SEV User Manual

Version: 02/05/2021

15

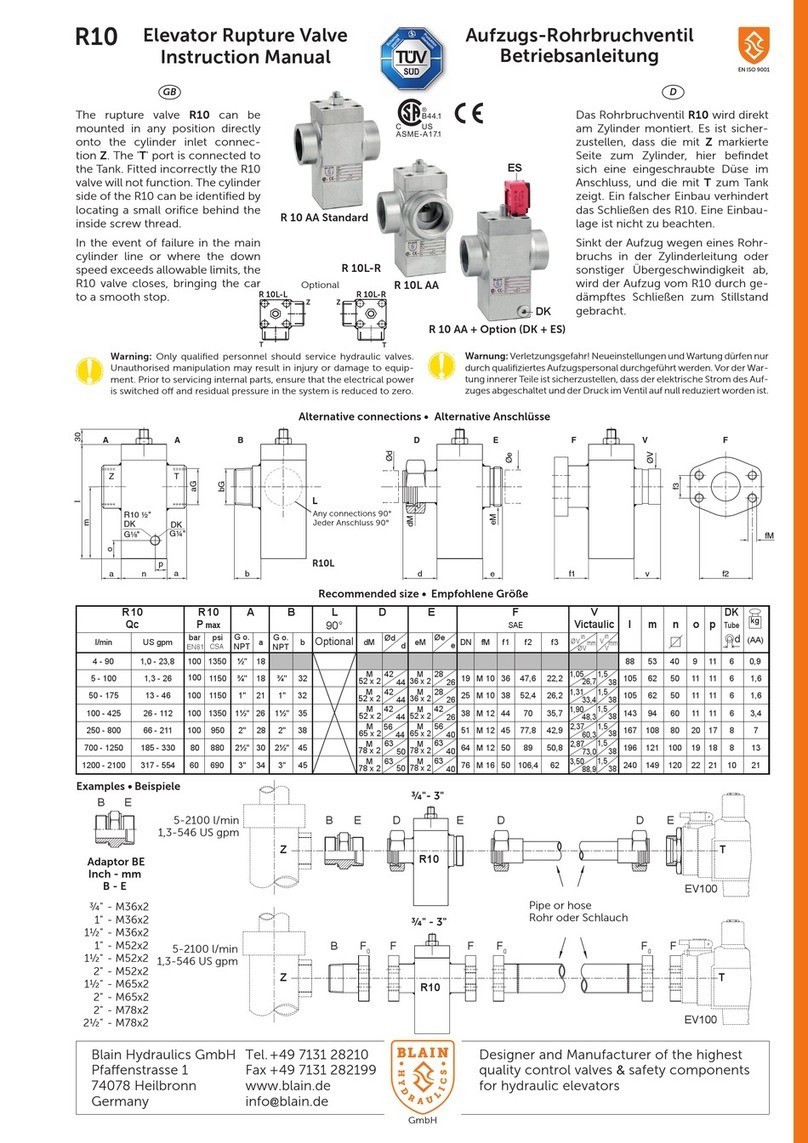

6. FLOW SENSOR AND SOLENOID ADJUSTMENTS

Adjustment of solenoid power levels A and C (already factory adjusted)

The adjust ent of the solenoid power level is necessary if parts of the solenoids have been changed during

servicing. Solenoid power level has to be adjusted to ensure the valves best possible perfor ance and to

produce a quick and s ooth initial ove ent of the car away fro the floor. The travel direction is shown by

the color of the LEDs. Green LEDs are referring to Up direction while red LEDs are used for Down direction.

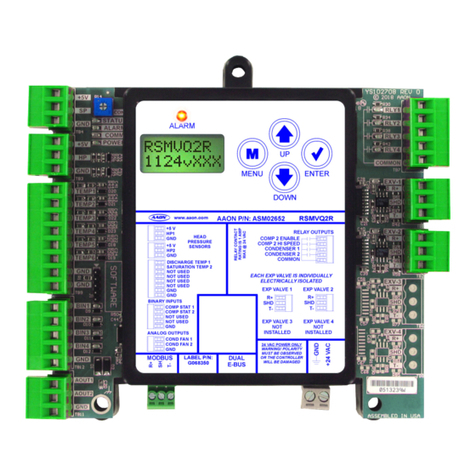

Within the “MAIN MENU” and the “Status”, the

digital value of the UP solenoid (A) or DOWN

solenoid (C) during an UP or DOWN travel is

displayed. Depending on travel direction, the

green LED for output signal A (Up) or red LED

for output signal C (Down) will be illu inated.

