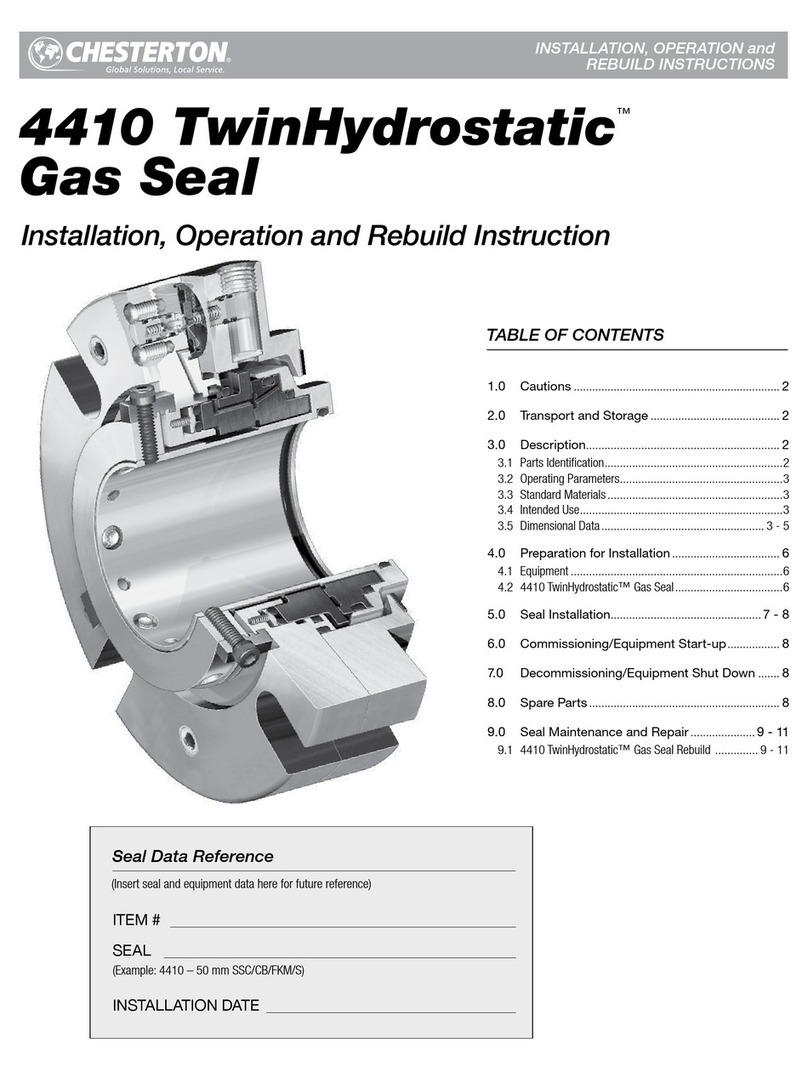

Chesterton TwinHybrid 4400H Owner's manual

4400H TwinHybrid™

Gas Seal

Installation, Operation and Rebuild Instructions

TABLE OF CONTENTS

INSTALLATION, OPERATION and

REBUILD INSTRUCTIONS

Seal Data Reference

(Insert seal and equipment data here for future reference)

ITEM #

SEAL

(Example: 4400H – 50 mm SSC/CB/FKM/S)

