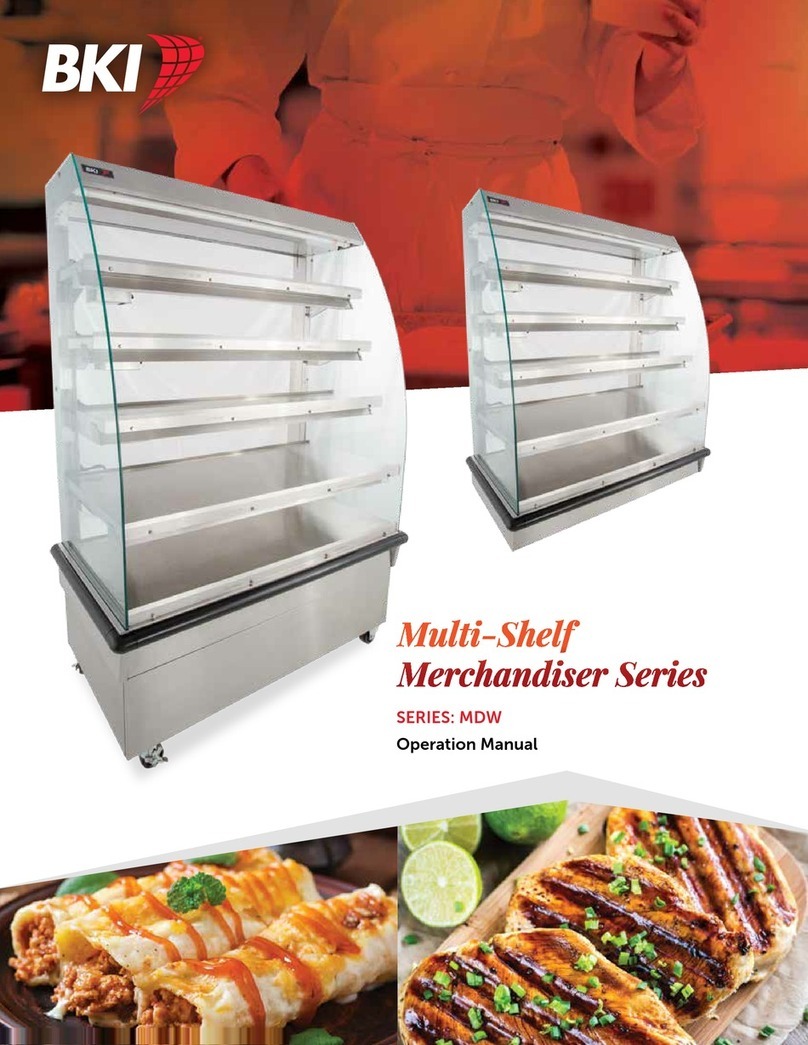

BKI HSS Series User manual

Series: HSS

Service Manual

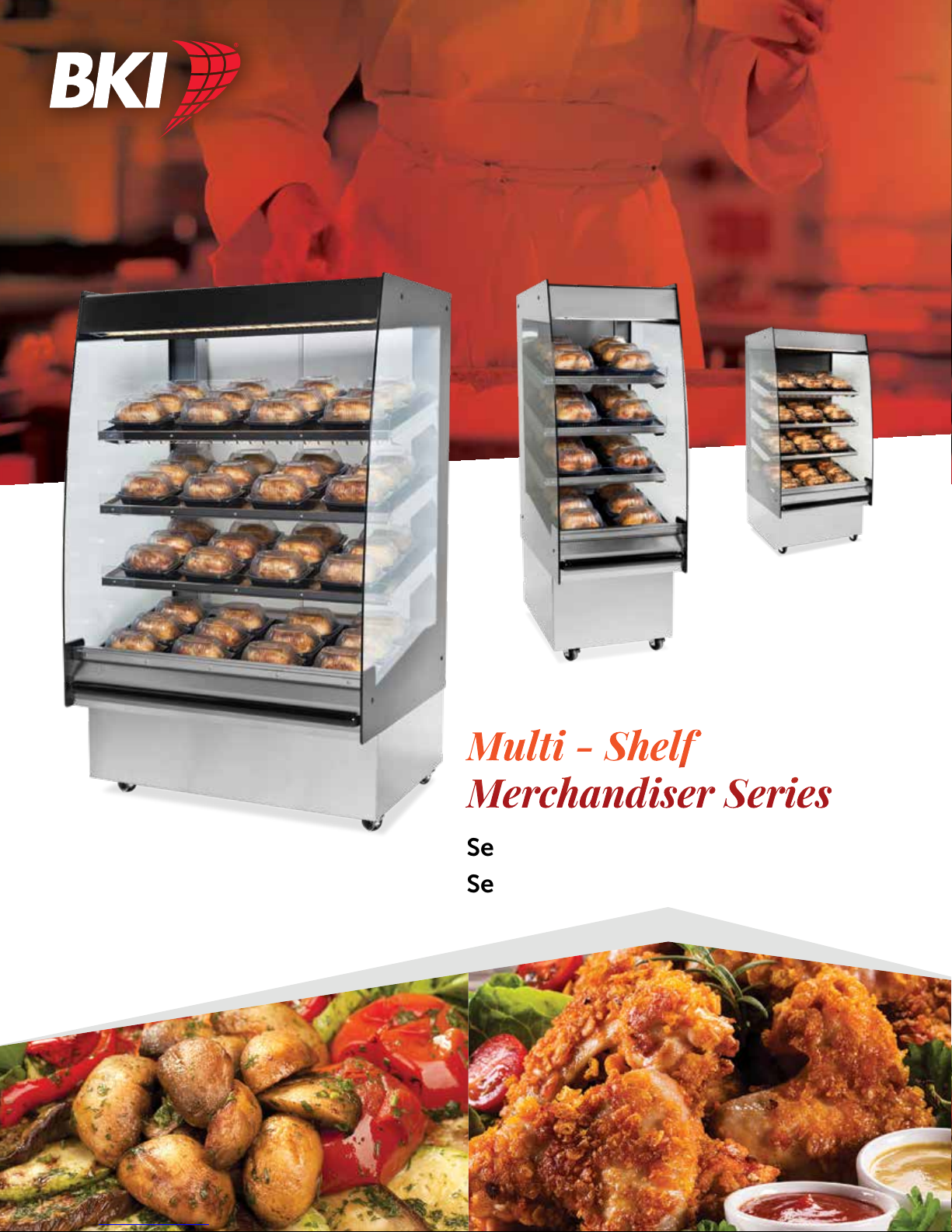

Multi- Shelf

Merchandiser Series

CS-TM-003.01 Revised 10/01/18

BKI LIMITED WARRANTY

2812 Grandview Drive • Simpsonville, SC 29680 • USA

(864) 963-3471 • Toll Free: (800) 927-6887 • Fax: (864) 963-5316

WHAT IS COVERED This warranty covers defects in material and workmanship under normal use, and applies only to the original

purchaser providing that:

9 The equipment has not been accidentally or intentionally damaged, altered or misused;

9 The equipment is properly installed, adjusted, operated and maintained in accordance with national and

local codes, and in accordance with the installation and operating instructions provided with this product.

9 The serial number rating plate affixed to the equipment has not been defaced or removed.

WHO IS COVEREDThis

warranty

is

extended

to the original

purchaser

and applies only

to

equipment purchased

for use

in the U.S.A.

COVERAGE PERIOD 9

Warranty claims must be received in writing by BKI within one (1) year from date of installation or within

one (1) year and three (3) months from data of shipment from the factory, whichever comes first.

9

COB Models: One (1) Year limited parts and labor.

9 COM Models: Two (2) Year limited parts and labor. COM convection ovens also have a two (2) year door warranty.

9

CO1 Models: Two (2) Year limited parts and labor. Five (5) Year limited door warranty.

9 BevLes Products: Two (2) Year limited parts and labor.

9

Warranty period begins the date of dealer invoice to customer or ninety (90) days after shipment date from

BKI, whichever comes first.

WARRANTY COVERAGE This

warranty

covers on-site labor, parts and

reasonable

travel

time

and travel e

xpenses

of

the

authorized

service

representative

up

to

(100) miles

round

trip and (2)

hours

travel time

and

performed

during

regular,

weekday

business

hours

.

EXCEPTIONS Any exceptions must be pre-approved in advance and in writing by BKI. The extended door warranty on

convection ovens years 3 through 5 is a parts only warranty and does not include labor, travel, mileage or

any other charges.

EXCLUSIONS 9

Negligence

or acts of

God,

9

Thermostat

calibrations

after (30) days

from

equipment

installation

date,

9 Air and g

as

adjustments,

9 Light

bulbs,

9 Glass doors and

door

adjustments,

9

Fuses,

9

Adjustments

to

burner

flames and

cleaning

of

pilot

burners,

9

Tightening

of screws

or

fasteners,

9 Failures

caused

by erratic

voltages

or gas suppliers,

9

Unauthorized

repair by

anyone

other

than

a BKI F

actory

Authorized

Service Center,

9

Damage

in

shipment,

9

Alteration,

misuse or

improper

installation,

9

Thermostats

and safety valves with

broken

capillary tubes,

9 Freight

–

other

than

normal UPS charges,

9

Ordinary

wear and

tear,

9 Failure to follow

installation

and/or

operating

instructions,

9 Events

beyond

control

of the

company.

INSTALLATION Leveling, as well as

proper

installation

and check out of all

new

equipment

-

per

appropriate

installation

and use materials – is t

he

responsibility of the

dealer

or installer, not the

manufacturer.

REPLACEMENT PARTS

BKI

genuine

Factory OEM parts receive a (90) day

materials

warranty

effective from the date of

installation

by a BKI F

actory

Authorized

Service

Center.

Warranty

is in lieu of all

other

warranties,

expressed

or implied, and all

other

obligations

or liabilities on the

manufacturer’s

part.

BKI shall in no

event

be liable for any special,

indirect

or

consequential damages,

or in any

event

for

damages

in excess of the

purchase

price of the unit. The repair or

replacement

of

proven

defective

parts shall

constitute

a

fulfillment of all

obligations

under

the terms of this

warranty.

CS-TM-003.01 Revised 10/01/18

Table of Contents

Table of Contents ................................................................................................................................................................. 1

Introduction ........................................................................................................................................................................... 2

Shipping Damage ............................................................................................................................................................... 2

Safety Precautions ............................................................................................................................................................. 3

Safety Signs and Messages .......................................................................................................................................... 3

Specific Precautions ...................................................................................................................................................... 3

Safe Work Practices ...................................................................................................................................................... 4

Health And Sanitation Practices .................................................................................................................................... 6

Food Handling ............................................................................................................................................................... 6

Storage Of Raw Meats .................................................................................................................................................. 6

Coding Cooked Foods ................................................................................................................................................... 6

Storage Of Prepared Foods ........................................................................................................................................... 6

Installation ............................................................................................................................................................................. 7

Floor Model ........................................................................................................................................................................ 7

Counter Model .................................................................................................................................................................... 8

Caster Model ...................................................................................................................................................................... 8

Wiring ................................................................................................................................................................................. 8

General Guidelines ........................................................................................................................................................ 8

Guidelines for European Appliances ............................................................................................................................. 8

Operation ............................................................................................................................................................................. 10

Controls and Indicators .................................................................................................................................................... 10

Power Up and Preheating ................................................................................................................................................ 10

Operational Guidelines ..................................................................................................................................................... 11

Unit Shutdown .................................................................................................................................................................. 11

Temperature Adjustment .................................................................................................................................................. 12

Maintenance ........................................................................................................................................................................ 13

Cleaning (Daily) ................................................................................................................................................................ 13

Troubleshooting ............................................................................................................................................................... 14

Parts Lists ........................................................................................................................................................................... 15

Exterior Parts ................................................................................................................................................................... 15

Shelves ............................................................................................................................................................................ 17

Blower / Heater Assembly ................................................................................................................................................ 18

Control Parts .................................................................................................................................................................... 19

Wiring Diagrams ................................................................................................................................................................. 20

Notes.................................................................................................................................................................................... 34

HSS Hot Food Merchandiser Introduction

CS-TM-003.01 Revised 10/01/18

2

Introduction

Your BKI HSS is a multi-deck, self-service hot food merchandiser. It utilizes a gentle hot air convection to maintain

products at a safe temperature for an extended period of time. The temperature of each heated zone can be controlled

independently. The shelves have a marine edge to retain spills and are made of stainless steel for durability and easy

cleaning.

The BKI name and trademark on this unit assures you of the finest in design and engineering -- that it has been built with

care and dedication -- using the best materials available. Attention to the operating instructions regarding proper

installation, operation, and maintenance will result in long lasting dependability to ensure the highest profitable return on

your investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If you have

any questions, please contact your BKI Distributor. If they are unable to answer your

questions, phone the applicable BKI Technical Services Department:

BKI North America: (864) 963-3471

BKI Europe: (44) 0870 9904242

Serious injury, equipment damage or death could result if attempting to install this unit

yourself. Ensure that an authorized BKI service agent install the oven.

Shipping Damage

Inspect all cartons and crates for damage as soon as they arrive. If damage to cartons or crates is found, or if a shortage

is found, note this on the bill of lading (all copies) prior to signing.

If damage is found when the equipment is opened, immediately call the carrier and follow up the call with a written report

indicating concealed damage to your shipment. Ask for an immediate inspection of your concealed damage item.

Packaging material MUST be retained to show the inspector from the carrier.

This equipment is carefully packed or crated at our factory. The carrier has assumed responsibility to delivery it safely. If

damaged, the owners must file claim with the carrier.

Do not place heavy objects on top of the unit or damage could occur. The units

are not structurally designed to support excessive external loading.

HSS Hot Food Merchandiser Introduction

CS-TM-003.01 Revised 10/01/18

3

Safety Precautions

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol. When you see this

symbol on your equipment, be alert to the potential for personal injury or property damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify specific areas

where potential hazards exist and special precautions should be taken. Know and understand the meaning of these

instructions, signs, and messages. Damage to the equipment, death or serious injury to you or other persons may result if

these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe practices.

This message is used when special information, instructions or identification are required

relating to procedures, equipment, tools, capacities and other special data.

Specific Precautions

California Residents Only. This product can expose you to chemicals including

chromium, and lead which are known to the State of California to cause cancer

and birth defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov.

Equipotential Ground Plane

When a high current flows through a conductor, differences in potential appear between

the conductor and nearby metallic surfaces near the appliance. As a result, sparks may

be produced between the appliance and surrounding metal surfaces. These sparks

could cause serious injury, damage, or fire.

