Black Bruin On-Demand User manual

Product manual

On-Demand Drive System

CTR101 / CTR201 and CVM120 / CVU200 valves

Contents

1 General instructions......................................................................... 4

1.1 About the manual............................................................................................................................................4

1.2 Intended use.....................................................................................................................................................4

1.3 Warranty............................................................................................................................................................. 5

1.4 Product identication..................................................................................................................................... 5

1.5 Revision comments.........................................................................................................................................5

2 Safety instructions........................................................................... 6

2.1 Warning symbols..............................................................................................................................................6

3 Product description.......................................................................... 7

3.1 Main components of the On-Demand Drive System..............................................................................7

3.2 Control systems............................................................................................................................................... 8

3.3 Working principle..............................................................................................................................................8

3.4 Driving mode.....................................................................................................................................................8

3.5 HDC function (Hill descent control) (option).............................................................................................9

3.6 Freewheeling mode.......................................................................................................................................10

4 System design.................................................................................. 11

4.1 Hydraulic motors.............................................................................................................................................11

4.2 Valves................................................................................................................................................................ 12

4.2.1 Valve models.................................................................................................................................12

4.2.2 Valve functions.............................................................................................................................12

4.3 Hydraulic system............................................................................................................................................13

4.4 Hydraulic connections..................................................................................................................................14

4.5 Port pairs.......................................................................................................................................................... 17

5 Control system.................................................................................18

5.1 Model series of the control system........................................................................................................... 18

5.2 Product identication code......................................................................................................................... 19

5.3 Control system connections....................................................................................................................... 19

5.3.1 Important notes........................................................................................................................... 19

5.3.2 Control system connection diagrams................................................................................... 20

5.3.3 Display cable with extension................................................................................................... 22

5.3.4 Pressure sensor cables............................................................................................................. 22

5.3.5 Brake signal cable.......................................................................................................................23

5.3.6 Valve cable, Y...............................................................................................................................23

5.3.7 Valve cable, straight...................................................................................................................23

5.3.8 Controller link cable....................................................................................................................24

5.3.9 Power cable types...................................................................................................................... 24

5.3.10 Protective caps............................................................................................................................25

5.3.11 Resistor plug for the CAN OUT connector............................................................................25

5.3.12 HDC / AUX valve cable (optional accessory).......................................................................26

5.3.13 Extension adapter cable for AUX valve (optional accessory)..........................................26

5.3.14 External alarm input cable (optional accessory).................................................................27

Contents

2 Product manual

6 Installation and commissioning.................................................... 28

6.1 Installation and the connections...............................................................................................................28

6.2 Power-up the control system.................................................................................................................... 30

6.3 Air bleeding procedure................................................................................................................................. 31

6.4 Examine the connections........................................................................................................................... 32

6.5 Test drive......................................................................................................................................................... 32

7 Technical data................................................................................. 34

7.1 Control device................................................................................................................................................ 34

7.2 Display..............................................................................................................................................................35

7.3 Display mount................................................................................................................................................ 36

7.4 Pressure sensor............................................................................................................................................. 37

7.5 CVM120 2WD valve........................................................................................................................................38

7.6 CVM120 2WD HDC valve.............................................................................................................................. 39

7.7 CVM120 4WD valve....................................................................................................................................... 40

7.8 CVM120 4WD HDC valve...............................................................................................................................41

7.9 CVU200 valve.................................................................................................................................................42

Contents

Product manual 3

General instructions

About the manual

This manual contains the technical instructions for the Black Bruin On-Demand Drive

System that uses CVM120/CVU200 valves and CTR101/CTR201 control systems.

Obey these instructions when you plan to use the products.

All information is based on information that was available at the time that this manual

was written. The manufacturer reserves the right to change the content of this

manual without further notice.

Please visit www.blackbruin.com for the most recent version of this manual. The

product datasheets and the 3D-models are available from the manufacturer by

request.

The operation instructions of CTR101/CTR201 control systems are in the operation

manuals:

• CTR101 control system Operation manual

• CTR201 control system Operation manual.

Note:

If there are dierences between the English text and its translation, the

English text is always the most accurate. This document is written in

Simplied Technical English (ASD-STE100).

Intended use

The CVM120/CVU200 valves and the CTR101/CTR201 control systems are part of the

Black Bruin On-Demand Drive System.

