(4) BISSELL FMH 175 High-Speed Floor Machine BISSELL FMH 175 High-Speed Floor Machine (13)

1.0 Safety Instructions

READ THIS MANUAL BEFORE OPERATING THE BISSELL BIGGREEN

COMMERCIAL HIGH-SPEED FLOOR MACHINE. KNOW THE PROPER

OPERATION, SAFETY INSTRUCTIONS, CORRECT APPLICATIONS AND THE

LIMITATIONS OF THIS EQUIPMENT BEFORE USE.

Reduce the Risk of Fire, Electric Shock or Injury

DO NOT USE ON WET SURFACES. DO NOT EXPOSE TO RAIN. STORE

INDOORS.

• The oor machine is designed for indoor use only. Do not

use outdoors. Do not expose to rain.

• DO NOT wash the motor with owing water. If the motor

gets wet, seek authorized service.

• Keep the vents on the air-cooled motor free from debris.

DO NOT operate with the motor covered or with vents

blocked. DO NOT use this machine as a oor sander.

• Never operate the oor machine near ammable dusts,

liquids or vapors. Never use ammable solvents as a

cleaning agent. Engine sparks and operating heat can

cause re.

• Never handle electrical equipment with wet hands. Never

operate this oor machine with bare feet.

• Unplug the oor machine when not in use and when

servicing the equipment. To unplug, grasp the plug not the

cord. Do not lift, pull or carry this oor machine by the

cord.

• DO NOT operate the oor machine with damaged handle

controls, cord or plug. If the equipment is not performing

properly, seek repair from a qualied service supplier.

• This oor machine is constructed with electrical

grounding at the plug. Operate only when connected to a

properly grounded outlet. See section 2.0 for grounding

details.

• Prevent electrical cord abuse. Do not close a door upon

the cord, drive equipment over it, or run the oor machine

over it. Do not expose the cord to hot surfaces. Do not

lift, pull or carry this oor machine by the cord.

• Never operate the oor machine over sharp objects that

can be thrown out and harm the operator and damage the

oor. Sweep hard oors before scrubbing or bufng.

• Train your staff in proper use of this oor machine.

WARNING – RISK OF EXPLOSION. When using this machine as a oor sander, sanding can produce

an explosive mixture of ne dust and air. Use any oor sanding machine only in a well ventilated area free

from any ames or sparks. WARNING OF POTENTIAL INJURY. THIS MACHINE HAS MOVING

PARTS – TO REDUCE RISK OF INJURY, UNPLUG BEFORE SERVICING.