HSS Hot Food Merchandiser Introduction

CS-TM-003.01 Revised 10/01/18

4

Full Disconnection for IEC / CE Regulations

In accordance with Local and/or National wiring codes, the installer must provide a

means of full disconnection for overvoltage Category III conditions. An IEC approved

cord and plug combination will meet this requirement.

Units not provided with a cord and plug do not meet this requirement. In accordance with

Local and/or National wiring codes, the installer must provide the means of full

disconnection.

Safe Work Practices

Wear Safe Clothing Appropriate To Your Job

Always wear insulated mitts when handling hot products or touching any hot metal

surface. You can buy insulated mitts at your local restaurant equipment supply store

or from your local BKI Distributor.

Always wear non-skid shoes when working around the oven or any other

equipment.

Always wear appropriate personal protection equipment during the cleaning

process to guard against possible injury.

WARNING – DANGEROUS VOLTAGE

This equipment uses high voltage. Serious injury can occur if you or any untrained

or unauthorized person installs, services, or repairs this equipment. Always Use an

Authorized Service agent to Service Your Equipment.

Keep this manual with the Equipment

This manual is an important part of your equipment. Always keep it near for easy

access. If you need to replace this manual, phone the applicable BKI Technical

Services Department:

BKI North America: (864) 963-3471

BKI Europe: (44) 0870 9904242

HSS Hot Food Merchandiser Introduction

CS-TM-003.01 Revised 10/01/18

5

Protect Children

Keep children away from this equipment. Children may not understand that this

equipment is dangerous for them and others.

NEVER allow children to play near or operate your equipment.

Keep Safety Labels Clean and in Good Condition

Do not remove or cover any safety labels on your equipment. Keep all safety labels

clean and in good condition. Replace any damaged or missing safety labels. Refer

to the Safety Labels section for illustration and location of safety labels on this unit.

If you need a new safety label, obtain the number of the specific label illustrated on

page 5, then phone the applicable BKI Technical Services Department:

BKI North America: (864) 963-3471

BKI Europe: (44) 0870 9904242

Be Prepared for Emergencies

Be prepared for fires, injuries, or other emergencies.

Keep a first aid kit and a fire extinguisher near the equipment. You must use a 40-

pound Type BC fire extinguisher and keep it within 25 feet of your equipment.

Keep emergency numbers for doctors, ambulance services, hospitals, and the fire

department near your telephone.

Know your responsibilities as an Employer

• Make certain your employees know how to operate the equipment.

• Make certain your employees are aware of the safety precautions on the

equipment and in this manual.

• Make certain that you have thoroughly trained your employees about operating

the equipment safely.

• Make certain the equipment is in proper working condition. If you make

unauthorized modifications to the equipment, you will reduce the function and

safety of the equipment.

HSS Hot Food Merchandiser Introduction

CS-TM-003.01 Revised 10/01/18

6

Health and Sanitation Practices

BKI hot food merchandisers are manufactured to comply with health regulations and are tested and certified to NSF and

FSA standards. You must operate the equipment properly, using only quality products and use meat thermometers to

insure meats are thoroughly cooked.

Food Handling

• Wash hands thoroughly in warm, soapy water after handling raw poultry or meats.

• Clean and sanitize all utensils and surfaces that have been in contact with raw products. Clean and sanitize the

meat forks or baskets between cooking.

• Never place cooked meats on the same surfaces used to prepare raw meats, unless the area has been

thoroughly cleaned and sanitized.

Storage of Raw Meats

• Designate an area or shelf strictly for the storage of all raw meats to be used.

• Raw product must always be stored at temperatures below 38° F. (3° C.).

• Never store or mix raw foods above cooked foods, as this is a health hazard. The drippings from raw foods

contaminate cooked or processed foods.

• All chicken and chicken parts to be stored overnight must be thoroughly iced down and refrigerated.

Coding Cooked Foods

All products cooked during the day should be sold the same day.

NOTE: It is not the intent of the rotisserie program to have unsold merchandise at the end of the cooking day. Follow your

company’s procedures for the handling of any leftover product.

Storage of Prepared Foods

• Cold foods should be kept at or below 38° F. (3° C.).

• Hot foods must be maintained to meet local health codes, usually a minimum 145° F. (63° C.).

HSS Hot Food Merchandiser Installation

CS-TM-003.01 Revised 10/01/18

7

END KICK PLATES

FIT BEHIND FRONT

KICK PLATES

RAISE LOWER

BEFORE LEVELING -

SLIDE KICK PLATES,

ENDS FIRST, BETWEEN

BASE FRAME & OUTER

PANELS.

SECURE IN RAISED

POSITION WITH TAPE.

DRILL FRAME 9/64"

TO MATCH HOLES

IN KICK PLATES

SECURE with SCR355

#8x1/2" BLACK SCREWS

SEAL KICK PLATES TO

FLOOR with SILICONE

Installation

Serious injury, equipment damage or death could result if attempting to install this

unit yourself. Ensure that an authorized BKI service agent install the unit.

Move the unit as close as possible to its permanent location before moving it off of the shipping pallet. Make certain there

are no separately packed accessories before discarding packaging material.

Floor Model

Follow the procedure below to level the unit and mount the kick plates.

1. Slide kick plates,

ends first, between

the base frame and

outer panels. Secure

in raised position with

tape. Make sure that

the end kick plates fit

behind the front and

rear kick plates.

2. Using a carpenter’s

level on the lowest

shelf, level the unit by

adjusting the leg

levelers at the

corners of the unit.

Raise the low end of

the unit to level it, do

not lower the high

end. Check for level

side-to-side and front-

to-back.

3. Remove the tape

from the kick plates

and make certain that

the kick plates are

flush to the floor.

4. Drill 9/64” [3.5 mm]

diameter holes in the

base frame to match

the pre-drilled holes

in the kick plates.

5. Attach the kick plates

to the base frame

with the #8x1/2” black

sheet metal screws

provided (SCR355).

6. Seal kick plates to

floor using a silicone-

type sealant (Dow

Corning RTV #732 or

equivalent).

Figure 1. Floor Model – Leveling & Kick Plate Mounting

HSS Hot Food Merchandiser Installation

CS-TM-003.01 Revised 10/01/18

8

Counter Model

Counter mounted units must be mounted on a level surface that can support the weight of the unit and it’s contents. Use a

carpenter’s level to level the unit.

These units are to be sealed to the counter if required by local health codes. Seal the perimeter of the units to the counter

using a silicone-type sealant (Dow Corning RTV #732 or equivalent).

Caster Model

Caster mounted units must be moved to a permanent location and the two swivel casters locked before using.

Do not place heavy objects on top of the unit or damage could occur. The units

are not structurally designed to support excessive external loading.

Wiring

Electrocution, equipment failure or property damage could result if an unlicensed

electrician performs the electrical installation. Ensure that a licensed electrician

perform the electrical installation in accordance with local codes, or in the absence

of local codes, with the National Electrical Code, ANSI NFPA 70-20XX.

This unit, when installed by an authorized BKI service agent, must be wired for use in accordance with all applicable local,

state, and federal codes. For specific electrical requirements and connections refer to the wiring diagram attached to the

unit or provided in the Service Manual.

General Guidelines

• In the absence of local codes refer to the latest edition of one of the following:

• National Electrical Code, ANSI/NFPA 70-20XX (USA) which can be obtained from:

The National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

• I.E.E. Wiring Regulations (Europe)

• Verify that the power supply conforms to the electrical rating listed on the oven data plate.

• Ensure that the appliance is grounded (earthed).

