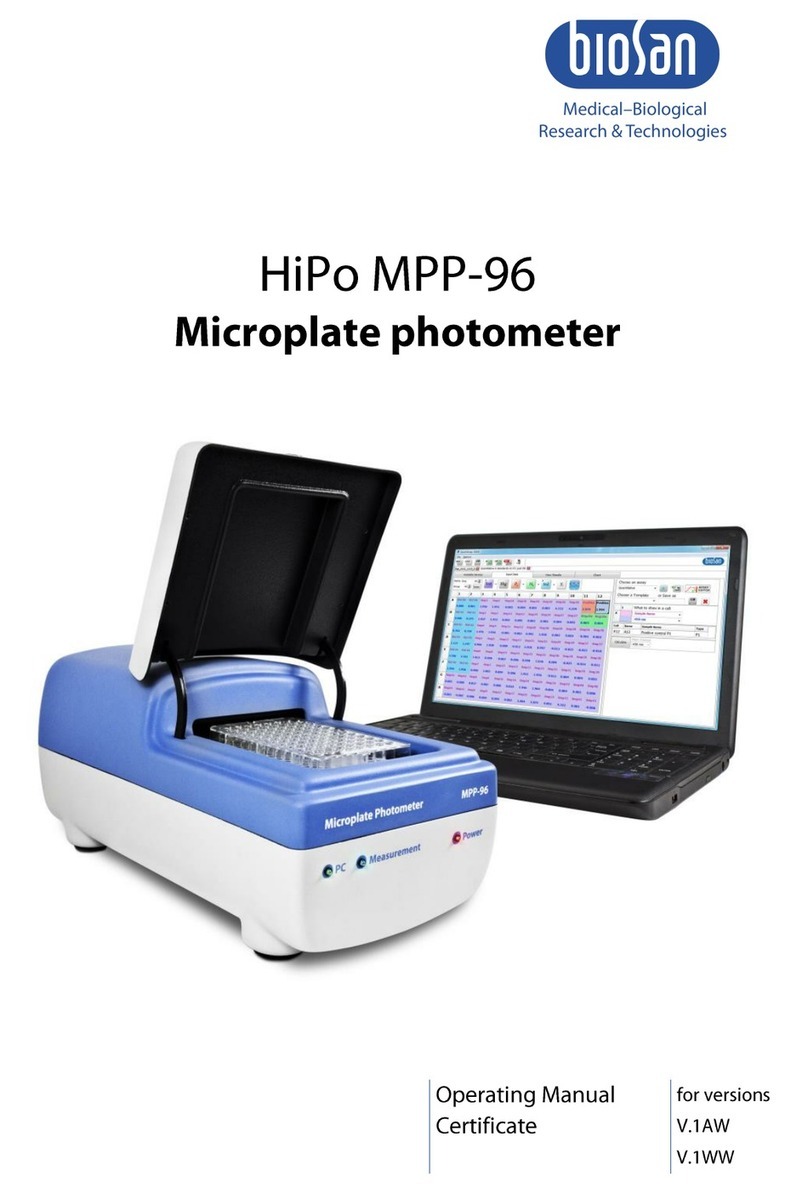

Biosan DEN-1 User manual

2

3

Contents

1. Safety Precautions...................................................................................................4

2. General Information .................................................................................................5

3. Getting started..........................................................................................................6

4. Operation .................................................................................................................8

5. Specifications...........................................................................................................9

6. Maintenance...........................................................................................................10

7. Warranty and Claims..............................................................................................10

8. EU Declaration of Conformity.................................................................................11

4

1. Safety Precautions

The following symbol means:

Caution: Make sure you have fully read and understood the present Manual

before using the equipment. Please pay special attention to sections

marked by this symbol.

GENERAL SAFETY

Use only as specified in the operating manual provided.

Save the unit from shocks and falling.

After transportation or storage, keep the unit under room temperature for 2-3 hrs

before connecting it to the electric circuit.

Before using any cleaning or decontamination methods except those recommended

by the manufacturer, check with the manufacturer that the proposed method will not

damage the equipment.

Do not make modifications in design of the unit.

ELECTRICAL SAFETY

Connect only to an external power supply with voltage corresponding to that on the

serial number label.

Use only the external power supply provided with this product.

Ensure that the power switch and external power supply are easily accessible

during use.

Disconnect the unit from the external power supply before moving.

If liquid penetrates into the unit, disconnect it from the external power supply and

have it checked by a repair and maintenance technician.

