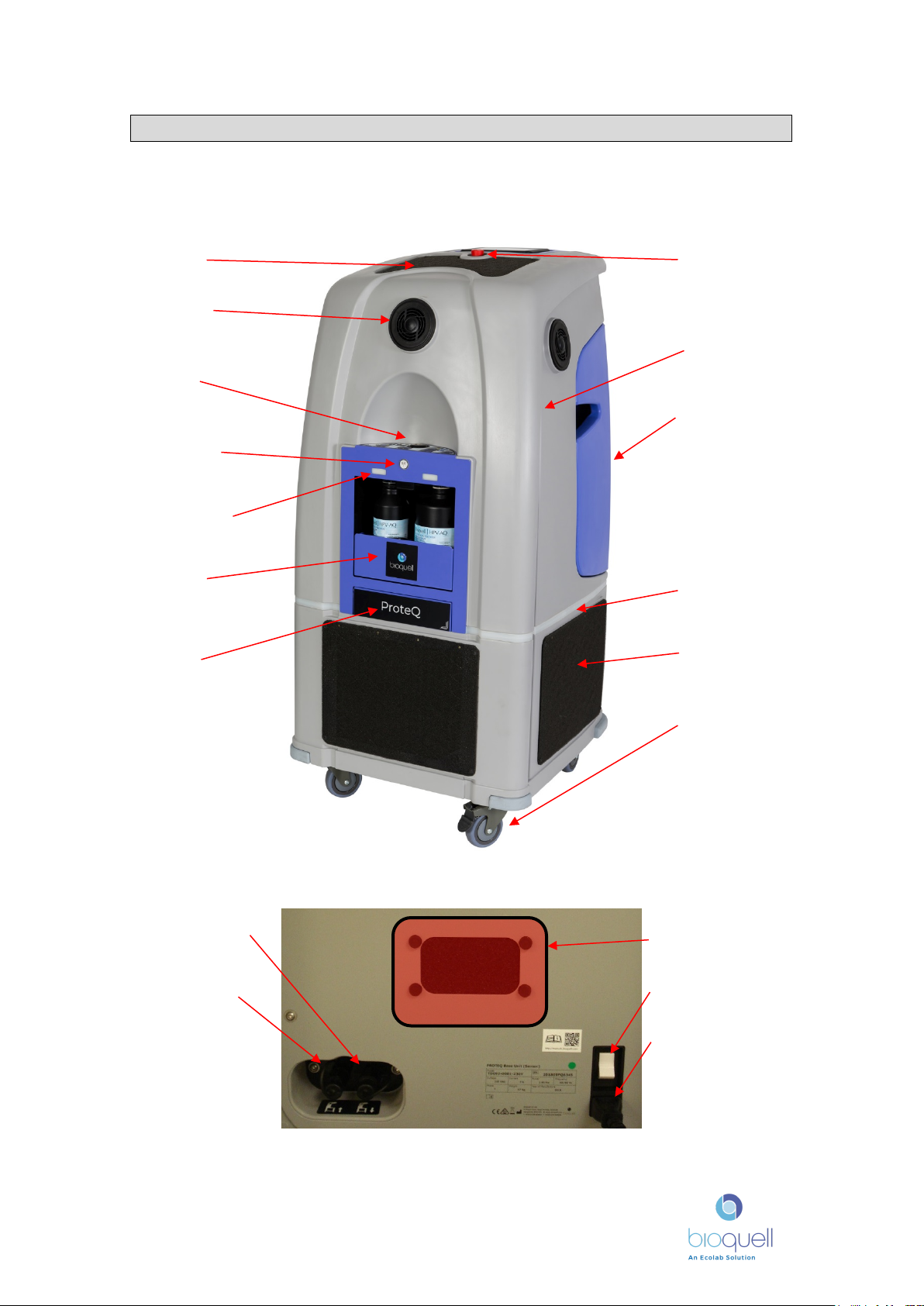

4PROTEQ DESCRIPTION

4.1 Main Module Features & Connections

4.1.1 Base Unit

Emergency

Process stop

Moulded

Handles

lectern –

Optional

Aeration units

stored behind.

Light ring

Aeration Unit

Braked Wheels

(2)

Top air inlet

filter

Air outlets (4)

Bottle

engagement

plunger

Wireless status

indicator

Bottle status

indication lights

Bottle

compartment

Safety

equipment

storage (Gloves

& goggles)

Air inlet must be kept

clear of obstructions

Power Switch

Power cable connection

Cycle stage volt free

signal

Remote start/stop

BACK PANEL

NOTE: The power cables supplied with the equipment must not be replaced with inadequately rated cables

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 12 of 58

4.1.2 Lectern

NOTE: The power cables supplied with the equipment must not be replaced with

inadequately rated cables

4.1.3 Aeration Unit (Optional)

Air inlet filter

Distribution fans

Wireless status

indicator

Handles

Power input and main

switch

Air outlet grille

Colour touch

screen

Printer

Wireless

network colour

Wireless

extension

module

connection

Sealing tape

Light ring

Hand held low

level hydrogen

peroxide sensor

Power cable

(Power input at

the rear)

Network socket

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 13 of 58

4.2 Hydrogen Peroxide Supply

The ProteQ HPV generator uses only Bioquell branded 35% wt/wt hydrogen

peroxide in either 2 litre or 950ml bottles. Each bottle label contains a Radio

Frequency Identification (RFID) tag which enables the amount of liquid in the

bottle to be read along with the expiry date.

If a Flexi Adaptor is being used fill only with approved Hydrogen Peroxide. Ensure

eye protection and gloves are worn as a minimum, and filling takes place in a

suitably ventilated area.

