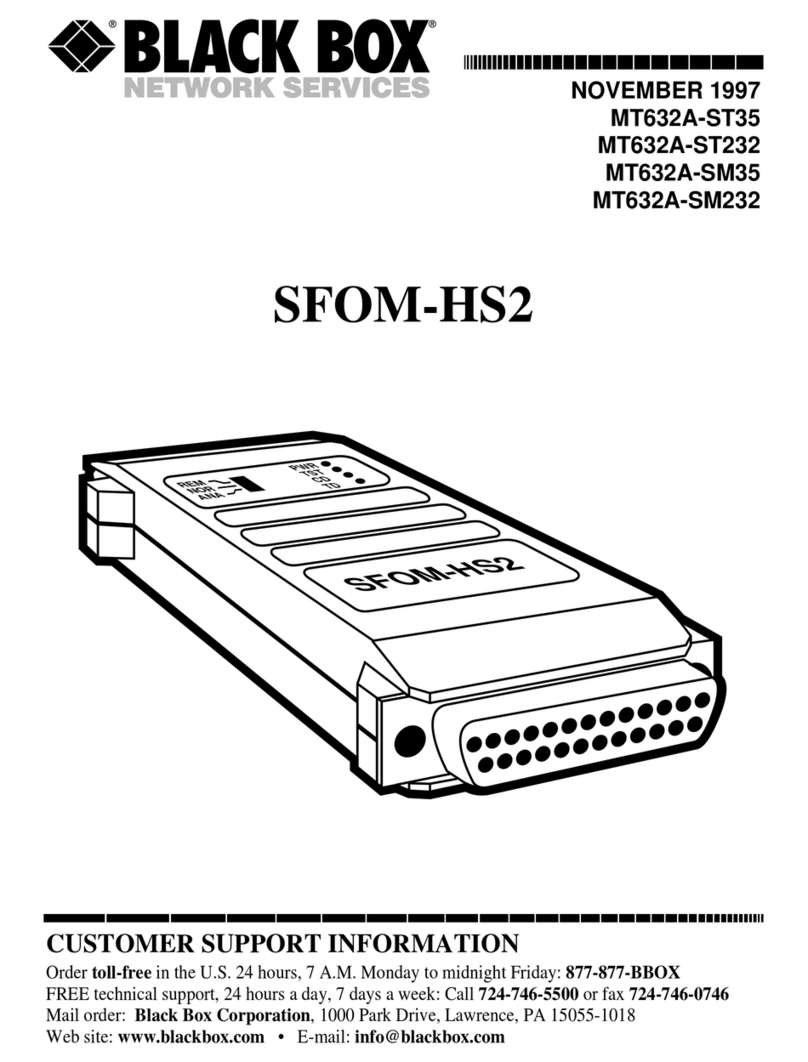

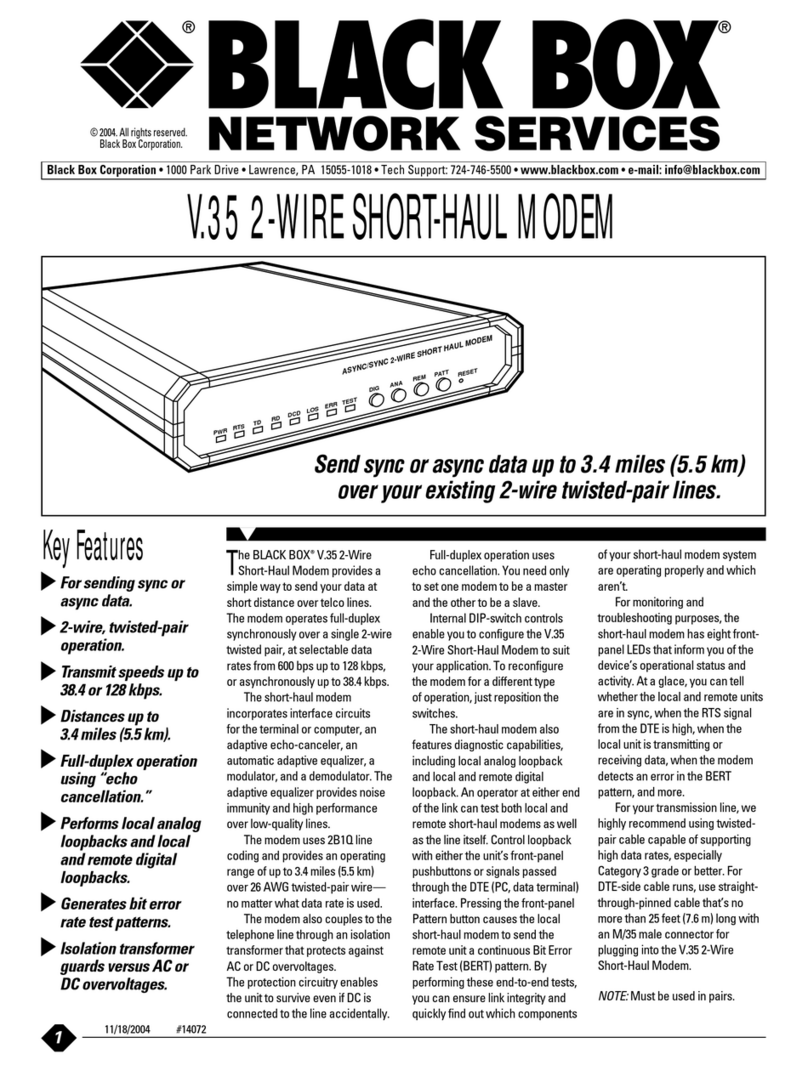

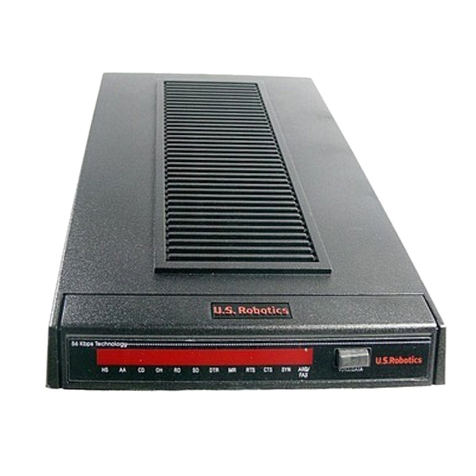

FRONT-PANEL INDICATORS AND THEIR FUNCTIONS:

PWR: Green LED is steadily lit while power is present.

RTS: Yellow LED is steadily lit while the Request to Send (RTS) signal from the DTE is high.

TD: Yellow LED is steadily lit while the local unit transmits steady SPACE. It flickers while the local unit transmit data.

RD: Yellow LED is steadily lit while the local unit receives steady SPACE. It flickers while the local unit receives data.

DCD: Yellow LED is steadily lit while:

a.) The local and remote units are in sync, and the local unit's DCD switch is set to "DCD"

b.) The local and remote units are in sync, the local unit's DCD switch is set to "CNT", and the remote unit has RTS high.

LOS: Red LED is steadily lit when synchronization between the local and remote units are lost.

ERR: Red LED is steadily lit when the local units PATT button is in the ON position (depressed) and the unit detects an error in the BERT pattern.

TEST: Yellow LED is steadily lit while the local units internal BERT is active (the PATT button is depressed) or the unit is in any of the three loopback modes.