Do not operate the unit in premises where condensation can form. Operating condi-

tions of the unit are defined in the Specifications section.

DURING OPERATION

Do not operate the unit in environments with aggressive or explosive chemical

mixtures. Please contact manufacturer for possible operation of the unit in specific

atmospheres.

Do not operate the unit if it is faulty or was installed incorrectly.

Do not use outside laboratory rooms.

Use the Select and Install buttons only for calibration of the unit according to p.

3.4. Do not press the buttons in other cases, as this can cause calibration reset and

may require recalibration.

BIOLOGICAL SAFETY

It is the user’s responsibility to carry out appropriate decontamination if hazardous

material is spilt on or penetrates into the equipment.

5

2. General Information

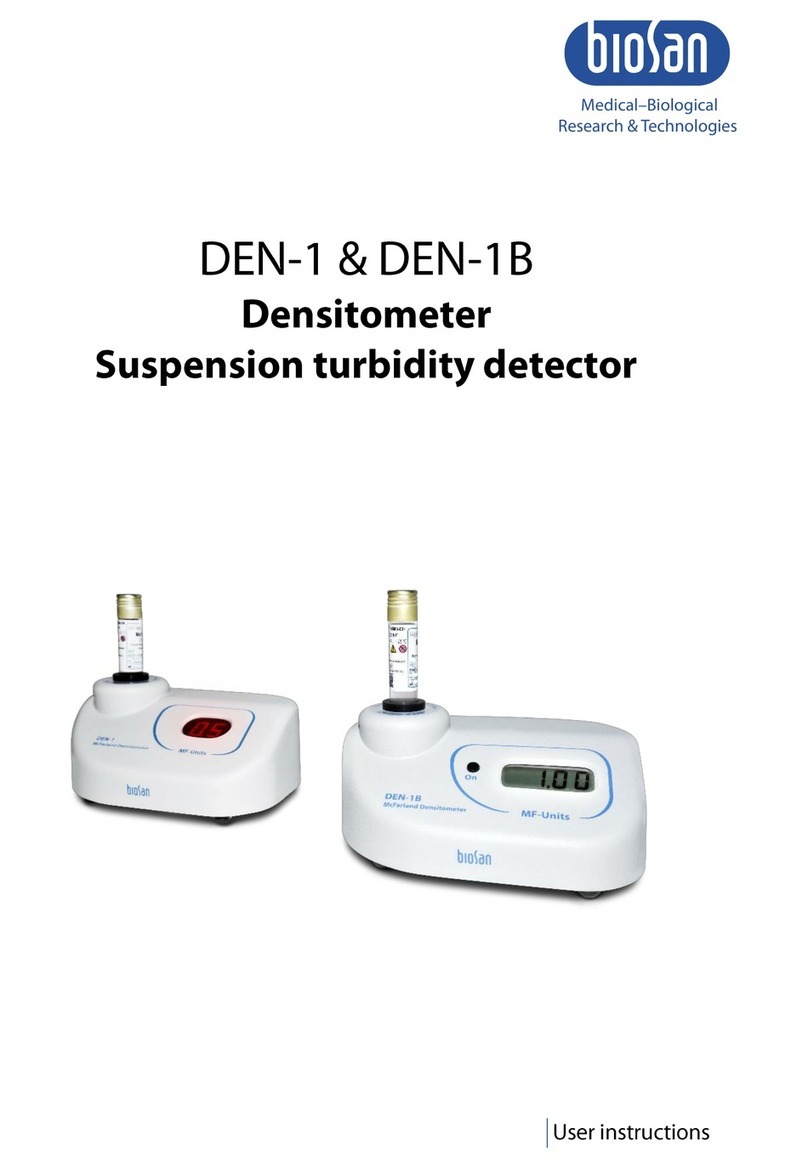

DEN-1 densitometer has been designed for solution turbidity measurement in the

range of 0.3 - 5.0 McFarland units (1x106- 15x106cells/ml). DEN-1 is capable of measur-

ing solution turbidity in a wider range (5.0 - 20.0 McFarland units) however, it is necessary

to remember that in this case the standard deviation values increase.

DEN-1 densitometer is used for determining concentration of cells (bacterial, yeast

cells) in the fermentation process, for detection of susceptibility of microorganisms against

antibiotics, for identification of microorganisms with various test systems, for measuring

optical density at fixed wavelength and for quantitative evaluation of dissolved substance

concentration.