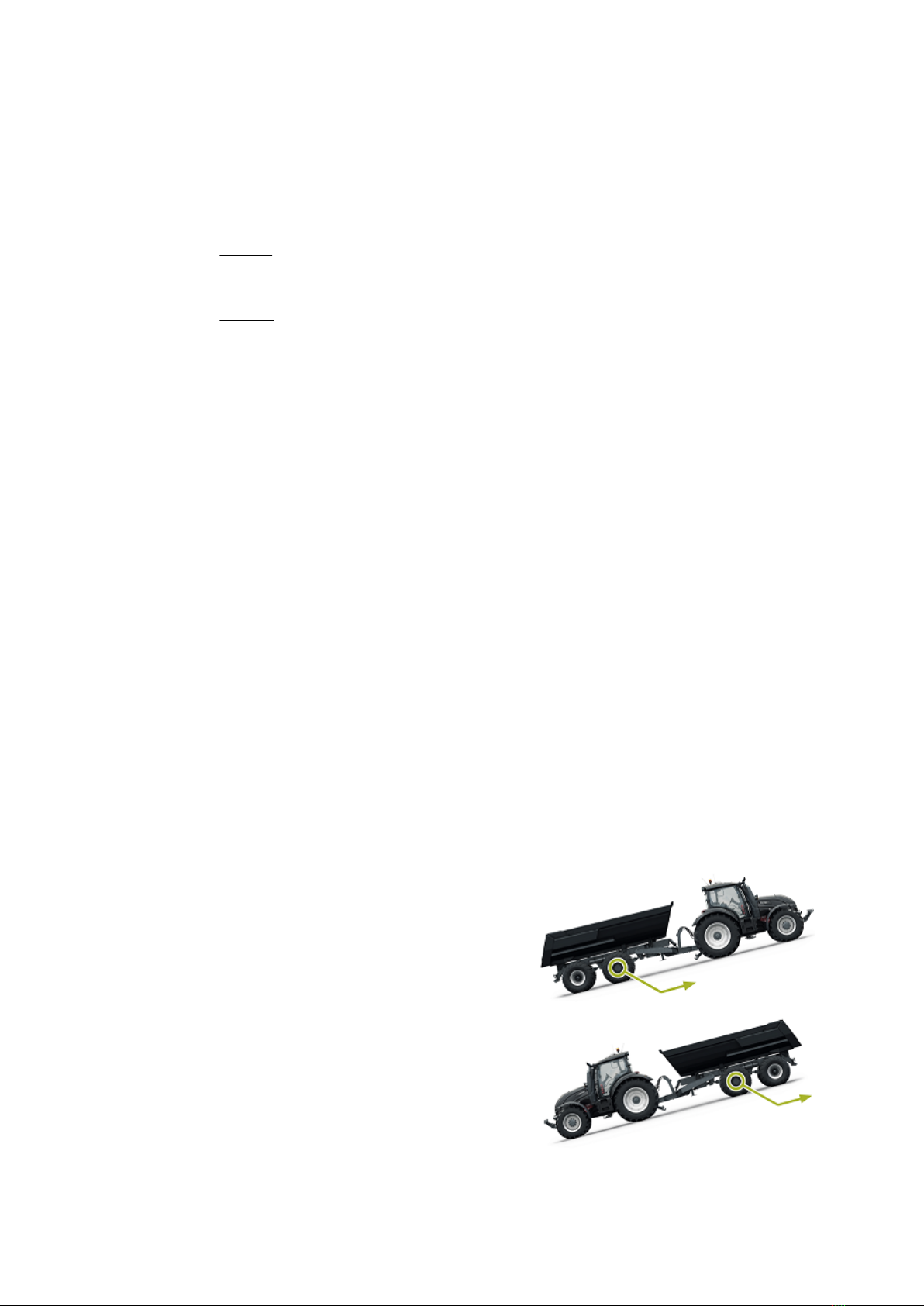

Black Bruin On-Demand Drive System is a transmission solution for tractor-driven

trailers and working equipment.

Black Bruin On-Demand Drive System is very applicable for equipment that

periodically requires additional power and is towed without hydraulics.

Black Bruin On-Demand Drive System is designed for o-road driving and must be

powered o when you drive in road trac.

Danger:

Make sure that you power o the system when you drive on road.

These products are only applicable to use together with the freewheeling Black Bruin

motors. The valves and the control systems are specially made for transmission

solutions with B200 series 2-speed motors. Please contact the manufacturer or their

representative who will help you to select the most applicable motor model for your

application.

The components of the On-Demand Drive System make driving functions easy to do.

The manufacturer of the nal product is responsible for the manufacture of the

machine and that the product is correct for the application it is specially made for.

1

1.1

1.2

General instructions

4 Product manual

Warranty

Check the package and the product for transport damage when receiving goods. The

package is not meant for long term storage; protect the product appropriately.

Do not dismantle the product. The warranty is void if the product has been

disassembled.

The manufacturer is not responsible for damages resulting from misinterpreted, non-

compliance, incorrect, or improper use of the product that goes against the

instructions given in this document.

Product identication

The valves and the control systems have identication plates.

Refer to the CTR101 or CTR201 Operation manual for the instructions on how to verify

the software version of the control system.

Figure 1. Identication plate of the valve.

1. Part number

2. Model

3. Serial number

4. Manufacturing date

5. Reference number

6. Maximum allowed operating

pressure

Figure 2. Identication plate of the control system.

1. Model

2. Part number

3. Serial number

Revision comments

26.02.2021 (Software version 03.02.00) - This manual is published.

Previous CTR100 control system products are in the "CVM/CVU/CTR Product

manual".

1.3

1.4

1.5

General instructions

Product manual 5

Safety instructions

The instructions that follow apply to all procedures related to the product. Read these

instructions fully and follow them carefully.

• Use necessary personal protective equipment when you do work with the product.

• Use correct support with the product. Make sure that the product cannot

accidentally fall or turn.

• Use only appropriate equipment and attachments when you lift and move the

product.

• Make sure that it is not possible to pressurize the hydraulic lines during product

installation and maintenance procedures.

• During the operation the product temperature can be over 60 ºC (140 °F). Hot

surfaces can burn you. Be careful of hot hydraulic uid when you disconnect the

hydraulic connections.

Warning symbols

The following symbols are used in this manual:

Note:

Useful information.

Danger:

Danger of death or injury.

Attention:

May cause damage to the product.