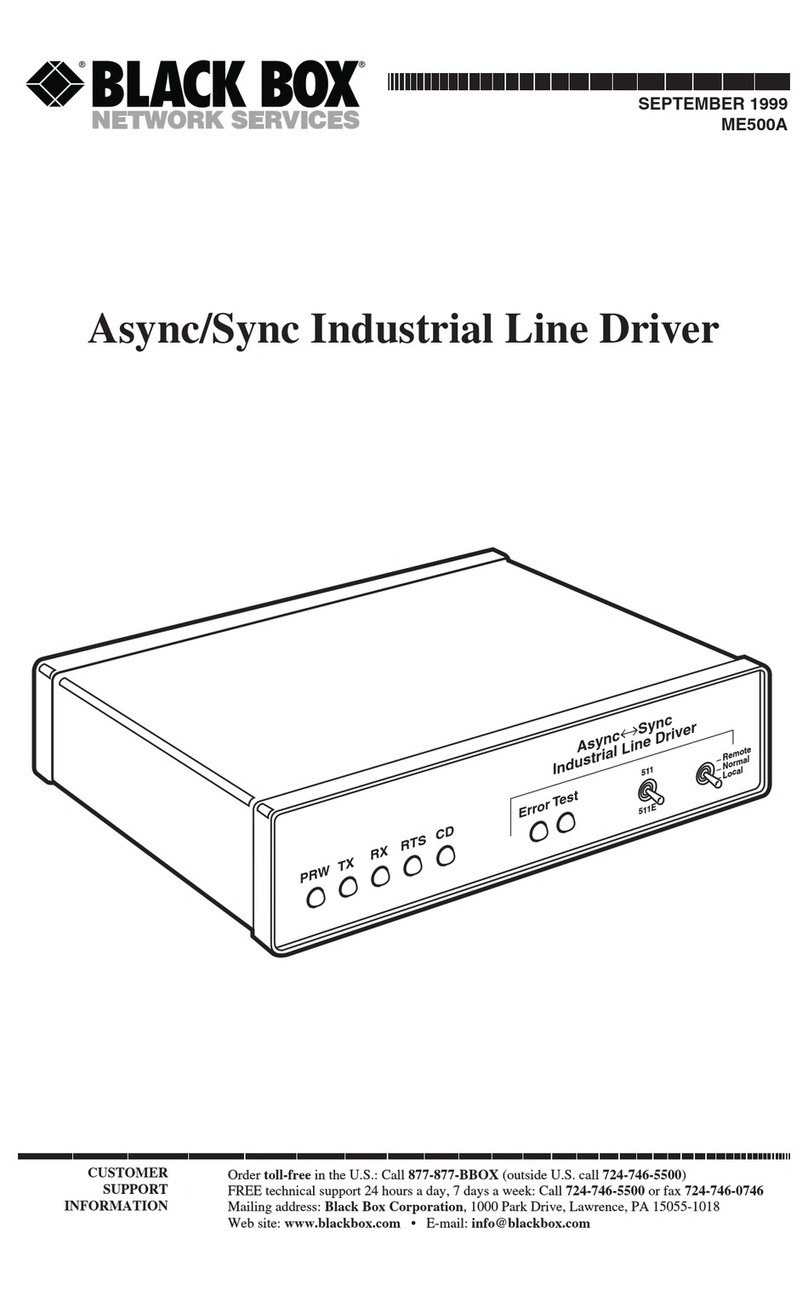

POWER-UP, NORMAL OPERATION, AND POWER DOWN:

Making sure that you follow the guidelines in the previous section, power up the Async/Sync 2-Wire Short Haul Modem by plugging its AC power cord to an working AC outlet. (The unit has no power switch. To power it down, unplug it). The PWR LED

should light, indicating that the unit is on. If the local and remote A/S2W SHM units are both operating and transmitting data, the unit's front-panel indicators should look like this:

PWR: Steadily lit

TD: Steadily lit or flickering depending on the data being transmitted.

RD: Steadily lit or flickering depending on the data being received.

RTS: Steadily lit or dark depending on the status of the RTS signal from the local DTE.

DCD: If the local unit's DCD jumper is set to DCD, steadily lit; if the local unit's DCD jumper is set to CNT,

steadily lit or dark depending on the status of the RTS signal from the remote unit.

LOS: Flashing until the units synchronize with each other, then dark.

ERR: Flashing until the units synchronize with each other, then dark.

TEST: Flashing until the units synchronize with each other, then dark.

If the LED's don't look like this, make sure that:

1. One A/S2W SHM's CLOCK jumper is set to internal (INT) or external (EXT) clock, and the other units CLOCK jumper is set to loopback (LBT) clock.

2. Both units four front-panel pushbuttons are in the OFF position (not depressed).

Once a A/S2W SHM begins operating normally, it will continue to do so indefinitely without needing to be attending, except when occasional monitoring of LED indicators is required.

POSITION/LABEL POSSIBLE SETTINGS FACTORY DEFAULT

Position 1 Async or Sync Operation Sync

ON = ASYNC

OFF = SYNC

Position 2 8 or 7 Data Bits 8 bits

ON = 8 bits

OFF = 7 bits

Position 3 Parity Enabled/Disabled Disabled

ON = Enabled

OFF = Disabled

Position 4 Even or Odd parity Even

ON = Even

OFF = Odd

Position 5 1 or 2 stop bits 1 bit

ON = 1

OFF = 2

