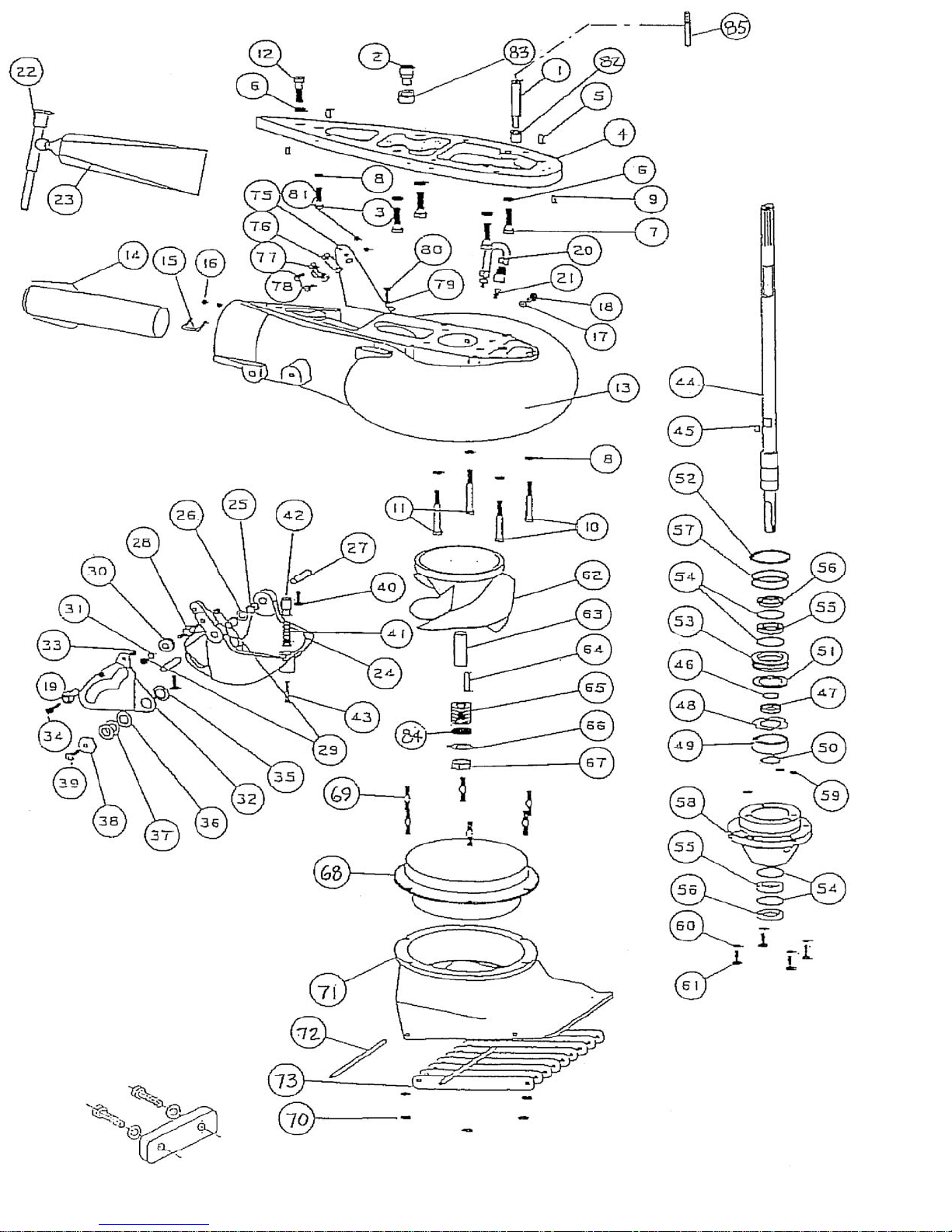

MODEL BC YAMAHA 40XMH 2 STROKE 2 CYL 40HP, 42.9 CU. IN.