2

2.1

Safety instructions

6 Product manual

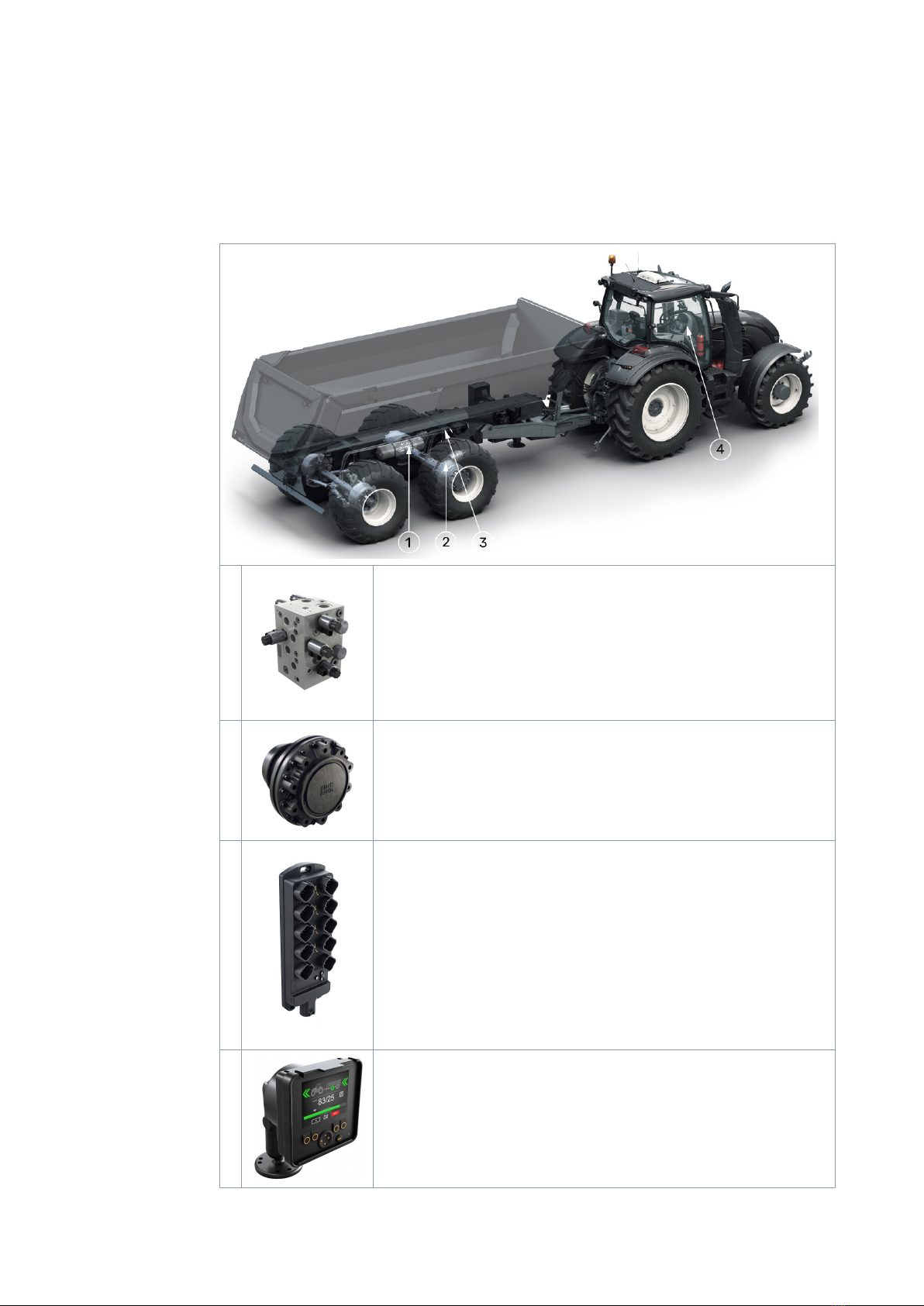

Product description

Main components of the On-Demand Drive System

1Valve

• Motor mode changes between driving and freewheeling

• Driving direction change

• Displacement control of two-speed motors

• Pressure level (tractive power) adjustment

• Assisting traction control (ATC)

• Hill descent control (HDC) function (in selected models).

2Hydraulic motor

• Wheel hub motor

• No pressure required in freewheeling mode

• More extensive driving speed range with inbuilt two-speed valve.

3Control device

• Controls the system functions

• Controls the valve

• Measures the pressure from the system’s pressure sensors

• Monitors the brake signal

• Monitors the external alarm signal (optional)

• Controls the application specic auxiliary valve (optional)

• Stores the system settings

• Collects the speed and direction information via tractor's ISOBUS

implement socket (CTR201).

4Display

• The system control element

• Shows information to the user about the operation of the system

• Many alternative languages.

3

3.1

Product description

Product manual 7

Control systems

The two control systems, CTR101 and CTR201, have functions to control the driving

mode in 2WD and 4WD applications.

CTR101 control system is applicable to all tractors. It provides driving functions that

you can activate with the system display. It can also automatically switch the system

to freewheeling mode if the working pressure drops due to increased driving speed.

CTR201 control system is applicable to tractors that have the ISOBUS implement

connector. It has automatic functions that use the tractor's speed and direction

information to make the operator’s work easier. If necessary, manual operation of the

system is also available.

Working principle

The Black Bruin On-Demand Drive System can use hydraulic motors in the operating

modes that follow:

• Driving mode

• Driving mode with HDC function (Hill descent control) (option)

• Freewheeling mode.

The chapters that follow give the working principles of these modes.

Driving mode

In this mode the motors help the vehicle to move in the direction of travel. You can

adjust the tractive power level to the driving conditions. The power level stays

constant also if the speed changes. When the tractor brakes the system reduces the

working pressure to the minimum level and the hydraulic motors do not have tractive

power.

2-speed hydraulic motors give wider speed range for the hydraulic drive.

If the vehicle wheels slip, the assisting traction control ATC increases the torque on

the wheels that have more traction.

Typical situations to operate in the driving mode are:

• Driving up steep slopes

• Moving rearward on steep slopes

3.2

3.3

3.4

Product description

8 Product manual

• Going across obstacles

• Driving on slippery or soft surfaces.

HDC function (Hill descent control) (option)

The HDC function helps when you drive the vehicle down on steep slopes, in both

forward and reverse driving modes.

When the HDC function is active, the wheel motors resist the wheel movement to the

driving direction. You can adjust the HDC power level during the operation.

Typical situations for the use of the HDC function are:

• Driving down steep slopes

HDC function o, vehicle accelerates.

• Driving down steep slopes

HDC function on, function helps the

vehicle to maintain the speed.

• Moving rearward on steep slopes

HDC function o, vehicle accelerates.

• Moving rearward on steep slopes

HDC function on, function helps the

vehicle to maintain the speed.

3.5

Product description

Product manual 9

Freewheeling mode

In the freewheeling mode you can freewheel the motors without energy loss or

overheating problems (stationary cylinder block - no centrifugal forces), even at high

speeds. You can engage the drive again during movement when the speed is in the

working range.

If the pressure level is not sucient due to increased driving speed, the control

system automatically switches to freewheeling. This protects the motor from

overloading.

The operator can also manually change the mode to freewheeling.

Typical situations to operate in the freewheeling mode are:

•When you drive on road

• When you do work above the maximum working speed range

• When the working conditions are easy.

3.6

Product description

10 Product manual

System design

Hydraulic motors

The technical data and the instructions to select the correct motor size are in the

product manual of each motor series.

The items that are important when you select the motors for your system are:

•The wheel load, radius and oset:

• These items give the minimum frame size for the motors.

•The required tractive force:

• The pressure available from the hydraulics and the radius of the wheel give the

necessary total displacement for the hydraulic motors. The necessary motor

displacement is the total displacement divided by two (2WD system) or by four

(4WD system).

•Maximum speed when the drive is in use:

• The available ow from the pump and the ow capacity of the selected valve

gives the maximum ow of the system. The 2-speed motor option makes it

possible to use the partial displacement of the motor. Thus, you can use the

drive in higher speed.

Guidelines to select the motors for the On-Demand Drive System:

•Necessary:

• Mechanical freewheeling

•Recommended:

• 2-speed function

• Possible to use also 1-speed motors

•Optional:

• Drum brake / disc brake

•Not compatible:

• Internal freewheeling valve

•Not compatible:

• Spring-loaded multidisc brake.

We recommend to use B200-series 2-speed motors for the On-Demand Drive

System. Please contact the manufacturer or their representative who will help you to

select the most applicable motor model for your application.