The operation principle is based on optical density measurement with digital

presentation of the results in McFarland units.

The unit is calibrated at the factory and saves calibration data when being switched

off. However, in can be calibrated by 2-6 points in 0.5 - 5.0 McFarland unit range if

necessary. Both commercial standards (e.g. produced by Prolab, Lachema, bioMerieux,

etc.) and the standards prepared in the laboratory can be used for calibration.

Table 1. Interpretation of McFarland Standard results into corresponding numeric values of

bacterial suspension concentration and their optical density at 550 nm.

McFarland

Standard

Composition

Interpretation

Concentration BaSO4

Bacterial

concentration*

Theoretical optical

density at 550 nm**

0.5

2.40x10-5 mol/l

1.5x106cells/ml

0.125

1

4.80x10-5 mol/l

3x106cells/ml

0.25

2

9.60x10-5 mol/l

6x106cells/ml

0.50

3

1.44x10-4 mol/l

9x106cells/ml

0.75

4

1.92x10-4 mol/l

12x106cells/ml

1.00

5

2.40x10-4 mol/l

15x106cells/ml

1.25

* Bacterial concentration depends on microorganism size. The numbers represent an average

value valid for bacteria. For yeasts, which are larger, these numbers should be divided by

about 30.

** Values correspond to optical densities of bacterial suspensions. The BaSO4solutions optical

density values differ, because the particle size and form differ from those of bacteria and light

is diffracted differently.

6

3. Getting started

3.1. Unpacking

Remove packing materials carefully and retain them for future shipment or storage

of the unit.

Examine the unit carefully for any damage incurred during transit. The warranty

does not cover in-transit damage.

Warranty covers only the units transported in the original package.

3.2. Complete set. Package contents:

Standard set

- DEN-1 Densitometer, suspension turbidity detector.........................................1 pce.

- External power supply .....................................................................................1 pce.

- Operating Manual, Certificate..........................................................................1 copy

- A-16 adapter for tubes 16 mm in diameter.......................................................1 pce.

Optional accessories

- CKG16 calibration kit for glass tubes 16 mm in diameter..........................on request

- CKG1802 calibration kit for glass tubes 18 mm in diameter......................on request

3.3. Set up:

- Plug the external power supply into the 12 V socket at the rear side of the unit

