TABLE OF CONTENTS

Page

NOTICE TO OWNERS AND OPERATORS ......................................... 1

SAFETY TIPS ............................................................... 2

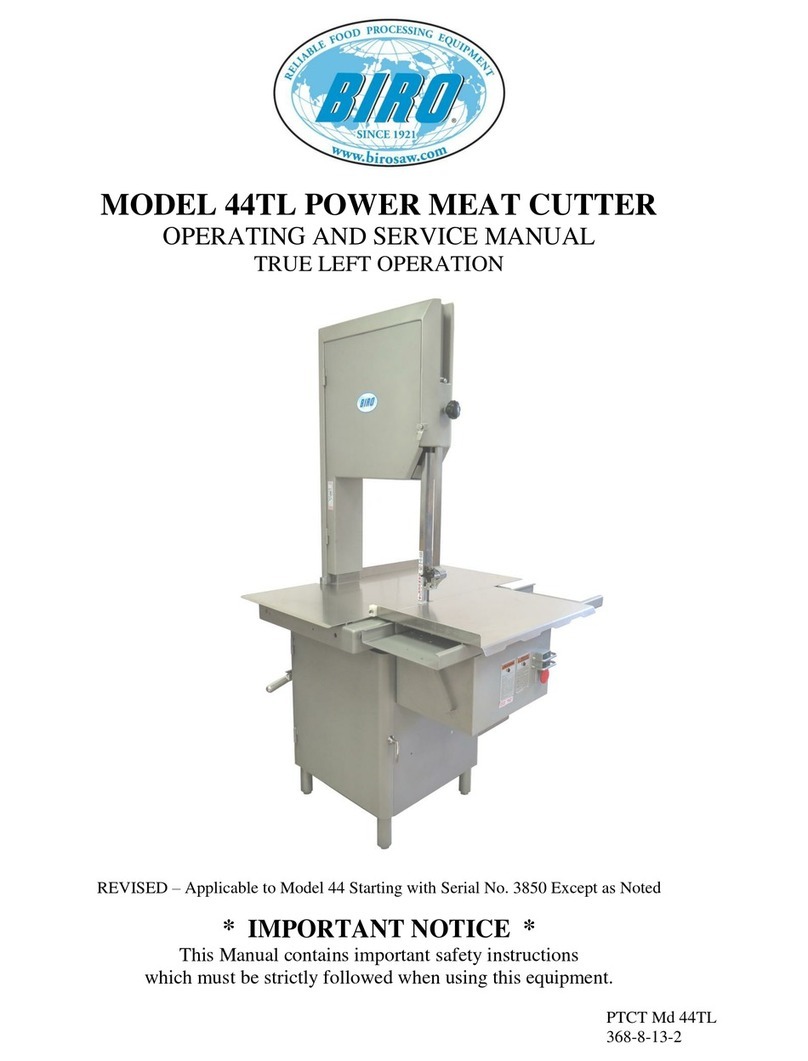

INSTALLATION ............................................................ 3-6

OPERATION ................................................................ 7

TO PROCESS PRODUCT ............................................... 7-8

CLEANING PROCEDURE ...................................................... 9

MAINTENANCE .............................................................10

GENERAL ............................................................10

LUBRICATION ......................................................11-12

WALL CHART (PART No. 671) ..................................................12

PARTS DIAGRAMS ........................................................13-20

SWITCH ASSEMBLIES AND SERVICE PARTS ......................................21

WIRING DIAGRAMS........................................................22-24

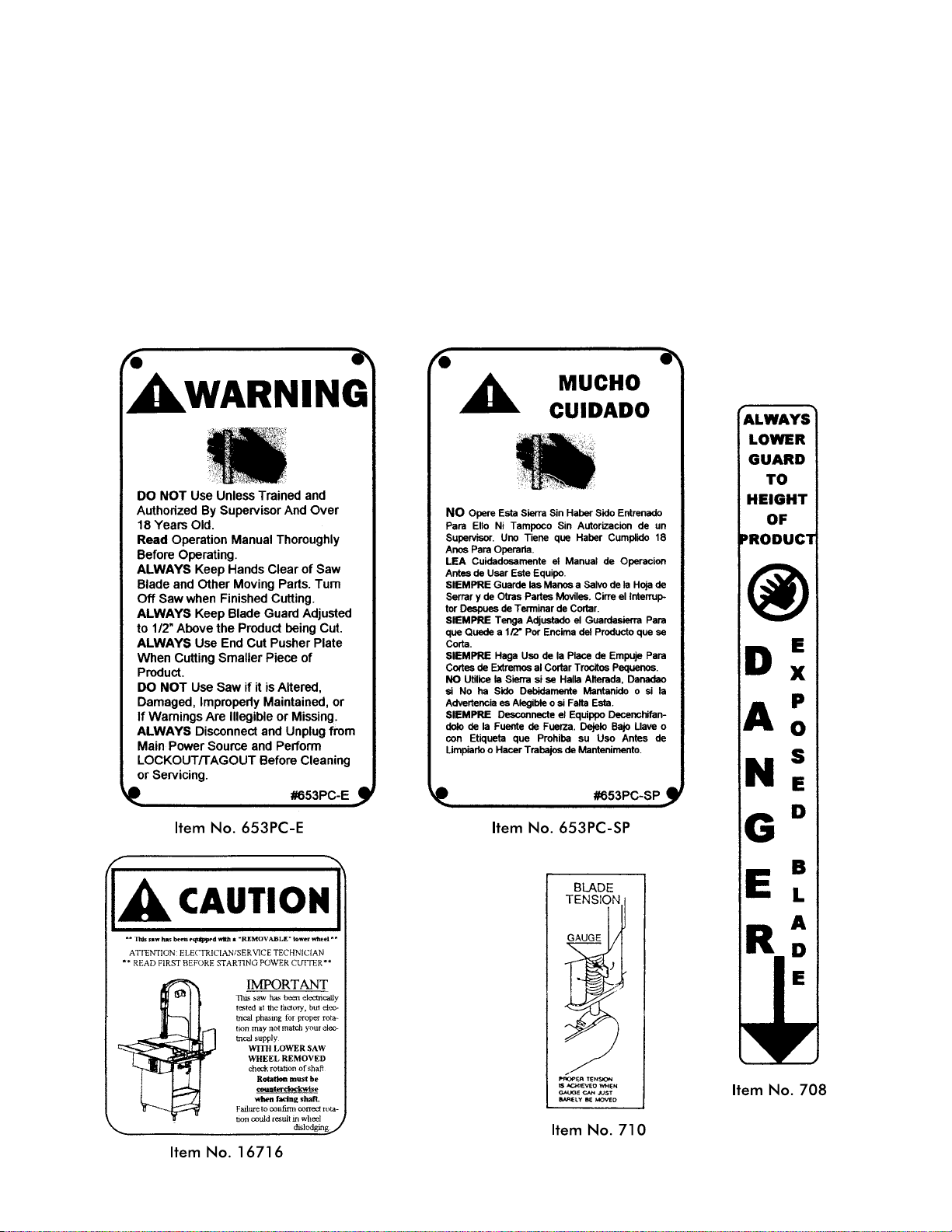

WARNING LABEL LOCATIONS ON MACHINE ......................................25

WEARABLE SAW PARTS ......................................................26

PARTS LIST/ORDERING.......................................................27

PARTS ASSEMBLIES LIST/ORDERING ...........................................28

OPERATOR’S SIGNATURE PAGE................................................29

LIMITED WARRANTY .........................................................30

NOTICE TO OWNERS AND OPERATORS......................................................................1

SAFETY TIPS........................................................................................................................2

INSTALLATION...............................................................................................................3-6

OPERATION........................................................................................................................7

TO PROCESS PRODUCT.........................................................................................8

CLEANING PROCEDURE.................................................................................................9

MAINTENANCE...............................................................................................................10

GENERAL................................................................................................................10

LUBRICATION..................................................................................................11-12

WALL CHART (PART NO. 671).......................................................................................12

OPERATOR’S NOTES.......................................................................................................13

PARTS DIAGRAM........................................................................................................14-22

OPERATOR’S NOTES.......................................................................................................16

SWITCH ASSEMBLIES AND SERVICE PARTS..............................................................23

WIRING DIAGRAMS...................................................................................................24-28

WARNING LABEL LOCATIONS ON MACHINE..........................................................29

WEARABLE SAW PARTS..................................................................................................30

PARTS LIST/ORDERING..................................................................................................31

PARTS ASSEMBLIES LIST/ORDERING..........................................................................32

OPERATOR’S SIGNATURE PAGE...................................................................................33

LIMITED WARRANTY......................................................................................................34