5MOVING THE PROTEQ

WARNING – Personal Protective Equipment must be used when

handling the bottles, which contain hydrogen peroxide. As a minimum

Bioquell recommend wearing suitable gloves and eye protection.

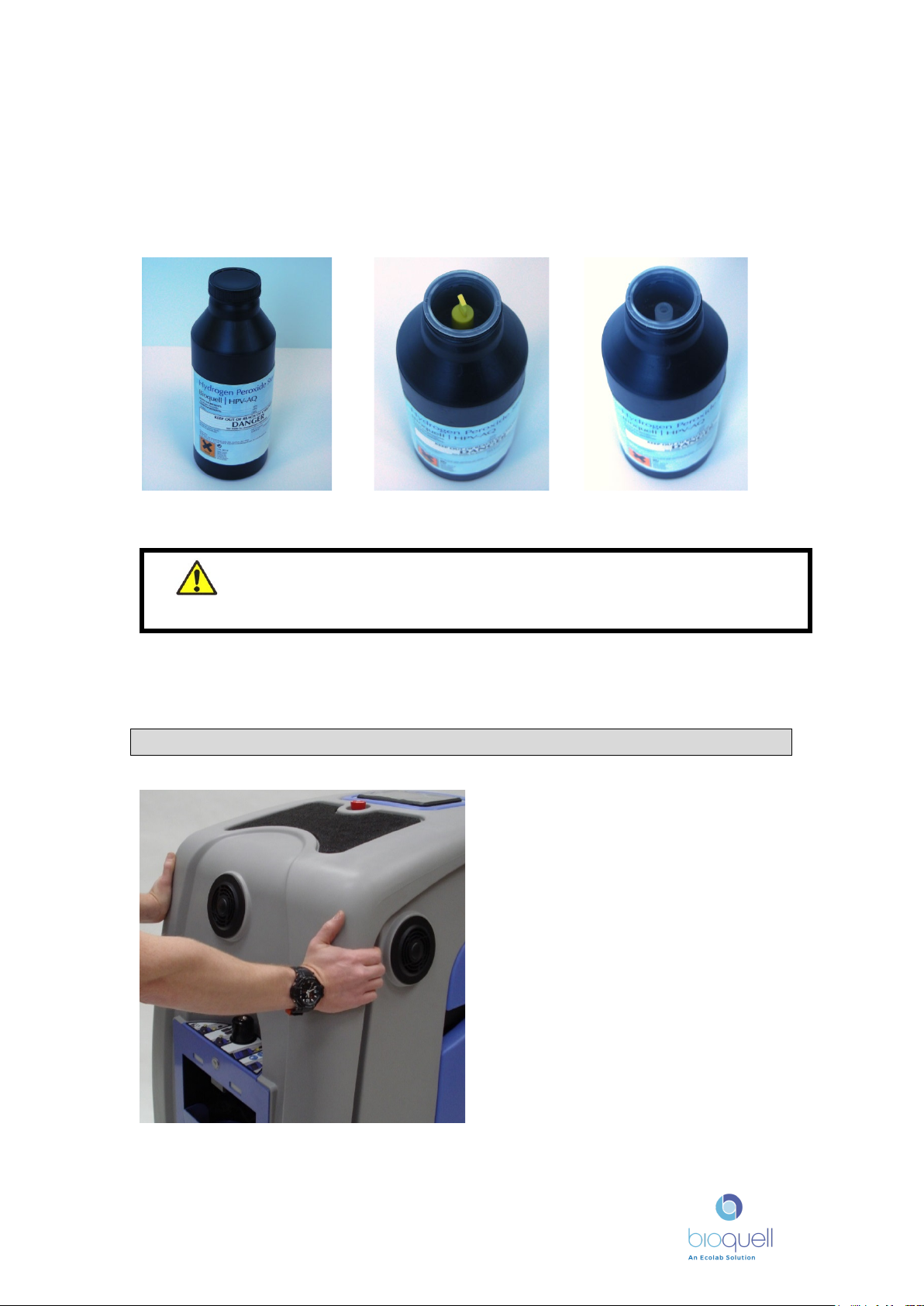

Unpacked bottle

Screw cap removed

Yellow inner cap

removed – ready for use

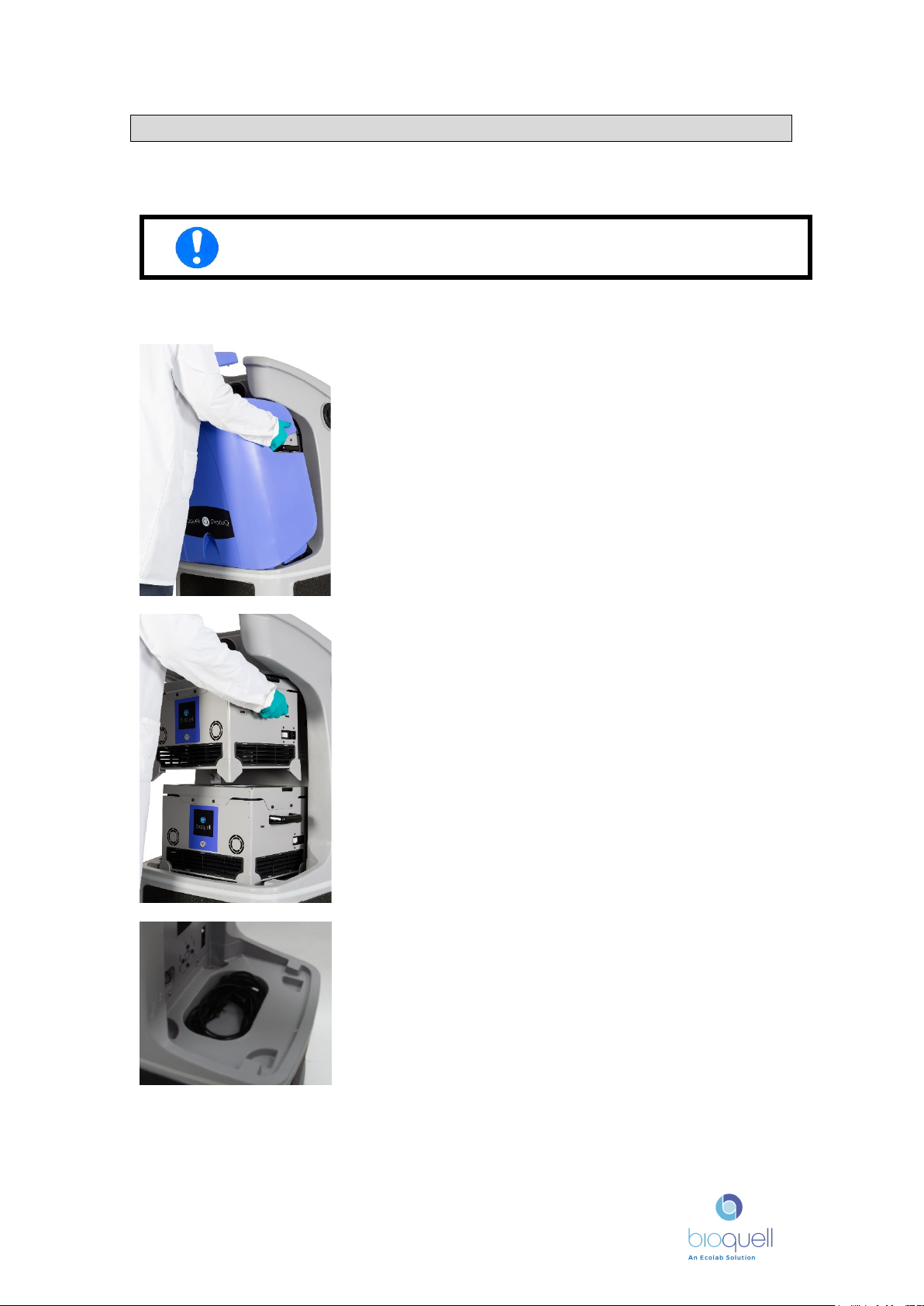

Hold the moulded handles on either

side with both hands when moving

the ProteQ, as shown.

The optional aeration units and the

lectern along with the cables and

accessories are all stored in the Base

unit.

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 14 of 58

6EQUIPMENT SET-UP

The ProteQ system can decontaminate a maximum total room(s) volume

of 250m3(8,800ft3), for larger rooms contact Bioquell.