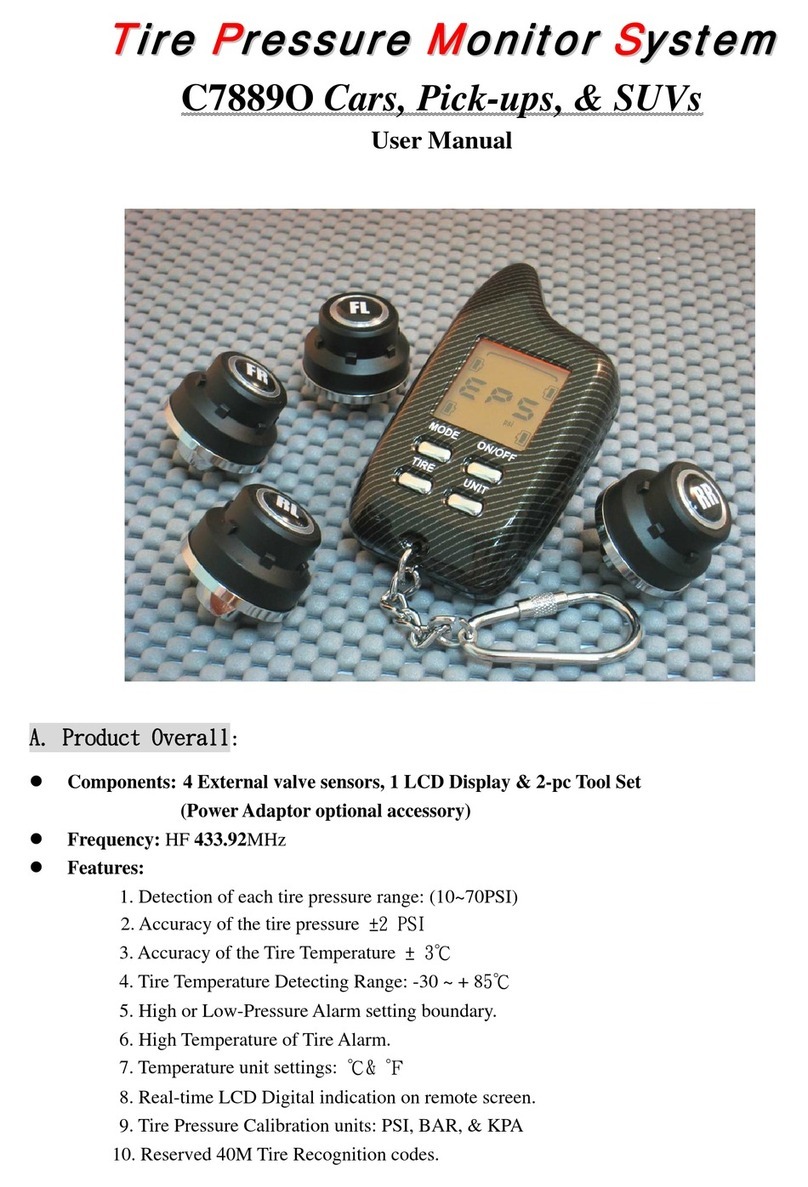

(fig.1/2).

- Place the unit on the horizontal even working surface;

Fig. 1. Rear panel

3.4. Calibration

The device is precalibrated at the factory for operation with the glass tubes 16 mm

in external diameter (see the label on the bottom side of the unit) at temperature

range from +15°C to +25°C and saves calibration data when switched off.

Note! To work with other type tubes (e.g. with different outer diameter or

bottom shape or different material, e.g. transparent plastic tubes) it

is necessary to perform calibration in the specified tubes, using

adapters, if necessary.

Perform calibration in the following sequence from the lower calibration value to the

higher values: 0.5, 1.0, 2.0, 3.0, 4.0, and 5.0. Use at least 2 points for calibration.

7

3.4.1. Switch ON (position I) the unit with the Power switch (Fig.1/1) on the rear panel.

3.4.2. Press the Select button (fig.1/3) on the rear panel. A flashing “0.5”appears on the

display, indicating that the unit is ready to measure calibration value of the first

point, 0.5 McF.

Note! Use a thin pin of maximum diameter 2 mm for pressing the Select

and Install buttons.

Note! Shake the tube with the standard solution, if necessary. It is

recommended to use vortex, e.g. Personal Vortex V-1 plus, for

shaking.

3.4.3. Insert the tube with the standard solution, corresponding to the calibration point

value, into the socket of Densitometer (fig.2/1).

3.4.4. Press the Install button (fig.1/4). First point “0.5” value is saved in the unit memory

and the next calibration point appears, flashing 1.0 indication on the display.

Note! Calibrate as many points as possible to obtain precise results. The

minimum requirement is to calibrate 2 points closest to the working

range limits (e.g. 0.5 and 5.0 for operation within 0.5 - 5.0 McF unit

range).

3.4.5. Repeat steps 3.4.3 - 3.4.4 until the calibration is completed (one to five times, as

many times as many points the chosen calibration curve has).

3.4.6. If a standard for a step is not available, press the Select button to skip to the next

calibration point.

3.4.7. After setting the last standard value “5.0” or skipping through it, the unit exits the

calibration mode automatically. The unit is ready for operation.

Note! If pressing the Install button during the calibration process does not

cause switching to the next standard value, it means that the stand-

ard currently inserted in the densitometer socket has lower turbidity

value than the previous standard. The inserted standard solution

turbidity does not correspond to the required value (try vortexing or

shaking the standard, or replace it).

3.5. Reset to factory calibration. To reset the calibration of the unit to factory settings,

ensure that you are in the working mode and the socket of the unit is empty. Press

and hold Install key for 5 seconds. The unit displays a dot ” .“, then changes it to

“0.0”. The unit is now reset.

3.6. Switch off the unit using the Power switch (position O). Disconnect the external

power supply from electric circuit.

8

4. Operation

Recommendation during operation

Keeping the unit switched on for 15 min before starting the operation for the opera-

tion mode stabilization is recommended.

If flat-bottomed tubes are used, the solution level should be higher than 7 mm from

a tube bottom; if round-bottomed tubes are used, the level should be higher than 12

mm from a tube bottom.

Check if the A-16 adapter is in the socket (Fig. 2/1). The device is calibrated for

operation with the glass tubes 16 mm in external diameter. Refer to p. 3.4. when us-

ing different tubes.

