Force America SSC6100 CAN ULTRA User manual

SSC6100

Spreader Control

Operation Manual

Firmware Version

0.54

SSC6100 Operation Manual

i

Table of Contents

Table of Contents ............................................................................................. i

Features and Controls .................................................................................... 1

LCD Screen ............................................................................................................................ 1

Operator Interface ................................................................................................................. 2

The Operation Screen ..................................................................................... 2

Navigation Controls .............................................................................................................. 3

Soft Switch Panes ................................................................................................................. 4

Header Bar ............................................................................................................................. 5

Data Items .............................................................................................................................. 6

Left Window Area .................................................................................................................. 7

Right Window Area ............................................................................................................... 7

Startup and Shutdown .................................................................................... 8

Startup.................................................................................................................................... 8

Driver ID ................................................................................................................................. 8

ESTOP .................................................................................................................................. 10

Shutdown ............................................................................................................................. 10

Backlighting and Speaker Volume ............................................................... 11

Spreading Modes .......................................................................................... 11

Standby ................................................................................................................................ 11

Blast ..................................................................................................................................... 12

Loop Modes ......................................................................................................................... 12

Operating Modes ........................................................................................... 13

Spreader On / Off ................................................................................................................ 13

Implements .......................................................................................................................... 14

Materials Menu .............................................................................................. 15

Spreading Modes .......................................................................................... 16

No Application Mode .......................................................................................................... 16

Granular / Prewet Application Mode ................................................................................. 16

Prewet / Spray Bar Application Mode ............................................................................... 18

Direct Liquid Application Mode ......................................................................................... 19

Simultaneous Granular / Prewet / Direct Application Mode ........................................... 20

Directional Spinner Mode................................................................................................... 22

Tow Plow Granular Mode ................................................................................................... 23

Tow Plow Direct Liquid Application Mode ....................................................................... 24

Dust Control Mode .............................................................................................................. 25

Herbicide Mode ................................................................................................................... 26

SSC6100 Operation Manual

ii

Unload Materials ................................................................................................................. 27

Simulated Speed ................................................................................................................. 28

Temperature Compensation .............................................................................................. 28

Joystick Operation ........................................................................................ 29

Patrol Commander® Ultra Joysticks ................................................................................ 29

CommandAll® Single Joystick .......................................................................................... 29

General Joystick Operation ............................................................................................... 30

PreCise®MRM ARC Air and Road Temperature ......................................... 33

Cameras ......................................................................................................... 33

Auxiliary Modes ............................................................................................. 34

Aux Power Mode ................................................................................................................. 34

Distance Measure ............................................................................................................... 35

Data Menu ...................................................................................................... 36

Current Totals ..................................................................................................................... 36

Season Totals ...................................................................................................................... 36

Error Log .............................................................................................................................. 37

Clearing Totals and Logs ................................................................................................... 37

PreCise®MRM Over-the-Air Communications ............................................ 37

Cell Status ........................................................................................................................... 37

GPS Status .......................................................................................................................... 37

Spreader Error Conditions ........................................................................... 38

Range Error ......................................................................................................................... 38

Feedback Error .................................................................................................................... 38

Feedback Error / Open Loop ............................................................................................. 39

Low Material ........................................................................................................................ 39

Low Liquid ........................................................................................................................... 39

Directional Spinner Feedback Error ................................................................................. 39

System Errors and Warnings ....................................................................... 40

Pop-up Errors ...................................................................................................................... 40

Header Bar Errors and Warnings ...................................................................................... 45

Joystick Error Codes .......................................................................................................... 49

Diagnostic Menu ............................................................................................ 50

Licensing and Source Code Availability ..................................................... 51

Appendix A – GNU General Public License, Version 2 .............................. 52

Appendix B - Data Items complete listing ................................................... 55

FORCE America Contact Information .......................................................... 59