4

4.1

System design

Product manual 11

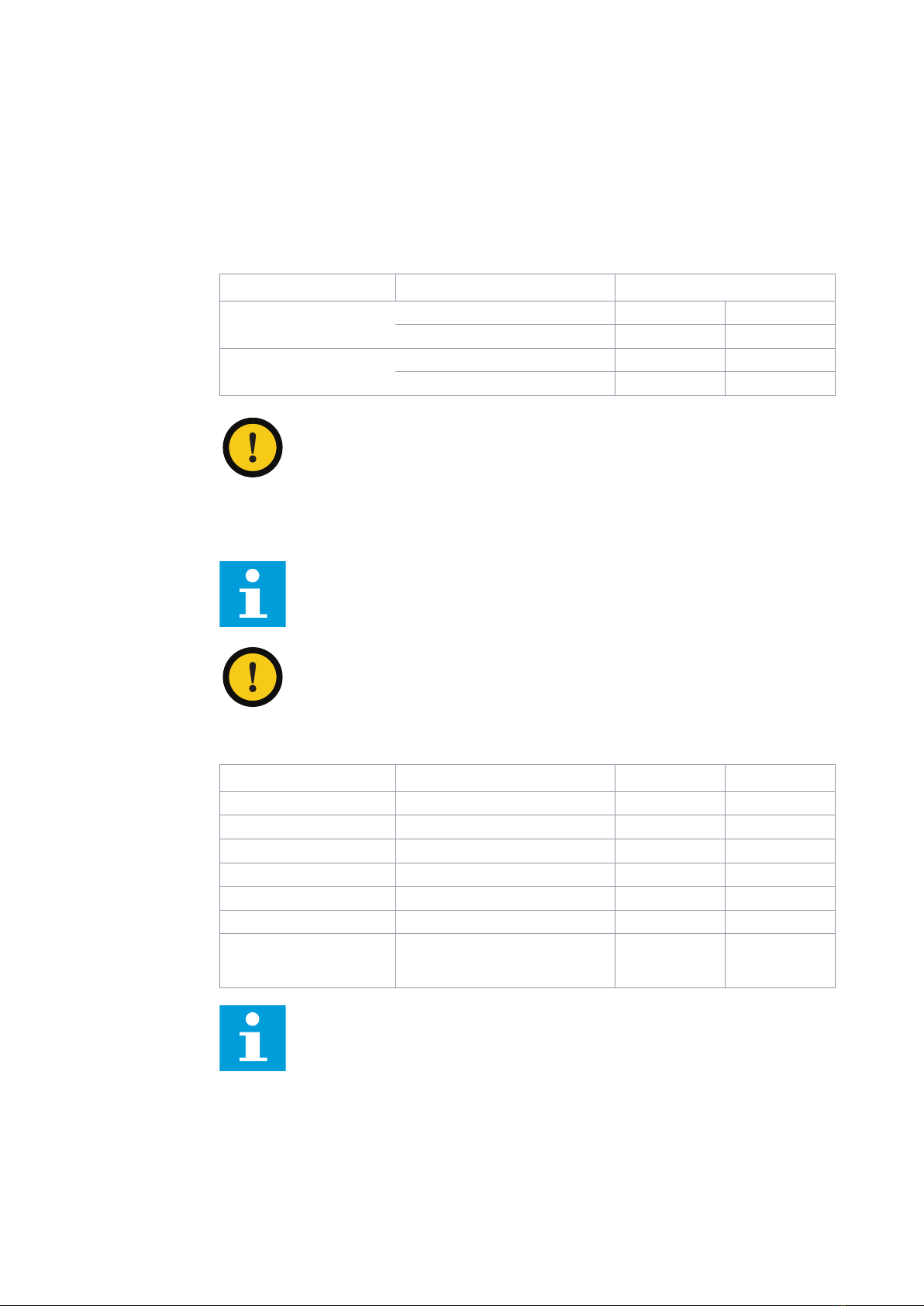

Valves

Valve models

Model series CVM120 / 2WD

CVM120 / 4WD

CVU200 / 2WD

Maximum ow rate (P->T) 120 l/min 200 l/min

Flow-rate limitation (in ATC function

(A1-B1 / A2-B2)*

2WD: 55 l/min / motor

40 l/min / motor (option) *

4WD: 28 l/min / motor

100 l/min / motor

80 l/min / motor (option) *

Compatible with xed displacement

pump ●

Compatible with load-sensing (LS)

pump ● ●

Hill descent control (HDC function) O (option)

Valve order code 2WD without HDC:

CVM120-A1H0T0V12S00

2WD with HDC:

CVM120-A1H1T0V12S00

4WD without HDC:

CVM120-A2H0T0V12S00

4WD with HDC:

CVM120-A2H1T0V12S00

2WD without HDC:

CVU200-A1H0T0V12S00

* Contact the motor manufacturer or its representative to order a valve for reduced

ow.

Valve functions

CVM120 and CVU200 valves have the in-built functions that follow:

• Mode change between the freewheeling and driving modes

• Drive direction control

• Motor 2-speed function control

• Flow limitation for Assisting traction control (ATC)

• Proportional pressure level control

• Proportional Hill descent control (HDC) (available in selected valve models).

When a wheel slips, the ATC function gives up to 50% of the maximum ow of the

valve to the wheel that slips. In the 4WD systems the maximum ow for each wheel is

25% of the maximum ow of the valve. In order to keep the pressure for the wheels

that have better grip, the pump must supply sucient ow to the wheel that slips.

CVM120 and CVU200 2WD valves are available with reduced ow capacity. With this

option the ATC functions also on reduced ow capacity. Contact the motor

manufacturer or its representative about this option.

4.2

4.2.1

4.2.2

System design

12 Product manual

Hydraulic system

When you plan to use the CVM120/CVU200 valves, make sure that:

• You use the CVU200 valve only in a system with a load-sensing pump and an LS

line.

• The CVM120/CVU200 valves are not applicable to use in closed-circuit hydraulic

systems.

• The hydraulic uid viscosity must be a minimum of 15 cSt. The recommended

viscosity is 25–50 cSt.

• The hydraulic uid must be clean and its quality must be in accordance with ISO

4406. The minimum quality of the hydraulic uid is 18/16/13.

The recommendations for the system ltration are in the table that follows:

Hydraulic supply High pressure lter (P) Return line lter (T)

Reservoir and pump in the tractor Required Optional

Reservoir and pump in the trailer Optional Required

• The hydraulic uid temperature must be below 75 °C.

