Black & Decker SCRUGUN 2020-10 User manual

Other Black & Decker Power Screwdriver manuals

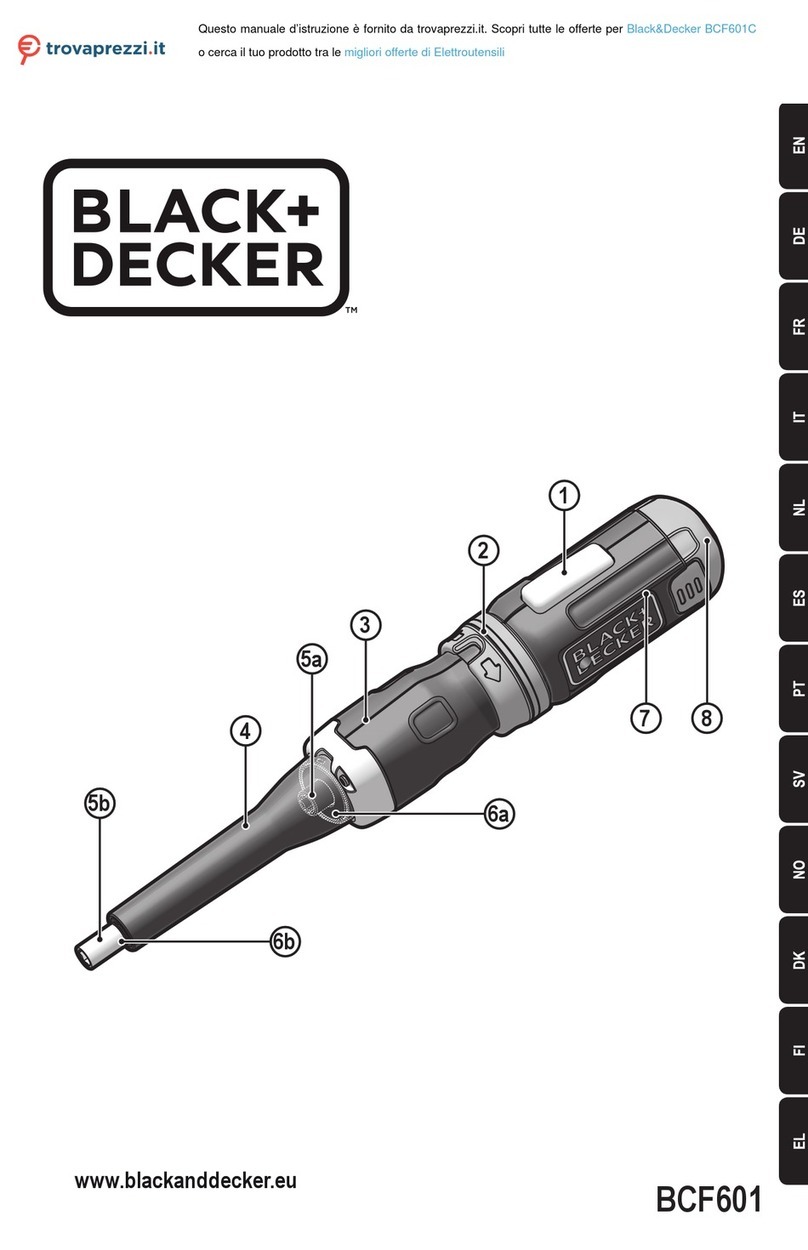

Black & Decker

Black & Decker BDCD112C User manual

Black & Decker

Black & Decker LDX120C User manual

Black & Decker

Black & Decker CS3652LC User manual

Black & Decker

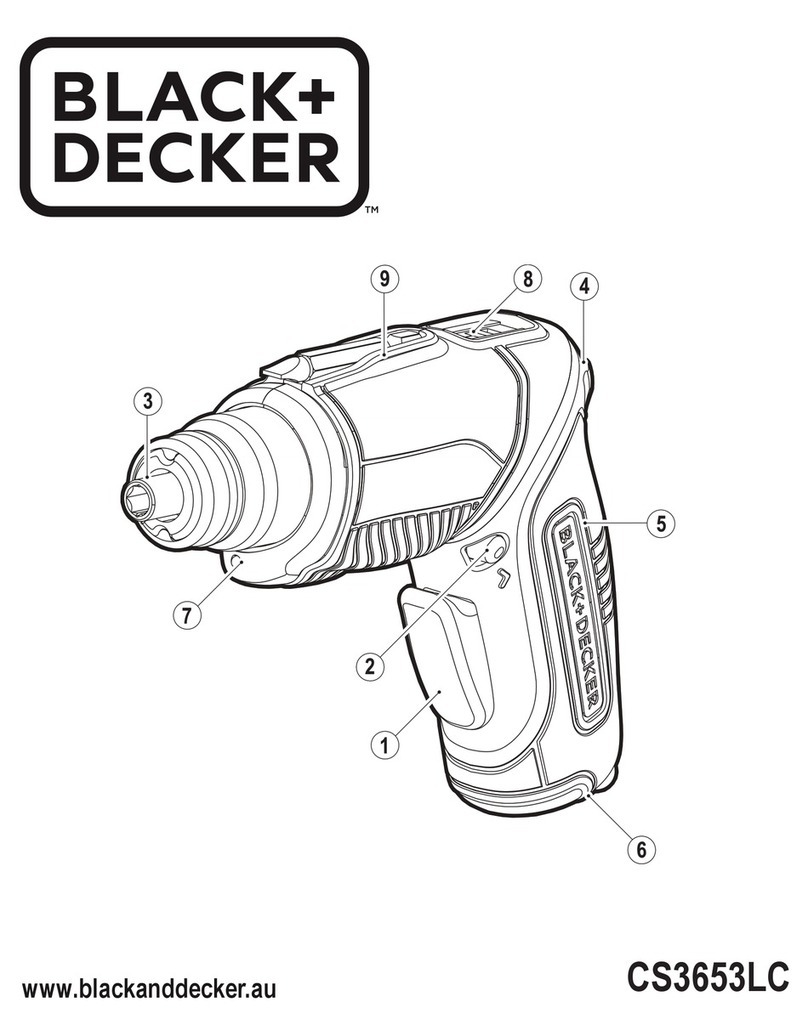

Black & Decker CS3653LC User manual

Black & Decker

Black & Decker KC600H User manual

Black & Decker

Black & Decker LI3100 User manual

Black & Decker

Black & Decker AD600-XE User manual

Black & Decker

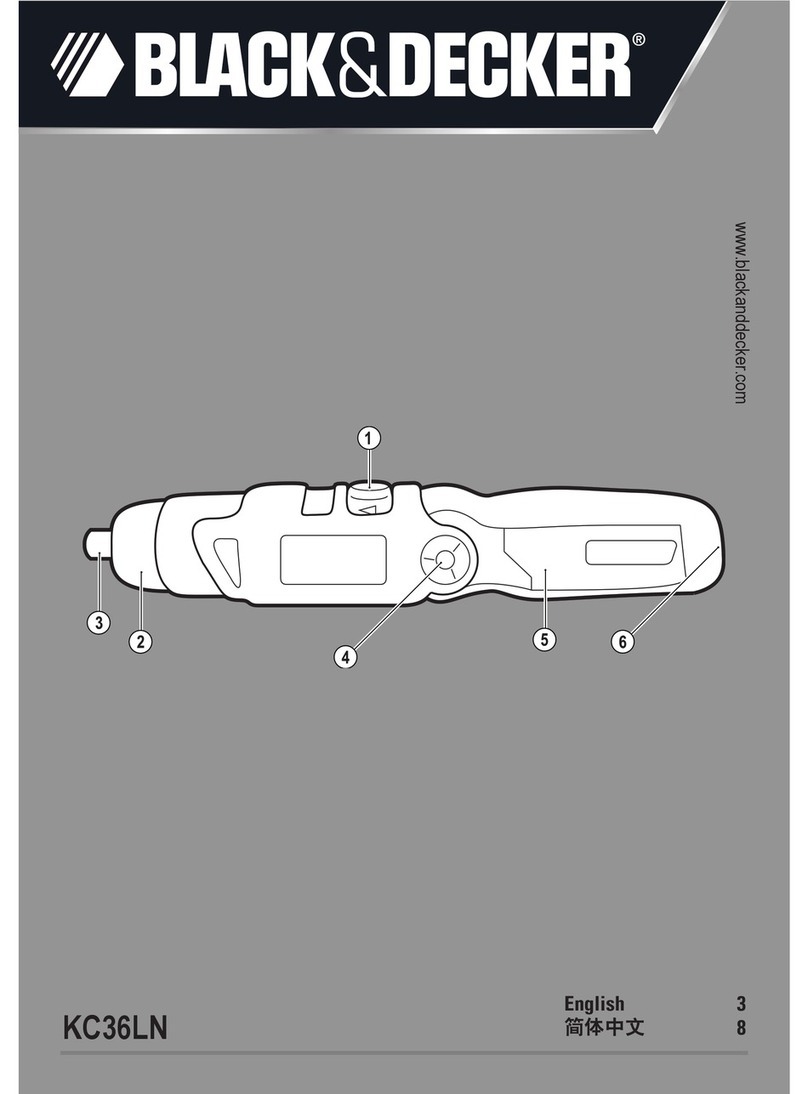

Black & Decker KC36LN User manual

Black & Decker

Black & Decker GC9600 User manual

Black & Decker

Black & Decker FireStorm FS360 User manual

Black & Decker

Black & Decker PLR36NC User manual

Black & Decker

Black & Decker 2037-220 User manual

Black & Decker

Black & Decker EGBL108 User manual

Black & Decker

Black & Decker KC9038 User manual

Black & Decker

Black & Decker PD400L User manual

Black & Decker

Black & Decker LD120 User manual

Black & Decker

Black & Decker SS12C User manual

Black & Decker

Black & Decker BDCDD12U User manual

Black & Decker

Black & Decker BL186 User manual

Black & Decker

Black & Decker LI2000 User manual