Guidelines for European Appliances

Note: - A method of disconnection from the main supply having a contact separation of least 3mm in all poles must be

incorporated in the fixed wiring.

• It is recommended that an R.C.D. with a 30ma trip and contact rating to suit the appliance current be installed

adjacent to the appliance.

• Type C/ 3 circuit breakers or appropriate rated fuses are recommended for installation at the supply end.

Note: - surge currents are present when this appliance is switched on from cold.

• Industrial plugs and sockets must comply with BS 4343/EN60309 (IEC309.2/CEE17).

HSS Hot Food Merchandiser Installation

CS-TM-003.01 Revised 10/01/18

9

Supply Cable Connection

• It is recommended that the power supply cable shall be an oil resistance sheathed flexible cable to BS 6007 (code

designation HO7 RN-F).

• It is required that the power supply cable connection to the appliance terminal block, the earth conductor is to be

made at least 50mm longer than the length of the live (L) and neutral (N) conductors so that if the supply cable is

strained the earth conductor is the last to become disconnected.

• To gain access to the control panel and mains block connection, remove the 4-side panel securing screws on the

drive side of the oven.

• The mains block is sited toward the bottom right hand side of the control box. Cable entry is provided through the

base of the oven.

• Refer to the mains wiring diagram for correct connection.

HSS Hot Food Merchandiser Operation

CS-TM-003.01 Revised 10/01/18

10

Operation

2

3

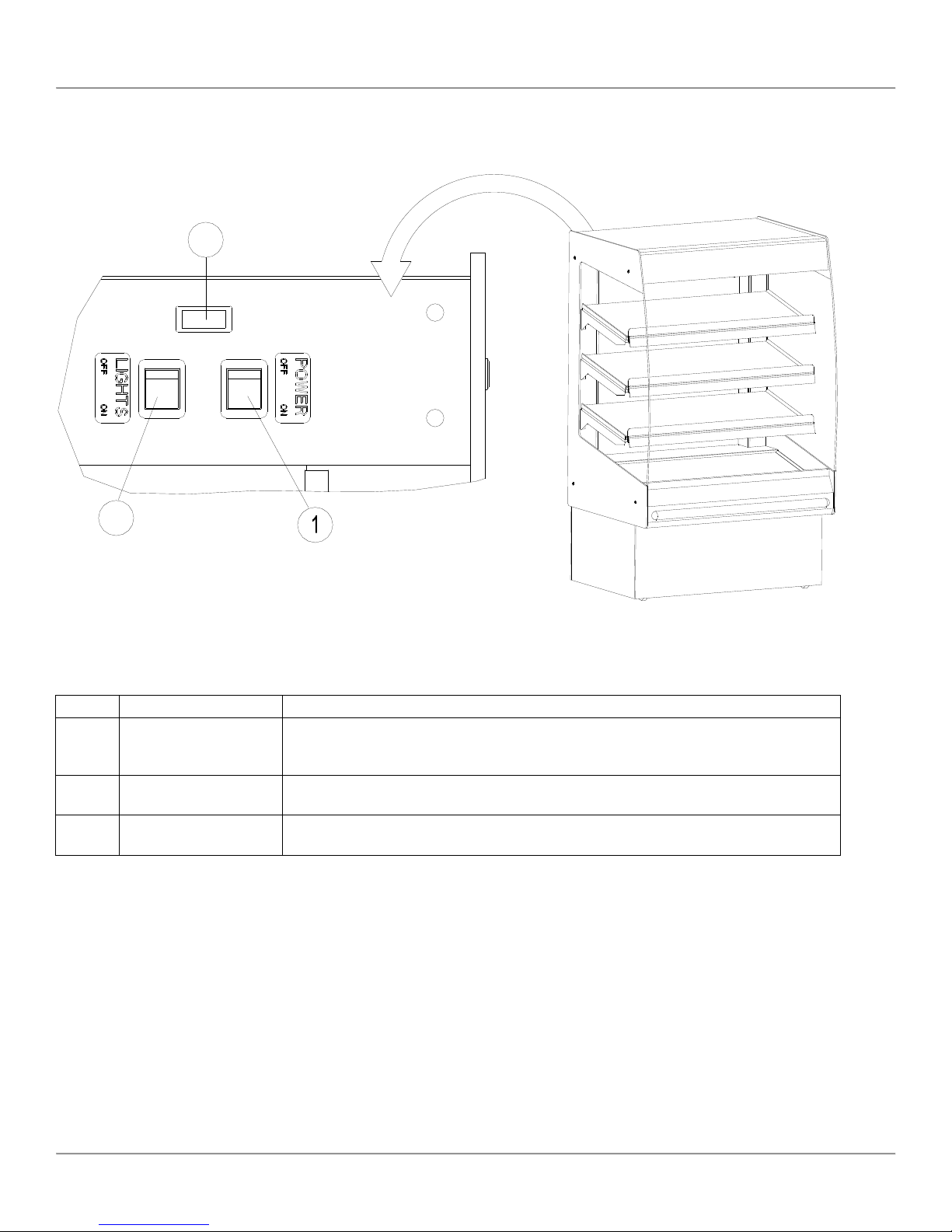

Figure 2. Main Power & Light Switches

Controls and Indicators

Item #

Description

Function

1

Main Power Switch

Turns power to the entire unit on or off. When placed in the on position, the

unit heats to the preset temperature. When placed in the off position, power is

removed from the entire unit.

2

Main Power Isolator

Light

This light illuminates to indicate that power is being applied to the unit from the

Main Power Isolator (Circuit Breaker).

3

Light Switch

Turns power to the lights on or off. Operates only when the Main Power

Switch is placed in the on position.

Power Up and Preheating

1. Ensure that the power supply cord is connected to an appropriate power receptacle.

2. Place the Main Power Switch in the ON position.

3. Place the Light Switch in the ON position.

4. Allow the unit to preheat for a minimum of 30 minutes before loading it with product.

HSS Hot Food Merchandiser Operation

CS-TM-003.01 Revised 10/01/18

11

Operational Guidelines

Unit is intended for pre-package food products only.

All food products should be preheated to 70°C (160°F ) minimum before being placed in the unit.

Only use product packaging suitable for the application.

Do not stack product packages on the shelf. Bottom of all product packages must be in contact with shelf service.

Maintain a minimum 50 mm [2 in.] space between the top of the product package and the bottom of the shelf above it.

Measure the internal temperature of the food products hourly with a food thermometer.

Check Federal and State Health and Sanitation Regulations for internal temperature required for holding cooked foods for

sale. Maintaining these temperatures often tends to allow continued cooking of certain products. Therefore, smaller

amounts of bulk foods should be displayed at non-peak periods and the unit refilled as needed.

Foods held for long periods of time are more difficult to maintain at proper temperature. Also, freshness and product

quality diminish if foods are held too long. Most areas of the country have sanitation regulations governing how long foods

can be held. Make certain to check with your local authorities.

Unit Shutdown

1. Remove product from the unit.

2. Place the Main Power Switch in the OFF position.

3. Place the Light Switch in the OFF position.

4. After the unit has cooled down, remove any residue from the shelves and clean the unit thoroughly with mild

soapy solution.

5. Clean and polish glass with a good quality glass cleaner.

DO NOT FLOOD! Use only enough solution the clean surface. Water or solution must

not drip down into base.

Never use ammonia based cleaners, abrasive cleansers or scouring pads.

HSS Hot Food Merchandiser Operation

CS-TM-003.01 Revised 10/01/18

12

70°C / 160°F

80°C / 175°F

90°C / 190°F

REMOVE COVER TO

ACCESS THERMOSTAT

Temperature Adjustment

The temperature of each shelf’s surface is individually controlled via an adjustable thermostat. All of the thermostats are

preset at the factory. It may be necessary to adjust the controls due to the food product type or store ambient conditions.

Remove power from the unit before adjusting the thermostats.

Failure to remove power from this unit may cause severe electrical shock. This unit may

have more than one disconnect switch.

The thermostats for the intermediate shelves are accessed by removing the lamp guard and lamp then the cover on the

face of the wireway below each shelf. The thermostat for the base warmer is accessed by removing the cover on the

lower back of the unit.

Temperature setting is indicated by the three holes in the thermostat mount. Refer to Figure 2 below. Adjust the

temperature setting of each thermostat up or down as required. It is recommended that the temperature setting not be

adjusted more than 5°C (8° F ).

After adjustment verify the temperature settings by monitoring the internal temperature of the food products. The

temperature should be adjusted to the lowest possible setting that will maintain the proper product temperature.

Figure 3. Thermostat Adjustment

HSS Hot Food Merchandiser Maintenance

CS-TM-003.01 Revised 10/01/18

13

Maintenance

Cleaning (Daily)

Cleaning is not only necessary for sanitary reasons, but will increase sales appeal and maximize operating efficiency of

the unit.

Failure to remove power from this unit may cause severe electrical shock. This unit may

have more than one disconnect switch.

Always wear appropriate personal protection equipment during the cleaning process to

guard against possible injury.

Never use ammonia based cleaners, abrasive cleansers or scouring pads. These may

damage the unit’s finish. Use only a mild soap and water solution.

DO NOT USE OVEN CLEANER on this machine. Caustic cleaners can cause damage to

the unit.

DO NOT FLOOD! Use only enough solution the clean surface. Water or solution must

not drip down into base

This appliance is not intended to be cleaned with a water jet. Never steam clean or get

excess water in the interior of the cabinet as this can damage unit.

1. Remove product from the unit.

2. Place the Main Power Switch circuit breaker in the OFF position.

3. Place the Light Switch in the OFF position.

4. After the unit has cooled down, remove any residue from the shelves and clean the unit thoroughly with mild

soapy solution.

5. Apply a soft, damp cloth with soapy water to the polycarbonate shelf risers. NOTE: DO NOT use glass cleaner or

paper towels on the polycarbonate shelf risers as they may scratch the surfaces.

6. Clean and polish glass with a good quality glass cleaner.

HSS Hot Food Merchandiser

CS-TM-003.01 Revised 10/01/18

14

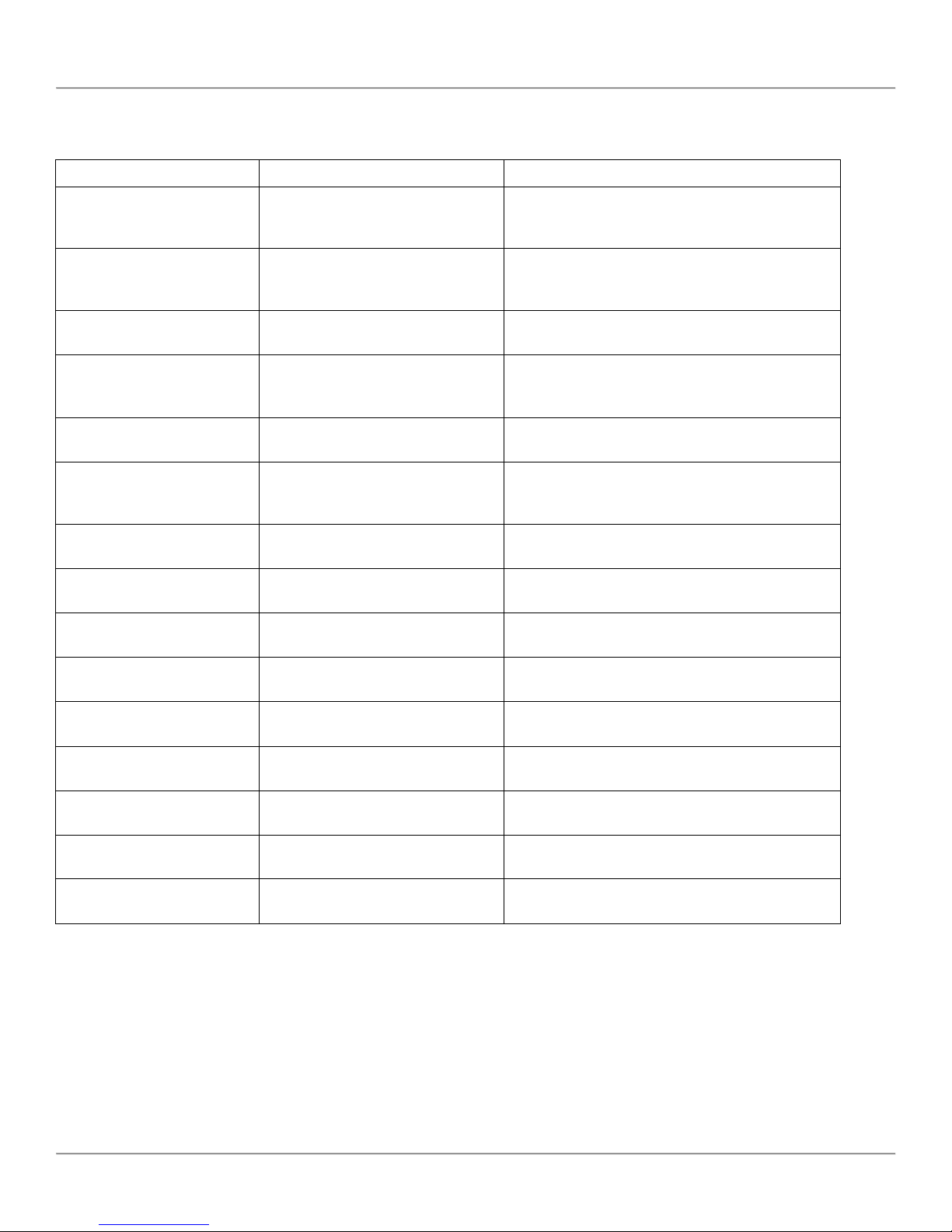

Troubleshooting

Problem

Cause

Possible Solution

Unit will not turn on.

Main Power Isolator Light

is not lit.

Unit power plug disconnected

(where applicable).

Plug unit into mating receptacle.

Problem with building power

supply

Check circuit breaker at building power panel.

If problem persists, contact BKI service agent

for corrective action.

Fuse in power cord plug is blown

(British units only).

Contact BKI service agent for corrective

action.

Unit will not turn on.

Main Power Isolator Light

is lit.

Defective contactor.

Contact BKI service agent for corrective

action.

Defective rocker switch

Contact BKI service agent for corrective

action.

Air curtain is weak or non-

existent.

Block air curtain discharge.

Remove any items blocking the air curtain

discharge. Make certain no signage is

obstructing discharge.

Defective fan(s)

Contact BKI service agent for corrective

action.

A shelf does not maintain

product temperature.

Shelf thermostat setting is too

low.

Contact BKI service agent for corrective

action.

Defective heating element(s).

Contact BKI service agent for corrective

action.

A shelf does not heat to

temperature.

Defective thermostat.

Contact BKI service agent for corrective

action.

Defective heating element(s).

Contact BKI service agent for corrective

action.

A shelf overheats.

Defective thermostat.

Contact BKI service agent for corrective

action.

Lights do not illuminate

when switch is on.

Blown fuse.

Contact BKI service agent for corrective

action.

Defective bulb.

Contact BKI service agent for corrective

action.

Defective ballast.

Contact BKI service agent for corrective

action.

HSS Hot Food Merchandiser Parts Lists

CS-TM-003.01 Revised 10/01/18

15

Parts Lists

Use the information in the section to identify parts. To order parts, call your local BKI sales and service representative.

Before calling, please note the model and serial numbers on the rating tag affixed to the unit.

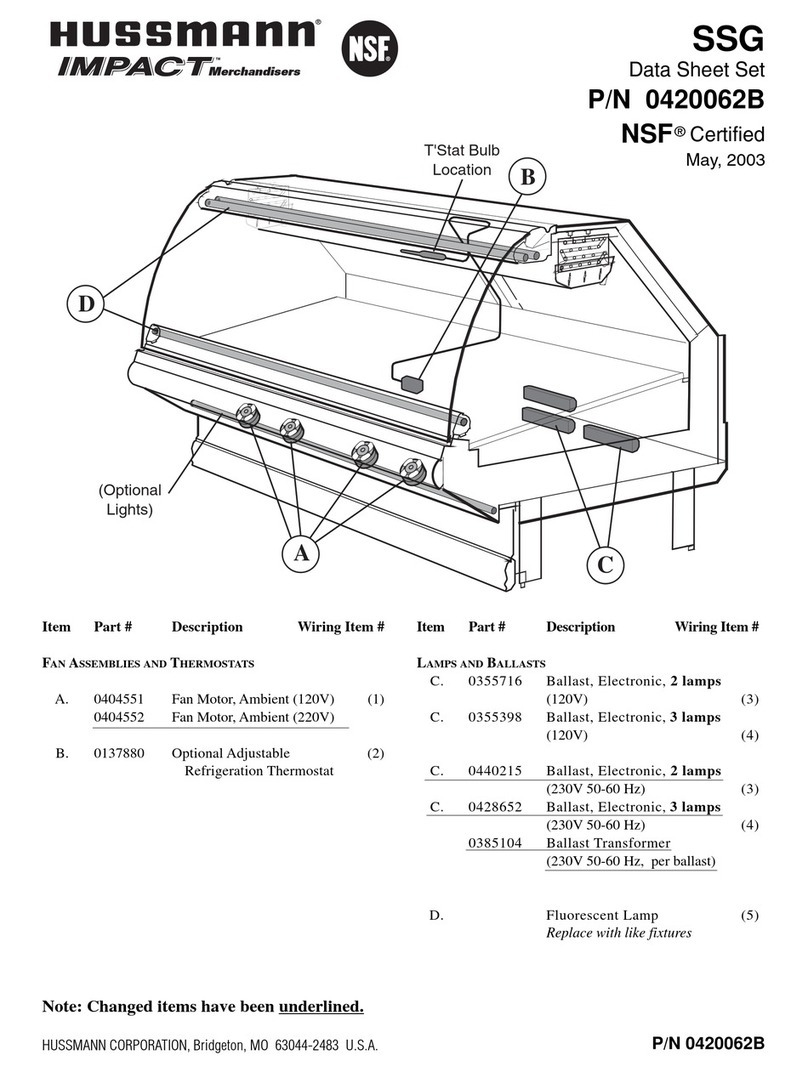

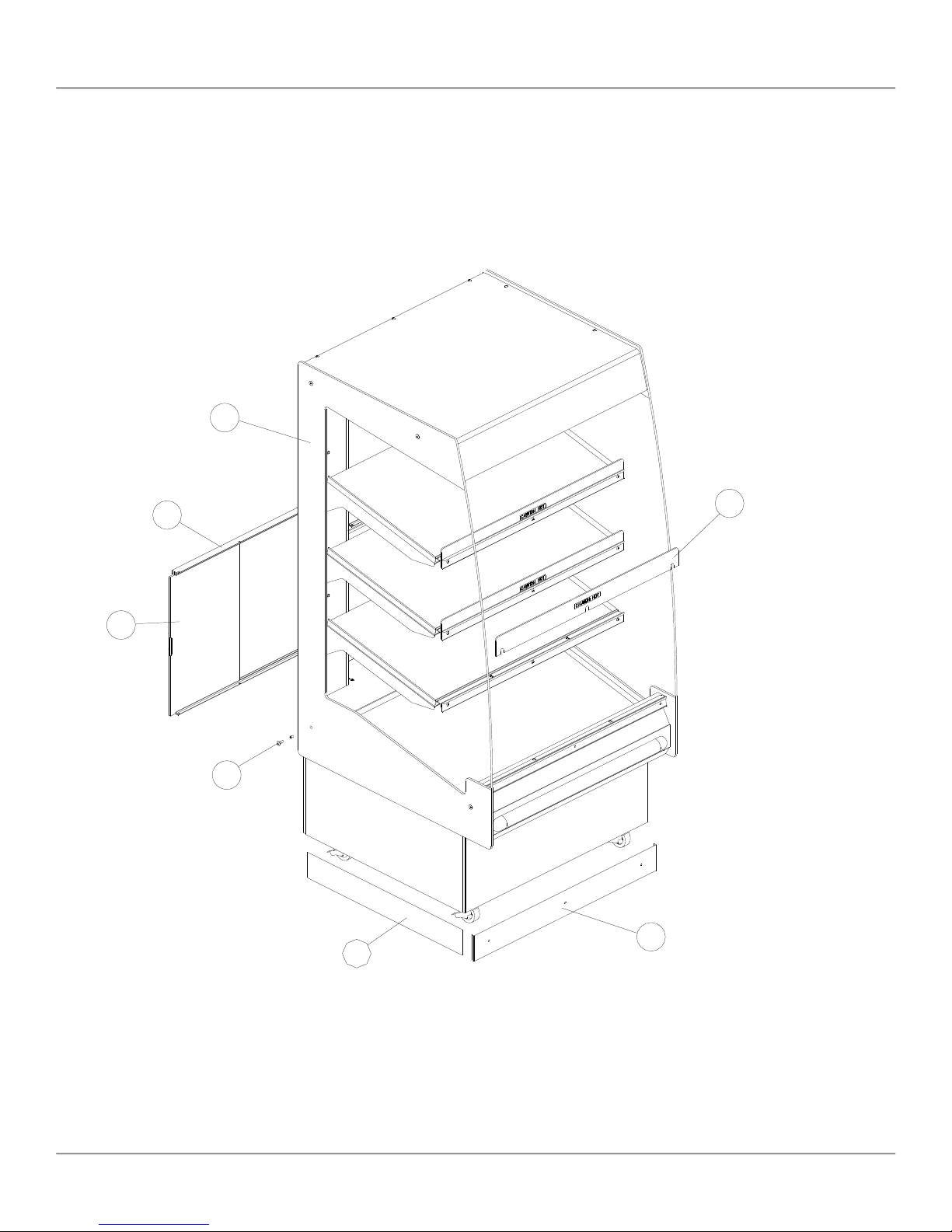

Exterior Parts

1

2

3

4

6

7

5

HSS Hot Food Merchandiser Parts Lists

CS-TM-003.01 Revised 10/01/18

16

Table 1. Exterior Parts

ITEM#

MODEL#

PART #

QTY

DESCRIPTION

1

HSS-2T

GL0425G

1

LH End Glass, Gray, HSS-2T

GL0424G

1

RH End Glass, Gray, HSS-2T

HSS-3T & 4S

GL0422M

1

LH End Glass, Black, HSS-3T & 4S

GL0422G

LH End Glass, Gray, HSS-3T & 4S

GL0423M

1

RH End Glass, Black, HSS-3T & 4S

GL0423G

RH End Glass, Gray, HSS-3T & 4S

HSS-4T & 5T

GL0420M

1

LH End Glass, Black, HSS-4T & 5T

GL0420G

LH End Glass, Gray, HSS-4T & 5T

GL0421M

1

RH End Glass, Black, HSS-4T & 5T

GL0421G

RH End Glass, Gray, HSS-4T & 5T

2

ALL

BLT248

8

Bolt, ¼”-20 Joint, Black

B0233

8

Bearing, Cylinder

3

HSS4-2T

AN7003700S

1

LH Inner Service Door

AN7003710S

1

