96-61836 • LANDA MVC • REV. 11/04 3

PRESSUREWASHER OPERATOR’S MANUAL

INTRODUCTION & IMPORTANT SAFETY INFORMATION

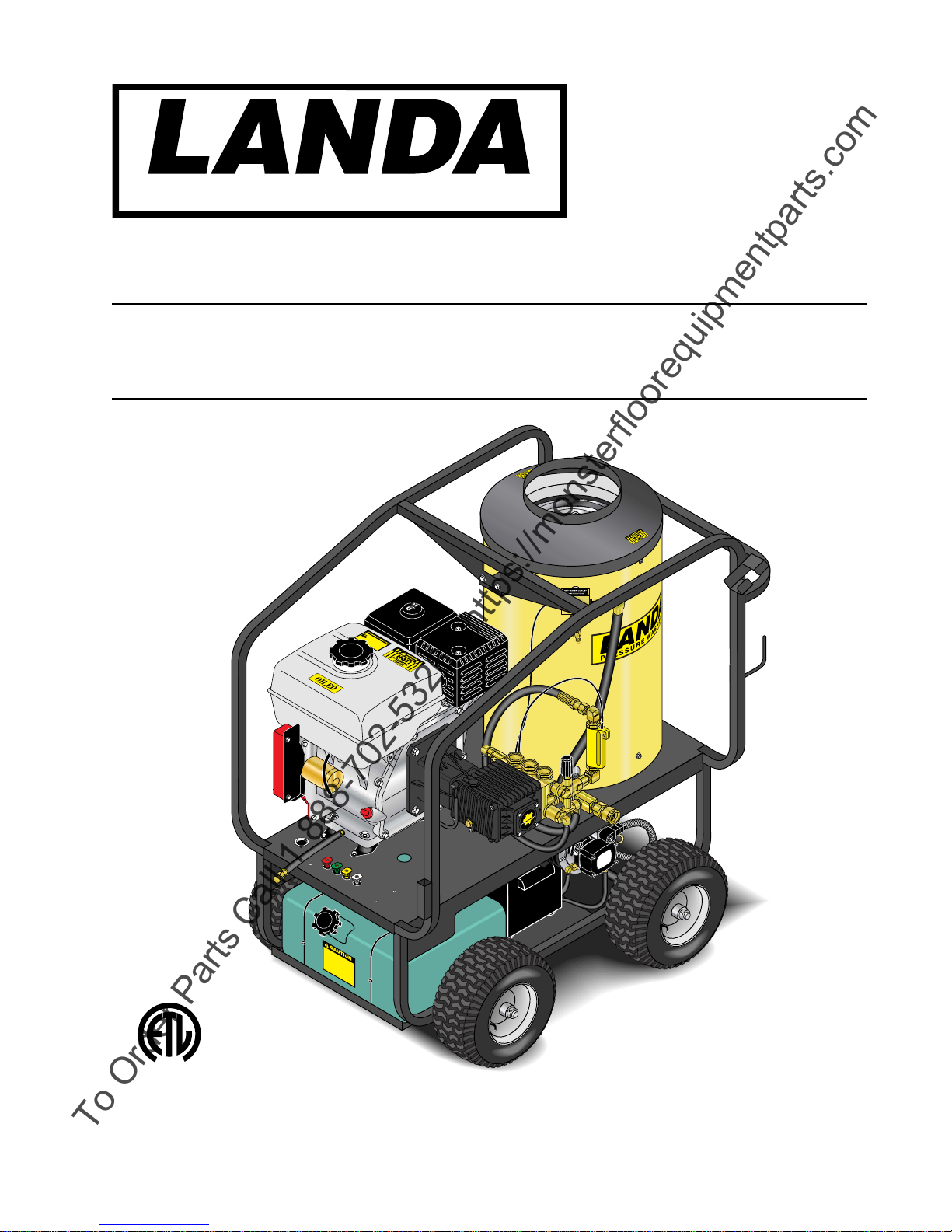

Thank you for purchasing a Landa Pressure Washer.

This manual covers the operation and maintenance of

the MVC3-30321, MVC4-30321, MVC4-30321E,

MVC4-30321E/S, MVC4-35321E, MVC3-30324,

MVC4-30324, MVC4-30324E, MVC4-30324E/S and

MVC4-35324Ewashers.Allinformation in this manual

is based on the latest product information available at

the time of printing.

Landa, Inc.reserves the right to make changes at any

time without incurring any obligation.

The MVC Series was designed for maximum

use of 4 hours per day, 5 days per week.

Owner/User Responsibility:

Theownerand/orusermust haveanunderstanding of

themanufacturer’soperatinginstructionsandwarnings

before using this Landa pressure washer.Warning in-

formationshould be emphasizedandunderstood.Ifthe

operator is not fluent in English, the manufacturer’s in-

structionsandwarnings shall be readtoanddiscussed

with the operator in the operator’s native language by

the purchaser/owner, making sure that the operator

comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’instructions.

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts,please specify model and

serial number.

IMPORTANT SAFETY

INSTRUCTIONS

WARNING:When using this machine basic precau-

tions should always be followed,including the fol-

lowing: CAUTION:To reduce the risk of

injury, read operating instruc-

tions carefully before using.

1.Read the owner's manual

thoroughly.Failuretofollowin-

structions could cause mal-

function and result in death,

serious bodily injury and/or

property damage.

