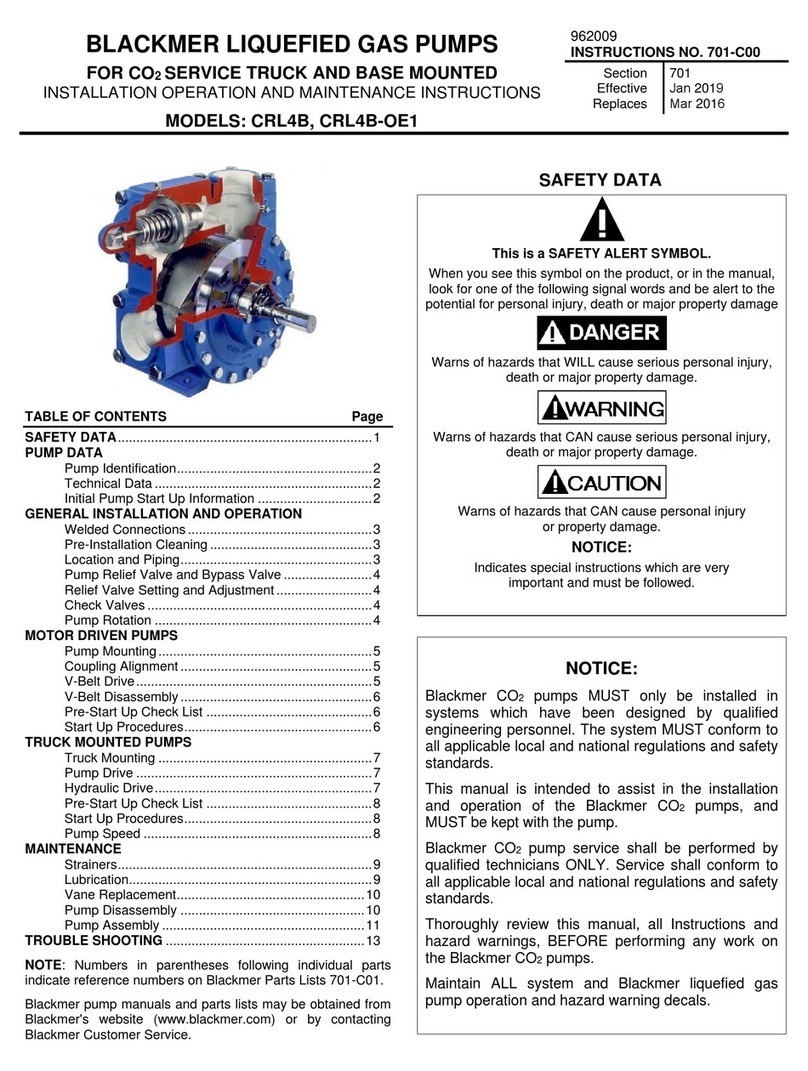

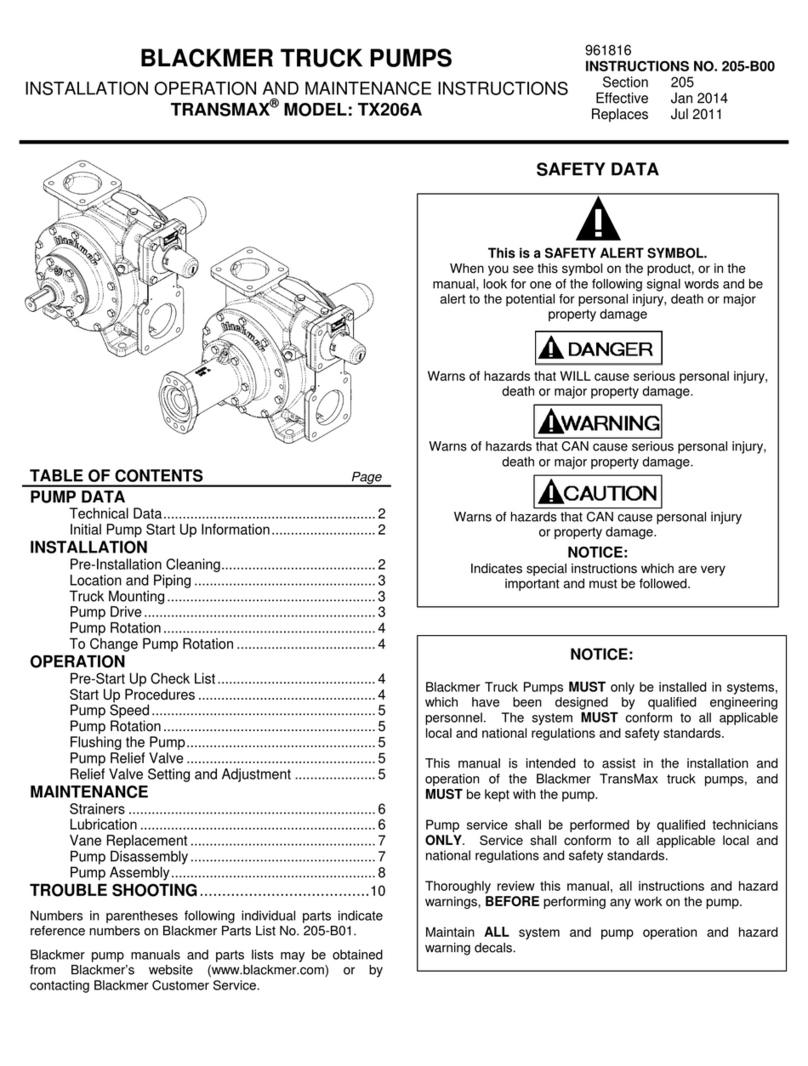

INSTALLATION AND OPERATION - CRL TRUCK MOUNTED PUMPS

6

TRUCK MOUNTING

CRL pump models can be bolted to the truck frame or on a

saddle hung below the frame, and MUST be adequately

supported.

Discontinued TCRLF4A pump models are designed to flange

mount directly to bob tail or transport tank in combination with

a commercial internal control valve. See Figure 6.

PRE-INSTALLATION CLEANING

Foreign matter entering the pump WILL cause extensive

damage. The supply tank and intake piping MUST be cleaned

and flushed prior to pump installation and operation.

LOCATION AND PIPING

An improperly designed piping system or improper unit

installation WILL significantly reduce pump performance and

life. Blackmer recommends the following piping system layout

and unit installation.

1. When locating the pump on the tank, safety must be the

first consideration. Other considerations include length of

drive line, accessibility for maintenance and convenience

of connections. See Figure 6.

2. The discharge hose and fittings must be large enough to

minimize the pressure drop in the system. The lower the

friction loss, the higher the flow rate.

3. Use a 11/2" or 2" vapor return line for all transport loading

and unloading. Without a vapor return line, back pressure

will build up in the receiving tank and pressure will be

reduced in the supply tank, resulting in reduced flow rate

and fluid bypassing.

4. Keeping the liquefied gas systems full of liquid, even when

idle, will keep the O-rings from changing shape, shrinking

or super cooling. Evaporation of liquefied gas leaves an

abrasive powder on the surface which can cause wear to

the pump, meter, and seals.

AUXILIARY INLET - DISCONTINUED TCRLF4A

PUMP MODELS

The auxiliary inlet port can be used as a fill connection for

bottom loading of the tank by stationary pumps at the terminal

or bulk plant. It can also be used as an auxiliary pump inlet,

allowing the pump to unload another tank in an emergency. To

minimize vapor formation, the auxiliary intake line must be as

large in diameter as the intake connection and as short as

possible. The line must be connected through a suitable

strainer, minimum 40 mesh. Reduce pump speed to a

maximum 400 RPM when using the auxiliary inlet to reduce

cavitation.

PUMP DRIVE

The pump may be driven by a power take-off through universal

joints. When using universal joints, a splined slip joint,

properly lubricated, must be used on the connecting jack shaft

to prevent end thrust on the pump shaft.

It is very important to install a proper drive line to avoid

excessive wear, vibration and noise (see Fig. 6 and Table 2).

General guidelines to follow for proper pump drive:

1. Do not use square slip joints.

2. Use the least number of jack shafts as is practical.

3. Use an even number of universal joints.

4. The pump shaft and power take-off shaft must be parallel in

all respects. Use an angular level measuring device to

ensure the PTO and pump shaft are parallel to each other.

The PTO shaft coming off at the transmission does not

need to be perfectly horizontal as long as the pump shaft is

parallel in all respects to the PTO shaft.

5. The yokes of the universals at both ends of the jack shaft

must be parallel and in phase.

6. The maximum recommended angle between the jack shaft

and the pump shaft is 15 degrees. Refer to Table 2.

Failure to follow any of these guidelines may result in a gallop

or uneven turning of the pump rotor, which will in turn cause a

surging vibration to the liquid stream and piping system.

Contact the supplier of the drive line components for specific

design assistance.

NOTICE:

BLACKMER CO2 TRUCK PUMPS MUST ONLY BE

INSTALLED IN SYSTEMS DESIGNED BY QUALIFIED

ENGINEERING PERSONNEL. SYSTEM DESIGN MUST

CONFORM WITH ALL APPLICABLE REGULATIONS

AND CODES AND PROVIDE WARNING OF ALL

SYSTEM HAZARDS.

FAILURE TO SET THE VEHICLE

EMERGENCY BRAKE AND CHOCK

WHEELS BEFORE PERFORMING

SERVICE CAN CAUSE SEVERE

PERSONAL INJURY OR PROPERTY

DAMAGE.

Hazardous machinery

can cause severe

personal injury or

property damage.

Table 2

Angle of Drive Shaft

1othrough 5o6othrough 10o11othrough 15o

Very Good Good Fair

HYDRAULIC DRIVE

CRL pumps may also be driven hydraulically. Hydraulic

motors must be well supported with their shafts parallel to the

pump shaft in all respects. Blackmer provides an optional

close-coupled hydraulic motor adapter. The adapter provides

for straight alignment of a hydraulic motor drive through a solid

coupling connected to a straight key pump shaft. This

coupling connection requires grease lubrication every three

months at minimum. Refer to the "Lubrication" section of this

manual.

Hazardous

machinery can

cause serious

personal injury.

A DRIVE SHAFT GUARD BETWEEN

THE PTO AND PUMP MUST BE

PROVIDED TO PREVENT PERSONAL

INJURY, PROPERTY DAMAGE, OR

DEATH.