INSTALLATION DATE

1.0 Cautions ................................................................... 2

2.0 Transport and Storage .......................................... 2

3.0 Description............................................................... 2

3.1 Parts Identification..........................................................2

3.2 Operating Parameters.....................................................3

3.3 Standard Materials .........................................................3

3.4 Intended Use..................................................................3

3.5 Dimensional Data ..................................................... 4 - 5

4.0 Preparation for Installation ................................... 6

4.1 Equipment .....................................................................6

4.2 4400H TwinHybrid™ Gas Seal........................................6

5.0 Seal Installation....................................................... 7

6.0 Commissioning/Equipment Start-up................. 8

7.0 Decommissioning/Equipment Shut Down ....... 8

8.0 Spare Parts .............................................................. 8

9.0 Seal Maintenance and Repair ..................... 8 - 11

9.1 4400H Trouble Shooting .................................................8

9.2 4400H TwinHybrid™ Gas Seal Rebuild Instructions.. 9 - 11

2

KEY

1 – Sleeve Assembly

2 – Shaft O-Ring

3 – Gasket

4 – Rotary O-Ring

5 – Rotary Seal Ring

6 – Adapter

7 – Rotary Cushion O-Ring

8 – Stationary Seal Ring

9 – Gland

10 – Inter Gland O-Ring

11 – OD Stationary O-Ring

12 – ID Stationary O-Ring

13 – Pusher Plate

14 – Lock Ring

15 – Centering Clip

16 – Socket Head Cap Screw

17 – Adjusting Screw

18 – Screw O-Ring

19 – Inboard Spring

20 – Diaphragm

21 – Actuator

22 – Snap Ring

23 – Seat O-Ring

24 – Seat

25 – Ball

26 – Outboard Spring

27 – Dog Point Set Screw

28 – Cup Point Set Screw

29 – Gland Screws

30 – Spring

31 – 1/4" Pipe Plug

32 – 1/8" Pipe Plug

33 – 3/8" Pipe Plug

34 – Cap Plug

35 – Filter Disk

36 – Retaining Clip

37 – Support Gasket

These instructions are general in nature. It is assumed

that the installer is familiar with seals and certainly with

the requirements of their plant for the successful use of

mechanical seals. If in doubt, get assistance from someone

in the plant who is familiar with seals or delay the installation

until a seal representative is available. All necessary auxiliary

arrangements for successful operation (heating, cooling,

flushing) as well as safety devices must be employed. These

decisions are to be made by the user. The decision to use this

seal or any other Chesterton seal in a particular service is the

customer’s responsibility.

Transport and store seals in their original packaging.

Mechanical seals contain components that may be subject to

alteration and ageing. It is therefore important to observe the

following conditions for storage:

Do not touch the mechanical seal for any reason while it is

operating. Lockout or uncouple the driver prior to personal

contact with the seal. Do not touch the mechanical seal

while it is in contact with hot or cold fluids. Ensure that all

the mechanical seal materials are compatible with the

process fluid. This will prevent possible personal injury.

• Dust free environment

• Moderately ventilated at room temperature

• Avoid exposure to direct sunlight and heat.

• For elastomers, storage conditions according to ISO 2230

should be observed.

1.0 CAUTIONS

2.0 TRANSPORT AND STORAGE

3.0 DESCRIPTION

3.1 Parts Identification

Figure 1

20

19

18

35

17

36

22

23

21

24

25

26

29

16

15

9

10

14

27

30

11

13

12

28, 31-34, 37 (not shown in this view)

3

6

4

1

5

2

7

8

3

3.0 DESCRIPTION cont.

3.2 Operating Parameters*

Speed Limits:

25 m/s (5000 fpm) Maximum

1,3 m/s (250 fpm) Minimum

Pressure Limits:

710 Torr (28" Hg) to 20 bar g (300 psig)

25 mm – 65 mm (1.000" -2.625")

510 Torr (20" Hg) to 17 bar g (250 psig)

70 mm – 90 mm (2.750" – 3.625")

Temperature Limits:

To 260°C (500°F) Maximum (elastomers)

* Consult Chesterton Mechanical Seal Application Engineering for higher

operating conditions.

3.3 Standard Materials

Faces:

Carbon Stationary Seal Ring

Sintered Silicon Carbide Rotary Seal Ring

Elestomers:

FKM, EPDM, FEPM, FFKM

Metal Parts:

316SS body

Alloy C-276 springs and drive pins

Hardened set screws (standard)

3.4 Intended Use

The mechanical seal is specifically designed for the intended

application and is to be operated within the operating

parameters as specified. For use beyond the intended

application and/or outside the operating parameters, consult

Chesterton Mechanical Seal Application Engineering to confirm

the suitability of the mechanical seal prior to putting the

mechanical seal in operation.