The digital value should be around 2100 ± 200

during constant travel while in full speed or

slow speed. Setting up this value is easier done

while travelling with slow speed since there is

ore ti e for adjusting. To alter the value, turn

the tri screw in or out. Turn clockwise to

increase digital value. Turn counter clockwise

to decrease digital value.

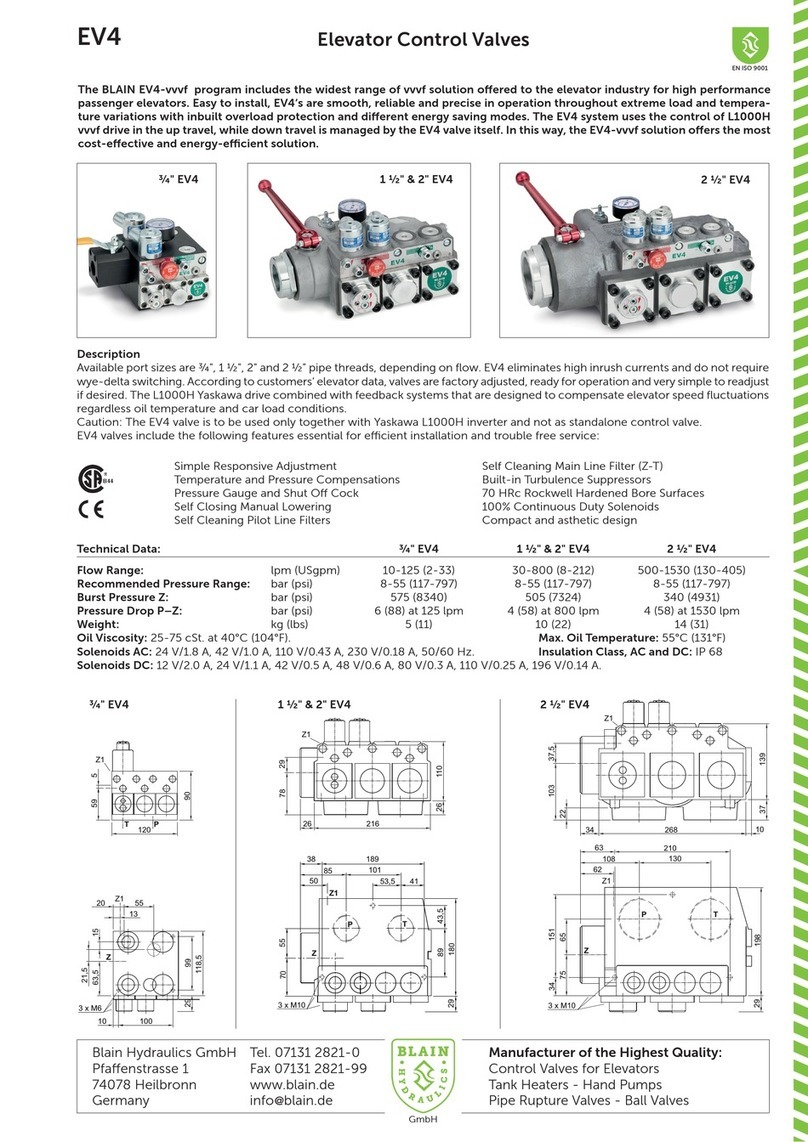

Adjustment of flow sensor

Attention!

Flow sensor is already factory adjusted. Readjusting is only necessary when replacing sensors.

Vertical sensor adjust ent

If the sensor value [ A] under static condition is not set between 4.8 and 5.3 A, close the ball valve and

open anual lowering to drop the valve pressure, loosen up the lock screw of the sensor and turn the

knurled sensor-head in or out until the value is between 4.8 and 5.3 A. Re-tighten the lock screw.