RH Outer Service Door

HSS3-3T & 4S

AN7003720S

4

Service Door, Lexan

HSS3-4T & 5T

AN7003730S

4

Service Door, Lexan

HSS4-3T & 4S

AN7003740S

4

Service Door, Lexan

HSS4-4T & 5T

AN7003750S

4

Service Door, Lexan

4

HSS3-3T & 4T

MB70034000

2

Door Track, Set (top & Bottom)

HSS4-3T & 4T

MB70034100

2

Door Track, Set (top & Bottom)

ALL

SCR268

12

Screw, #8 x ½” Flat Head

5

HSS2

R0177

2, 3 or 4

Shelf Riser

HSS3

R0181

2, 3 or 4

Shelf Riser

HSS4

R0178

2, 3 or 4

Shelf Riser

ALL

N0594

2, 3 or 4

Decal, Caution Hot

6

HSS4-2T

FB70005601

1

Front Kick Plate, Bright SSTL

FB70005701

1

Rear Kick Plate, Bright SSTL

HSS2-3T, 4S, 4T & 5T

FB70036451

2

Front & Rear Kick Plate, Black

HSS3-3T, 4S, 4T & 5T

FB70036551

2

Front & Rear Kick Plate, Black

HSS4-3T, 4S, 4T & 5T

FB70036651

2

Front & Rear Kick Plate, Black

7

HSS4-2T

FB67636301

1

Left End Kick Plate, Bright SSTL

FB67636401

1

Right End Kick Plate, Bright SSTL

ALL OTHERS

FB70036351

2

End Kick Plate, Black

HSS Hot Food Merchandiser Parts Lists

CS-TM-003.01 Revised 10/01/18

17

THERMOSTAT ACCESS

TABS ON GUARD

INSERT INTO SLOTS

IN SHELF WIREWAY

1

4

5

2

3

6

7

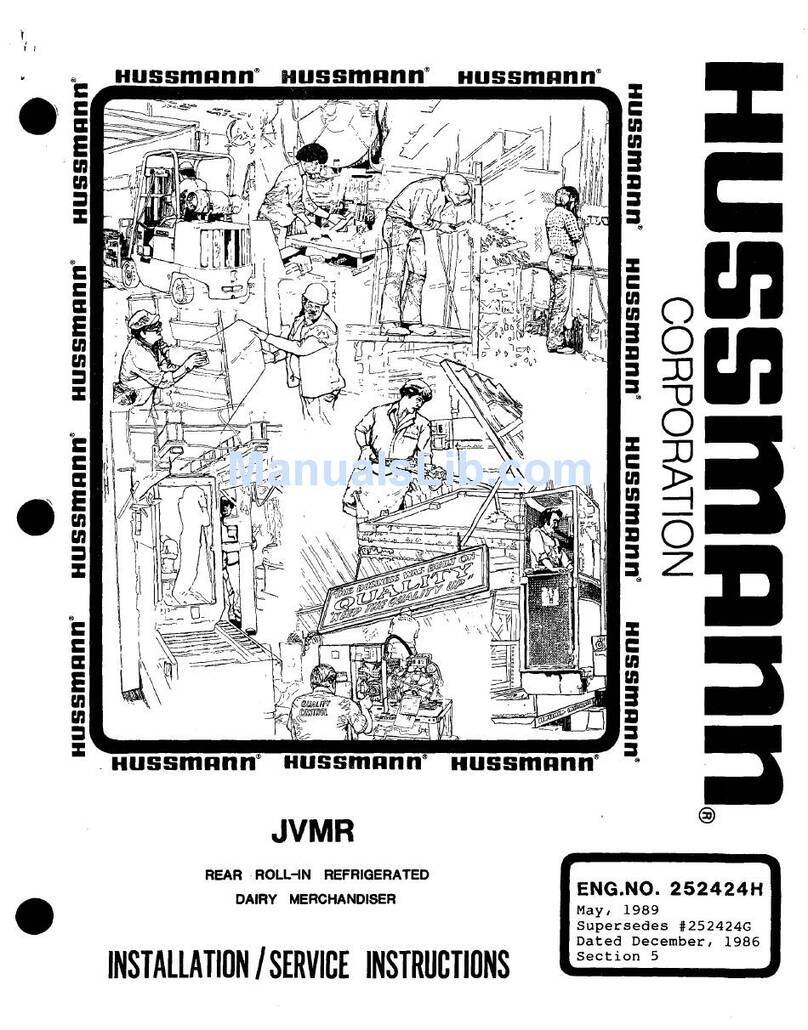

Shelves

Table 2. Shelf Parts

ITEM#

MODEL#

PART #

QTY

DESCRIPTION

1

HSS2

C0157

1

Heating Element, 300W, 208V

C0158

1

Heating Element, 300W, 230V

HSS3

C0763

1

Heating Element, 450W, 208V

C0762

1

Heating Element, 450W, 230V

HSS4

C0157

2

Heating Element, 300W, 208V

C0158

2

Heating Element, 300W, 230V

2

ALL

T0106

1

Thermostat. 85-230F

TP0040

6”