• You must monitor the hydraulic uid temperature level during operation.

• It is very important to make sure that the cooling is sucient during the use of the

Hill descent control (HDC) option. If the cooling is not sucient, the hydraulic uid

temperature can raise during the continuous use of the HDC function at high

pressure. The conditions that have an eect on the necessary cooling capacity

are, for example:

• The working pressure

• The ow

• The ambient temperature

• The duty cycle.

Note:

The working pressure line (P) of the system must have a pressure relief

valve to limit the main pressure before the CVM120/CVU200 valve.

• We recommend that the hose sizes you use agree with the connections on the

valve. Very small hose diameter causes pressure loss and interference in the

operation.

• The position of the drain line (“C” in the hydraulic connection diagram) branching

point must be as close to the valve as possible.

• You can use the pressure accumulators in the motor case drain-lines to extend

the lifetime of the motor sealing. The use of the accumulators:

• Can cut the case pressure peaks during drive activation

• Makes the transition smoother from high ow drive to the freewheeling mode.

• Refer to the product manual of the motor series for more detailed information.

4.3

System design

Product manual 13

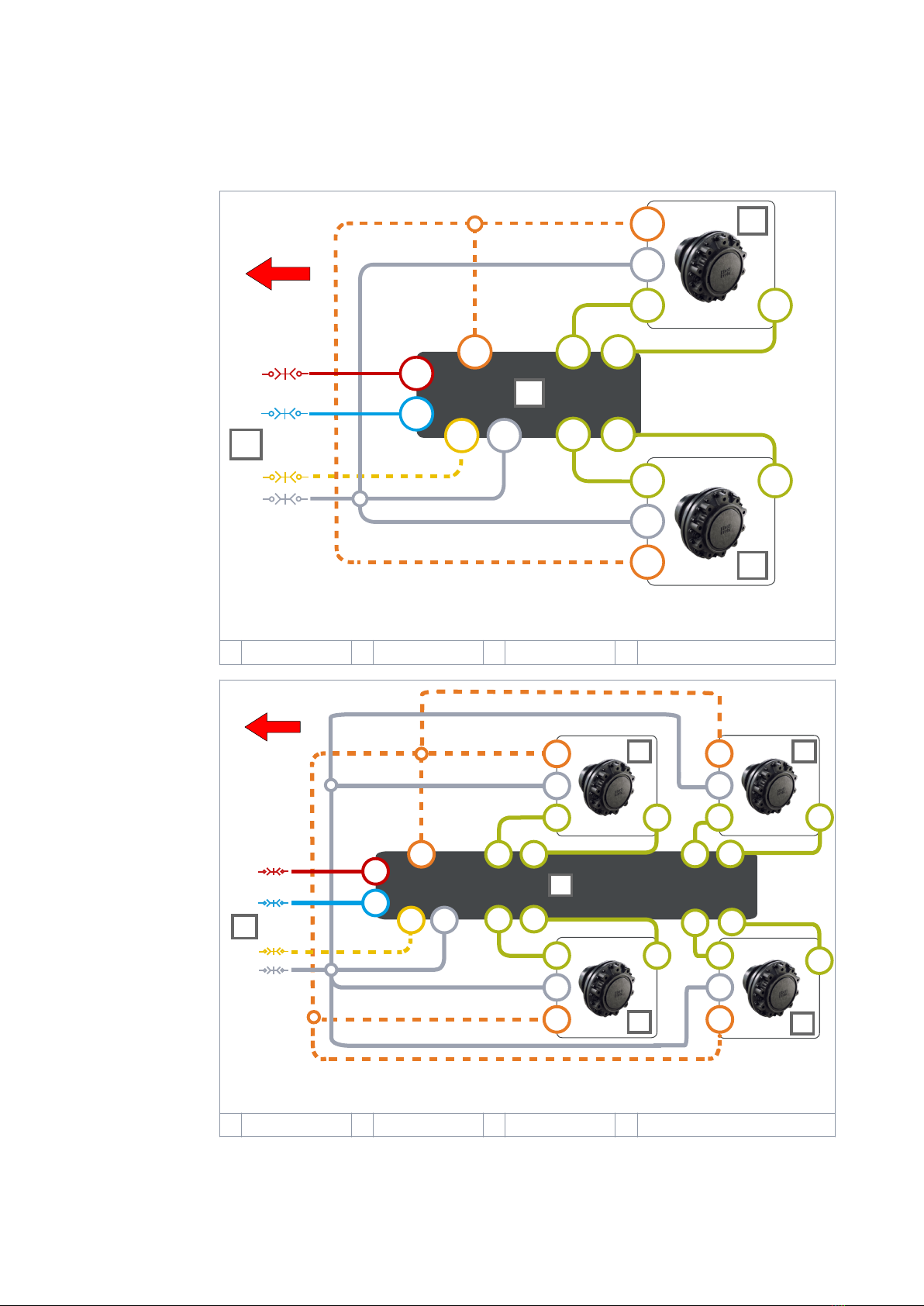

Hydraulic connections

Y

LS

P

C*

Y

A

A

A

B

B

B

T

C

C*

**

***

Y

**

2

3

4

1

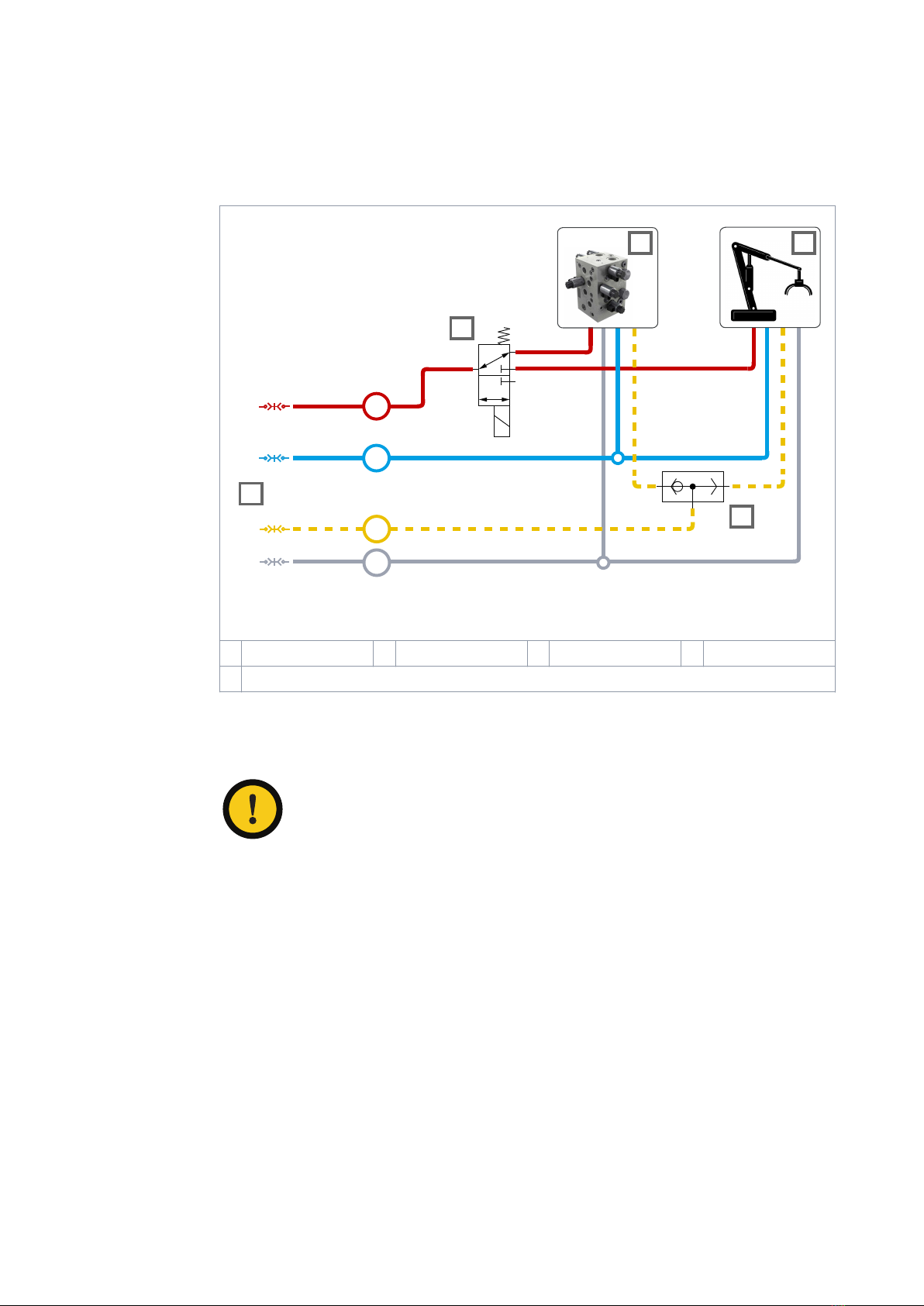

Figure 3. Connection diagram, 2WD.

1Valve 2 Motor, right 3 Motor, left 4 Hydraulic lines to the tractor

Y

LS

P

C*

Y

A

A

A

B

B

B

T

C

**

B

2

1

C*

A

2

33

4

**

A

A B

B

C*

**

Y

C*

**

Y

Y

***

Figure 4. Connection diagram, 4WD.

1 Valve 2 Motor, right 3 Motor, left 4 Hydraulic lines to the tractor

* The drain line (C) has a mark (C2) in motors with ushing line (C1).

4.4

System design

14 Product manual

** Make sure that you verify the rotating direction of the left motor from the

datasheet of the motor. Make sure that you connect the left motor correctly. Refer to

the table that follows for the left motor connections.

*** Driving direction.

Table 1: Connections, motor to valve.

Vehicle side Motor type Connections: motor to valve

Right side 1-speed A to A B to B

2-speed, CW preferred A to A B to B

Left side 1-speed A to B B to A

2-speed, CCW preferred A to A B to B

Attention:

The direction of rotation of the right motor must be CW.

Do not use 2-speed motors in the CW direction on the left-hand side.

We recommend that you use a Power Beyond hydraulic interface that connects to a