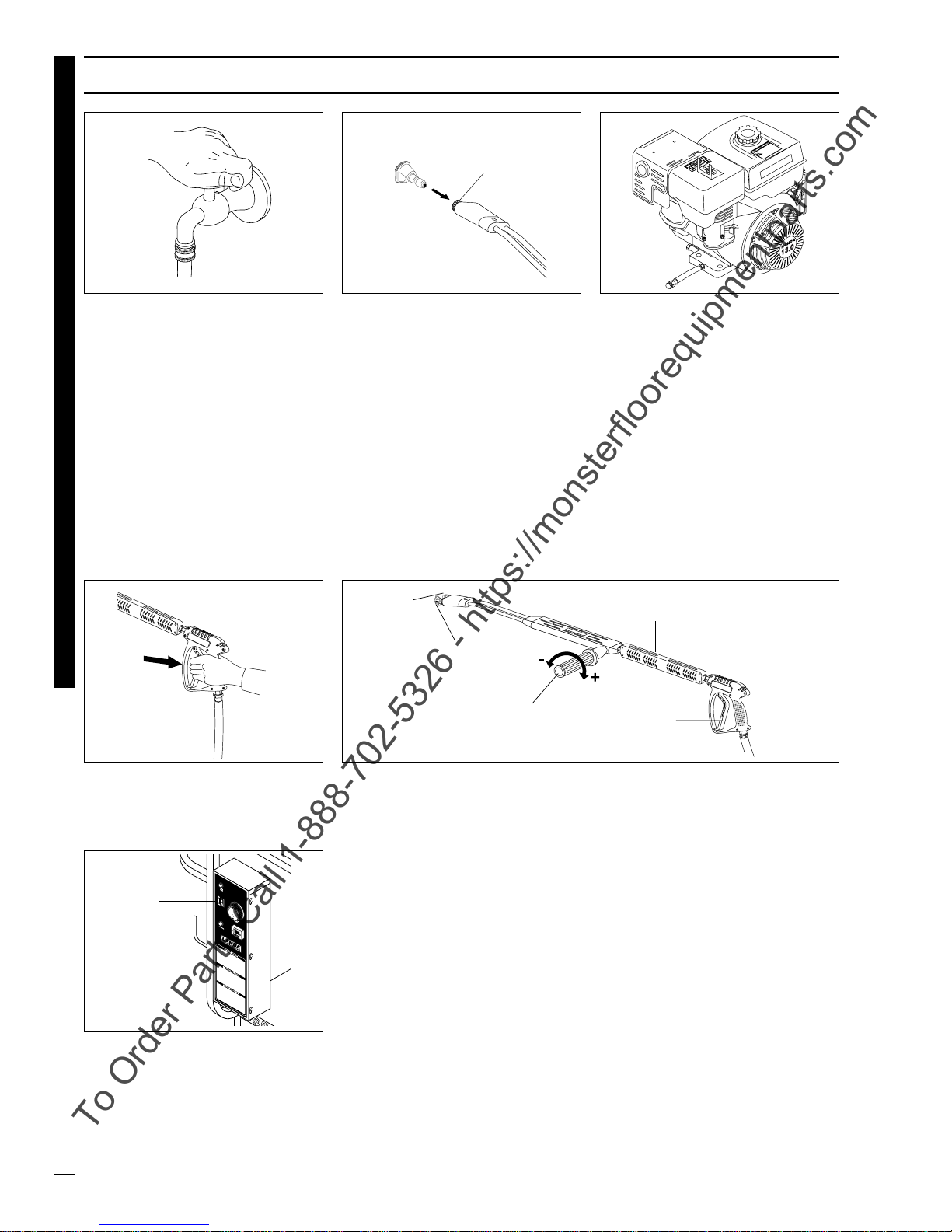

2. Know how to stop the machine and bleed pres-

sures quickly. Be thoroughly familiar with the con-

trols.

3. Stay alert - watch what you are doing.

4. Allinstallationsmustcomplywith local codes.Con-

tact your electrician, plumber, utility company or

the selling distributor for specific details.

WARNING: Flammable liquids

can create fumes which can ig-

nite causing property damage

or severe injury.

5. Risk of explosion - do not

spray flammableliquidsorop-

erateinanexplosivelocation.

Operate only where open

flame or torch is permitted.

WARNING: Do not place machine near flammable

objects when the engine is hot.

WARNING: Keep water spray

awayfromelectricalwiringor fa-

tal electric shock may result.

WARNING: Spray gun kicks

back. Hold with both hands.

6. Grip cleaning wand securely

with both hands before start-

ing the cleaner. Failure to do

thiscouldresultin injuryfrom

a whipping wand.

WARNING: Risk of fire. Do not

add fuel when the machine is

operating.

7. Allowenginetocool for2min-

utes before refueling. If any

fuelisspilled,makesurearea

is dry before testing spark

plug or starting the engine.

(Fire and/or explosion may

occur if this is not done.)

Gasolineenginesonmobileorportableequipment

shall be refueled:

a. Outdoors;

b. With the engine on the equipment stopped;

c. With no source of ignition within 10 feet of the

dispensing point;

d. With an allowance made for expansion of the

fuel should the equipment be exposed to a

higher ambient temperature.

Inanoverfillingsituation,additionalprecautionsare

necessary to ensure that the situation is handled

in a safe manner.

WARNING

KEEP WATER SPRAY

AWAY FROM

ELECTRICAL WIRING.

WARNING

RISK OF EXPLOSION:

USE CAUTION WHEN

REFUELING.

READ OPERATOR’S

MANUAL THOROUGHLY

PRIORTO USE.

CAUTION

WARNING

RISK OF EXPLOSION:

DO NOT SPRAY

FLAMMABLE LIQUIDS.

ToOrderPartsCall1-888-702-5326-https://monsterfloorequipmentparts.com