4

KEY (chart)

A – Shaft Size

B – Maximum Gland Diameter

C – Stuffing Box Inside Diameter

F – Outboard Seal Length

G – Maximum Bolt Circle by Bolt Size

H – Slot Width

T – Shaft O-Ring

U – Rotary Seal O-Ring

V – Rotary Cushion O-Ring

W – Stationary Seal O-Ring (outside diameter)

X – Stationary Seal O-Ring (inside diameter)

Y – Gland Adaqpter O-Ring

3.0 DESCRIPTION cont.

3.5 Dimensional Data (Drawings)

Figure 2

B

H

G MIN

C

F

TA VU Y W X

5

3.0 DESCRIPTION cont.

3.5 Dimensional Data (cont.) – Table 1

METRIC - Millimeters

BY BOLT CIRCLE

O-RINGS

SEAL

SIZE

SHAFT

SIZE

GLAND

OD

STUFFING

BOX BORE

OB

LENGTH

SLOT

WIDTH SHAFT ROTARY CUSHION STAT.

OD

STAT.

ID

GLAND

ADPT.

A B C F G MIN H T U V W X Y

MAX MAX MAX 10 mm 12 mm 16 mm 20 mm

25 mm 25 102 52 54 73 11 -120 -134 -024 -134 -124 -139

28 mm 28 102 52 54 76 11 -122 -136 -026 -136 -126 -141

30 mm 30 102 58 54 80 11 -123 -138 -028 -138 -128 -143

32 mm 32 111 62 54 83 85 14 -124 -140 -029 -140 -130 -145

35 mm 35 111 62 54 83 85 14 -126 -140 -029 -140 -130 -145

38 mm 38 114 67 54 86 88 14 -128 -142 -030 -142 -132 -147

40 mm 40 127 69 54 89 91 14 -129 -144 -031 -144 -134 -149

43 mm 43 139 72 54 92 94 14 -131 -146 -032 -146 -136 -150

45 mm 45 139 75 54 95 97 14 -133 -148 -033 -148 -138 -151

48 mm 48 139 82 54 101 103 14 -134 -150 -034 -150 -140 -152

50 mm 50 139 82 54 101 103 14 -136 -150 -034 -150 -140 -152

55 mm 55 152 91 54 111 113 117 18 -139 -151 -036 -152 -144 -153

60 mm 60 152 92 54 112 114 118 18 -142 -152 -037 -152 -146 -153

65 mm 65 164 103 57 123 125 129 18 -145 -153 -040 -154 -151 -155

70 mm 70 196 113 64 135 139 18 -232 -242 -151 -242 -235 -246

75 mm 75 202 119 64 141 145 18 -234 -244 -152 -244 -237 -248

80 mm 80 208 125 64 149 152 18 -236 -246 -153 -246 -239 -250

85 mm 85 211 129 64 151 155 159 21 -237 -247 -153 -247 -240 -251

90 mm 90 216 135 64 158 162 166 21 -239 -249 -154 -249 -242 -253

INCH

BY BOLT CIRCLE

O-RINGS

DASH

NO.

SHAFT

SIZE

GLAND

OD

STUFFING

BOX BORE

OB

LENGTH

SLOT

WIDTH SHAFT ROTARY CUSHION STAT.

OD

STAT.

ID

GLAND

ADPT.