6.1 Setting-up the ProteQ

Do not tread on aeration units, or use them as a step. Always place on

the floor

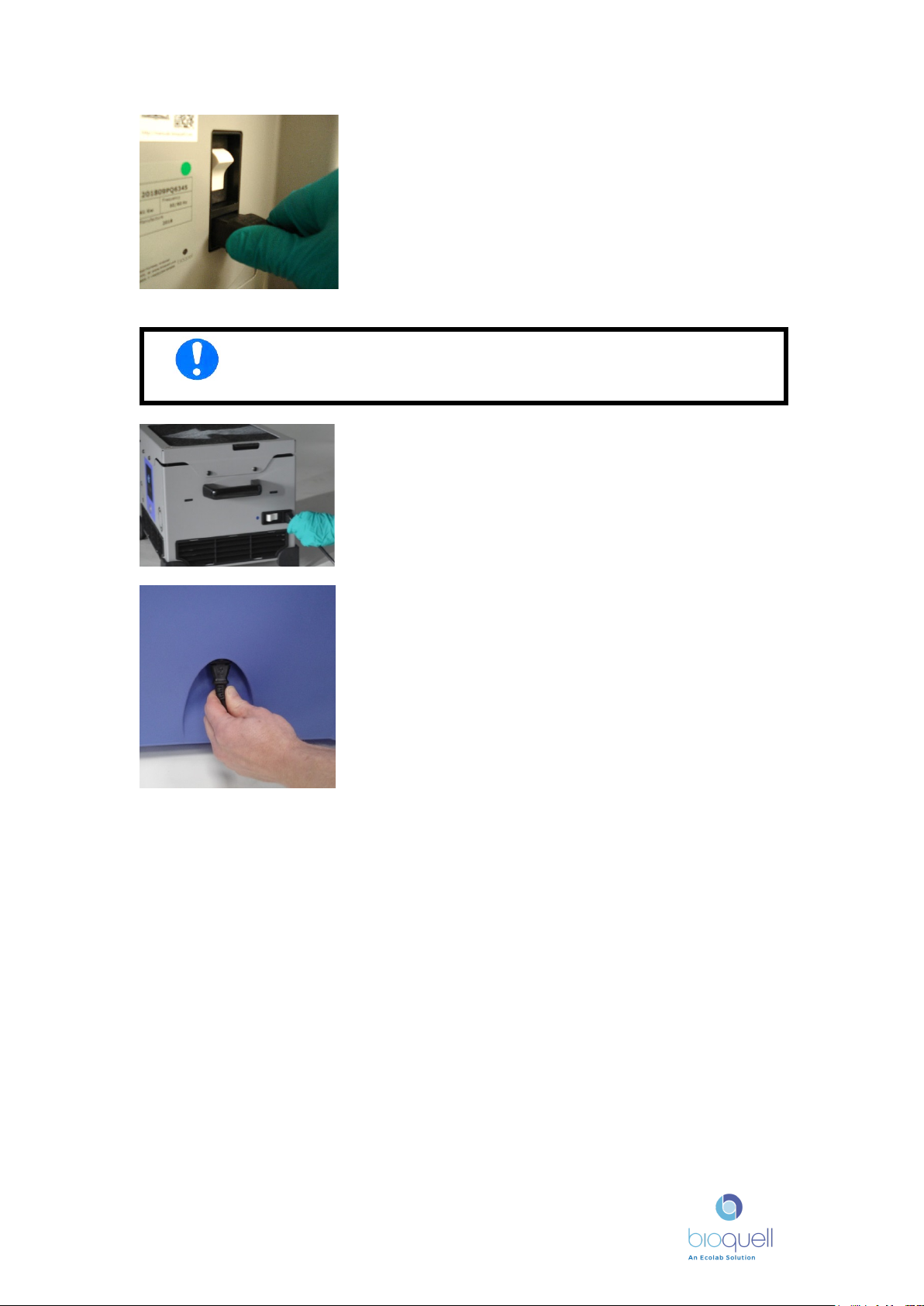

Outside the room to be decontaminated, remove

the lectern by holding the handles of the lectern

and leaning the top back.

Place the lectern by the door.

Wheel the Base unit into the room, to its validated

position.

If there are aeration units they must be placed in

to their validated positions in the room. NOTE the

arrows on the top of the aeration units must be

pointing in their validated direction, usually away

from the main unit. If the aeration units are not to

be used place them outside the room.

The cables for the Base unit and the aeration units

are in the bottom of the unit, under where the

aeration units are stored.

DO NOT USE ANY DAMAGED CABLES, replace

with adequately rated alternatives

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 15 of 58

6.2 Measuring the room

If a ‘Parametric’ cycle is to be run then the room volume must be known. If this is

not already known it is recommended to use the optional device available which

will accurately measure the volume of a room, see section 18. For rooms or suites

which are more complicated than a rectangular room it may be necessary to

measure several volumes and add them together.

Ensure no objects (including paper) that might cause blockage of the

air inlet to the left and above the power switch are in the cable

storage area. See section 4.1.1.

Plug the longer power cable into the base unit, and the

other end into an earthed socket, and turn the power

on. Turn on the white switch on the Base unit above the

power connection. The light ring will illuminate. Ensure

the white switch is not obstructed, as it is the main

disconnect device.

If the ProteQ is to communicate with the building’s

systems then it may be necessary to connect the

interface cables to the voltfree / remote start stop

connectors, see Section 4.1.1.

Plug the shorter cables into the side of the aeration

units, and plug the other end into an earthed electrical

socket. Note - up to three aeration units can be

plugged into the same socket. Do not plug them into

the same socket as the Base unit if supply is 100V or

120V.

Turn on the power at the back of the aeration unit

using the white switch and after a short time the fan

will start, and the wireless indicator will illuminate.

Ensure the white switch is not obstructed, as it is the

main disconnect device.

Remove the wound power cable from the lectern, and

plug the cable into the socket at the lower rear of the

lectern. Plug into an earthed electrical socket, and turn

the power on. The screen will illuminate.

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 16 of 58

7LOADING HYDROGEN PEROXIDE BOTTLES

7.1 Bottle Indicators

The ProteQ calculates the amount of peroxide required for the cycle. If it is loaded

with an insufficient amount it will not allow the cycle to start.

The unit will always take hydrogen peroxide from a part full bottle first, until it is

empty. Either 2 litre or 950ml bottles can be used.