1

Features and Controls

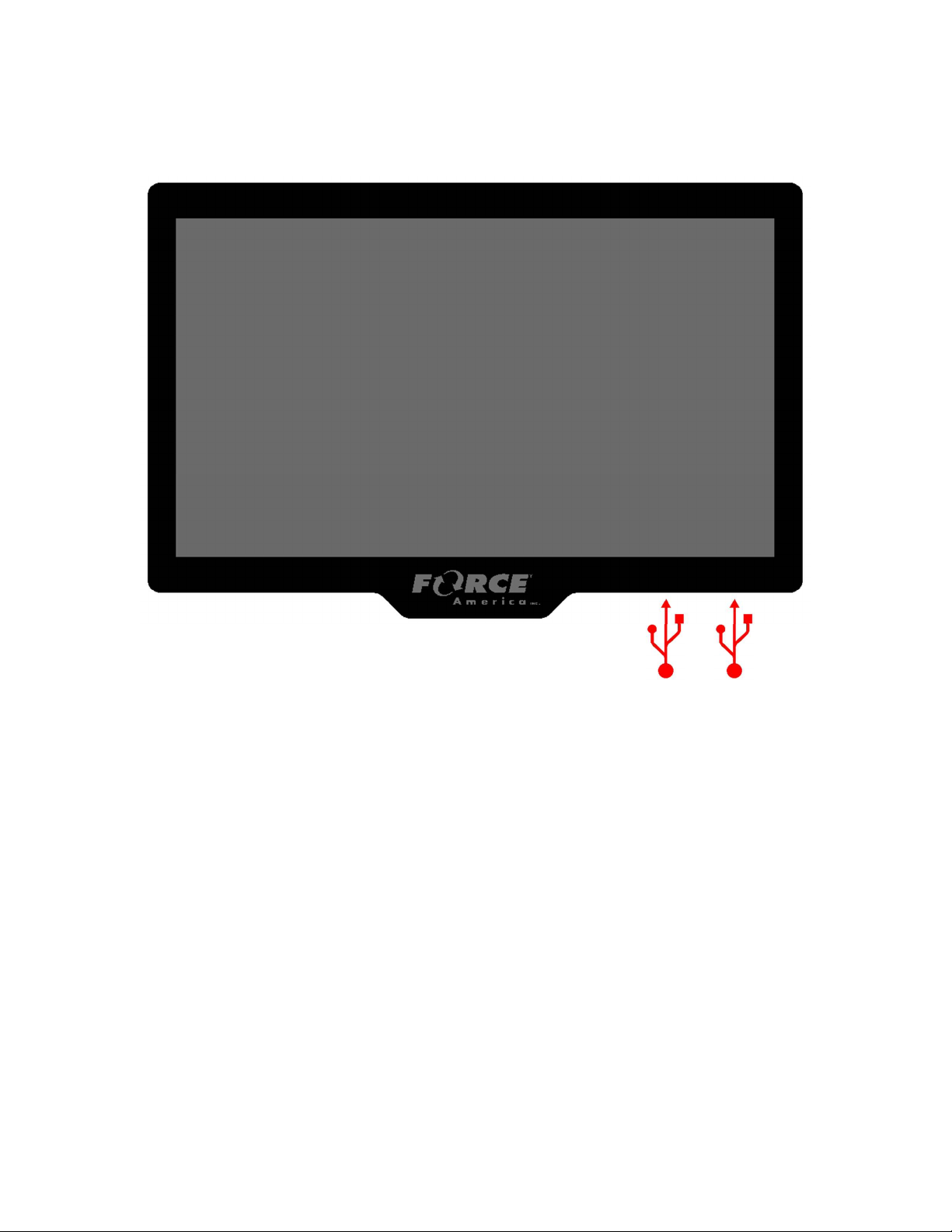

LCD Screen

The main system component of the 6100 is the 10” LCD touchscreen which displays operating

parameters, optional camera views and allows selection and adjustment of the various operating

modes.

It also features two USB ports on the lower right surface that can be used for system upgrades,

saving and loading calibration settings, as well driver identification. The locations of these are

shown by the red USB symbols.

2

Operator Interface

The Operator Interface provides controls for many functions of the SSC6100 control system. It is

designed to provide ergonomic and tactical controls while operating the vehicle. The specific

functions of the knobs, joystick, and pushbuttons for each operating mode are described in the

associated sections of this manual.

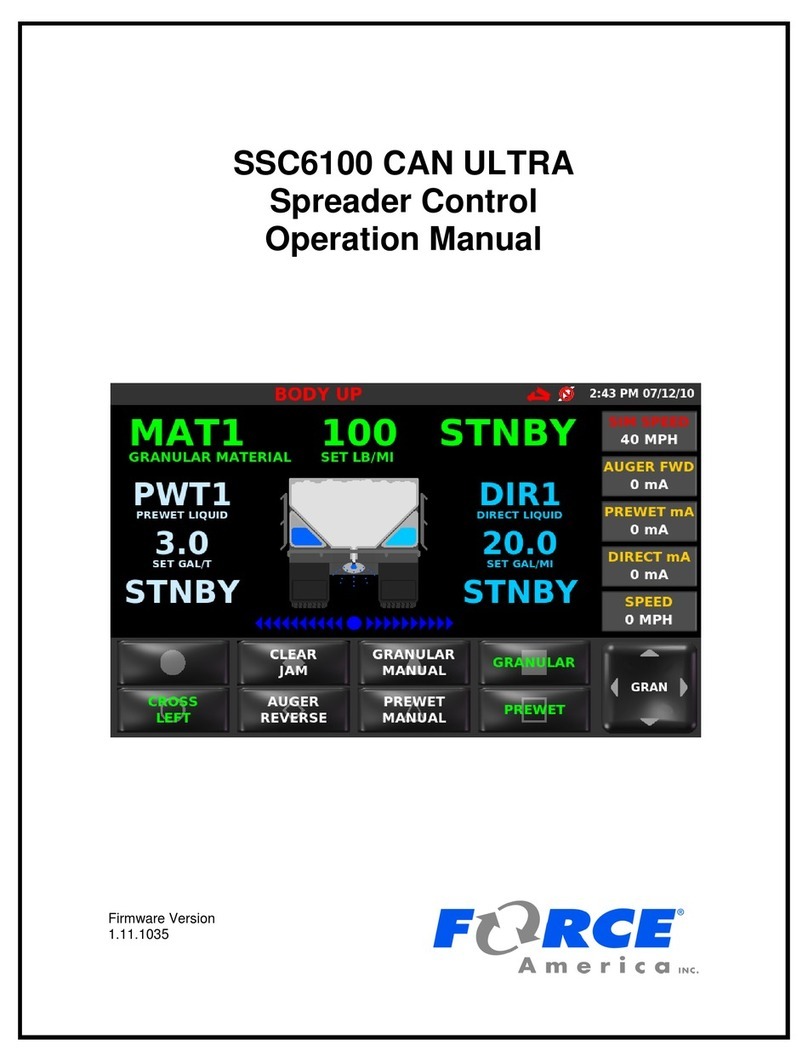

The Operation Screen

The Operation Screen is the main screen of the SSC6100, and provides controls for all of the

system functions as well as access to the Data, Calib, Unload, and Material Selection menus. It

is divided into six distinct areas described below.

3

Navigation Controls

The touch screen navigation controls area and Nav Stick joystick provides a way to change

between views on the screen, select panes of Soft Switches, and make adjustments to settings.

The up, down, left, right, and select functions can be done using Nav Stick on the operator

interface or also with the touchscreen on the display.

4

Soft Switch Panes

The touchscreen soft switch pane area and the associated buttons on the operator interface

provides access to an array of various switch functions. The name of the current pane is

displayed on the lower left corner of the screen.

The left and right navigational controls scroll between the available panes of Soft Switches. The

individual Soft Switches can be operated either by touching the Soft Switch button on the screen

or pressing the associated button on the operator interface. Soft Switches that toggle a function

Off and On indicate when the function is On by showing the button text in Green.

The number of and types of soft switch panes varies with each configuration of the system. Each

section of this manual will describe the function of each of the Soft Switches on their associated

switch pane(s).