A B C F G MIN H T U V W X Y

MAX MAX MAX 3/8" 1/2" 5/8" 3/4"

-8 1.000 4.000 2.03 2.125 2.86 .44 -120 -134 -024 -134 -124 -139

-9 1.125 4.000 2.06 2.125 2.99 .44 -122 -136 -026 -136 -126 -141

-10 1.25 4.000 2.29 2.125 3.11 .44 -124 -138 -028 -138 -128 -143

-11 1.375 4.360 2.45 2.125 3.24 3.36 .57 -126 -140 -029 -140 -130 -145

-11 OS 1.375 5.385 3.27 2.125 3.98 4.11 .44 -126 -140 -029 -140 -130 -150

-12 1.500 4.485 2.65 2.125 3.36 3.49 .57 -128 -142 -030 -142 -132 -147

-13 1.625 4.985 2.71 2.125 3.49 3.61 .57 -130 -144 -031 -144 -134 -149

-14 1.750 5.485 2.83 2.125 3.61 3.74 .57 -132 -146 -032 -146 -136 -150

-14 OS 1.750 6.635 3.90 2.125 5.36 5.48 5.61 .57 -132 -146 -032 -146 -136 -153

-15 1.875 5.485 2.96 2.125 3.74 3.86 .57 -134 -148 -033 -148 -138 -151

-15 OS 1.875 5.985 3.96 2.125 4.86 4.98 5.11 .57 -134 -148 -033 -148 -138 -153

-16 2.000 5.485 3.21 2.125 3.97 4.10 .57 -136 -150 -034 -150 -140 -152

-17 2.125 5.985 3.46 2.125 4.22 4.34 4.47 .69 -138 -151 -035 -151 -142 -152

-17 OS 2.125 6.985 4.40 2.125 5.74 5.86 5.99 .69 -138 -151 -035 -151 -142 -154

-18 2.250 5.985 3.58 2.125 4.35 4.48 4.60 .69 -140 -151 -036 -152 -144 -153

-19 2.375 5.985 3.61 2.125 4.41 4.53 4.66 .69 -142 -152 -037 -152 -146 -153

-20 2.500 6.485 3.83 2.125 4.59 4.72 4.84 .69 -144 -152 -038 -153 -148 -154

-20 OS 2.500 7.760 5.40 2.125 6.49 6.61 6.74 .69 -144 -152 -038 -153 -148 -157

-21 2.625 6.445 4.06 2.227 4.85 4.98 5.10 .69 -146 -153 -040 -154 -151 -155

-21 OS 2.625 6.980 4.92 2.227 5.73 5.86 5.98 .69 -146 -153 -040 -154 -151 -157

-22 2.750 7.710 4.46 2.500 5.37 5.50 .69 -232 -242 -151 -242 -235 -246

-23 2.875 7.830 4.59 2.500 5.47 5.60 .69 -233 -243 -151 -243 -236 -247

-24 3.000 7.940 4.71 2.500 5.60 5.73 .69 -234 -244 -152 -244 -237 -248

-25 3.125 7.990 4.84 2.500 5.75 5.87 .69 -235 -245 -152 -245 -238 -249

-26 3.250 8.190 4.96 2.500 5.87 6.01 .69 -236 -246 -153 -246 -239 -250

-27 3.375 8.310 5.09 2.500 5.97 6.10 6.22 .81 -237 -247 -153 -247 -240 -251

-28 3.500 8.440 5.21 2.500 6.14 6.25 6.38 .81 -238 -248 -154 -248 -241 -252

-29 3.625 8.490 5.34 2.500 6.27 6.38 6.52 .81 -239 -249 -154 -249 -242 -253

6

1 If practical, place the dial indicator tip

on the end of the shaft sleeve or on a

step in the shaft to measure end play.

Alternately push and pull the shaft in

the axial direction. If the bearings are

in good condition, end play should

not exceed 0,13 mm (.005").

3 Remove all sharp corners, burrs, and

scratches on the shaft, especially in

areas where the O-Ring will slide, and

polish if necessary to achieve a 0,8

micron (32 microinch) Ra finish. Make

sure the shaft or sleeve diameter is

within 0,05 mm (.002") of nominal.

4 Use a dial indicator to measure the

shaft runout in the area where the

seal will be installed. Runout should

not exceed 0,001 mm TIR per

millimeter (.001 inch TIR per inch) of

shaft diameter.