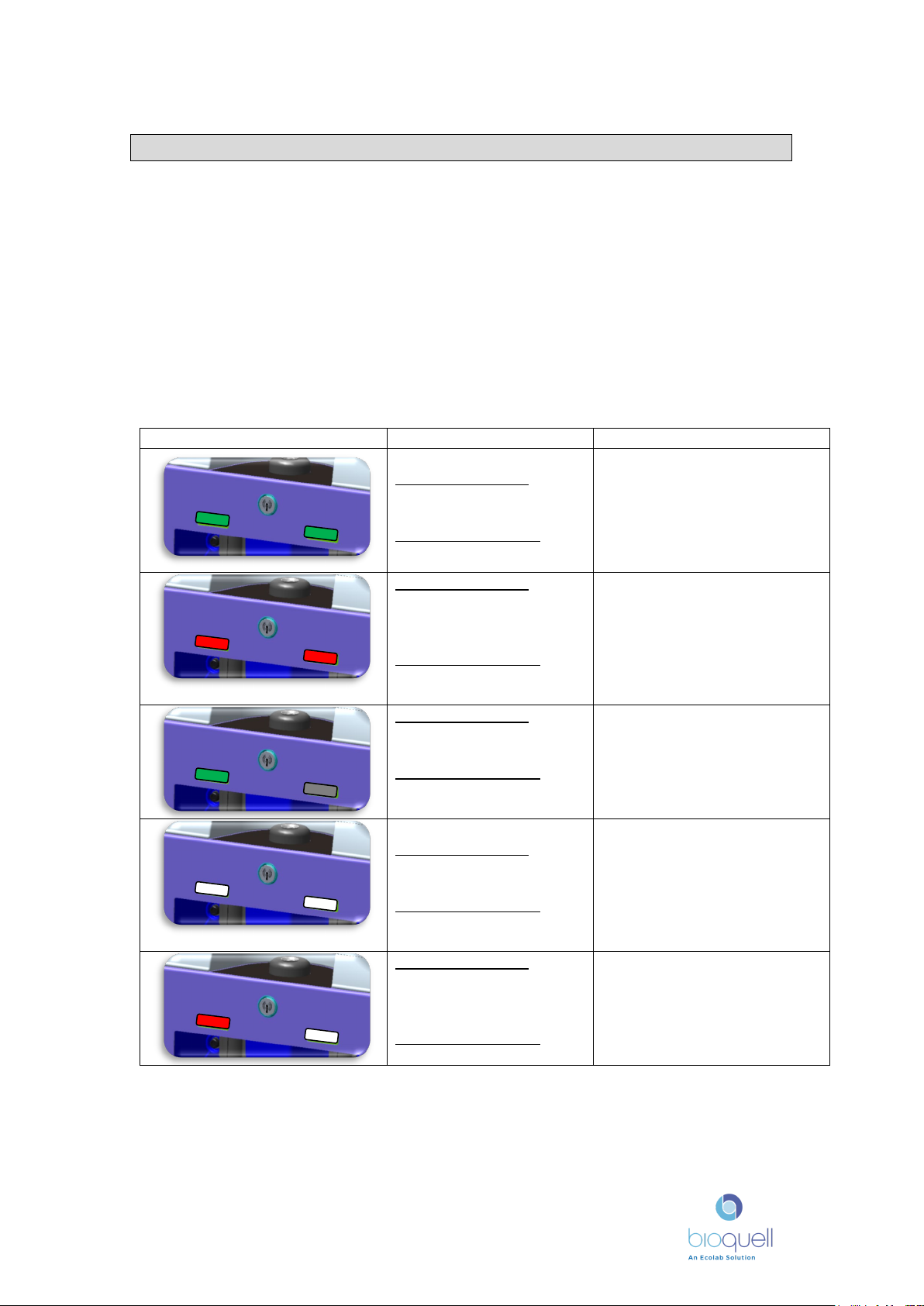

The table below explains the actions required for the different combinations of

bottle indicators; note - these lights only operate when the bottle holder is closed

and the plunger is down. If the lights are reversed to those shown, the action is

the same as that stated, but for the other side.

Light colour above bottle

Bottle Status

Action

Left Hand Bottle:

Enough for a cycle

Right Hand Bottle:

Enough for a cycle

There is sufficient liquid to

run the cycle, no action

required.

Left Hand Bottle:

Empty, expired or no

bottle present

Right Hand Bottle:

Empty, expired or no

bottle present

Both bottles are empty,

expired or no bottle in

place. Replace the bottles

with new ones

Left Hand Bottle:

Full

Right Hand Bottle:

No bottle present, or

empty or expired

There is one full bottle with

sufficient liquid to run the

cycle.

Left Hand Bottle:

Part used

Right Hand Bottle:

Part used

Both bottles have liquid but

the total is insufficient to

run the cycle. One of the

bottles requires replacing

with a full bottle or one

which has a sufficient

amount of liquid.

Left Hand Bottle:

Empty, expired or no

bottle

Right Hand Bottle:

Part used

Place a new bottle in the

left hand side (a part used

bottle may also be tried). If

sufficient liquid both lights

will go green.

If the indicator light is red, the bottle could be empty or expired and should be

disposed of according to local regulations. If empty, it could still contain up to

80ml of hydrogen peroxide.

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 17 of 58

If a Flexi Adaptor is fitted the left hand light will illuminate green and the right

hand will be unlit. No other colours will be seen.

7.2 Installing Hydrogen Peroxide Bottles

The following instructions explaining how to install bottles must be followed; in

addition, there is an illustration of the procedure on the vaporizer module above

the bottle enclosure. Before loading a 950ml bottle ensure the insert is present,

see section 7.3.

WARNING: Use Personal Protective Equipment when handling hydrogen

peroxide bottles. As a minimum, wear suitable gloves and goggles.