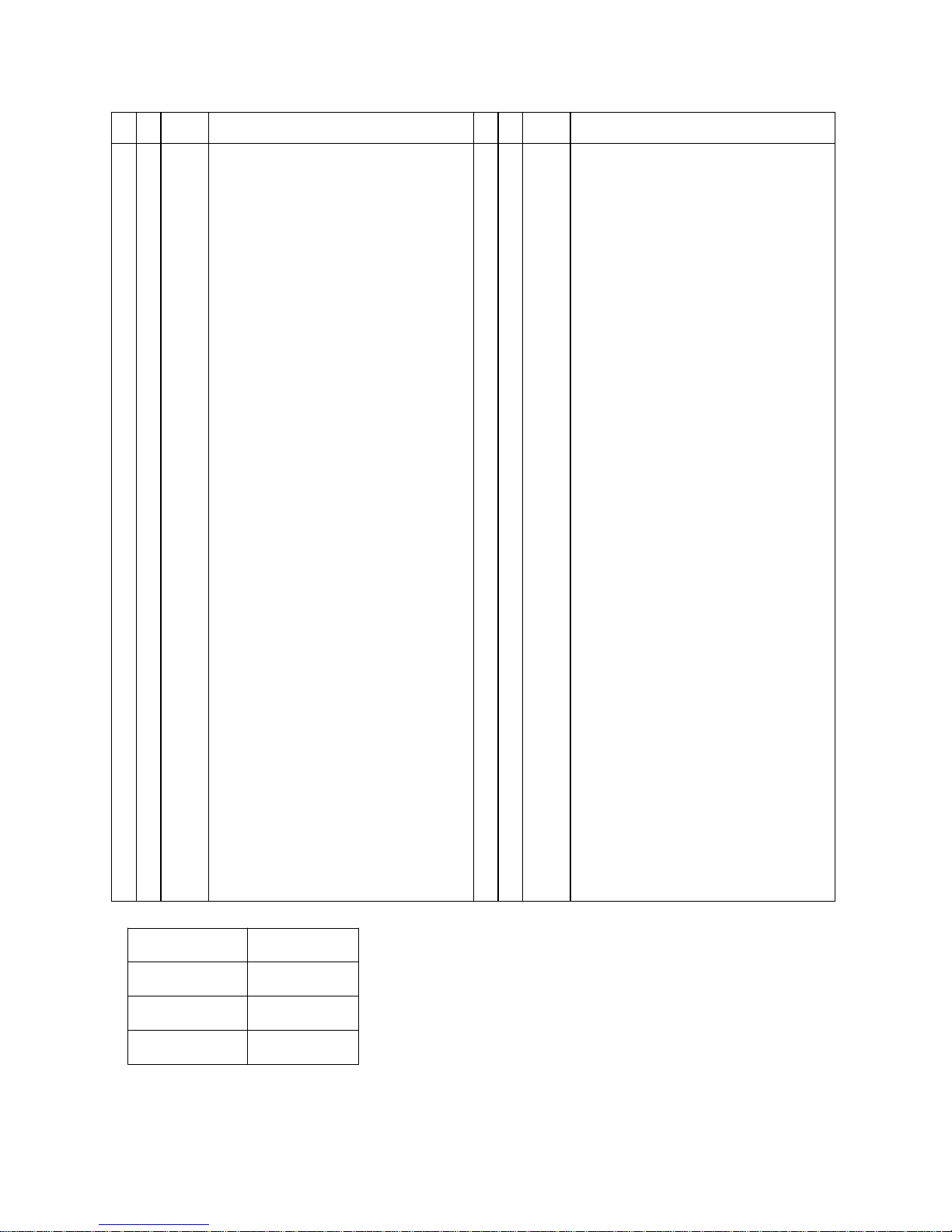

REF QTY PART DESCRIPTION REF QTY PART DESCRIPTION

NO. NO.