Attention: Adjusting the sensor value below 4.5 A ay cause the

sensor to press against the flow eter!

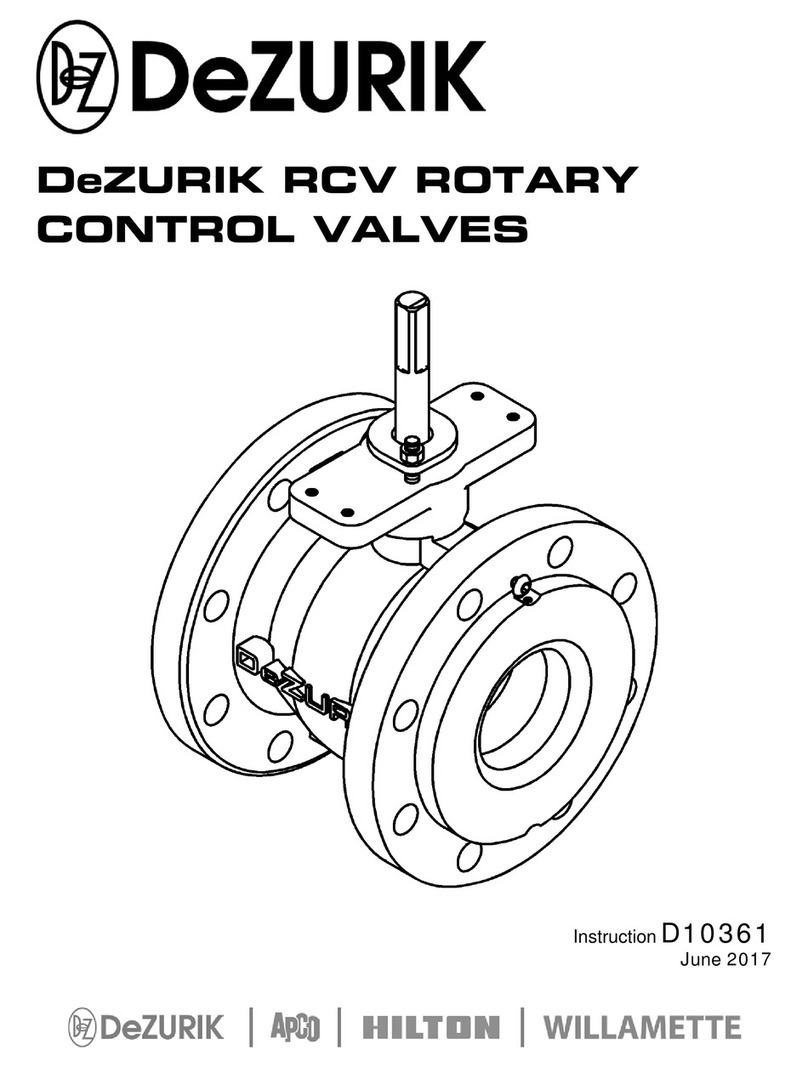

Radial sensor adjust ent

For radial adjust ent of the sensor loosen the bushing lock

nut (4), without turning the sensor bushing (2). Operate the

elevator to run Up and Down at leveling speed. Measure

the speed with stop watch or tacho eter. Levelling speeds

for both directions should have the sa e value. If Down

leveling speed is slower than Up leveling speed, rotate the

bushing (2) clockwise by 15° and re- easure the leveling

speeds. If Down leveling speed is faster than Up leveling

speed, rotate the bushing (2) counter-clockwise by 15° and

re- easure the leveling speeds.

Repeat the process of rotating the bushing in clockwise or

anti-clockwise as required to set the Up and Down leveling

speeds to be practically the sa e. Re-tighten the bushing

lock nut once the setup is finished.

1 Sensor head

2 Sensor bushing

[19 (3/4”) spanner]

3 Sensor lock screw

(3 Allen key)

4 Bushing lock nut

[32 (1 1/4”) spanner]

1

2

3

4

Tri screws at

solenoids A and C

(3 Allen key)