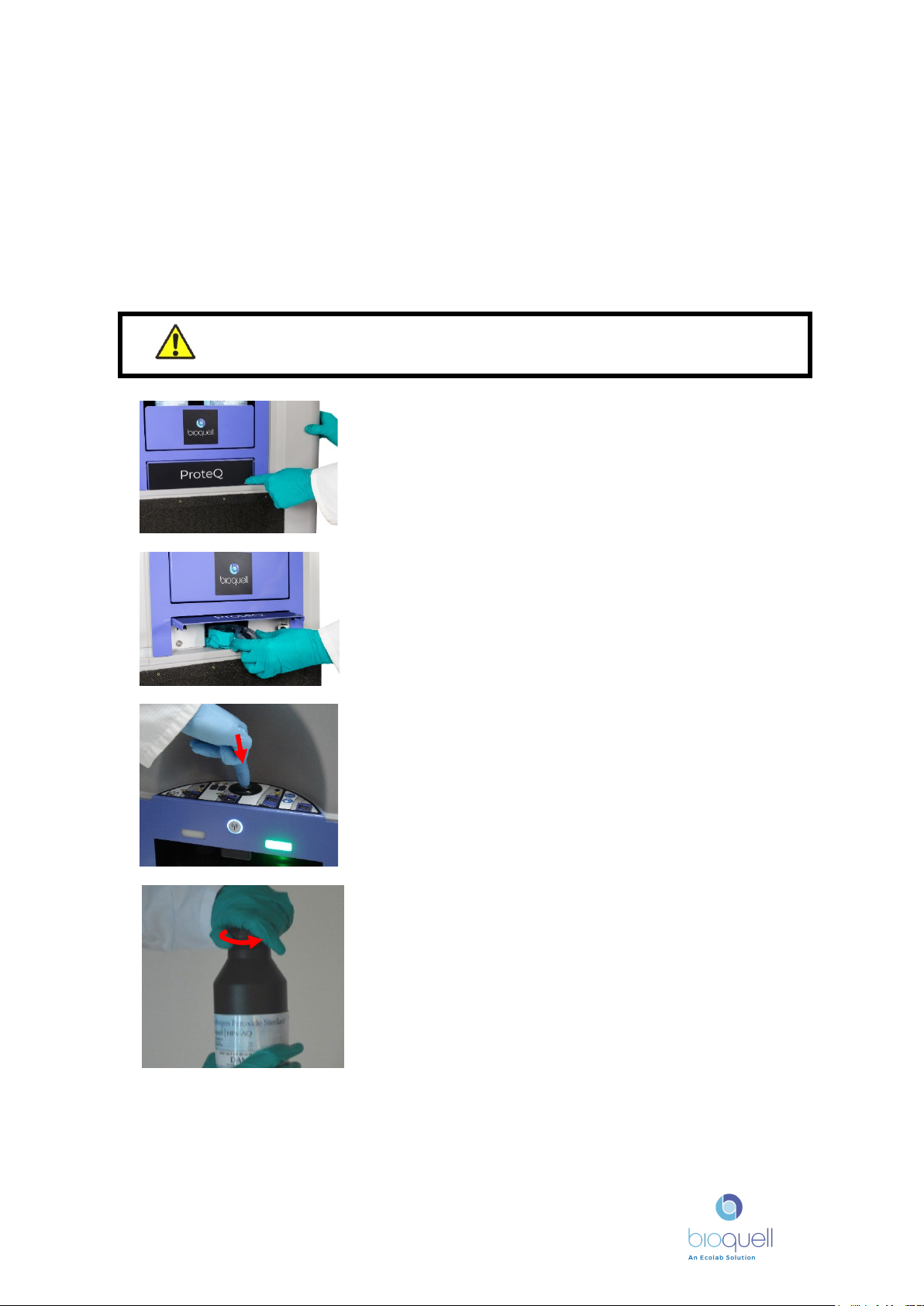

Press the bottom right hand side of the flap

under the bottle storage compartment.

The flap will spring-up.

Remove a pair of gloves and goggles. Put them

on before handling the bottle of hydrogen

peroxide.

Loading new bottles:

STEP 1:

To access the bottles push the silver button at

the centre of the black plunger. The plunger will

be released and will move up.

STEP 2:

Obtain a new bottle and check the outer bag for

any signs of liquid. If liquid is present, do not