5 Protect the shaft O-Ring by

lubricating the shaft with a clean

silicone based lubricant, such as that

provided with the seal.

6 Check availability of clean dry

barrier gas. The seal uses gas

(Nitrogen) to seal the product from

the environment and lubricate the seal

faces. 2,4 lpm (5 SCFH) of barrier

gas must be available at 2 bar (30

psi) over the maximum stuffing box

pressure and filtered to a maximum

particle size of 3 microns with a dew

point of <-29°C (-20°F). Alternate gas

can be used for barrier gas supply if

it is compatible with the product and

the environment.

4.0 PREPARATION FOR INSTALLATION

4.1 Equipment

.005"

0,13 mm

<

ø

1000

ø

<

32 µ"

0,8 µmRa

ø

<

.002"

0,05 mm

±

2 If possible, attach a base dial

indicator to the shaft and rotate both

the indicator and shaft slowly while

reading the runout of the stuffing box

face. Misalignment of the stuffing box

face relative to the shaft should not

exceed 0,005 mm TIR per mm (.005

in per inch) of shaft diameter.

The stuffing box face must be flat

and smooth enough to seal the

gland. Surface roughness should

be 3,2 microns (125 microinch) Ra

maximum for gaskets and 0,8 micron

(32 microinch) Ra for O-Rings. Steps

between halves of split case pumps

should be machined flat. Make sure

the stuffing box is clean and clear

along its entire length.

ø

ø

200

<

125 µ"

3,2 µm

4.2 4400H TwinHybrid™

Gas Seal

1 Review seal packaging ensuring no

damage or shortage has occurred to

the contents.

2 Review the seal fit dimensions in

Table 1 to ensure the equipment to be

sealed has the required dimensions.

3 Record the seal Item Number

and Name found on the label for

referencing when contacting AW

Chesterton Application Engineering.

4 Check the chemical listing to

determine if the O-Rings installed in

this seal are compatible with the fluids

being sealed.

IM P ORTANT:

5Check the rotation of the pump and

the rotation arrow on the gland OD

(and/or gland face) ensuring both

are the same direction.

6Make sure all set screws are

engaged in the sleeve but do not

protrude into the inside diameter

of the seal sleeve.

7

1 Slide the seal onto the shaft.

2 Reassemble the pump and make

necessary shaft alignments and

impeller adjustments. The impeller

can be reset at any time, as long as

the centering clips are in place and

the seal set screws are loosened

while the shaft is being moved.

3 The 1/4 dog point set screws (marked

1, 2, 3) go into the small holes in the

sleeve.

Do not disengage these

screws from the sleeve when

positioning the seal.

4 The centering clips have been preset

at the factory. If for any reason you

loosen or remove the centering clip

cap screws, re-tighten each cap

screw finger tight (approximately 1,7

N-m [15 inch-pounds] of torque).

CAUTION:

Make sure the lip on the end of the

gland is inside the inner centering clip

groove and the lock ring lip engages

the outer centering clip groove.

5 Orient the gas barrier supply and flush

connections to the location required.

TABLE 2 – Gland Port Functions

“B” Barrier Gas Supply

“F” Flush - Environmental

“M”* Monitor Port

“X” Manufacturing Port (Do Not Use)

*Previously identified as “BG”

CAUTION:

All ports are plugged prior to

shipping. These plugs prevent dirt and

contaminants from entering the seal.

When plugs are removed ensure that

dirt, liquid and contamination, which

could cause seal malfunction, do not

enter the seal ports.

6 Tighten the stuffing box bolts evenly

to the recommended torque value in

TABLE 3.

**Stuffing box bolts vary per

application. Actual torque required

is based on bolt size and bolt

manufacturers’ recommended torque.