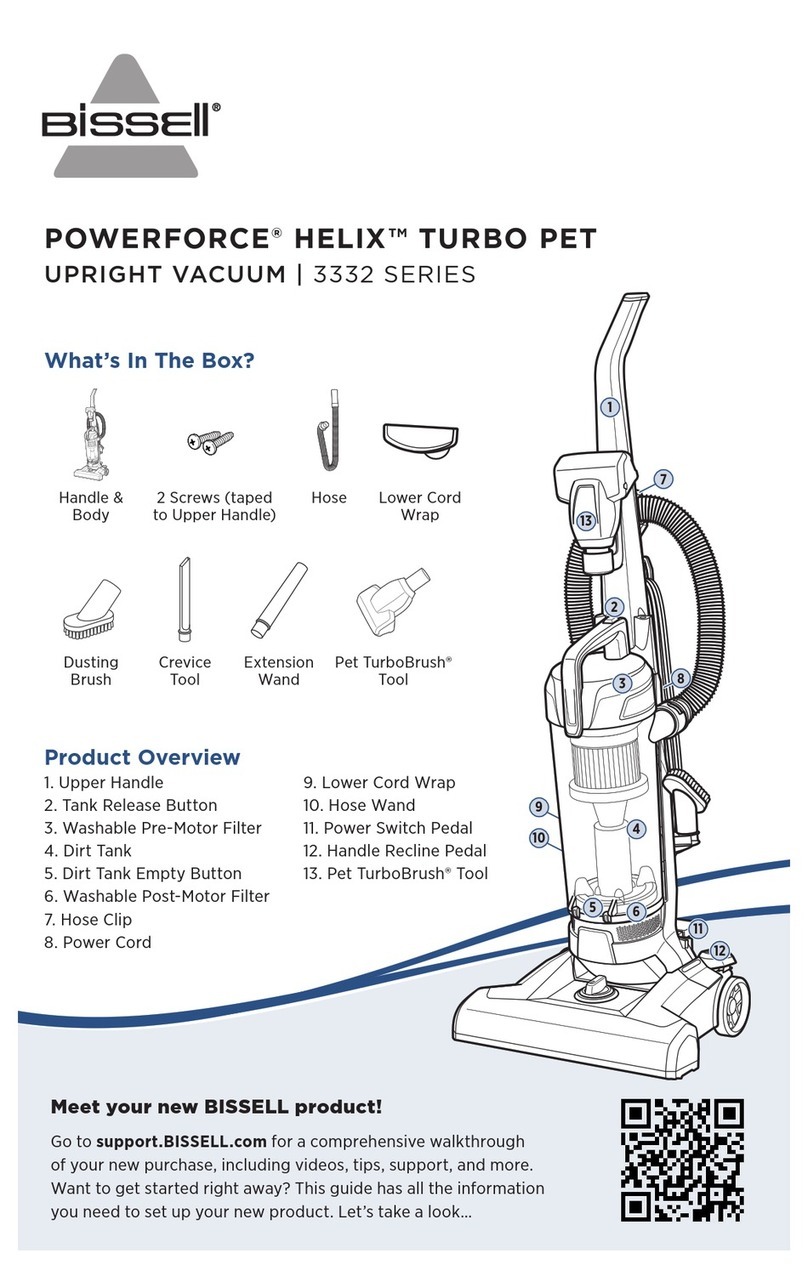

8.0 Machine Parts List

Drawing No. Description Part No. Qty.

1 Switch Box Back A-104 1

2 Handle Tube Screw B-23 2

3 Switch Box Closing Screw B-21 4

4 Strain Relief Clip M-213 1

5 Ground Wire Screw B-68 2

6 Black Hand Grip with Green Band M-218-G 2

8 Handle Tube Insert M-247 1

9 Handle Tube Assembly M-206 1

10 Cable Hook Screw B-2 2

11 Cable Hook A-164 1

12 Sliding Collar A-111 1

13 Cam Washer B-37 1

14 Cam Lock Wing Nut B-25 1

15 Cam Split Washer B-39 1

16 Bent Brace M-216 2

17 Yoke Bolt B-18A 2

18 Yoke Nut B-19 2

19 Handle Tube Cable G-16 1

20 Black Rubber Cable Connector M-249 1

21 Cable Grommet B-63 1

22 Rectangular Hole Cam Washer B-67 1

23A Cam Assembly See Exploded View 1

23.1 Cam Handle Cover C-105 1

23.2 Cam Handle C-100 1

23.3 Cam Rivet B-24 1

23.4 Cam Rivet Hubcap B-79 1

23.5 Cam Eyebolt C-110 1

23B Complete Cam Assembly Kit (Includes 1 of each

Drawing Numbers: 13, 14, 15, 22, 23.1, 23.2, 23.

3, 23.4, 23.5) CCA 1

24 50-Foot, 14/3-Gauge Power Cord - Yellow G-14-50-Y 1

25 Switch Mounting Plate G-30-B 1

26 Switch Plate Screw B-1 2

27 Int. Tooth Lock Washer (for Switch) B-35 1

28 Insulated Flag Wire Connector G-48 1

29 On/Off Switch and Plate Assembly G-30-AB 1

30 Lock Washer B-33 1

31 Trigger Return Spring G-30-CT057 1

32 Label for Switch Box 1

33 Switch Box Front A-103 1

34 Wire Connector G-47 1

35 Trigger A-105 2

36 16” Crossbar M-211-A 1

37 Safety Interlock Assembly SIA-1R 1

38 Trigger Pin B-70 2

39 Crossbar Screw B-22 2

40 Acorn Nut for Yoke Pin B-8 2

41 Rubber Yoke Spacer B-5 2

42 Yoke Pin B-7 1

43 Yoke A-1001 1

44 Drip Cap Mounting Screw B-151 3

45 66 Frame Drip Cap Cover M-242-1A 1

46 66 Frame Drip Cap Cover Bumper - Green M-239-G 1

47 Cork Drip Cap Gasket M-248 1

48 Motor 66 Frame 1.5 HP with Gearbox, 50 HZ, 220V MOTOR/GBLH/E220 1

50 Hub Caps V0038 2

51 Spring Washer B-51 4

52 6” Wheels M-245 2

53 1/2” Flat Washer B-29 2

54 Spring B-30 2

55 Axel M-240 1

56 Label for Motor 1

57 Main Machine Frame A-166 1

58 Apron Mounting Thumb Screw B-96 4

59A Bumper 15” - Green M-232-15/G 1

59B Bumper 17” - Green M-232-17/G 1

59C Bumper 19” - Green M-232-19/G 1

59D Bumper 21” - Green M-232-21/G 1

60A Apron 15” A-167 1

60B Apron 17” A-169 1

60C Apron 19” A-171 1

60D Apron 21” A-172 1

61 Scrubber Plug B-50 1

62 Base Casting Screw B-95 3

63 1/4” Medium Split Washer B-32 3