5

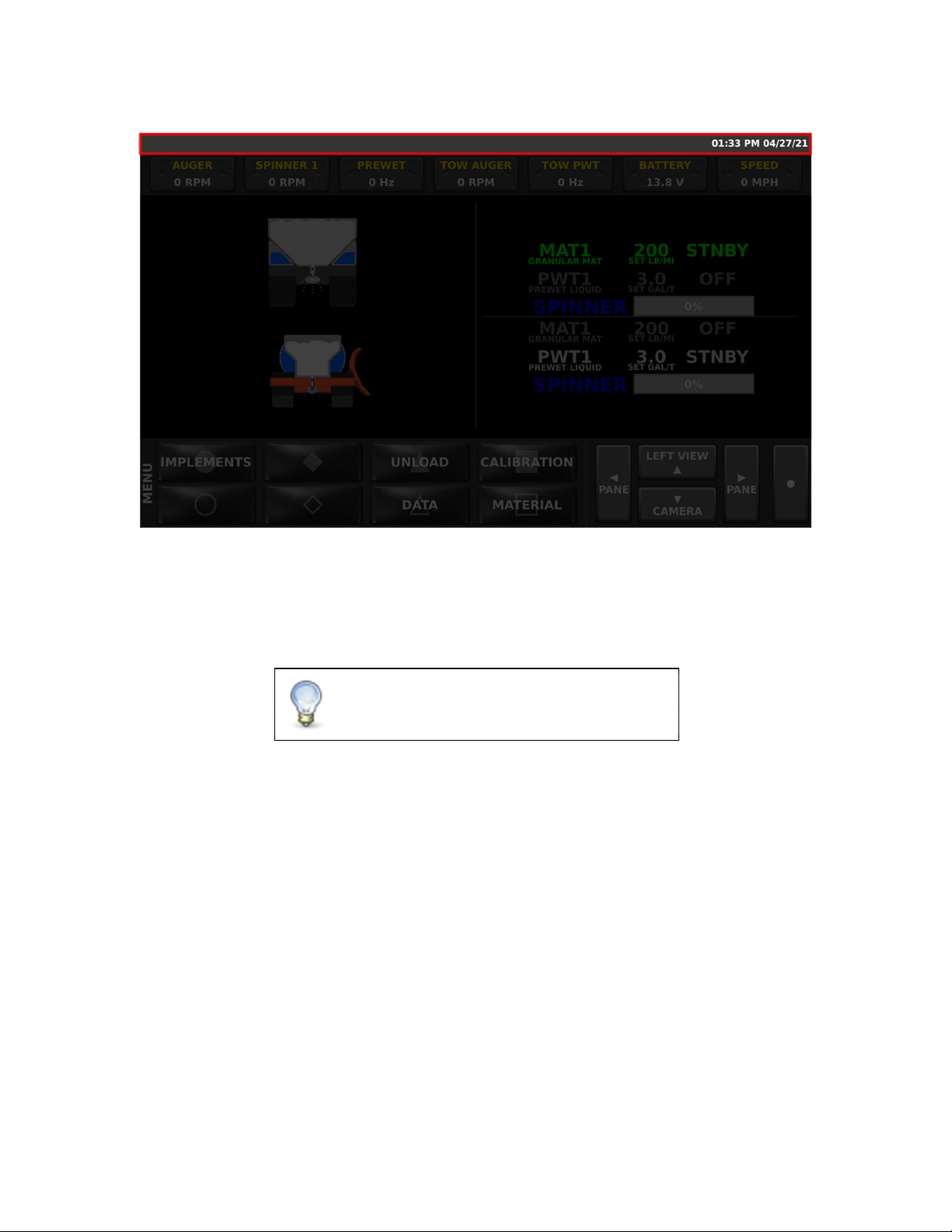

Header Bar

The Header Bar appears across the top of the screen. System Time and Date will be displayed

on the right side of the Header Bar. The time is set automatically, including any Daylight Savings

Time changes your time zone supports.

The header bar also can show system status, warning, and error messages. If two or more

system status messages are active, the messages will sequence through each one.

For more information on specific warnings or

errors see Header Bar Errors and Warnings on

page 45.

