3.0Operations

3.1. TestingEnvironment: 25 1

,

relativehumidity:60%~70%.

3.2. Turnonthepowerswitchwhichison the back oftester, buzzerbuzzing.

3.3 Liquidcrystalscreen showssequentiallyon the maininterfaceasfollowing.

Timeofwholecourse20h

Compensating timing 00:00:00

Running cycle0000.0

Testtiming 00:00:00

3.4. Accordingtoestimated inkdryingtime, adjust“timeofwholecourse”(tacitlyapprove20h)

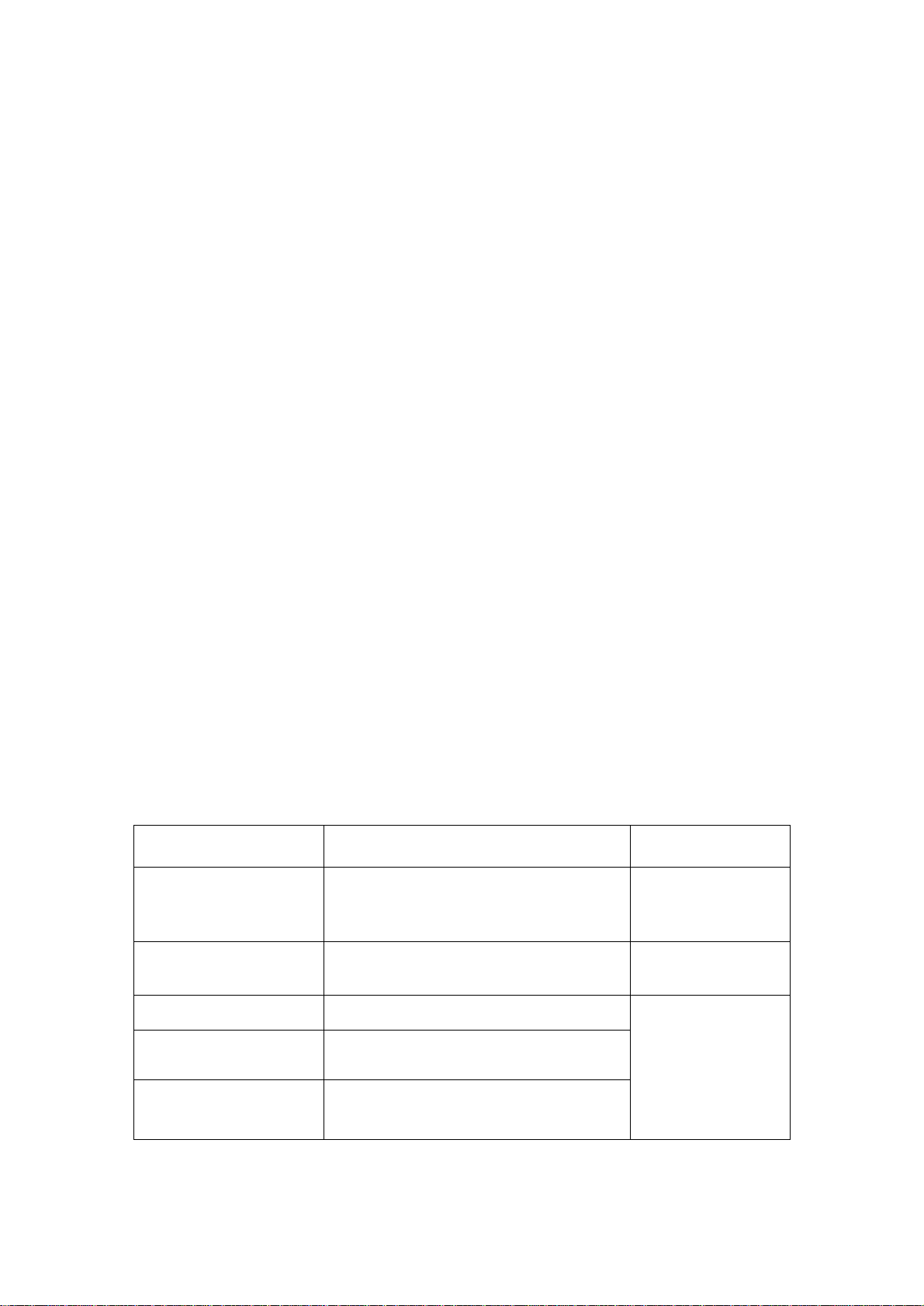

Contrast tableforTimeofwholecourse&Timepercycleforroller(intervalbetween twostainstrips

on theparchment paper)asfollowing:

Timeofwholecourse (h) 05 06 07 08 09 10 1112

Timepercycleforroller(min)

2.533.544.555.56

Timeofwholecourse (h) 13 14 15 16 17 18 19 20

Timepercycleforroller(min)

6.577.588.599.510

3.5 Weightest sample&standardwhite&dryoil on the analyticalbalanceaccordingtofollowing

proportion,theyshall behomogeneous; Weighstandardsample&standardwhite&dryoil usingsame

method, theyshall behomogeneous.The proportion forink&dryoil:

Resinink:testsample(standardsample)ink:standardwhite&dryoil=95:5

Oil ink:testsample(standardsample)ink:standardwhite&dryoil=90:10

3.6 Afterblendedhomogeneously,Standardsampleisparalleltotest sample, coat 30cmlength. Press

“Start Stoptiming”keyandstart test timing&compensatingtiming; parchment papercoveringon test

sample,wrapthemtogether&fixed byadhesiveband on the roller.

3.7 Movepressuretyretothe right ofscrewstem, forceon parchment paper; Press run “key”and start

rollerrevolving(automaticallystopcompensatingtiming), pressuretyrestart toscratch.

3.8 Duringrunning, Press “Stop”keytostoprollerrevolving(automaticallyrestart compensatingtiming)

soastoobservescratchcondition; thenrepress “run”keytorerun roller(automaticallystop

compensatingtiming).

3.9 When test timingreachestimeofwholecourse orpressuretyretoucheslimit switchon the

left, automaticDryingTesterautomaticallystoprunning, buzz three timesand staydisplayon the display

screen. Press “Stop”keyafternoscratchonthepressuretyre,thenimmediatelypress “Start Stop

timing”keytostoprollerrevolving, and stay “compensatingtiming”display.

3.10 Takeoffparchment paperand check spacernumberbetween twostainstrips,multiplyspacer

numberbytimepercyclethen add compensatingtiming, that isinkdryingtime. Calculatedifference

between test sampleand standardsample, check ifit issuitable.

3.11 “Cleartiming”keymust bepressed tocleandisplay, thennexttest canbedone.