5.0 SEAL INSTALLATION

TABLE 3 – Recommended Torque Values

Seal Size Dog Point &

Cup Point Set Screws Gland Screws Stuffing Box Bolts**

up to 65 mm

(up to 2.625")

5,7 - 6,8 N-m

(50 - 60 in-lbf)

12,2 N-m

(9 ft-lbf)

27 - 40 N-m

(20 - 30 ft-lbf)

>65 mm up to 90 mm

(>2.625" up to 3.625")

7,3 - 8,3 N-m

(65 - 75 in-lbf)

12,2 N-m

(9 ft-lbf)

34 - 48 N-m

(25 - 35 ft-lbf)

IM P ORTANT:

The stuffing box bolts must be

tightened before tightening the set

screws onto the shaft or seal port

connections.

7 Tighten 1/4 dog point set screws

(marked 1, 2, 3) in two steps:

Step 1 – snug to finger tight; Step

2 - retighten 1/4 dog point set screws

evenly with the hex key provided and

to the recommended torque value in

TABLE 3.

IM P ORTANT:

All three 1/4 dog point set screws must

be tightened FIRST.

8 Evenly tighten the cup point set

screws (marked 4, 5, 6) to the shaft

using recommended torque value in

TABLE 3. If rotation of the lock ring

is required for tightening set screw,

loosen but do not remove centering

clips.

IM P ORTANT:

The cup point set screws installed in

the lock ring are hardened steel and

have metric threads: for 25 mm – 65

mm (1.000" thru 2.625") seals use a

3 mm hex key; for 70 mm – 90 mm

(2.750" thru 3.625") seal use a 4 mm

hex key. Stainless steel cup point

set screws are provided in the seal

accessory kit, which may be used for

low pressure, non-hardened shaft/

shaft sleeve applications.

9 Remove socket head cap screws and

centering clips from the lock ring and

retain for later use.

10 Ensure that the gland is properly

centered over the sleeve. To do

this, turn the shaft toward the

directional arrow by hand to ensure

the seal turns freely. I metal to metal

contact is detected within the seal

it is improperly centered. Replace

centering clips finger tight, loosen

gland bolts, tighten clips, re-tighten

gland bolts and remove clips. If metal

to metal contact is still detected,

check concentricity of the shaft to the

stuffing box.

THE BARRIER GAS SUPPLY AND

FLUSH CONNECTIONS ARE 1/4" NPT.

11 If a flush/recirculation port is

required, remove the shipping plug

and connect the pump discharge/

suction to the flush port marked “F”

using a recirculation line (bleed from

discharge [API Plan 11] or connected

to suction [API Plan 13]). This is

recommended in seal applications

where the barrier gas supply may

be disrupted during operation. This

connection may also be used to

monitor stuffing box pressure by

installing a connection to a gauge or

pressure transducer.

12 Connect the barrier gas supply

port marked “B”. Purge the barrier

gas supply line from the barrier

gas supply manifold or system.

Prior to connecting to the seal port

ensure the supply line is free of

contamination, dirt and liquid and

no burrs, restrictions or liquid legs

are present. Full pressure barrier gas

supply can be piped directly to the

barrier supply port.

The seal In-Gland Control System

(IGCS) will maintain a factory preset

differential pressure between the

barrier gas at the seal interface and

the product pressure in the stuffing

box.

13 All ports must either be connected

to piping or have a metal pipe

plug installed. Use Chesterton

recommended PTFE tape to install

piping or plugs.

It is recommended to monitor barrier

gas pressure. Use the gauge port

connection marked “M”* (located

opposite the barrier gas supply port).

IM P ORTANT:

All plastic shipping plugs must be

replaced.

CAUTION:

Operation without sufficient barrier

gas supply can cause a loss in seal

performance or failure. The barrier

gas supply must be on whenever

the pump is pressurized or contains

liquid product. The seal will regulate

the usage of barrier gas; do not limit

the flow by use of flow restrictors or

valves.