6

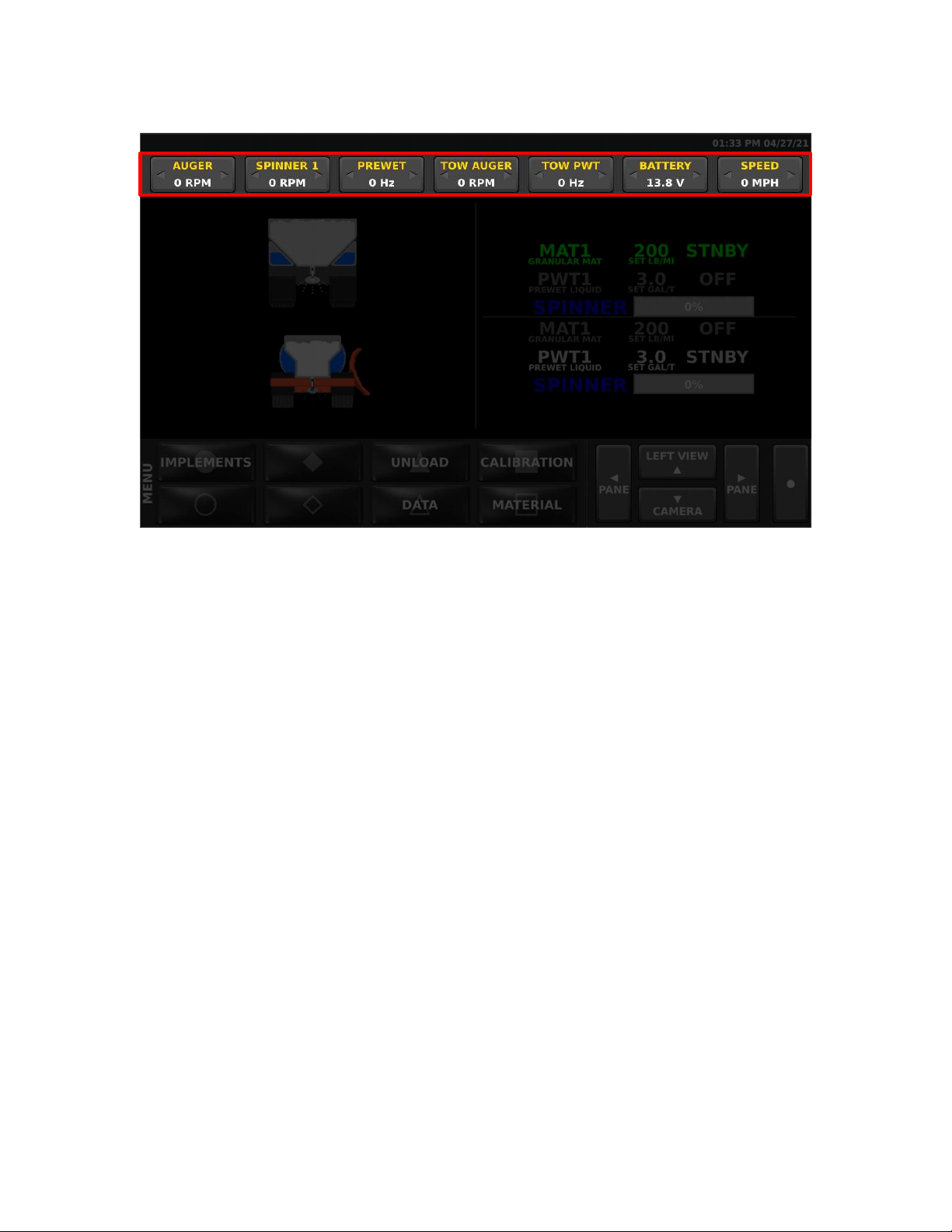

Data Items

Directly below the header bar is a row of data items that can be customized to show a number of

different types of information. Tap the left or right triangles to choose what information is

displayed on each item. For a list of all the available data items and their description, see

Appendix B - Data Items complete listing on page 55.

7

Left Window Area

The left window can display a variety of information depending on how the system is configured.

By default, it displays an image of the currently active spreader system on the vehicle. If enabled,

this window can also display road and air temperature, a joystick guide if applicable, and camera

images. Pressing up on the Nav Stick, or the up arrow on the Nav Stick Pushbutton will cycle

through the possible options for this window. Pressing down on the Nav Stick, or the down arrow

on the Nav Stick Pushbutton will cycle through camera images, if equipped.

Right Window Area

8

The right window by default displays spreader rate information. If enabled, this window can also

display camera images. Pressing down on the Nav Stick Pushbutton, or the down arrow on the

Nav Stick will cycle through camera images, if equipped. If the spreader power switch is off, the

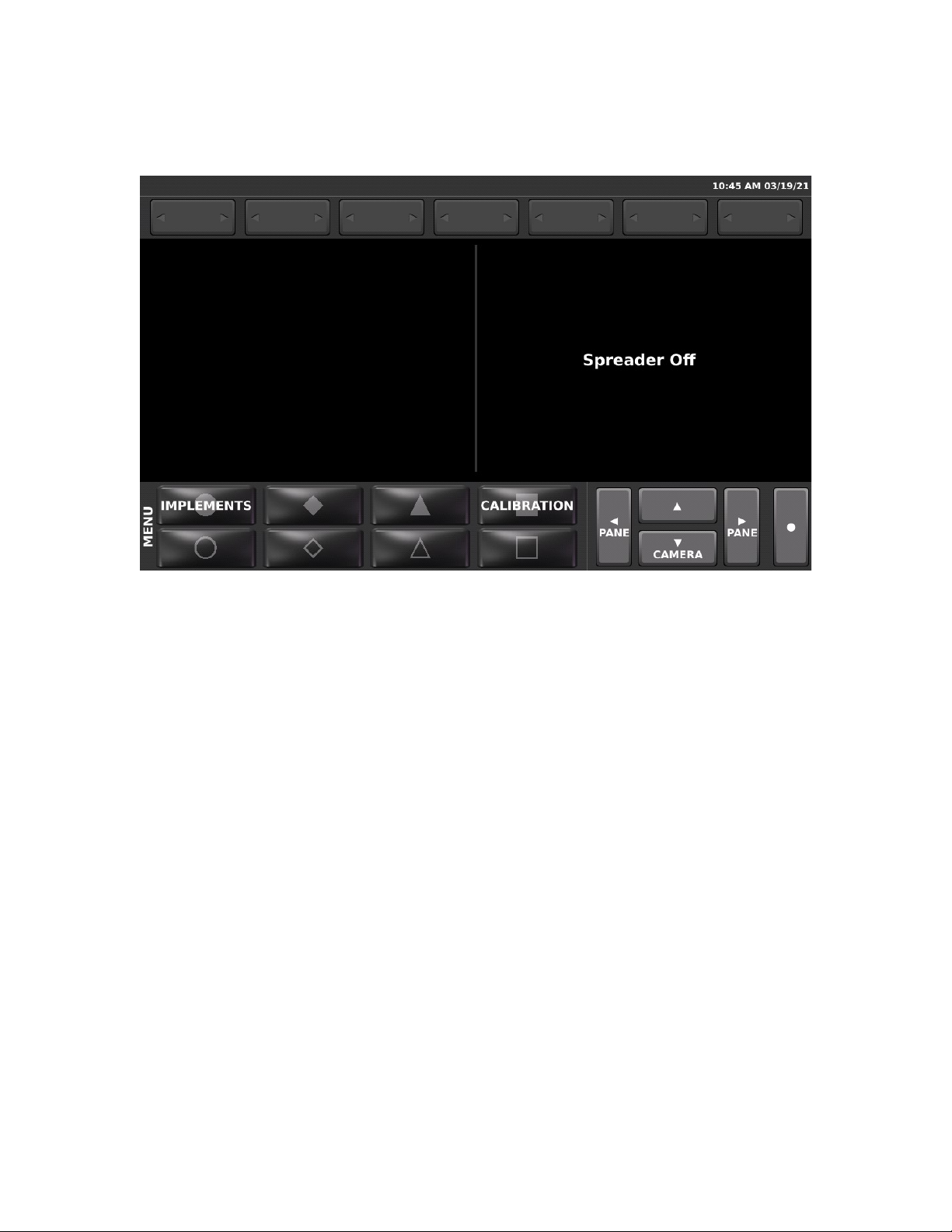

spreader screen with display “Spreader Off”.