use the bottle. Treat the liquid as hydrogen

peroxide and take the necessary precautions. If

no liquid is present, remove the bottle from the

bag, and remove the lid carefully by turning

counter clockwise. Retain the lid.

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 18 of 58

Bottles may be left in the vaporizer between decontamination cycles. Discard part

used bottles if left for more than a month.

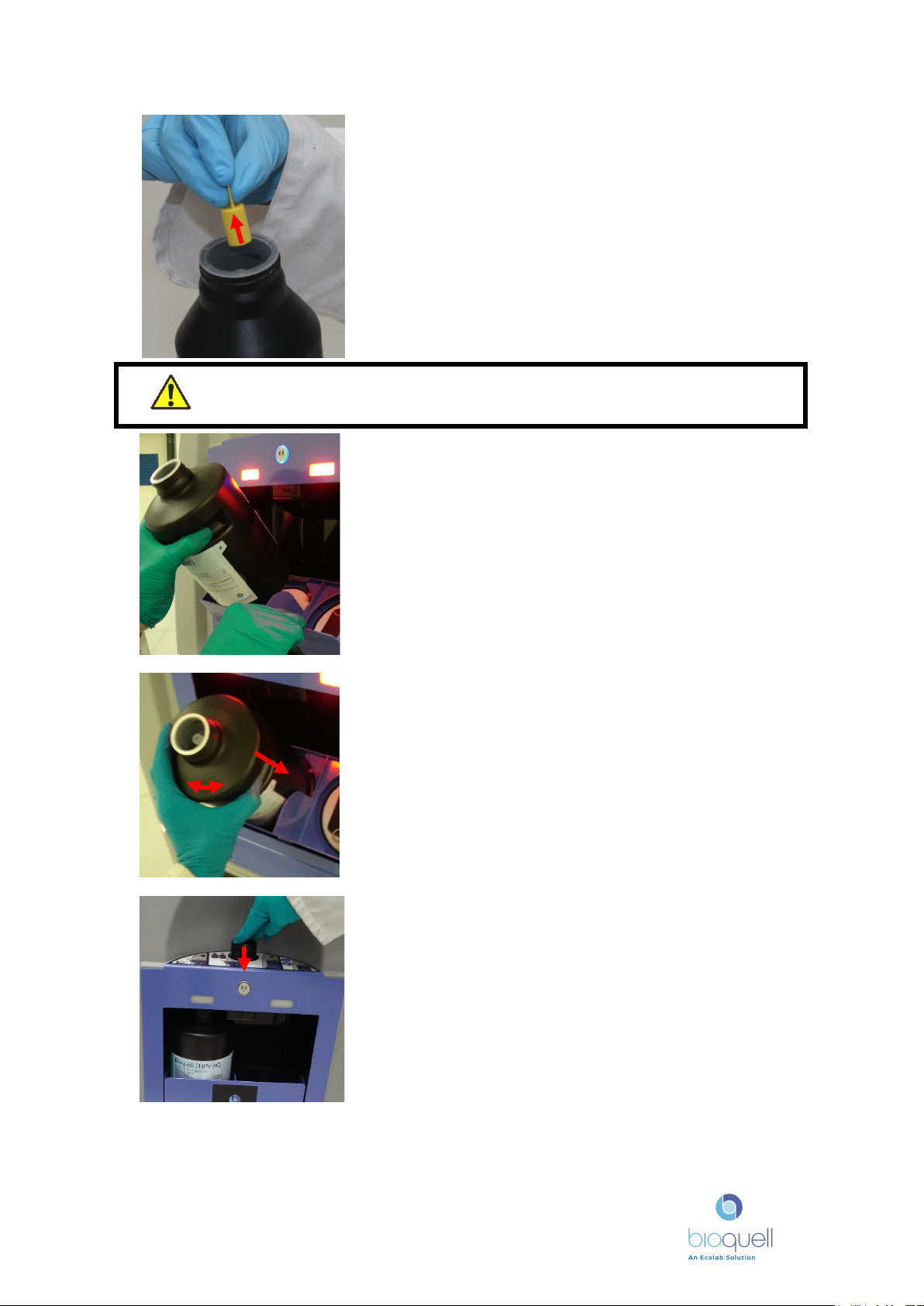

STEP 3:

Carefully remove the internal rubber yellow cap

by pulling it off. Retain the cap.