Fig. 2. Front panel

4.1. Connect the external power supply to electric circuit.

4.2. Switch ON the unit using the Power switch (Fig.1/1) on the rear panel (position I).

4.3. The following indication can appear on the display (fig.2/2):

“0.0” means that the unit is calibrated and ready for operation (if no any tube insert-

ed);

“CC” (flashing) means that the unit is not calibrated. Calibrate the unit.

“EE” means that operator error message. Switch OFF the unit and then switch ON

again.

4.4. Shake the tube with the solution (it is recommended to use vortex, e.g. Personal

vortex V-1 plus, for shaking) and insert it into the socket (fig.2/1). The McFarland

value for the solution appears on the display (fig.2/2).

4.5. Glass and transparent plastic tubes (16 or 18 mm in external diameter) can be used

for work with DEN-1 densitometer. An adapter must be used for work with tubes,

which are 16 mm in external diameter.

Note! Calibrate the unit each time the tube type (e.g., a tube with different

outer diameter, bottom shape or material, i.e. transparent plastic

tubes) is changed.

4.6. After finishing the operation, switch OFF the unit using the Power switch (position

O). Disconnect the power supply from electric circuit.

9

5. Specifications

The unit is designed for operation in cold rooms, incubators and closed laboratory

rooms at ambient temperature from +4°C to +40°C in a non-condensing atmosphere and

maximum relative humidity 80% for temperatures up to 31°C decreasing linearly to 50%

relative humidity at 40°C.

5.1. Light source.........................................................................................................LED

5.2. Wavelength.......................................................................................λ = 565 ±15 nm

5.3. McFarland unit range .........................................................................0.3 - 20.0 McF

5.4. Display resolution..........................................................................................0.1 McF

5.5. Accuracy, of the full scale.................................................................................. + 3%

5.6. Measurement time ...............................................................................................1 s

5.7. Sample volume, minimum...................................................................................2 ml

5.8. External diameter of tube..................................16 mm (using adapter A-16) or 18 mm

5.9. Display ................................................................................................................LED

5.10. Dimensions ....................................................................................165x115x75 mm

5.11. Input current/power consumption..................................................12 V, 80 mA / 1 W

5.12. External power supply................................................................................................

..........................................................input AC 100-240 V 50/60 Hz, output DC 12 V

5.13. Weight*.............................................................................................................0.7 kg

Replacement

parts

Description

Catalogue number

A-16

Adapter for tubes 16 mm in external diameter

BS-050102-AK

Optional

accessories

Description

Catalogue number

CKG16

Calibration kit for glass tubes 16 mm in diameter.

Latex particles.

BS-050102-BK

CKG1802

Calibration kit for glass tubes 18 mm in diameter.

Barium sulphate BaSO4.

BS-050102-GK

Biosan is committed to a continuous program of improvement and reserves the right

to alter design and specifications of the equipment without additional notice.

* Accurate within ±10%.

10

6. Maintenance

6.1. If the unit requires maintenance, disconnect the unit from the electric circuit and

contact Biosan or your local Biosan representative.

6.2. All maintenance and repair operations must be performed only by qualified and

specially trained personnel.

6.3. Standard ethanol (75%) or other cleaning agents recommended for cleaning of

laboratory equipment can be used for cleaning and decontamination of the unit.

7. Warranty and Claims

7.1. The Manufacturer guarantees the compliance of the unit with the requirements of

Specifications, provided the Customer follows the operation, storage and transpor-

tation instructions.

7.2. The warranted service life of the unit from the date of its delivery to the Customer is

24 months (excluding the consumables, i.e. calibration kits). Contact your local dis-

tributor to check availability of extended warranty.

7.3. Warranty covers only the units transported in the original package.

7.4. If any manufacturing defects are discovered by the Customer, an unsatisfactory

equipment claim shall be compiled, certified and sent to the local distributor ad-

dress. Please visit www.biosan.lv, Technical support section to obtain the claim

form.

7.5. The following information will be required in the event that warranty or post-warranty

service comes necessary. Complete the table below and retain for your records.

Model

DEN-1 Densitometer, Suspension turbidity detector

Serial number

Date of sale

11

8. EU Declaration of Conformity

Unit type Densitometers

Models DEN-1, DEN-1B

Serial number 14 digits styled XXXXXXYYMMZZZZ, where XXXXXX is

model code, YY and MM –year and month of production,

ZZZZ –unit number.