Startup and Shutdown

Startup

The 6100 automatically powers up with the vehicle dash key ignition. As the system boots, it will

display a splash screen with a bar graph that tracks the boot progress until it is ready for

operation.

Driver ID

If Driver ID mode is enabled, the SSC6100 will require the user to log in before the system will

operate the spreader features. Joystick functions can still be operated without logging in.

Spreader material and usage data is recorded for the currently logged in driver. Be sure to use

the LOGOUT button on the MENU Softswitch pane when finished to ensure that all data is

recorded under the correct driver.

Three methods of identification are supported depending on which one has been selected in

Calibration.

9

Driver ID Key

This method requires a USB driver key to log in to the system. Insert a pre-programmed USB

Driver ID Key into either of the USB ports on the lower right side of the screen. Additional driver

ID keys can be programmed in the Calibration menu. See the SSC6100 Calibration manual for

more information.

Numeric Driver ID Entry

Alphanumeric Driver ID Entry

For the Numeric or Alphanumeric Driver ID modes, enter your numeric Driver ID using the on-

screen keypad and press the Enter button.

Pressing the ABC or 123 button toggles the entry screen between letters and numbers. The

Underscore button may also be used as part of the password text.

10

ESTOP

The SSC6100 has an emergency stop feature that is activated by pressing the red ESTOP

pushbutton located near the Operator Interface control. When ESTOP is activated the screen

shows the red Emergency Stop Activated message and a buzzer sounds. In addition, all outputs

are immediately shut off, the system enters Standby mode, and if the system is configured with a

Low Oil PTO or diverter valve, these will be shut off as well.

To cancel the ESTOP, rotate the red ESTOP pushbutton clockwise and let it pop back out. After

ESTOP mode is cleared, follow the ESTOP Cleared, System Reactivating warning message to

ensure that the vehicle is clear of personnel before pressing the Nav Stick to reactivate the

system outputs.

Shutdown

The 6100 automatically begins a shutdown process when power is no longer detected from the

key switch. A built-in timer prevents the system from shutting down during engine starting.

To reduce the risk of death or injury, ensure

that all personnel are clear from moving

machinery before activating outputs.

11

Pressing the Nav Stick Pushbutton will bypass the timer and immediately start the shutdown

process.

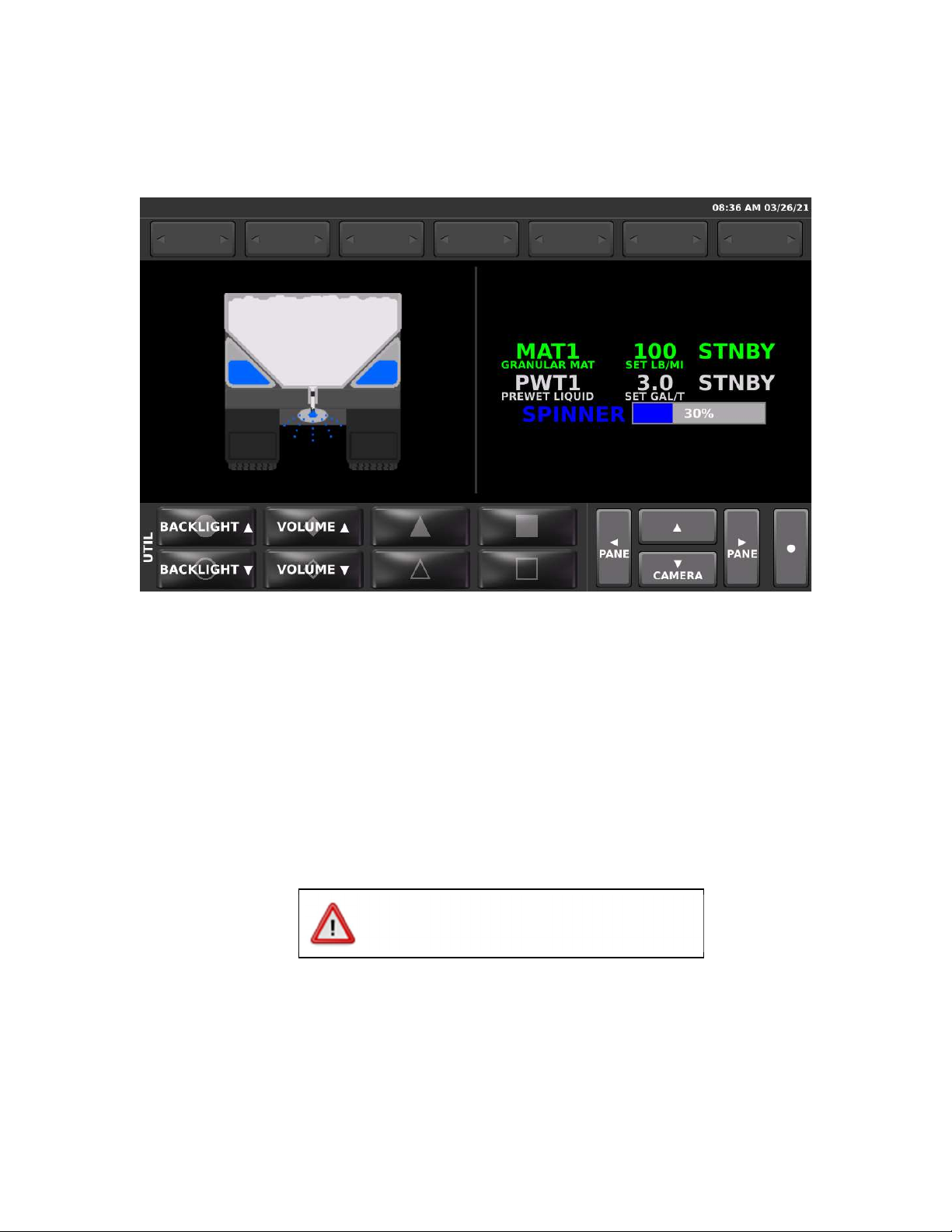

Backlighting and Speaker Volume

The intensity of the LCD backlighting and volume of the speaker can be adjusted on the UTIL

Soft Switch pane. As the speaker volume is adjusted, the speaker sounds a tone to show how

loud or soft the setting is.

Spreading Modes

Standby

Standby mode is generally used to start and stop the spreader at specific points on the route.

The SSC6100 system starts up in Standby mode with all the spreader outputs deactivated.

Pressing the Green knob on the Operator Interface toggles spreader in and out of Standby mode.

The Actual rates shown on the screen will read “STNBY” to indicate when the spreader is in

Standby mode. When the system is out of Standby and the vehicle is moving, the actual rates

will be displayed in this area.

Note that some menus and functions require that the 6100 to be in standby mode for them to be

accessed. Check to make sure the spreader is in Standby mode if you are having difficulty

accessing a certain function.

To reduce the risk of death or injury, ensure

that all personnel are clear from moving

machinery before activating outputs.

12

Blast

Blast is a spreader feature that is generally used to run the outputs at a higher than normal rate in

order to “Blast” a portion of road with extra material. Blast is activated by pressing the Blue knob.

Depending on the calibration settings, the blast mode may be set up to operate on a timer or

distance function that keeps the blast active for a certain amount of time or distance. The blast

mode in this case can be cancelled by pressing the Blue knob a second time.

When Blast is activated, the granular row will display the word “BLAST” instead of the material

name.

Note that activating blast while the vehicle is not moving will activate the outputs.

Loop Modes

The SSC6100 can apply most materials in one of three loop modes:

Closed-Loop Mode

Closed-Loop Mode is the default operating mode for spreading material. It uses the

vehicle speed and sensors on the material outputs to measure actual rates and apply

adjustments on the fly to increase material application accuracy. Outputs will

automatically start and stop with the vehicle.

Open-Loop Mode

Open-Loop Mode uses vehicle speed and a calculation to control the material outputs.

Because it doesn’t use a feedback sensor it is not as accurate as Closed Loop. Outputs

will automatically start and stop with the vehicle.

Manual Mode

Manual Mode does not vary its output rate with vehicle speed. Instead, granular or

prewet liquid material is applied at a constant rate. Materials spread in manual mode are

spread less accurately than in open-loop or closed-loop mode. Outputs do not start and

stop with the vehicle.

To reduce the risk of death or injury, ensure

that all personnel are clear from moving

machinery before activating outputs.

13

Operating Modes

Spreader On / Off

The 6100 system operates many aspects of the hydraulic system including joystick and spreader

functions. For off-season use where the spreader controls are not required, a Spreader Power

rocker switch can be used to remove the spreader functions from the operation screen and

prevent outputs from being activated.

This switch is located near the operator interface controls. When this spreader switch is off, the

operation screen appears as shown.

14

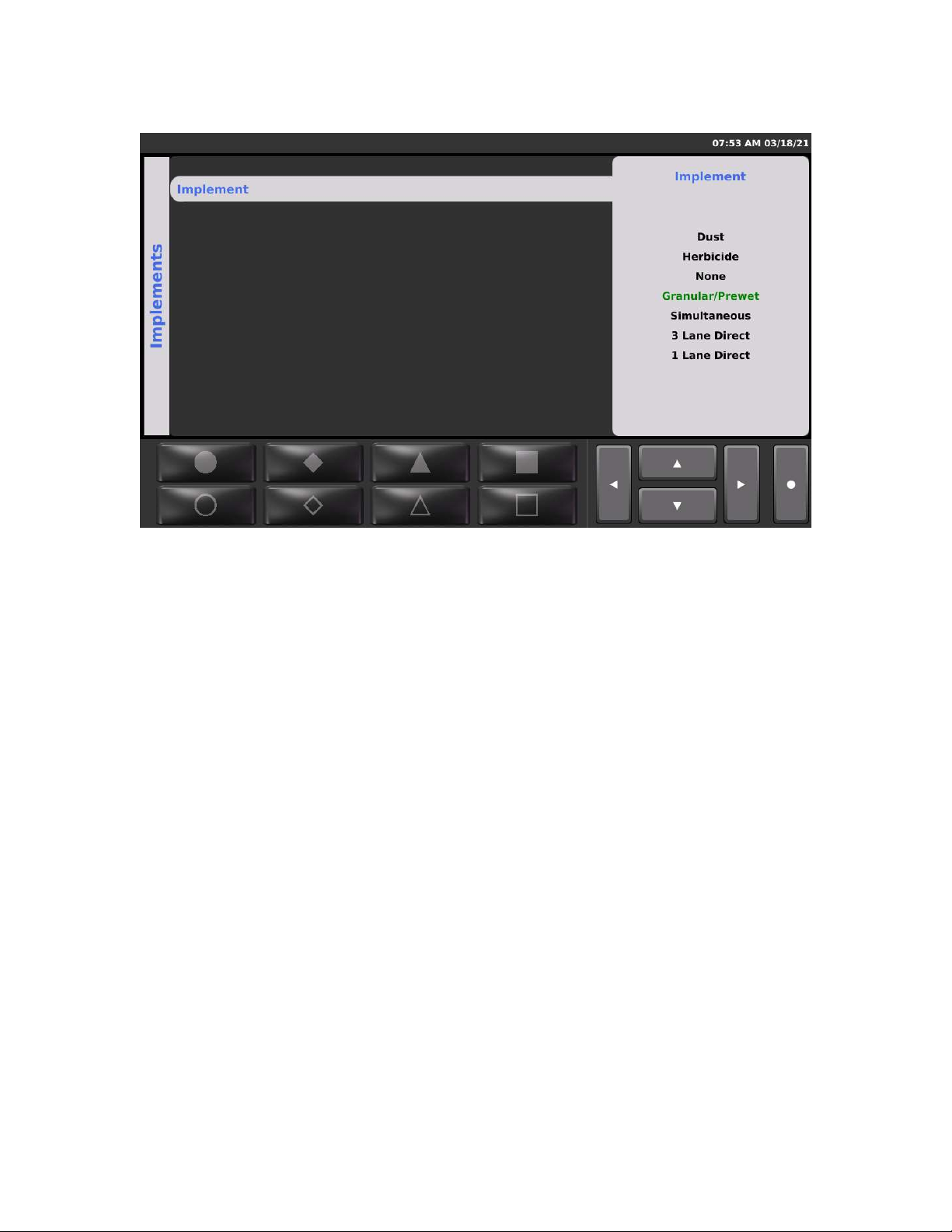

Implements

The SSC6100 system can optionally be configured to operate multiple types of equipment

allowing the vehicle to be tailored for spreading various materials or performing seasonal work.