WARNING: Use the finger grips in the 2 litre bottle to hold the bottles

securely and safely. If using a 950ml bottle the insert must be fitted.

STEP 4:

For 2 litre bottle:

Pull the bottle tray open with one hand while

holding the bottle with the other using the

finger grips. These should be facing forward for

correct alignment. Then slide the bottle in.

For 950ml bottles:

Pull the bottle tray open with one hand while

placing the bottle in the insert in the bottle

carrier with the other. An insert must be

present, see section 7.3

Ensure that the stud at the bottom of the holder

lines-up with the indent on the bottom of the

bottle. It may be necessary to rotate the bottle

until it drops down into its correct position.

The label in the bottom of the bottle holder also

illustrates this.

STEP 5:

Push the black plunger down until it clicks and

stays down.

Note – avoid pressing the silver button during

this step, as the silver button releases the

mechanism.

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 19 of 58

To remove bottles: Release the plunger as shown in STEP 1 and remove the

bottle. Ensure that both the yellow cap and the bottle’s screw cap are put back

on, even if the bottle is empty.

7.3 Fitting Insert for 950ml Bottle

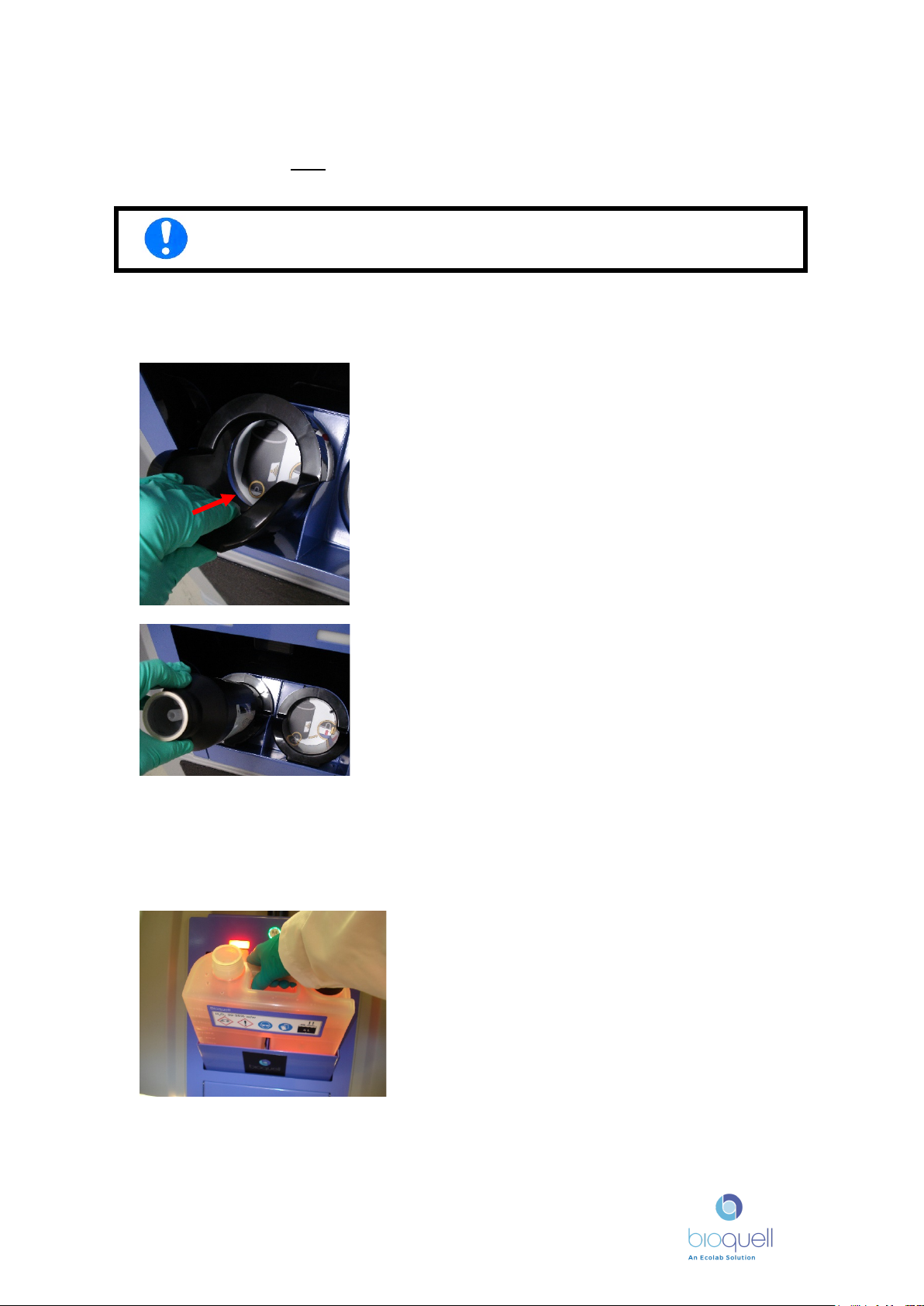

When a 950ml bottle is required an insert must be placed in the bottle holder.