Position 6 * DCD independent or controlled by RTS DCD independent

ON = DCD

OFF = CNTL

Position 7 ** DSR always ON or follows DTR DSR ON

ON = DSR

OFF = DTR

* If DIP Switch Position 6 is set to :

1.) DCD: The DCD signal is ON as long as the local unit is in proper

synchronization with the remote unit. The DCD signal is OFF when

digital loopback is active or when there is no synchronization (for

example, while the unit is receiving the remote loopback command).

2.) CNT: The local unit's DCD signal follows the remote unit's RTS signal.

** If DIP Switch Position 7 is set to:

1.) DSR: The DSR signal is ON as long as the local unit is receiving AC

power; it does not indicate the existence of a communication channel

or the status of the remote site.

2.) DTR: The local unit's DSR signal follows the remote unit's DTR signal.

FUNCTION/LABEL POSSIBLE SETTINGS FACTORY DEFAULT

Clock-Source (CLOCK) Jumper For master units, select either INT

internal timing (INT) or external

timing (EXT).

For slave units, always select

loopback (received) timing (LBT)

Local Loopback (LLB) Jumper Enable/Disable control of local DIS

analog loopback testing with

signals from the DTE.

Remote Loopback (RLB) Jumper * Enable/Disable control of remote DIS

digital loopback testing with signals

from the DTE.

Chassis Ground (CHASS_GND) Tie Signal Ground to Chassis CON

Jumper (Protective, Frame) Ground or

isolate the two grounds from

each other.

Only connect the RLB and LLB jumpers (that is, set them to EN [enabled]) if you want to be able to turn local

analog or remote digital loopbacks on and off from the DTE using the proper RS-232 or V.35 signals. The

settings of these jumpers have no effect on the ANA and REM pushbutton switches on the unit's front-panel; you

will be able to control loopback testing with those buttons whether these jumpers are connected or not. (There

is no way to control local digital loopback through the local DTE interface; you must use the DIG button to do

that.)

DIP SWITCH SETTINGS: