203-A00 page 7/12

MAINTENANCE

PUMP DISASSEMBLY

NOTICE:

Follow all hazard warnings and instructions provided in

the “Maintenance” section of this manual.

1. Starting on the inboard (driven) end of the pump, clean

the pump shaft thoroughly, making sure the shaft is free of

nicks and burrs. This will prevent damage to the

mechanical seal when the inboard head assembly is

removed.

2. Remove the inboard bearing cover capscrews (28) and

slide the inboard bearing cover (27A) and gasket (26) off

the shaft. Discard the bearing cover gasket.

3. Remove the outboard bearing cover capscrews (28) and

slide the outboard bearing cover (27A) and gasket (26) off

the shaft. Discard the bearing cover gasket.

4. To remove the locknuts and lockwashers (24A and 24B):

a. Bend up the engaged lockwasher tang and loosen the

set screw (24C) in the lock nut.

b. Rotate the locknut (24A) counterclockwise to remove it

from the shaft.

c. Slide the lockwasher (24B) off the shaft. Inspect the

lockwasher for damage and replace as required.

d. Repeat steps a, b and c on the opposite shaft end.

5. Remove the head capscrews (21) and carefully pry the

head (20) away from the cylinder. Jack screw holes are

provided on the STX3 if needed.

6. Slide the head off the shaft. The head O-ring (72), bearing

(24), and mechanical seal (153) will come off with the

head assembly. Remove and discard the head O-ring.

a. Pull the bearing (24) from the housing in the head.

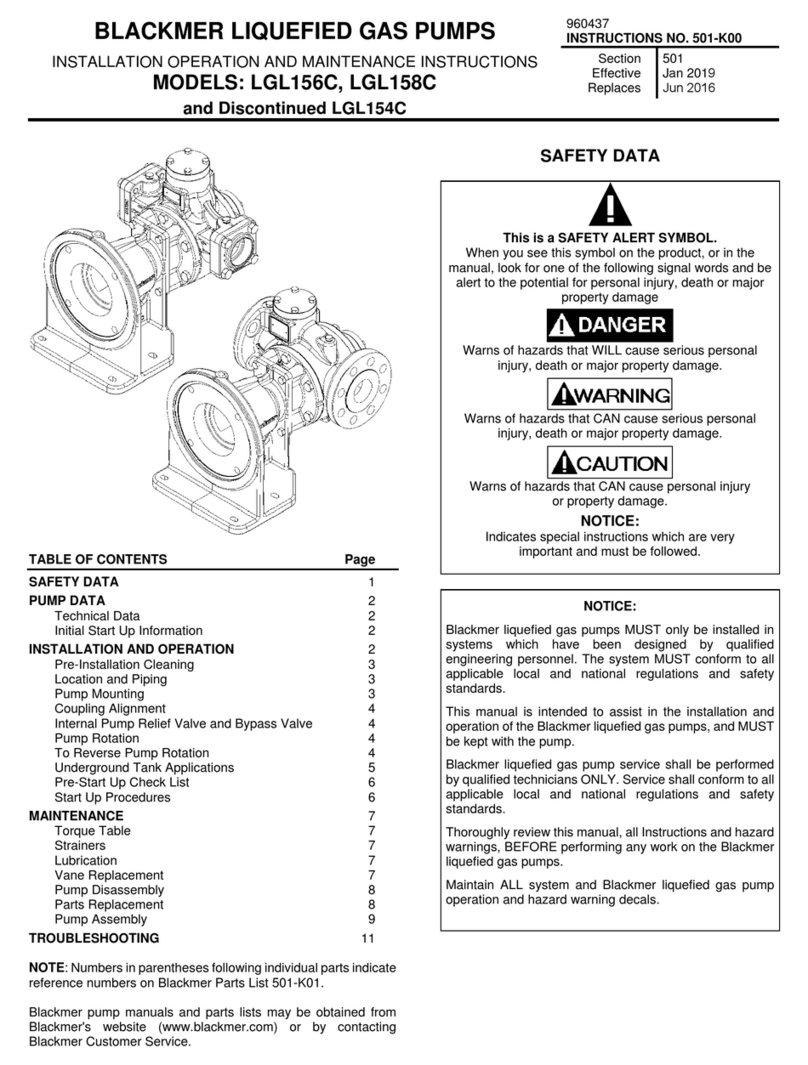

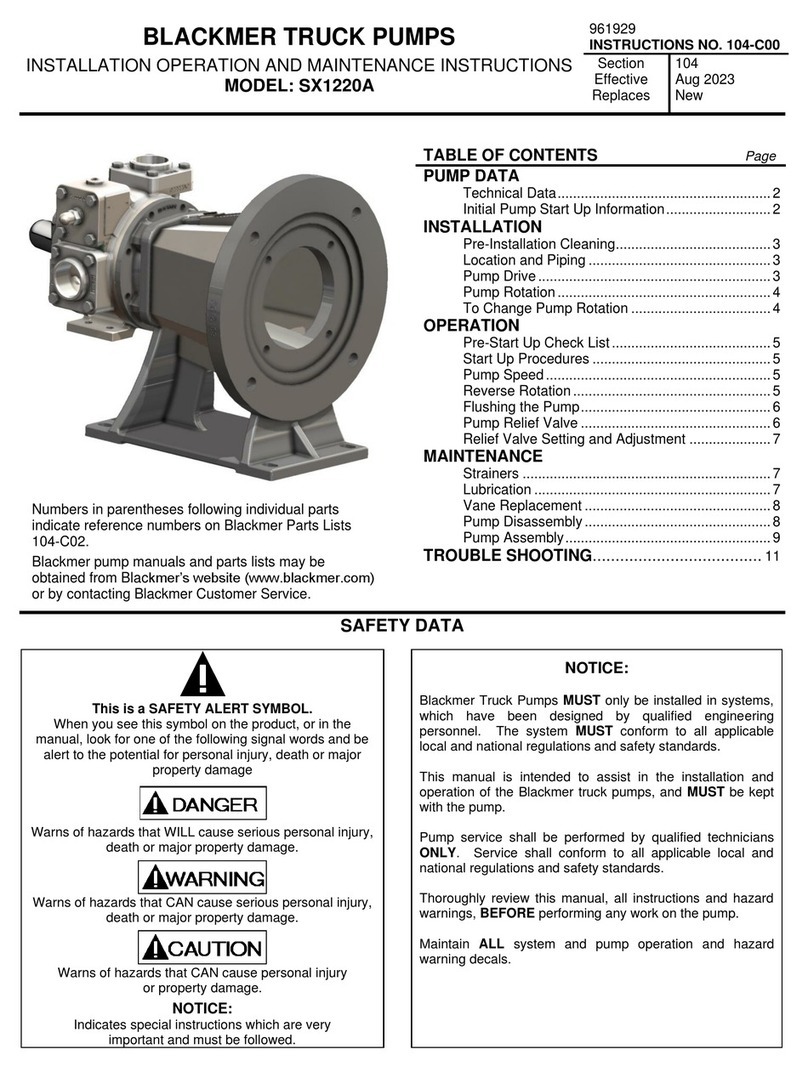

b. To remove the mechanical seal (153), use two screw

drivers to gently push the backside of the seal jacket

to push the seal from the head (see Figure 6). Use

care when placing the screwdrivers to prevent

damage to the seal faces. Remove and discard

mechanical seal O-rings.

Figure 6

7. Pull the rotor and shaft (13) from the cylinder. While one

hand is pulling the shaft, the other hand should be cupped

underneath the rotor to prevent the vanes (14) and push

rods (77) from falling out. Carefully set the rotor and

shaft, vanes and push rods aside for future vane

replacement and reassembly. (STX1220 models do not

use pushrods.)

8. Remove the remaining components from the outboard

side of the pump, as instructed in steps 5 and 6 above.

PUMP ASSEMBLY

Before reassembling the pump, inspect all component

parts for wear or damage, and replace as required. Wash

out the bearing/seal recess of the head and remove any

burrs or nicks from the rotor and shaft.

1. Reassemble the OUTBOARD side of the pump first:

2. Install a new head O-ring (72) in the groove in the head.

Note: For ease of installation, soak the head O-ring in

200°F (93°C) water.

3. Install the head (20) on the outboard side of the cylinder.

Install and uniformly tighten four head capscrews (21) 90°

apart; torque to 25 lbs. ft (34 Nm).

4. MECHANICAL SEAL

Apply a small amount of motor oil in the head recess.

Push the mechanical seal assembly (153) into the recess

of the head with seal jacket drive tangs inward. The pin in

the stationary seat must be between the lugs in the back

of the head recess.

5. Hand pack the ball bearing (24) with grease. Refer to the

"Lubrication" section for the recommended grease.

6. Install the bearing into the head recess. The bearing balls

should face outward, with the grease shield inward.

Ensure the bearing is fully and squarely seated against

the mechanical seal. Install two 3/8" (10 mm) washers

and two bearing cover capscrews (28) to clamp the

bearing for proper bearing locknut adjustment (see Figure

7). The washers and capscrews will be removed after the

locknuts are adjusted. Leave the two capscrews and

washer in place to retain the bearing during assembly.

Figure 7 Clamping the Bearing

7. Turn the pump cylinder around and begin assembly on

the opposite, inboard end.

8. Inspect the vanes (14) and push rods (77) for wear and

damage, and replace as follows:

a. Partially install the non-driven end of the rotor and

shaft (13) into the open side of the pump cylinder.

b. Leave part of the rotor outside of the cylinder so that

the bottom vanes can be installed and held in place as

the push rods are installed in the push rod holes of the

rotor. Insert the new vanes into the rotor slots with the

rounded edges outward, and the vane relief grooves

facing TOWARDS the direction of rotation. See Fig. 4.

c. After the bottom vanes and push rods are installed,

insert the rotor and shaft fully into the cylinder.

(STX1220 models do not use pushrods.)

d. Install the remaining vanes into the top positions of the

rotor. Rotate the shaft by hand to engage the drive

tangs of the seal jacket in the rotor slots.