1 1 1910 SHIFT ROD TUBE BC 48 1 1536 THRUST WASHER

2 1 1377 WATER TUBE EXTENSION - AJ 49 1 504 BEARING 7205B-UA

3 1 591 BOLT HEX HD M8-1.25 X 30MM 50 1 511 TRUARC 5100-98

4 1 1366 ADAPTER PLATE AJ 51 1 1535 SPACER

5 2 616 DOWEL PIN 6 X 16 MM 52 1 512 TRUARC N5002-212ZD

6 5 636 WASHER SPRING LOCK M10 53 1 433 UPPER SEAL CARRIER W/ SEALS & O RINGS

7 4 592 BOLT HEX HD M10-1.25 X 35MM 54 4 517 SPIROLOX RR-150S

8 5 640 WASHER SPRING LOCK 5/16 55 2 506 SEAL INNER

9 2 631 DOWEL PIN 3/16 X 1/2 56 2 507 SEAL OUTER 6324-S

10 2 603 BOLT HEX HD 5/16-18 X 2 1/2 57 2 526 O RING 568-135 3/32X1 15/16X2 1/8

11 2 599 BOLT HEX HD 5/16-18 X 2 3/4 58 1 1932 BEARING CARRIER W/SEALS & O RINGS BC

12 1 607 BOLT HEX HD 3/8-16 X 1 1/2 59 3 521 O RING 568-011 1/16X5/16X7/16

1918 VOLUTE WITH GATE BC 60 4 638 WASHER SPRING LOCK 1/4

13 1 1917 VOLUTE WITH EXHAUST TUBE BC 61 4 573 BOLT HEX HD 1/4-20 X 3/4

14 1 80 EXHAUST TUBE ASSY MEDIUM 2 62 1 8.23 IMPELLER 6 1/8 W/36 SLEEVE

15 1 846 CLIP EXHAUST TUBE 1 62 1 1737 IMPELLER 6 1/8 W/36 SLEEVE, STAINLESS

16 2 621 NYLOC 10-32 63 1 36.1 SHAFT SLEEVE PLASTIC MEDIUM

17 1 1025 WASHER FIBER M8 64 1 1705 IMPELLER TEE KEY - 1/2 ROUND

18 1 1024 BOLT HEX HD M8-1.25 X 12 65 8 21 SHIM WASHER MEDIUM

19 1 553.2 BALL END 1/4X10-32 CABLE 66 1 805 NUTKEEPER MED/PKG 2 PER BAG

20 1 975 LUBE HOSE ASSY 67 1 22.1 SHAFT NUT 5/8-18 BRASS

21 1 539 ZIRC FITTING 1/4-28 1447 INTAKE ASSY 6 1/8 FLANGED W\ GRILL & LINER

22 1 550 GREASE GUN 68 1 1521 LINER 6 1/8 FLANGED