load sensing pump. If it is not available, connect the lines P and T to the tractor

valves.

Note:

The ow direction is from line P to line T.

Attention:

Do not put together lines C and T.

Always connect the line C to the reservoir without valves.

Table 2: Port sizes.

Port Description CVM120 valve CVU200 valve

P Pump - Working pressure inlet G3/4" G1"

T Tank - Return line G3/4" G1"

C Drain – Case leakage G3/4" G1"

A1, B1, A2, B2 Working lines for the motors G1/2" G3/4"

Y 2-speed function control line G3/8" G3/8"

LS Load-sensing line G1/4" G1/4"

MC, MP, M_A2, M_B2

Measurement points for

C, P, A2, B2 G1/4" G1/4"

Note:

The motor datasheet has the motor port types and the rotating direction.

Selector valve

If you use the same hydraulic supply also to other functions (e.g. crane) with the

drive system, you must usually separate the circuits with a selector valve. An

example of a hydraulic system with a 3/2 selector valve is in the diagram that follows.

In this example the selector valve (1) connects the working pressure (P) line to either

System design

Product manual 15

the CVM120/CVU200 valve (2) or to the crane valve (3). If the vehicle has a load-

sensing system, a shuttle valve (4) is also necessary. The shuttle valve lets the

selected valve to control the working pressure level.

LS

P

T

C

4

2

1

3

5

Figure 5. Connection diagram, selector valve.

1 Selector valve 2 CVM120/CVU200 3 Crane valve 4 Shuttle valve

5 Hydraulic lines to the tractor

The CTR101 and CTR201 control systems have an “AUX output” function to control

the external valve from the display. You can use this to control the selector valve. A

maximum permitted current for the valve is 4 A (48 W, 12 V DC)

Attention:

You must connect the pressure inlet port (P) of the CVM120/CVU200 valve

to the de-energized position of the selector valve. The auxiliary valve

output is always de-energized during the driving mode and can energize

only in the freewheeling mode.

You can also use the auxiliary output function for other control purposes in the

maximum current range.

System design

16 Product manual

Port pairs

The port pairs of valve lines A and B have A1/B1 and A2/B2 marks.

Always connect each motor to a port pair as shown in the gure below.

Figure 6. The port pairs.

You can connect left and right side motors to one of the two port pairs.

4.5

System design

Product manual 17

Control system

Model series of the control system

The table that follows shows the dierences between the two control system models,

CTR101 and CTR201.

The CTR201 control system can use the vehicle speed and direction information

through the tractor ISOBUS implement-connector to control the driving functions.

CTR101 CTR201

Connection to tractor ISOBUS implement-connector -●

Drive activation functions:

Automatic, when the tractor starts to move - ●

Automatic, when the system goes back to the

working speed range -●

Manual drive activation ● ●

Automatic drive direction selection (ISOBUS) - ●

Manual drive direction selection ● ● *M)

Tractive power cut-o during braking ● ●

Switching to freewheeling:

Automatic, based on low pressure ● ●

Automatic, based on speed (ISOBUS) - ●

Manual freewheeling ● ●

Shifting between low and high-speed range (2-speed

function):

Manual shift ● ● *M)

Automatic shift - ●

Assisting traction control modes (ATC):

Automatic mode, activation and deactivation

based on speed -●

Activated after forward drive activation for a set

time ●-

Continuous operation ● ●

4WD valve control O O

HDC valve control *) ● ●

Auxiliary valve output function *) ● ●

External alarm input *) ● ●

- = not available, ● = available, O = option

M) Available when you operate the CTR201 in the manual mode.

*) Refer to the “Control system connections” for the necessary cables (see chapters

HDC / AUX valve cable (optional accessory) on page 26, Extension adapter cable for

AUX valve (optional accessory) on page 26 and External alarm input cable (optional

accessory) on page 27).

5

5.1

Control system

18 Product manual

Product identication code

The table that follows gives the identication codes for the model series of the

CTR101 and CTR201 control system.

You can use the identication code to order the control system.

CTR101/CTR201 SERIES MODEL CODE AAAAAA-BB-CCC-DDD-EE-FF

On-Demand Drive control-system series CTR101 and CTR201

AAAAAA: Control

system series

AAAAAA-BB-CCC-DDD-EE-FF CTR101 CTR201

CTR101 ●

CTR201 ●

BB: Conguration AAAAAA-BB-CCC-DDD-EE-FF CTR101 CTR201

2WD A1 : Single controller for 2WD ● ●

4WD A2 : Dual controller for 4WD ● ●

CCC: Software AAAAAA-BB-CCC-DDD-EE-FF CTR101 CTR201

B00 : Standard software for CTR101 ●

C00 : Standard software for CTR201 ●

DDD: Supply kit AAAAAA-BB-CCC-DDD-EE-FF CTR101 CTR201

I10 : 10 m power / ISOBUS cable

with ISOBUS implement connector

and terminating bias circuit

●

P10 : 10 m power cable with free +/-

leads ●

EE: Options 1 AAAAAA-BB-CCC-DDD-EE-FF CTR101 CTR201

H0 : default / not dened ● ●

FF: Options 2 AAAAAA-BB-CCC-DDD-EE-FF CTR101 CTR201

C0 : default / not dened ● ●

Control system connections

Important notes

When you plan to use the CTR101/CTR201 control system, make sure that:

• The nominal operating voltage of the control system is 12 V. Do not connect the

system to a dierent voltage.

• The current requirement of the power supply of the system is 15 A. Make sure that

you always use a connection with a fuse.

• When the control device has no power, the system switches the motors to

freewheeling. Make sure that you can switch o the power supply to the control

device from the tractor's cab.

5.2

5.3

5.3.1

Control system

Product manual 19

• Attach the control device near the valve and in a location where the mechanical

shocks or wear cannot cause damage to it. If necessary, use mechanical

protection.

• Make sure that the installation location of the cables:

• Does not cause too much force on the cables

• Is not abrasive

• Does not let the cables catch between the moving parts of the machine and

break them.

• The system components are classied as water-resistant, but do not put the

components fully into water.

• Install the display in the tractor cab. Use the mounting set that is supplied with

the display. It includes a mounting frame and a pivot arm.

• You must start the control device again if the display cable disconnects and you

connect it when the control system power is on. Switch the power o and on

again.

•CTR201: Make sure that the tractor obeys the ISOBUS class 2 requirements. The

automatic drive control mode will not operate correctly with an ISOBUS class 1

tractor.

•CTR201: Always use the ISOBUS implement connector (IBBC) when you connect

the system to the tractor.