These configurations are called Implements.

If your system supports multiple configurations there will be an Implements button on the MENU

Soft Switch pane. Press this button to choose between the available Implement configurations

using the Nav Stick controls

Note that the system must be in standby and the vehicle speed must be less than 5 MPH,

including Simspeed.

Each system is custom programmed at the factory to fit the specific needs of each vehicle. For

changes to the implements or how they behave, please contact a FORCE America

Representative for assistance.

15

Materials Menu

The Material Selection Menu allows you to choose between different materials for each of the

spreading modes. The list of available materials is configured and calibrated for each mode in

the Calibration settings.

To access the Materials Menu and make changes, scroll to the MENU Soft Switch pane and

press the Material Soft Switch. Use the Navigation Up and Down Controls to select a material

and press the Nav Stick to enter the menu.

Note that if the material you wish to select is not visible, exit the Material menu and select a

different Implement using the Implement menu.

Choose the desired material by name and press the Nav Stick button to select and activate that

material.

If temperature compensation mode is enabled, a Temperature Profile menu will allow selection

between one of three optional compensation profiles.

Exit the Material menu using the Navigation Control Left direction.

16

Spreading Modes

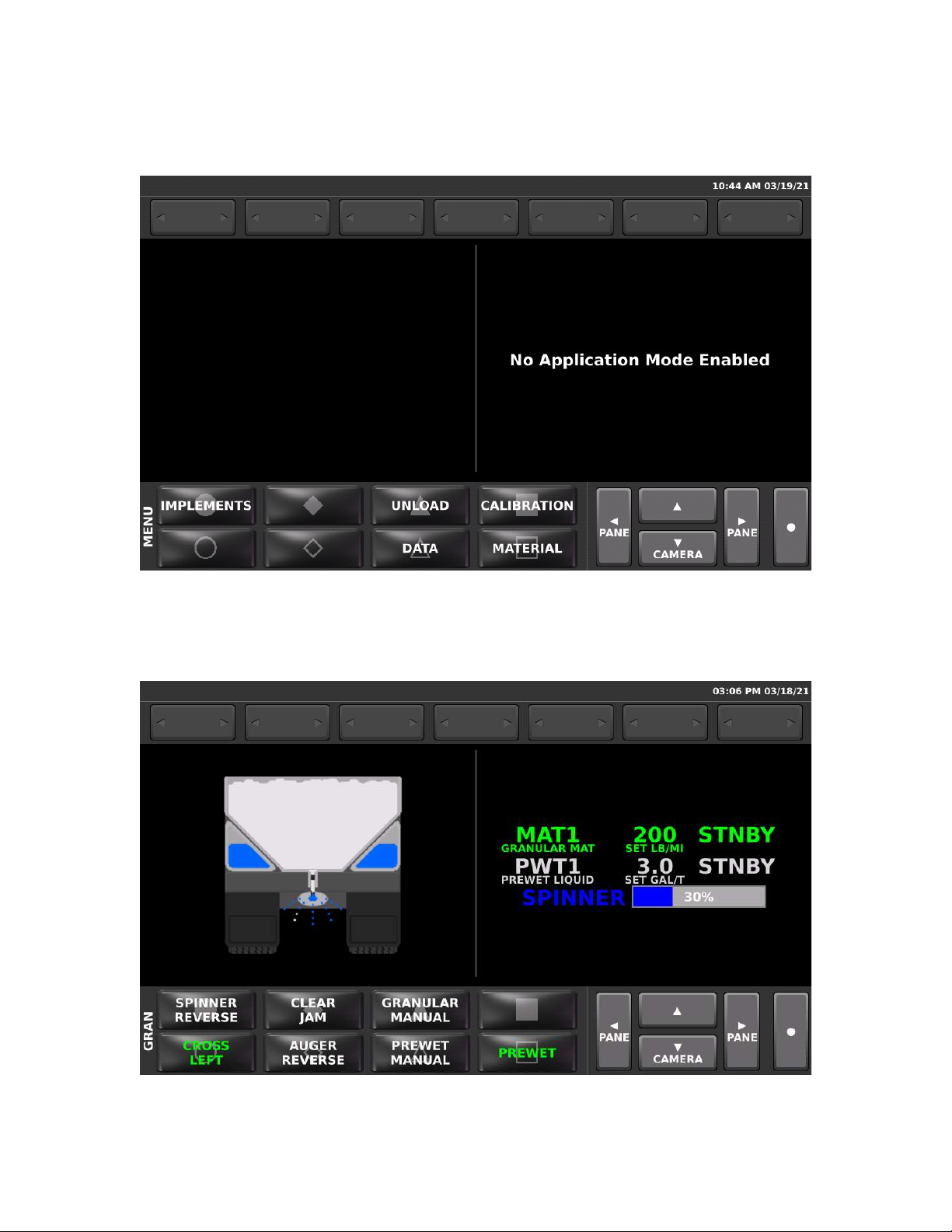

No Application Mode

Selecting an Implement type of “None” is generally used to disable seasonal functions and

prevent accidental activation of hydraulic functions. In this mode, the spreader functions will not

run, but Joystick functions will still operate normally.