23 1 552 GREASE 10 OZ TUBE 630-AA 69 6 1300 STUD - INTAKE MEDIUM

24 1 1175 REVERSE GATE, MEDIUM 70 6 623 NYLOC 1/4-20

25 2 535 NYLINER 3/8 1D X 11/16 71 1 1326 INTAKE PAINTED ONLY MED FLANGED

26 1 1177 SPRING GATE PIVOT 3/8 72 2 14 GRILL ROD

27 2 822 PIN GATE PIVOT 3/8 MEDIUM 73 9 16 GRILL BAR MEDIUM

28 1 1043 SHAFT ROLLER 171 BRACKET ASSY MORSE W/CLAMP & HARDWARE

29 2 624 NYLOC 1/4-28 75 1 156 BRACKET CABLE SUPPORT

30 1 1042 ROLLER ASSY 76 1 542 SHIM MORSE A035777

31 1 635 1/4 WASHER AN960C416 77 1 543 CLAMP CHRYS 154317

32 1 1035 SHIFT CAM MEDIUM 78 2 561 FL HD SLOTTED 10-24 X 5/8

33 1 623 NYLOC 1/4-20 79 2 635 1/4 WASHER AN960C416

34 1 573 BOLT HEX HD 1/4-20 X 3/4 80 2 572 BOLT HEX HD 1/4-20 X 5/8

35 1 1037 BUSHING CAM 81 2 619 NYLOC 10-24

36 1 1038 WASHER CAM 82 1 1650 CUSHION-SHIFT ROD GUIDE

37 2 1039 SHIM-CAM 83 1 1912 SPACER-WATER TUBE

38 1 1036 CAM ECCENTRIC DRILLED 84 1 1718 TORSIONAL DAMPER 5/8

39 1 574.1 BOLT HEX HD 1/4-20 X 1 PATCH 85 1 1911 SHIFT ROD GUIDE

40 2 574 BOLT HEX HD 1/4-20 X 3/4 PATCH

41 1 1170 SPRING GATE BUMPER

42 1 1169 GATE BUMPER

43 1 559.2 FIL HD SLOTTED 10-32 X 1 1/4 PATCH

44 1 1908 SHAFT ONLY, BC, 14T 26 3/8 LG

1909 SHAFT ASSY COMPLETE, BC, 14T W/1275 KEY

45 1 1275 KEY, TEE WATER PUMP

46 1 41 SHAFT BEARING THRUST RING

47 1 477 COLLAR BACKFIT 7205

SIZE TORQUE

1/4-20 (M6) 8-9 FT-LBS

5/16-18 (M8) 12 FT-LBS

3/8-16 (M10) 22 FT-LBS

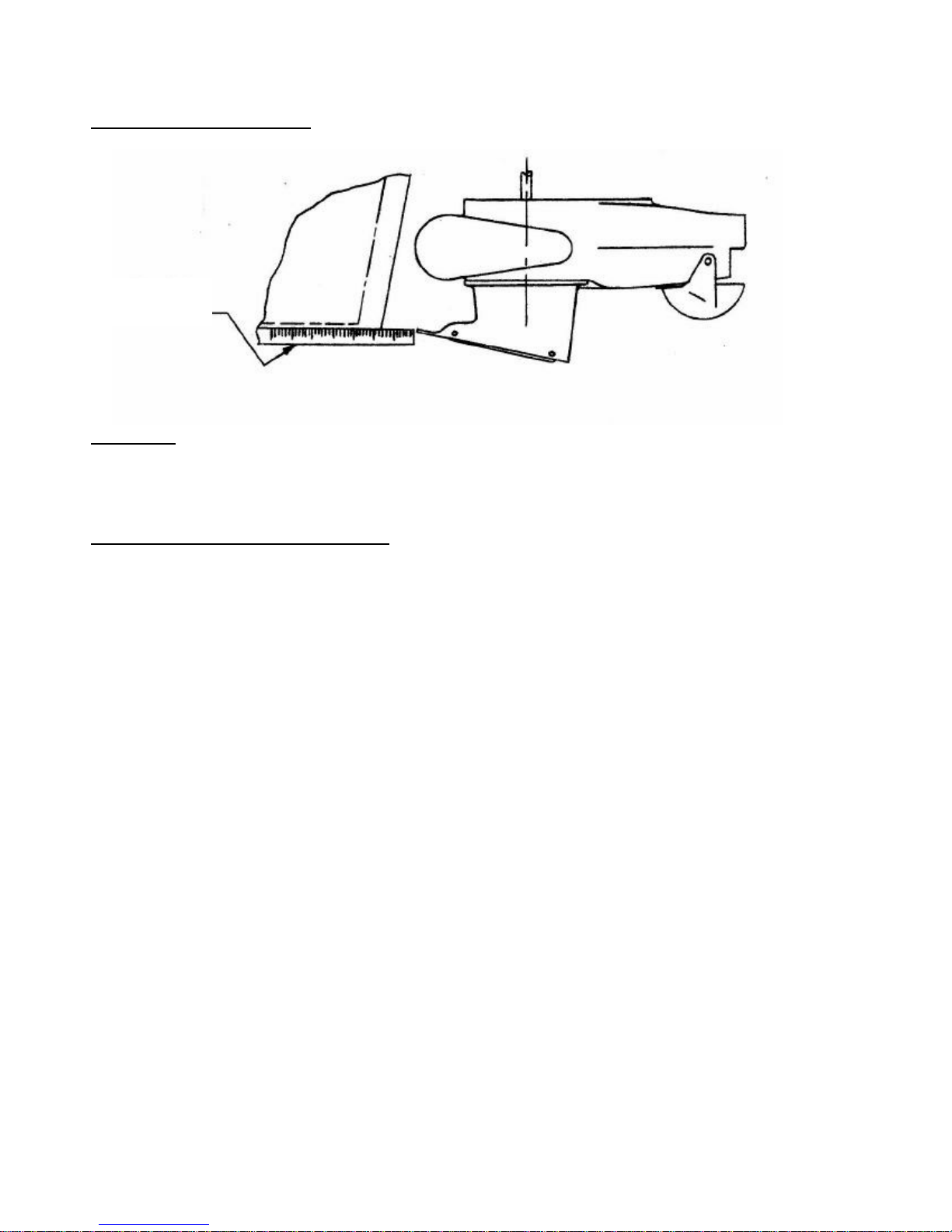

TILLER STEERING

SHIFT CABLE ASSY 1914

BEARING, SEAL, SNAP & “O” RING KIT 803.1