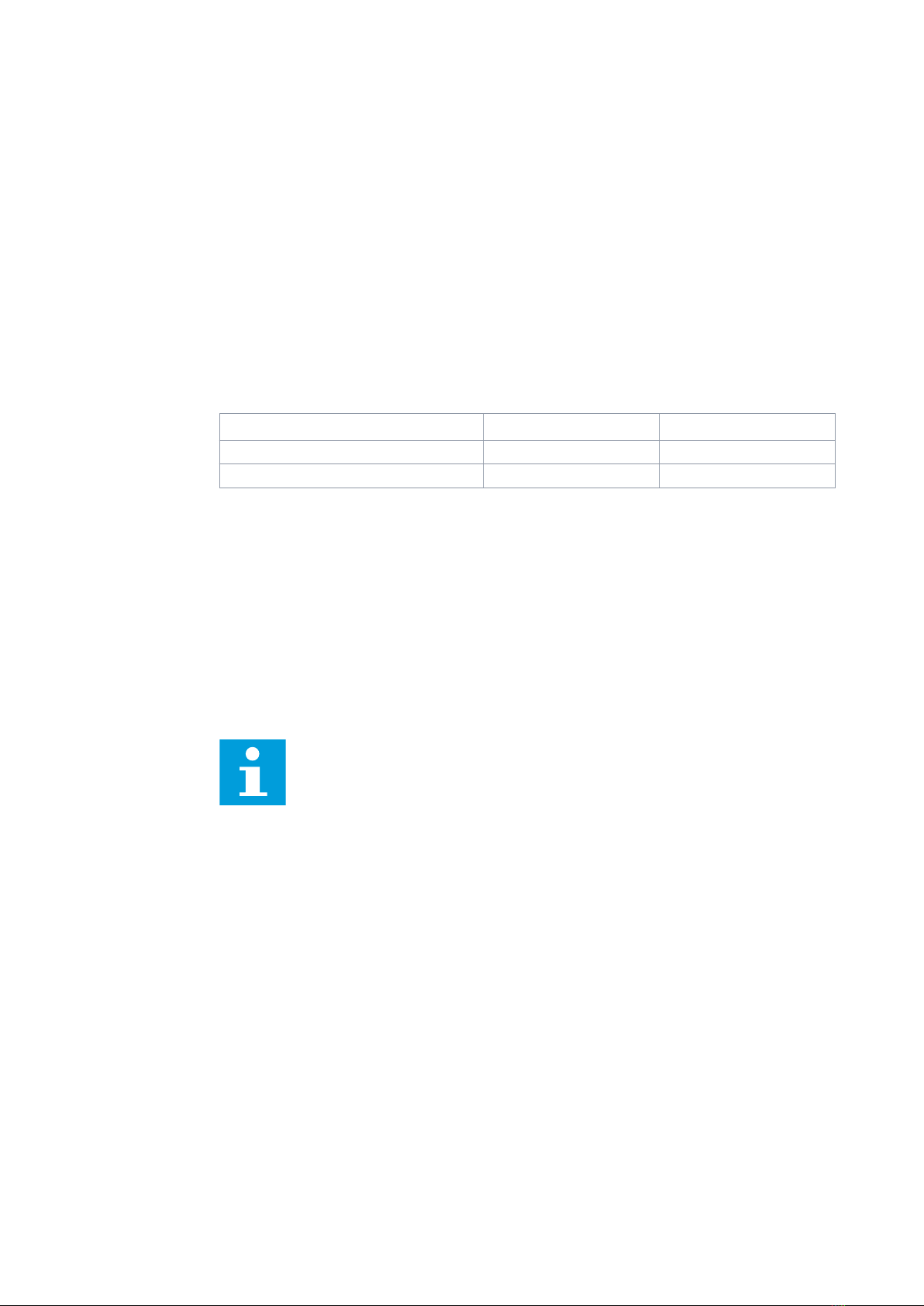

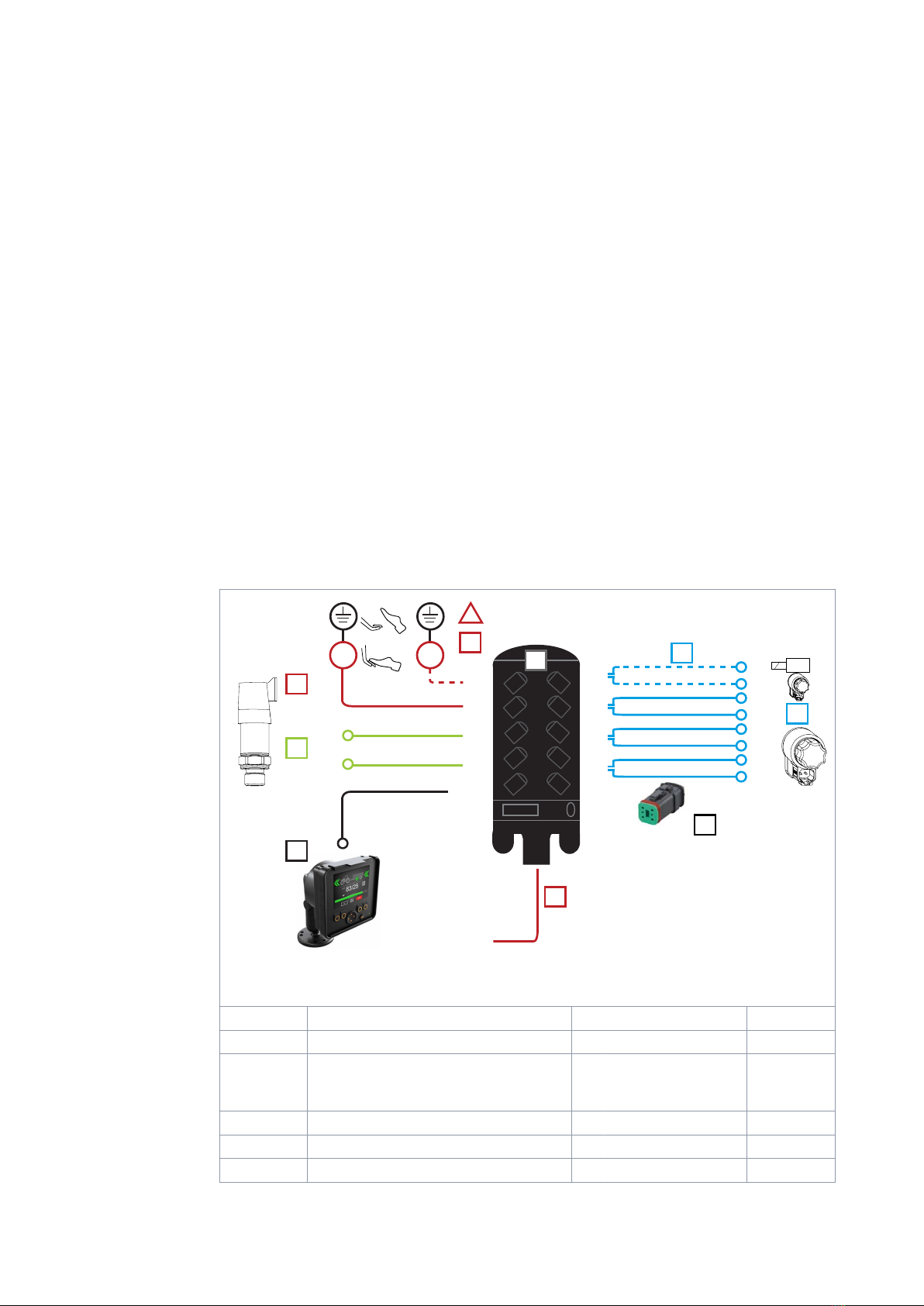

Control system connection diagrams

8

6

4

2

CAN OUT

7

5

3

1

CAN IN

6

3

2

WV1

P_A

WV3

M_B

M_A

PDB

+12V

12 V DC

WV2

2

1 PDB2

P_B

1

4

+12V

5

89

7

!

AUX

Figure 7. Connection diagram, 2WD.

1 Control device

Cables Description Cable ID Length [m]

2 Valve cables

WV1 / P_A

WV3 / P_B

PDB / WV2

1

3 Brake signal cable Brake_sig 10

4 Pressure sensor cables M_A, M_B 1

5 Display cable + extension Display 10 + 0.3

5.3.2

Control system

20 Product manual

This manual suits for next models

4

Table of contents

Other Black Bruin Control System manuals

Popular Control System manuals by other brands

Velleman

Velleman CAMSET24 user manual

Duro Dyne

Duro Dyne DuroZone RED-4 installation instructions

Medem

Medem SEC-Le V4 installation instructions

PAW

PAW HeatBloC K33R Installation and operation instruction

Contro l4

Contro l4 Control4 Smart Home quick start guide

Force America

Force America SSC6100 CAN ULTRA Operation manual