1809 Century Avenue, Grand Rapids, Michigan 49503-1530, U.S.A.

Telephone: (616) 241-1611 / Fax: (616) 241-3752 Form 605

FAILURE TO RELIEVE SEAL SUPPORT

SYSTEM PRESSURE, PRIOR TO

PERFORMING MAINTENANCE, CAN

RESULT IN SERIOUS PERSONAL

INJURY OR PROPERTY DAMAGE.

Hazardous pressure

can cause serious

personal injury or

property damage

IF PUMPING HAZARDOUS OR TOXIC

FLUIDS, SEAL SUPPORT SYSTEM

OIL MAY CONTAIN HAZARDOUS OR

TOXIC FLUIDS. CARE MUST BE

TAKEN TO PROPERLY CONTAIN AND

DISPOSE OF FLUIDS OR VAPORS

CONTAINED IN SEAL SUPPORT

SYSTEM.

Hazardous or toxic

fluids can cause

serious injury.

NOTICE:

THE APPROPRIATE BLACKMER PUMP MANUAL AND

PARTS LIST MAY BE OBTAINED FROM THE

BLACKMER WEBSITE (WWW.BLACKMER.COM) OR BY

CONTACTING BLACKMER CUSTOMER SERVICE.

PUMP INSTRUCTION SHEETS AND PARTS LISTS

Pump

Model

Pump

Instruction

Sheet

Pump Parts

Lists

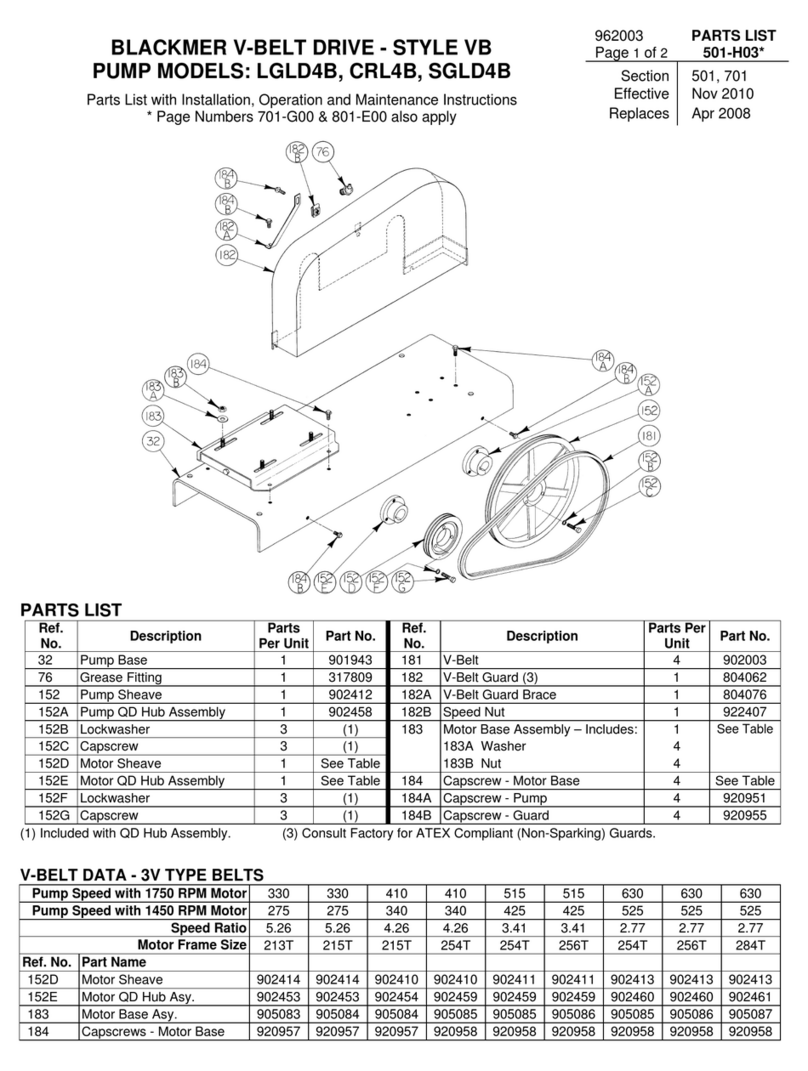

SGL(W)D3 801-B00 801-B01

SGL(W)D4 801-B00 801-B02

NOTICE:

MAINTENANCE AND TROUBLE SHOOTING MUST BE

DONE BY AN INDIVIDUAL EXPERIENCED WITH PUMP

MAINTENANCE AND THE TYPE OF SYSTEM INVOLVED.

NOTICE:

THE FOLLOWING INSTRUCTIONS INCLUDE ONLY THE

STEPS NECESSARY TO REMOVE AND REPLACE THE

BLACKMER CARTRIDGE MECHANICAL SEAL. BEFORE

PROCEEDING, READ AND FOLLOW ALL MECHANICAL

SEAL RELATED INSTRUCTIONS AND HAZARD

WARNINGS PROVIDED IN THE APPROPRIATE PUMP

"INSTALLATION, OPERATION AND MAINTENANCE”

MANUAL.

PLAN 52/53 CARTRIDGE MECHANICAL SEAL

REMOVAL PROCEDURE

1. Drain all seal oil by removing the bottom drain plug.

Warning: The oil may contain pumping fluid

and/or vapor. Take proper precautions.

2. Remove cartridge capscrews (22) from head ring (20)

3. Thread 2 capscrews into opposite, blind threaded

holes as shown in Figure 1. Attempt to gently

removed seal cartridge from head ring (20) and

rotor/shaft (13) using capscrews as handles.

Figure 1 – Removal Capscrew Location – Plan 53

4. If cartridge cannot be removed by pulling, insert 3

capscrews (22) into cartridge threaded jacking holes

and slowly tighten until cartridge is lifted off of shaft.

PLAN 53 CARTRIDGE MECHANICAL SEAL

DISSASSEMBLY PROCEDURE

1. Remove snap ring from shaft drive collar(153N) as

shown in Figure 2.

Figure 2 – Snap Ring Removal (Plan 53)

2. Separate the rotating face (153A) from the stationary

cartridge (153R) by gently pressing on the inner drive

collar (153N).

3. Remove outer carbon (153B) and inner carbon

(153J). If required gently pry with a pry bar to

remove.

4. Remove dynamic o-rings (153C and 153H), backer

rings (153G and 153D), and springs (153F).

5. Clean cartridge (153R) ensuring all surfaces are free

of contaminates. Pay special attention to o-ring

grooves.

PLAN 52 COMPONENT MECHANICAL SEAL

DISSASSEMBLY PROCEDURE

1. Remove head ring (20) by removing all capscrews

(21) and separating from casing (12).

2. Loosen rotating face capscrews (153K) and remove.

See Figure 3.

Cartridge

Removal Holes

Threaded

Jacking Holes (3)

Snap Ring