Manufacturer SIA BIOSAN

Latvia, LV-1067, Riga, Ratsupites str. 7/2

Applicable Directives EMC Directive 2014/30/EU

LVD Directive 2014/35/EU

RoHS2 2011/65/EU

WEEE 2012/19/EU

Applicable Standards LVS EN 61326-1: 2013

Electrical equipment for measurement, control and

laboratory use. EMC requirements. General requirements.

LVS EN 61010-1: 2011

Safety requirements for electrical equipment for

measurement, control, and laboratory use. General

requirements.

We declare that this product conforms to the requirements of the above Directives

____________________ ____________________

Signature Signature

Svetlana Bankovska Aleksandr Shevchik

Managing director Engineer of R&D

____________________ ____________________

Date Date

Biosan SIA

Ratsupites 7, build. 2, Riga, LV-1067, Latvia

Phone: +371 6742 6137

Fax: +371 6742 8101

http://www.biosan.lv

Edition 2.03 –January 2017

Other manuals for DEN-1

1

Table of contents

Other Biosan Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Lufft

Lufft CHM 15k user manual

Siemens

Siemens 5SV8 200-6KK Operating and mounting instructions

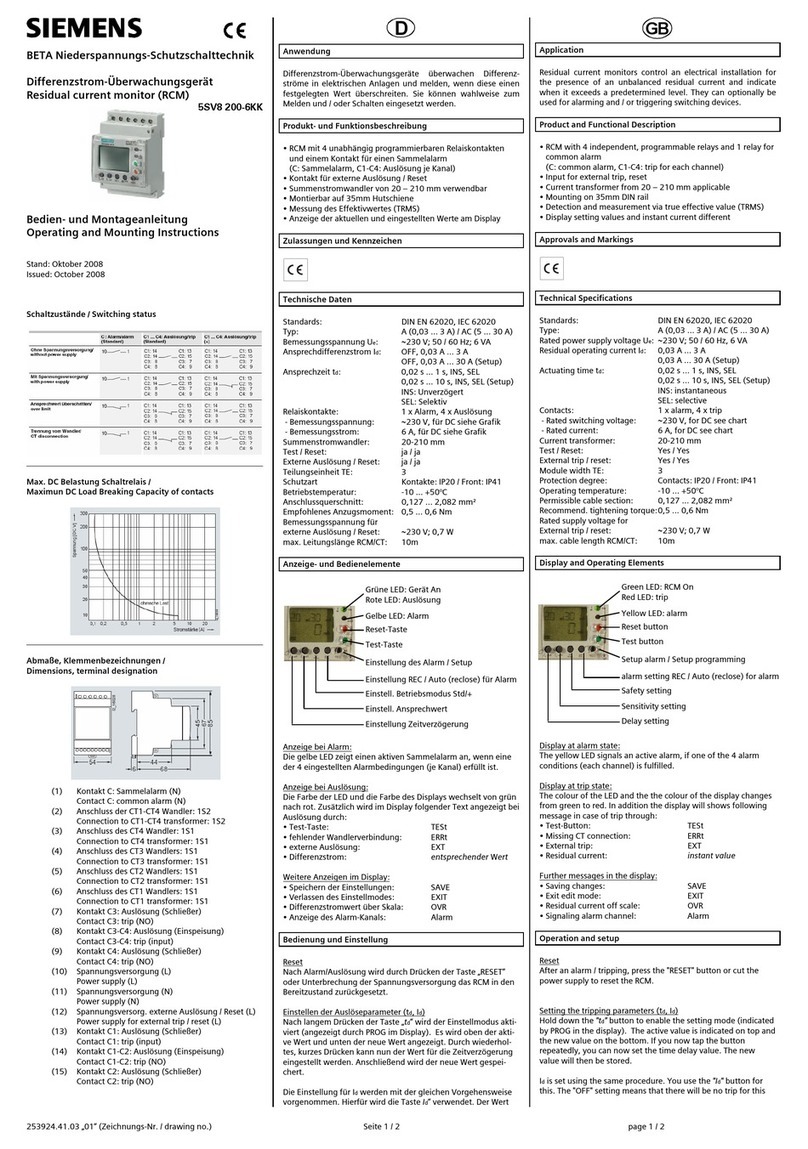

Altronics

Altronics Redback Q 2001 operating instructions

Thermo Scientific

Thermo Scientific Thermo Scientific AquaSensors RDO Pro-X manual

Shodex

Shodex IC YS-50 Operation manual

GTS

GTS SWR ENGINEERING ProSens operating instructions