8

TABLE 4 – 4400H Trouble Shooting

Problem Check IGCS Pressure Differential Solution

High gas usage reading If “M”* Monitor of Face Pressure - “F” Stuffing Box Pressure =

<2,4 bar (35 psi) IGCS is dirty and cleaning or rebuild is required. IGCS may be purged

through the “M” port via a quick actuation of a ¼ turn valve.

>2,1 bar (30 psi)

Ensure seal is square to the pump shaft. Check barrier gas supply line

downstream of flow meter for leaks. Check “M”* port and instrumenta-

tion for leaks. Plan to rebuild seal - most commonly an O-Ring issue.

Low gas usage reading If “M”* pressure - “F” Stuffing Box pressure =

<1,2 bar (18 psi) Restore Barrier gas pressure

>1,5 bar (22 psi) OK and ensure seal gland is not hot.

Product leaking out If “B” Barrier gas pressure is:

>1,7 bar (25 psi) over “F” Stuffing Box pressure Check shaft O-Ring, stuffing box gasket

<1,4 bar (20 psi) over “F” Stuffing Box pressure Restore Barrier gas pressure and dry out seal

Pump loses prime Gas Usage is:

High Vent stuffing box to lower pressure

Normal Operate to right of BEP

6.0 COMMISSIONING / EQUIPMENT START UP

7.0 DECOMMISSIONING / EQUIPMENT SHUT DOWN

8.0 SPARE PARTS

9.0 SEAL MAINTENANCE AND REBUILD

9.1 4400H Trouble Shooting

1. If possible, turn the shaft by hand to ensure free rotation with no shaft binding.

A slight drag may be found due to the seal faces but the shaft should rotate freely.

2. Ensure the pump is primed and all piping connections are correctly fitted and

fittings are leak-free. Fill and vent the equipment in accordance with the instructions

of the equipment manufacturer. Ensure barrier gas is connected and available to the

4400H gas seal. Confirm correct shaft rotation direction for the installed seal.

3. Before starting the equipment, ensure all nuts and screws are securely fastened.

4. Take all necessary precautions and follow normal safety procedures before starting

the equipment.

Ensure that the equipment is de-energized and de-pressurized. If the equipment

has been used on toxic or hazardous fluids, ensure that the equipment is correctly

decontaminated and made safe prior to commencing work. Ensure that the pump is

isolated and check that the stuffing box is drained from any fluid and pressure is fully

released. Dismantle the equipment according to the equipment instruction manual

and remove the seal in the reverse order to installation. In case of disposal, ensure the

local regulations and requirement for disposal or recycling of the different components

in the seal are adhered to.

Use only Chesterton original spare parts. Use of non-original spare parts represents

risk of failure, danger to persons/equipment and voids the product warranty.

Spare Parts Kit can be purchased from Chesterton, referencing the recorded seal

data from cover page.

In Gland Control System Rebuild/Spare Parts Kit must be ordered separate from

4400H TwinHybrid™ Gas Seal Rebuild/Spare Parts Kit. Reference the recorded seal

data from cover page when ordering IGCS Rebuild/Spare Parts Kit.

10

9.0 SEAL MAINTENANCE AND REBUILD cont.

9.2 4400H TwinHybrid™Gas Seal Rebuild Instructions (cont.)

13

11

8

14

27

28

28

27

15 16

12

˜20X

B X

B X

14 15

28

27

28

13a

20

3

36

33

35

21

17

19

18

X

B

X

19

6

29

F

B

X

X

18

20

21

B

X

17

23 22

24

25

26

B

X

16

10

B

X

M

M

FORM NO. 072907 REV 3 PRINTED IN USA 6/14

860 Salem Street

Groveland, MA 01834 USA

Telephone: 781-438-7000 Fax: 978-469-6528

www.chesterton.com

© A.W.Chesterton Company, 2014. All rights reserved.

® Registered trademark owned and licensed by

A.W.Chesterton Company in USA and other countries.

Chesterton ISO certificates available on www.chesterton.com/corporate/iso

DISTRIBUTED BY:

Table of contents

Other Chesterton Food Saver manuals