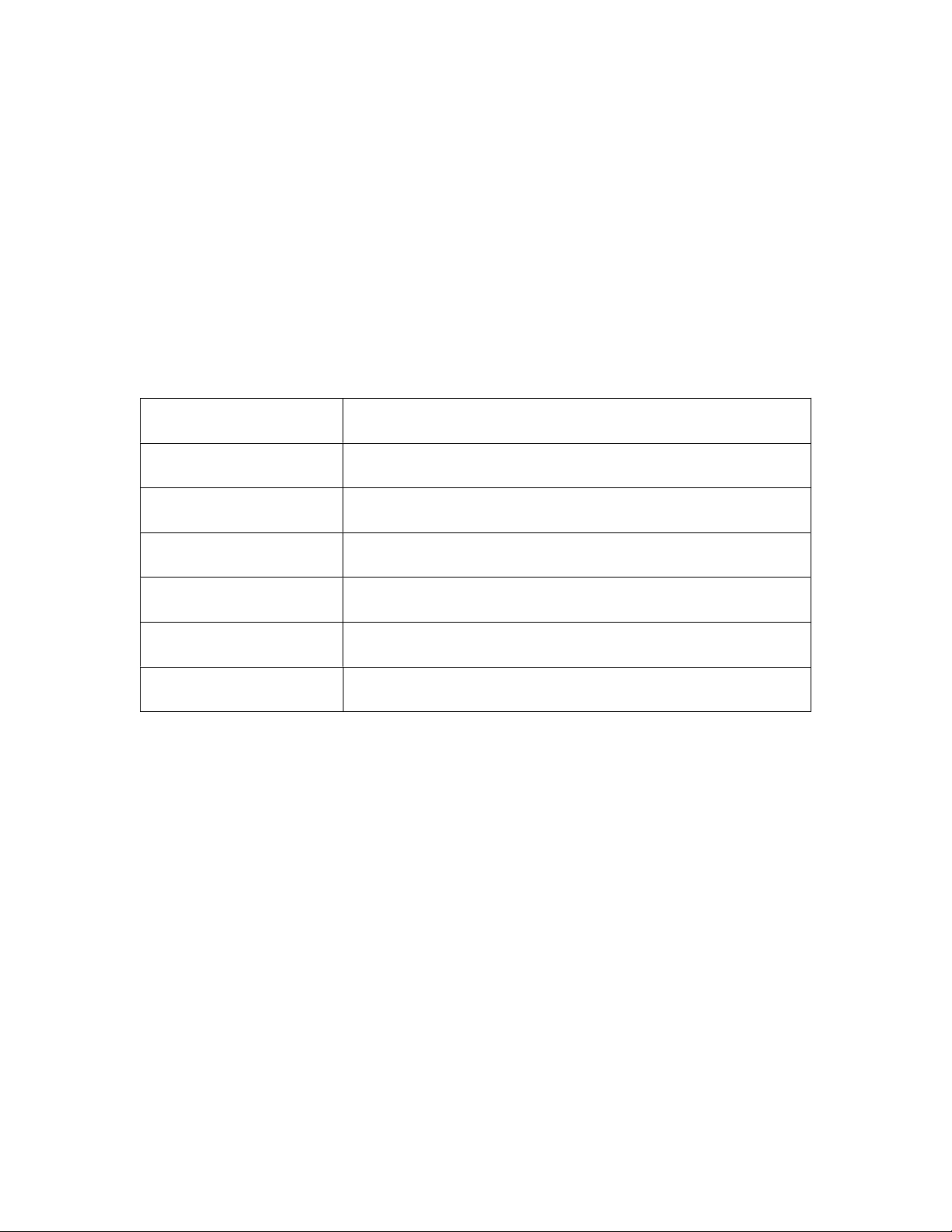

Granular / Prewet Application Mode

This mode applies granular material with the option to apply prewet.

17

The green text contains information about the granular material, its set rate, and its actual output

rate. The granular rate is adjusted using the Green knob on the Operator Interface.

The white text contains information about your prewet material, its set rate, and its actual output

rate. The Prewet rate is adjusted by rotating the Nav Stick knob, if applicable. If the prewet

system is configured for gravity feed, no rates will be displayed. When the Prewet Soft Switch is

off, this line is grayed out and shows “OFF” for the actual rate.

The blue text and bar graph shows the relative spinner speed in percentage. The spinner speed

is adjusted using the Blue knob on the Operator Interface.

Granular and Prewet Soft Switches

The GRAN Soft Switch pane controls the granular functions. It may have additional options

available depending on how the system is configured. The following table describes each option.

SPINNER REVERSE Reverses the rotational direction of the spinner

CLEAR JAM Momentarily reverses the auger to attempt to clear a jam. The

auger reverses only for as long as the button is held.

GRANULAR MANUAL Toggles granular manual mode Off and On

CROSS LEFT / RIGHT Toggles between a left and right cross conveyor direction

AUGER REVERSE Toggles the direction of the auger to spread material in the

opposite direction.

PREWET MANUAL Toggles the Prewet manual mode material Off and On

PREWET Toggles the Prewet output Off and On

Adjustable Gate Mode

The granular system can be set up to use an adjustable gate mode. In this mode, the height of

the conveyor gate can be varied to cover a wider range of spreading rates. For accurate

spreading, it is important that the SSC6100 spreader control gate setting matches the actual

height of the gate.

Note that spreading with an incorrect gate heigh will result in inaccurate material rates and

inaccurate material usage data.

To remind users to check the gate height, a “Check Gate Setting” pop-up message box appears

whenever the material is changed. Press the Nav Stick pushbutton to clear the message box and

then use the Gate Height menu option to enter the correct gate height for the current gate setting

on the conveyor.

Two Position Gate Mode

For additional assurance that the correct gate height is set, the SSC6100 can be configured to

use a two position gate with sensors. In this mode, each material is set in calibration to use an

either “low” or “high” gate setting. When a material is selected, electrical sensors on the gate

confirm whether the gate is in the correct position. If it is in the wrong position for the selected

Other manuals for SSC6100 CAN ULTRA

4

Table of contents

Other Force America Control System manuals