Foil Tape, 3” Wide

3

ALL

K0049

1

Knob, Thermostat

4

HSS2

FL0047

1

Lamp, Coated Fluorescent, F14T5

HSS3

FL0044

1

Lamp, Coated Fluorescent, F21T5

HSS4

FL0045

1

Lamp, Coated Fluorescent, F28T5

5

ALL

LH0025

2

Lampholder, T5

6

HSS2

WB70003700

1

Shelf Top, HSS2

HSS3

WB70028900

1

Shelf Top, HSS3

HSS4

WB70003800

1

Shelf Top, HSS4

7

HSS2

FB70025103

1

Lamp Guard, Shelf

HSS3

FB70030103

1

Lamp Guard, Shelf

HSS4

FB70025203

1

Lamp Guard, Shelf

HSS Hot Food Merchandiser Parts Lists

CS-TM-003.01 Revised 10/01/18

18

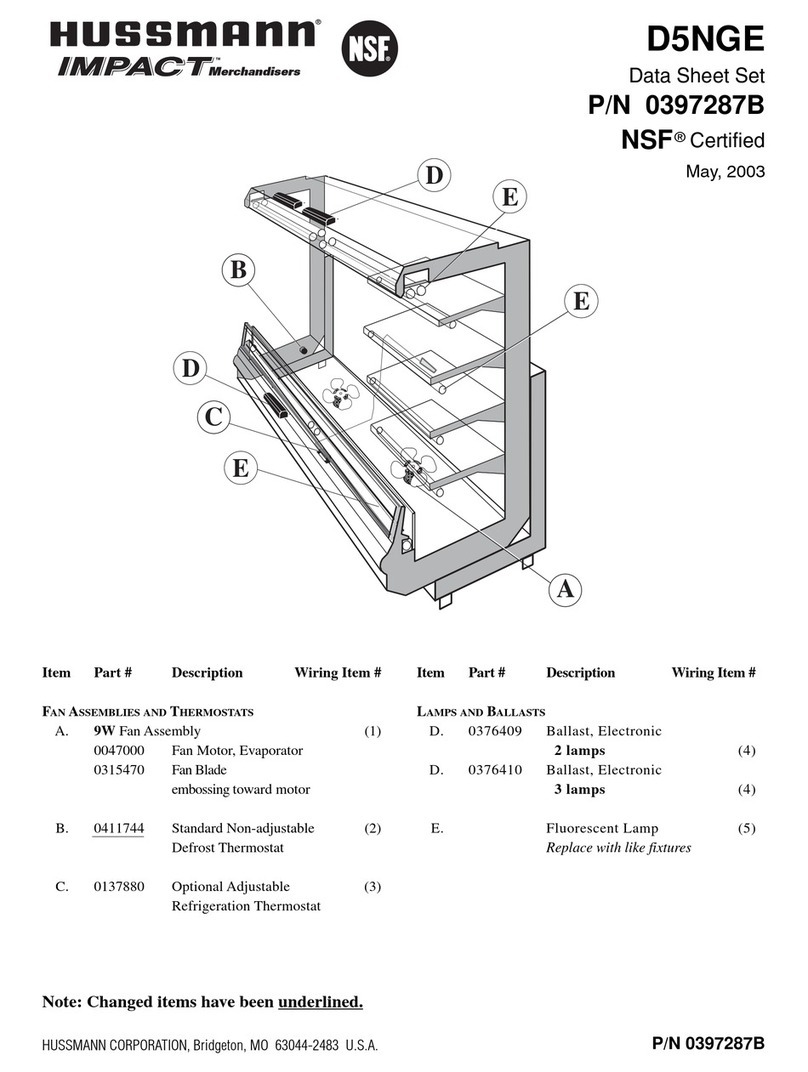

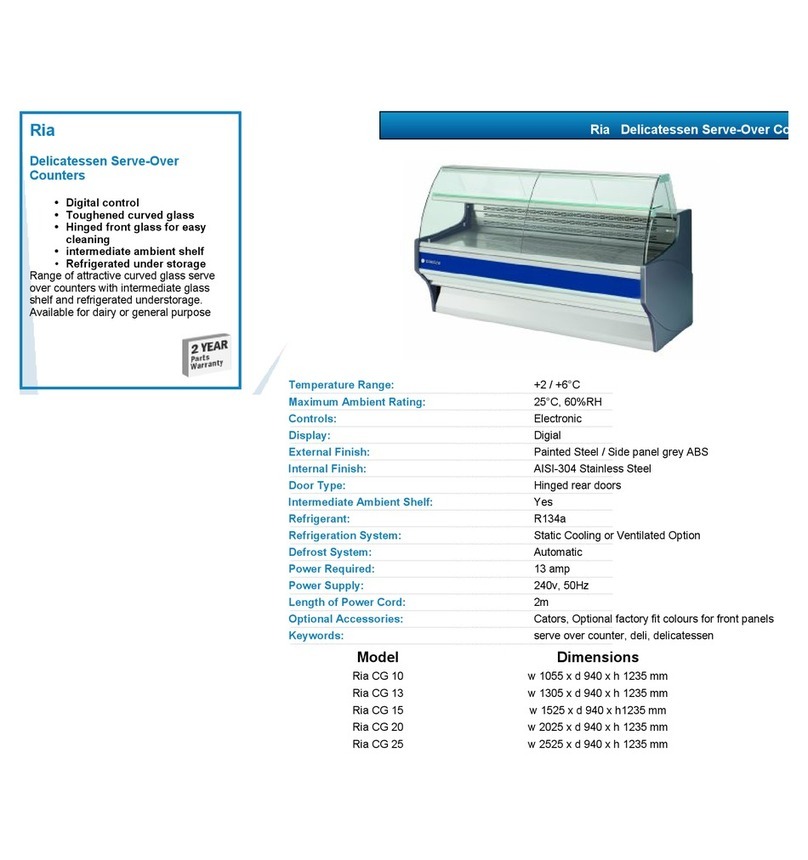

Blower / Heater Assembly

Table 3. Blower / Heater Assembly Parts

ITEM#

MODEL#

PART #

QTY

DESCRIPTION

1

HSS2-3T, 4S, 4T &5T

EN7003680S

1

Fan, 368 mm, 230V, Capacitor Type

HSS3-3T, 4S, 4T &5T

EN7003690S

2

Fan, 306 mm, 230V, Capacitor Type

HSS4-3T, 4S, 4T &5T

EN7003680S

2

Fan, 368 mm, 230V, Capacitor Type

HSS4-2T

EN7003670S

2

Fan, 368mm, 230V, Shaded Pole Type

ALL

SCR004

4

Screw, #8 x 3/8” Philips Head

2

HSS2-3T, 4S, 4T &5T

C0349

1

Heating Element, 2 x 925W, 230V

HSS3-3T, 4S, 4T &5T

C0761

2

Heating Element, 2 x 750W, 230V

HSS4-3T, 4S, 4T &5T

C0349

2

Heating Element, 2 x 925W, 230V

HSS4-2T

C0349

2

Heating Element, 2 x 925W, 230V

ALL

SCR004

2

Screw, #8 x 3/8” Philips Head

3

ALL

T0107

1

Thermostat, 280F, N.O.

ALL

SCR117

2

Screw, #6-32 x 3/8” Phillips Head

ALL

NUT262

2

Nut, #6-32 Lock

4

HSS2-3T, 4S, 4T &5T

FB70017503

1

Upper Duct, Heater

HSS3-3T, 4S, 4T &5T

FB70027703

2

Upper Duct, Heater

HSS4-3T, 4S, 4T &5T

FB70017503

2

Upper Duct, Heater

HSS4-2T

FB70017503

2

Upper Duct, Heater

ALL

NUT286

2

Nut, #10-32 Keps

5

HSS2-3T, 4S, 4T &5T

FB70034218

1

Mount, Blower & Heater

HSS3-3T, 4S, 4T &5T

FB70034318

2

Mount, Blower & Heater

HSS4-3T, 4S, 4T &5T

FB70034218

2

Mount, Blower & Heater

HSS4-2T

FB70034218

2

Mount, Blower & Heater

6

ALL

FB70036009

2

End Flange, Blower

ALL

SCR004

4

Screw, #8 x 3/8” Philips Head

1

2

3

4

5

6

This manual suits for next models

18

Table of contents

Other BKI Merchandiser manuals

BKI

BKI Mobile Merchandiser MM4 User manual

BKI

BKI MDW series User manual

BKI

BKI SM-24 User manual

BKI

BKI Sandwich Merchandiser SM27 User manual

BKI

BKI Heated Display Merchandisers CSWG User manual

BKI

BKI Mobile Hot Food Series User manual

BKI

BKI Self Service Hot Food Merchandiser MODEL... User manual

BKI

BKI Mobile Merchandiser MM4 User manual