7.4 Flexi Adaptor

Fill the flexi adaptor with Bioquell approved Hydrogen Peroxide and place lids on

both left and right hand sides and wear eye protection and gloves as a minimum

when carrying it.

WARNING: Always replace the yellow cap, otherwise hydrogen peroxide

liquid may build up in the top of the bottle.

Place the insert into the bottle holder, ensuring it

is all the way down. It is possible to have a mix

of size of bottles if required.

Remove cap on left hand side and place into

the bottle carrier in the orientation shown,

shut and push plunger down as described in

section 7.2.

BIOQUELL PROTEQ USER MANUAL -EN

TD092-O&M-001

REVISION 5 DRAFT

Page 20 of 58

8OPERATION

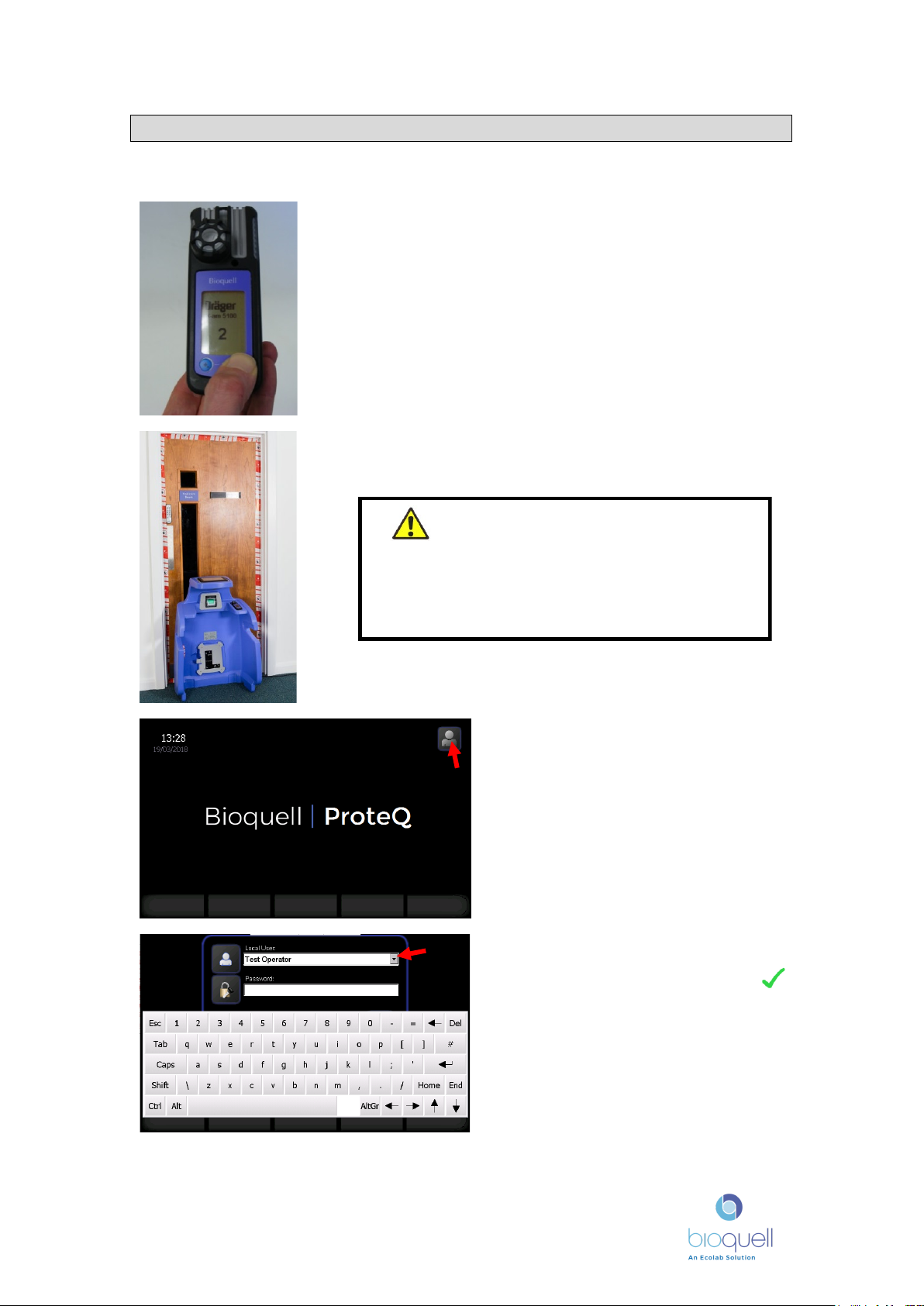

8.1 Running a Cycle

Check that the low level hydrogen peroxide sensor is

working. To start remove the cap over the sensor if

present and then hold down the green button. The

display will count down from 3 and then start. Place

the sensor in the recess on the lectern. If the sensor

is not working, do not run a cycle. The sensor may

be stored on the lectern, see section 4.1.2

Ensure the door is sealed, this is likely to require

taping. A roll of tape is supplied on the lectern.

WARNING – Ensure all possible openings

and conduits into the enclosure are

properly sealed. If large leaks occur and

high concentration Hydrogen Peroxide

escapes into areas where people are

present it can cause serious harm. Use

tape provided to seal door.

Press icon in top right of screen to

login, if using local logins use the

down arrow to select user name

from the list and enter password –

touching the data entry box a

keyboard will appear.

If using network login (Windows)

then ensure that an ethernet cable

is connected between the lectern

and the local network, and enter

user name and password using the

keyboard which appears when the

data entry box is touched. Press .

When logged IN the User Name will

be displayed in the top right of the

screen. The Login period will expire

after 5 minutes of inactivity if not in

cycle, after which it will be

necessary to log on again.

Table of contents

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual