Blain Hydraulics SEV User manual

Smart Servo Electronic Valve manual

SEV User Manual

Version: 02/2020

2

Copyright ©2020

Blain Hydraulics GmbH

All rights reserved. No part of this manual may e reproduced, stored in a retrieval system, or transmitted, in

any form, or y any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of Blain Hydraulics.

Moreover, Blain Hydraulics reserves the right to change the information contained in this manual without any

notice

Every precaution has een taken in the preparation of this manual. Nevertheless, Blain Hydraulics assumes

no responsi ility for damages resulting from the misuse of the information contained in this pu lication

For support please contact

Technical support

Sales

Pfaffenstrasse 1

74078 Heil ronn, Germany

Tel: +49-7131-282132 | Fax: +49-7131-282199

Email: info@ lain.de | www. lain.de

Pfaffenstrasse 1

74078 Heil ronn, Germany

Tel: +49-7131-28210 | Fax: +49-7131-282199

Email: info@ lain.de | www. lain.de

SEV User Manual

Version: 02/2020

3

TABLE OF CONTENTS

1.

General information ..................................................................................................................................... 4

1.1

Safety precautions & general warnings .............................................................................................. 4

1.2

Product introduction ............................................................................................................................ 4

1.3

Waranty information ........................................................................................................................... 4

2.

The SEV card .............................................................................................................................................. 5

2.1

LED Diagnostics ................................................................................................................................. 6

3.

The SEV valve ............................................................................................................................................. 7

3.1

Valve operation ................................................................................................................................. 10

4.

Electrical installation .................................................................................................................................. 12

5.

Control valve installation ........................................................................................................................... 13

6.

Flow sensor and solenoid adjustments ..................................................................................................... 14

7.

Wi-Fi connectivity & security ..................................................................................................................... 15

8.

Setup procedure ........................................................................................................................................ 16

8.1

Software menu overview .................................................................................................................. 16

8.2

Main menu ........................................................................................................................................ 17

8.3

Update .............................................................................................................................................. 25

9.

Errors ......................................................................................................................................................... 26

10.

Monitoring .................................................................................................................................................. 27

11.

Selection charts – valve inserts ................................................................................................................. 29

12.

Trou leshooting ......................................................................................................................................... 30

12.1

General errors................................................................................................................................... 30

12.2

Up direction travel ............................................................................................................................. 31

12.3

Down direction travel ........................................................................................................................ 32

13.

Flow – pressure chart (metric & imperial) ................................................................................................. 33

SEV User Manual

Version: 02/2020

4

1. GENERAL INFORMATION

1.1 SAFETY PRECAUTIONS & GENERAL WARNINGS

Installation, operation and servicing of the SEV

should only e performed y qualified

personnel. Before installing the SEV package,

the " uick Start Guide" should e read,

understood, and all safety precautions

mentioned in these documents and warnings

must e followed. The SEV must e installed

according to the descriptions in this technical

manual and in accordance with the local

elevator safety codes and directives.

1.2 PRODUCT INTRODUCTION

The SEV package consists of:

1) SEV valve

2) Electronic card

3) User manual

The valve: The smart servo electronic valve has een integrated with a pressure and temperature sensor

alongside a flow meter. The intelligent design has een further improvised y removing some adjustments to

simplify and quicken the set-up process. Integration of pressure and temperature sensors ena le excellent

ride quality y providing real time compensation to pressure and temperature changes.

The smart electronic card: The on oard we server and Wi-Fi on the electronic card allows users with any

Smart phone, Ta let, Laptop or PC having Wi-Fi connection possi ilities to connect with the card and set-up

the system, make changes or even see the travel graphs of the elevator. The platform is system independent

and can e accessed using any standard we rowser independent of the operating system of the device used

for interacting with the card. The Wi-Fi connectivity makes it very easy to use any smart device for set-up, fine

tuning and real time monitoring from a distance without the hassle of using different ca les and compati le

devices in a machine room. Since the complete system is platform independent, there is no need to download

and install any app or software. The em edded software on electronic card stores all the settings, information

and travel logs. The set- y-step set up guide and multilingual interface software in SI and Imperial units make

inputting and monitoring information very easy.

1.3 WARANTY INFORMATION

Blain's SEV User Manual is provided for qualified personnel, who are competent in installing, adjusting and

servicing of hydraulic elevators. Blain Hydraulics assumes no lia ility for any personal injury, property damage,

losses or claims arising from in appropriate use of its product or incompetence of the installer.

Warranty expires, if:

Components or spare parts different than the original ones are installed.

Elevator system or SEV is installed or serviced y unqualified personnel.

SEV package is installed in any location without applying the elevator safety codes (EN81-20/50,

ASME 17.1 or the existing local code).

Figure 1: Smart Servo Electronic Valve

SEV User Manual

Version: 02/2020

5

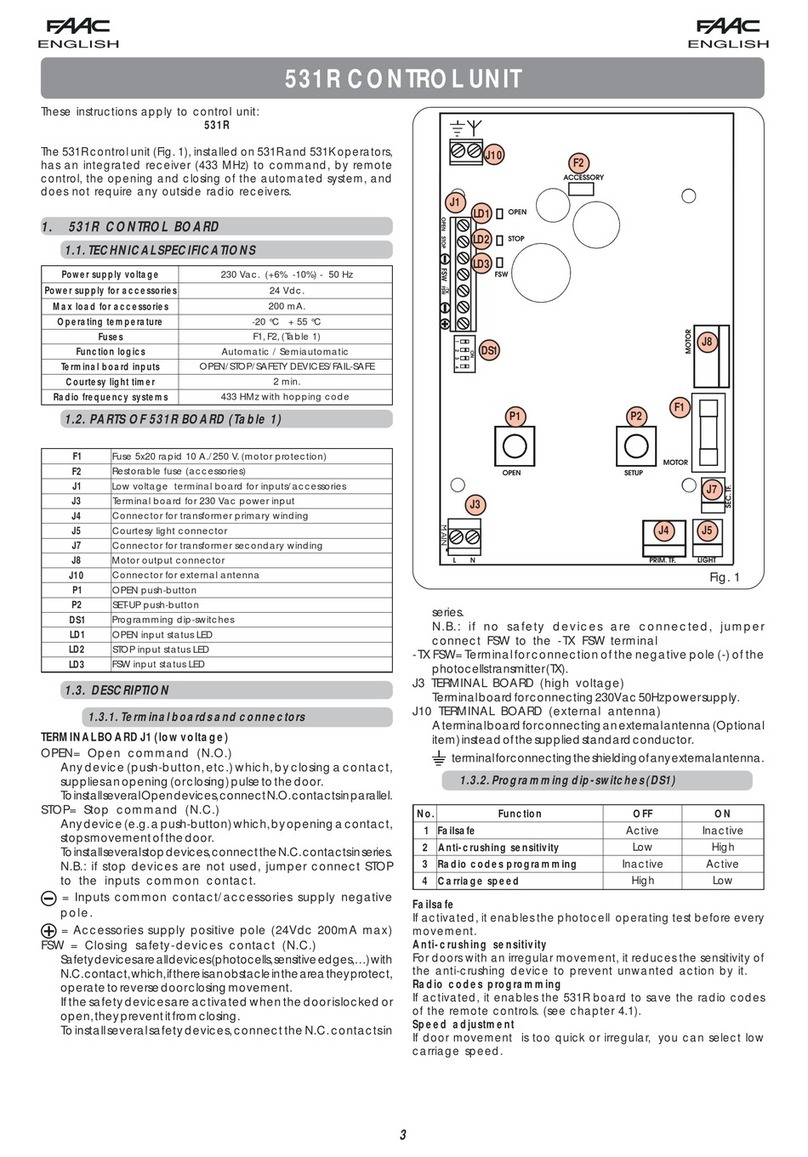

2. THE SEV CARD

A Mode switch I Input signals

B Memory card slot J Output signals

C Jumper for data upload K Error relay

D Type plate L Power supply 24 V DC / 18 V AC

E Flow sensor adjustment feed ack M Error / warning LED

F Temperature sensor connection N Power LED

G Pressure sensor connection O Quit / confirm utton

H Flow sensor connection P Spot for additional interface PCB

Blain 000000

SEV07 - 0000

C

O

L

K

A

B

E

D

F

G

H

I

J

M

N

P

SEV User Manual

Version: 02/2020

6

2.1 LED DIAGNOSTICS

SWITCH LED

If switch “1” is in „ON“-

position, the LED will

flash slowly. Once a

connection to a smart

device is esta lished,

the LED glows

continuously.

POWER LED

The green power LED

will continuously glow

as long as the

electronic card is

supplied with power.

INPUT AND OUTPUT SIGNAL LEDs

D (red), C (red), B (green), A (green) and Ins

(yellow) are reflecting the input signals into

the electronic card.

Down (red) and Up (green) are the

corresponding output signals and indicate the

travel direction.

BOOT LOADER LEDs

If the jumper is set in

non- ridged mode, the

green and red LED will

light up alternately.

Setting the jumper in

ridged mode causes

the red LED to glow

continuously and the

green LED to flash

slowly. If an update is

eing processed, the

green LED will flash

rapidly until the update

is finished.

Green

Red

STATE LED

The orange state LED flashes

slowly. Any other ehaviour is

related to communication

pro lems and reflects a defect.

FLOW LEDs

They indicate if the

sensor has een

adjusted properly. If

the adjustment is set

higher or lower than

the range, the

corresponding LEDs

will light up to signal,

that the sensor has to

e readjusted.

SENSOR LEDs

These will glow green if

the pressure-

temperature sensor is

connected properly.

Orange

Red

DIAGNOSTIC LEDs

The orange “Warning”

LED lights up in case

of an unexpected

ehaviour. If there is a

major fault interfering

with the normal

operation of the valve

like the flow sensor or

a coil eing defect, the

“Error” LED will light

up and prevent the

SEV from functioning

until the error has

een quit with the help

of the “OK” utton.

SEV User Manual

Version: 02/2020

7

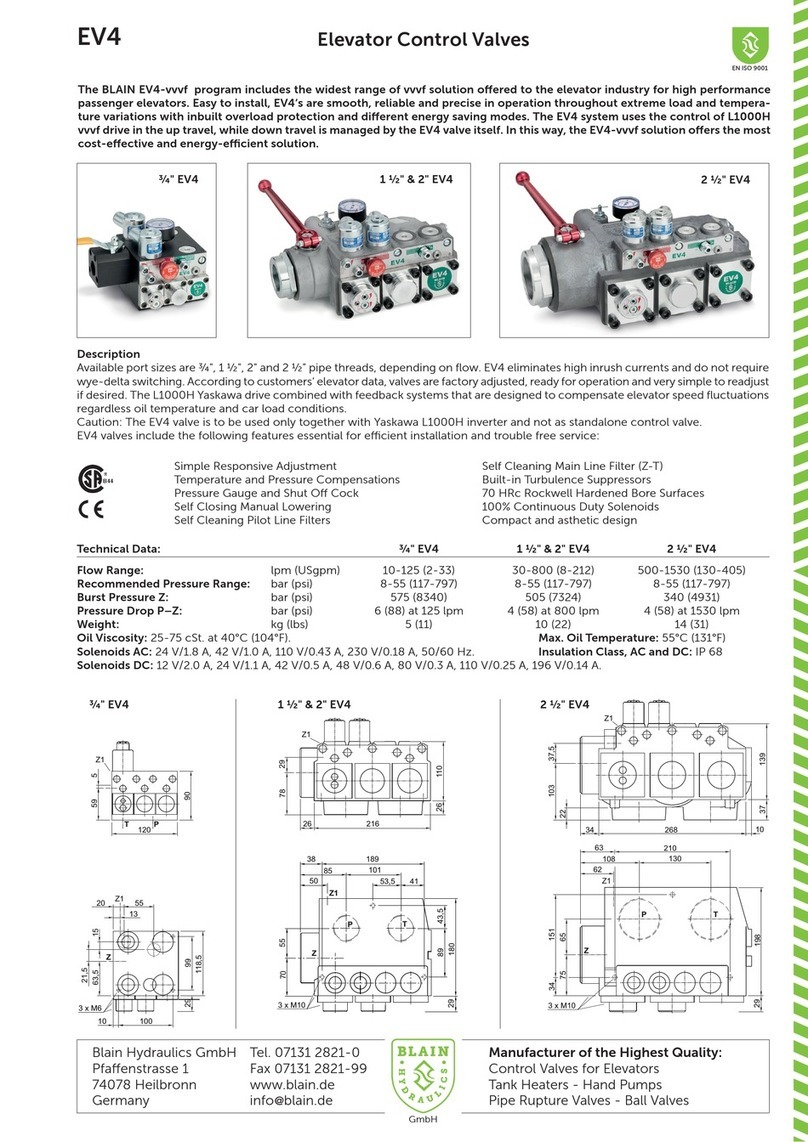

3. THE SEV VALVE

The Blain Servo Electronic Valve (SEV) is controlled y closed loop digital electronics, providing

consistent acceleration and deceleration of hydraulic elevators largely independent of load and

oil temperature. An electronic card regulates the performance of the car via proportional solenoid

valves. The elevator operation can e monitored, recorded and adjusted y a smart device using

Wi-Fi connectivity. Additional intermediate speed for maintenance runs can also e programmed.

Figure 2: SEV valve sizes

SEV valves include the following essential features:

Self-cleaning pilot line filters Temperature and pressure compensation

Self-cleaning main line filter (Z-T) Built-in tur ulence suppressors

70HRc hardened ore surfaces Pressure gauge and shut off cock

100% continuous duty solenoids Self-closing manual lowering

Technical data

1” SEV

1½” SEV

2” SEV

Flow range l/min

(USgpm)

40-180

(10-48)

-430

(-114)

-580

(-153)

Pressure range ar (psi) 9-70 (130-1000)

Burst

p

ressure

ar (psi) 400 (5750)

Pressure loss

(static)

ar

(psi)

≈ 2 – 3 ar (29 – 44 psi)

depending on flow and valve port size

Weight

kg (l s) 10 (22)

Oil viscosity 22-75 cSt. at 40°C (104°F)

Max. oil t

emperature

14°-61°C (57°-142°F) for oil VG46; 200 cSt – 20 cSt.

Optimal

oil t

emperature

25°-50°C (77°-122°F) for oil VG46; 100 cSt – 30 cSt.

Ambient temp range 0°-70°C (32°-158°F)

Insulation c

lass, AC and DC

IP 68

Coils

AC

24 V/1.8 A, 42 V/1.0 A, 110 V/0.43 A, 230 V/0.18 A

Coils DC

12 V/2.0 A, 24 V/1.1 A, 42 V/0.5 A, 48 V/0.6 A, 80 V/0.3 A, 110 V/0.25 A,

196 V/0.14 A

Elec.

c

ard

i

nput

24 V DC / 18 V AC

Elec. card w

eight

0.5 Kg (1.1 l s)

Up travel Up to 1.0 m/s (197 fpm). 1 Full Speed, 1 Leveling Speed, 1 Inspection speed.

Down travel Up to 1.0 m/s (197 fpm). 1 Full Speed, 1 Leveling Speed, 1 Inspection speed.

SEV User Manual

Version: 02/2020

8

Figure 3: SEV valve dimensions

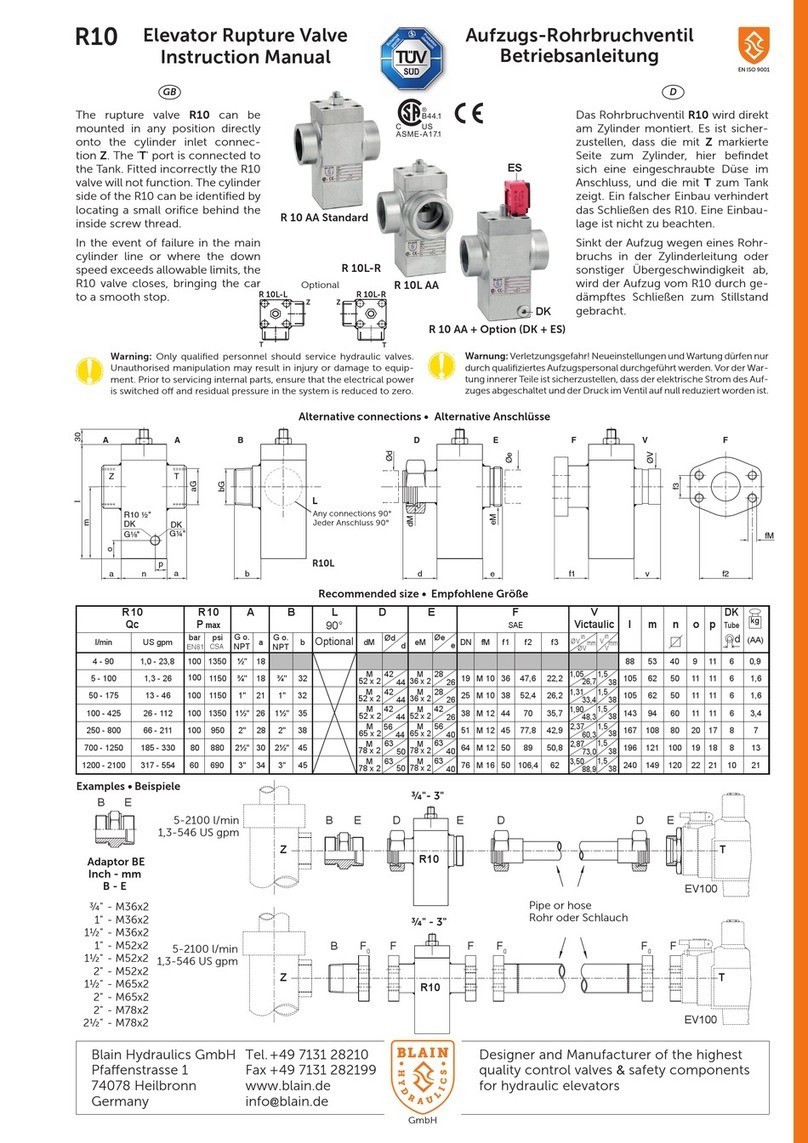

Optional Equipment

EN Emergency coil DH High pressure switch

CSA CSA coils DL Low pressure switch

KS Slack rope valve BV Ball valve

HP Hand pump HX/MX Auxiliary down valve

Figure 4: Hydraulic circuit

Control Elements

Down adjustments

C Solenoid Down control U Bypass valve 7 Full speed limitation

D Solenoid Down start/stop V Check valve 9 Manual lowering speed

H Manual lowering X Down valve

S Pressure relief valve Y Down leveling valve

1” SEV

1½” SEV 2” SEV

SEV User Manual

Version: 02/2020

9

Ca in

Q

I

pT

T

P

9 7

H S

A

C D

Control elements

A Solenoid Up control I Flow sensor V Check valve

C Solenoid Down control pT Pressure-temp.-sensor X Down valve

D Solenoid Down start/stop Flow meter Y Manual lowering valve

E Short delay valve R Flow ring 2 Pilot orifice Up

F Filter S Pressure relief valve 8 Pilot orifice Down

H Manual lowering U Bypass valve

R

E

Horizontal

section

Vertical

section

Z

8 2

X

V

U

Y

CT

AT

D C A

8 2

S

H

F

XC

UC

Figure 5: ut section view of the SEV valve

Cylinder

Connections

P Pump port

T Tank port

Z Cylinder port

Pilot pressure chambers

UC Bypass cham er

XC Down valve cham er

Adjustment UP

AT Up trim (page 13)

Adjustments DOWN

CT Down trim (page 13)

7 Full speed limitation

9 Manual lowering speed

SEV User Manual

Version: 02/2020

10

3.1 VALVE OPERATION

UP operation

1. With an Up signal, the pump-motor is energized and the electronic card´s Up program starts

simultaneously. Oil flows through orifice 2 into the ypass pilot cham er UC.

2. Coil A is energized and solenoid A (normally open) from the card and partially closes, reducing

the volume of pilot oil flowing out from the ypass pilot cham er.

3. The ypass valve U egins to close as pressure increases in the ypass pilot cham er. As the

ypass valve U closes, the check valve V egins to open as a steadily increasing volume of oil

flows into the cylinder of the elevator, displacing the flow meter .

4. The inductive flow sensor I, measures the increasing displacement of the flow meter. This value

is compared in the card with the target flow value, which prescri es the acceleration, full speed,

deceleration and levelling speed of the car. Correction of the measured flow rate is made y

varying the power from the card to coil A, controlling the position of the ypass valve through

pilot pressure in cham er UC.

5. The comparison and correction of the measured flow to target flow values, continue throughout

the complete Up operation of the elevator.

DOWN operation

(Caution! Voltage for coil D comes directly from the elevator´s controller, not from the SEV

card)

6. With a Down signal, coil D is energized, solenoid D (normally closed) opens and the electronic

card´s Down program starts simultaneously.

7. Coil C is energized from the card and solenoid C (normally closed) partially opens allowing oil

to pass through fixed orifice 8 escaping from the down valve pilot cham er XC through solenoid

D (fully open) ack to tank.

8. The down valve X egins to open as pressure decreases in the down valve pilot cham er XC.

As the down valve opens, a steadily increasing volume of oil flows from the elevator´s cylinder

into the tank, displacing the flow meter .

9. The inductive sensor I measures the increasing displacement of the flow meter. This value is

eing compared y the card with the set value of the target flow.

10. Correction of the measured flow rate is made y variation of power from the card to coil C

controlling the position of the down valve through pilot pressure in cham er XC.

11. The comparison and correction of the measured flow to target flow values continue throughout

the complete Down operation of the elevator.

SEV User Manual

Version: 02/2020

11

Inspection Speed

Besides full speed and levelling speed, an optional inspection speed is included in the electronic

card´s software. Up and down inspection speeds can e independently adjusted etween 0.05 m/s

and 0.30 m/s.

Valves are already adjusted and tested. Check electrical operation efore changing valve settings.

Test that the correct coil is energized y removing the nut and raising the coil slightly to feel magnetic

pull.

S Pressure relief valve: Turning it ‘In’ (clockwise) produces a higher, ‘out’ (c-clockwise) a lower

maximum pressure setting. After turning out, open manual lowering H for an instant to release

pressure inside the valve.

Important: When testing the pressure relief valve, do not close ball valve sharply.

KS Slack rope valve: Coils C and D must e de-energized! The KS is adjusted with a 3 mm Allen

key. Turning the screw K ‘in’ results in a higher pressure setting and ‘out’ in a lower pressure setting.

To adjust, turn K all the way ‘in’, then turn K ‘out’ until the empty car just egins to descend, then

turn out another half a turn to ensure that with cold oil the empty car can e lowered as required.

Figure 6: SEV adjustments and explosion drawing

Adjustments Highlighted valve parts

CT Trim solenoid C H Manual lowering

S Pressure relief valve X Down valve

AT Trim solenoid A Y Down levelling valve

KS Slack rope valve V Check valve

9 Manual lowering speed U Bypass valve

7 Maximum speed

limitation

KS 9 7

CT S AT

SEV User Manual

Version: 02/2020

12

1 2 3 4 5 6 7 8 9 10 11 12 13 16 17 18

19 20

21

22

23

24

25

Voltage

for

coil D

Lift Controller SEV card

R1

Card internal relay

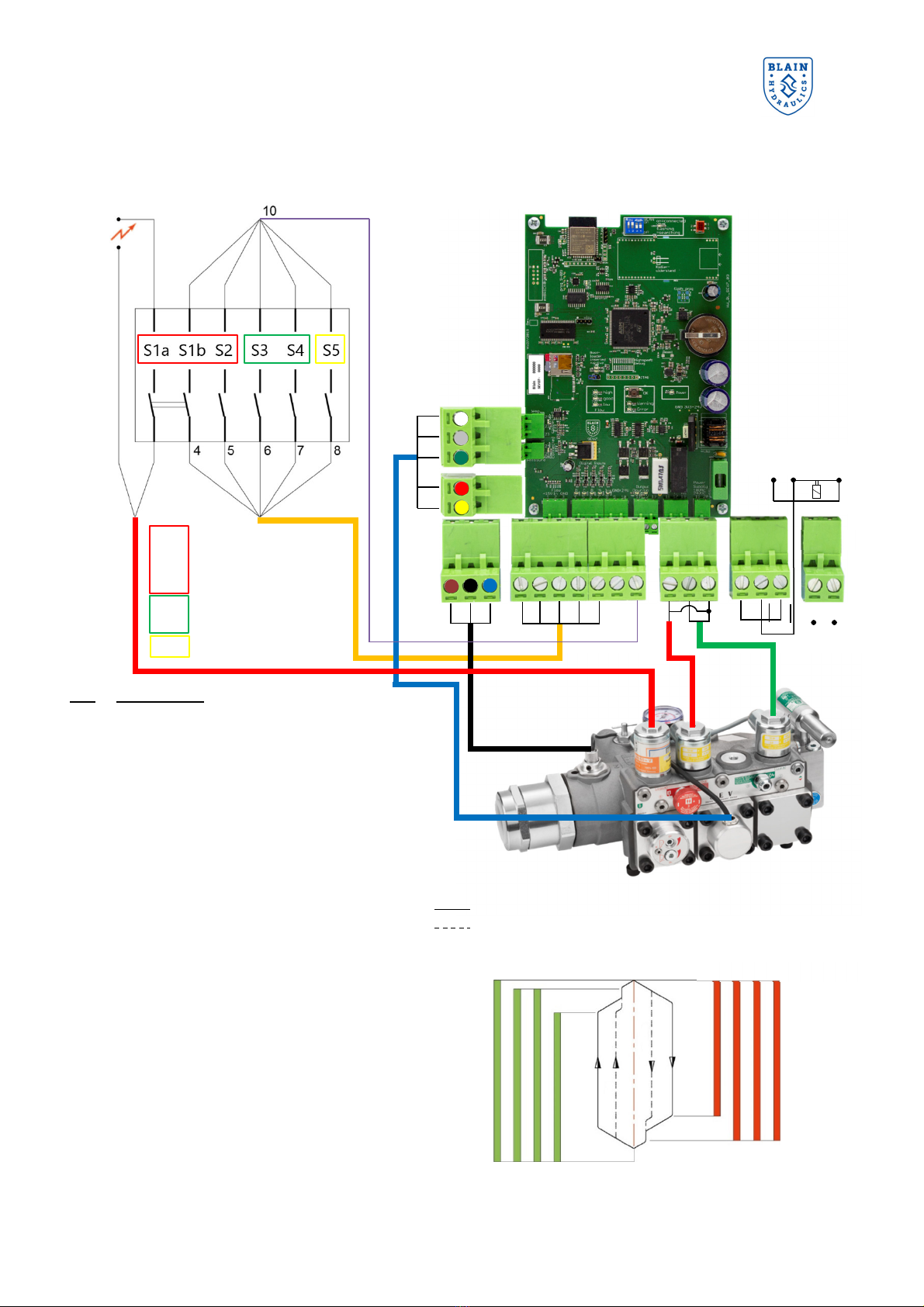

4. ELECTRICAL INSTALLATION

PIN Explanation

1 Power supply 15 V ( rown wire)

2 Sensor signal ( lack wire)

3 Neutral ( lue wire)

4 Input signal "S1 " Down start/stop – D

5 Input Signal "S2" Down control – C

6 Input signal "S3" Up full speed – B

7 Input signal "S4" Up control – A

8 Input signal "S5" inspection – I

9 Input signal neutral (ext. supply)

10 Input signal 24 V DC

11 Output signal "C" Up

12 Output signal "A" Down

13 Output signal neutral for Up and Down

16 Error relay NC – closed if OK – open if fault

17 Error relay COM

18 Error relay NO – open if OK – closed if fault

19 Supply voltage ground

20 Supply voltage live 18V AC / 24V DC

21 PT100 C (white wire)

22 PT100 B (grey wire)

23 PT100 A (green wire)

24 24 V (red wire)

25 4-20 mA (yellow wire)

S1a Down levelling (coil D)

S1 Down levelling

S2 Down full speed

S3 Up full speed

S4 Up levelling

S5 Inspection

24 V DC

18

V AC

Electrical travel

Sequence UP DOWN

Normal travel: S3+S4 S1a+S1 +S2

Inspection: S3+S4+S5 S1a+S1 +S2+S5

Slow speed: S4 S1a+S1

S5 S4 S3

Motor

S2 S5 S1b S1a (coil D

SEV User Manual

Version: 02/2020

13

5. CONTROL VALVE INSTALLATION

Check the following:

1. The flow on the data plate of the valve complies with the flow rate of the pump (±10 %).

2. The minimum and maximum static pressures on the valve data plate is in accordance with those of the

elevator.

3. The electrical supply to the SEV card is 24 VDC / 18 VAC and 50 VA.

4. The star delta timer is set to etween 0.3 and 0.4 secs.

5. The flow ring R, ypass valve U and down valve X are correct using chart A at rear of the hand ook.

6. The flow sensor is adjusted etween 4.8 and 5.3 mA

Installation of the SEV Valve onto the Power Unit

For a compact and time saving installation as well as easier servicing and protection of the flow meter, cylinder

connection Z of the SEV is fitted with the Blain all valve G1“, 1.5“, 2“or 2.5“.

Installation of the SEV Card into the Controller

The SEV Card can e connected into any standard type hydraulic elevator controller. The power to coils A and

C is supplied from the card. Power to coil D is directly provided y the main controller. Page 11, shows the

detailed wiring diagram for connecting the SEV card to the elevator controller.

Installation of Deceleration Switches in the Elevator Shaft

Slow-down (deceleration) and stop switches should e set according to the following recommendations

Recommended switch positions and levelling speeds

Metric

Imperial

Travel

speed

Decel.

switch

before floor

Levelling

speed

Stop

switch

before

floor

Travel

speed

Decel.

switch

before

floor

Levelling

speed

Stop

switch

before

floor

m/s

cm

m/s

cm

ftm

i

n

f

t

m

in

0.3 25 0.06 1.0 60 10 12 0.4

0.4 45 0.06 1.0 80 17 12 0.4

0.5 60 0.06 1.0 100 24 12 0.4

0.6 75 0.06 1.0 120 30 12 0.4

0.7 95 0.07 1.5 140 37 14 0.6

0.8 110 0.07 1.5 160 43 14 0.6

0.9 130 0.08 2.0 180 51 16 0.8

1.0 145 0.08 2.0 200 57 16 0.8

Depending on customers priorities, for travelling time or stopping accuracy, the recommended values for

levelling speeds may e modified, i.e. for faster floor to floor times; faster levelling speeds, for more accurate

floor stops; slower levelling speeds.

SEV User Manual

Version: 02/2020

14

6. FLOW SENSOR AND SOLENOID ADJUSTMENTS

Adjustment of solenoid power levels A and C (already factory adjusted)

The adjustment of the solenoid power level is necessary if parts of the solenoids have een changed during

servicing. Solenoid power level has to e adjusted to ensure the valves est possi le performance and to

produce a quick and smooth initial movement of the car away from the floor. The travel direction is shown y

the color of the LEDs. Green LEDs are referring to Up direction while red LEDs are used for Down direction.

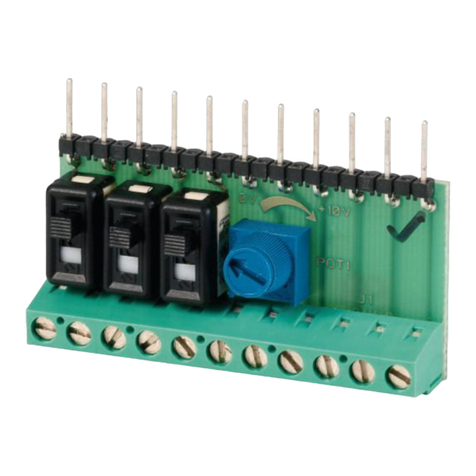

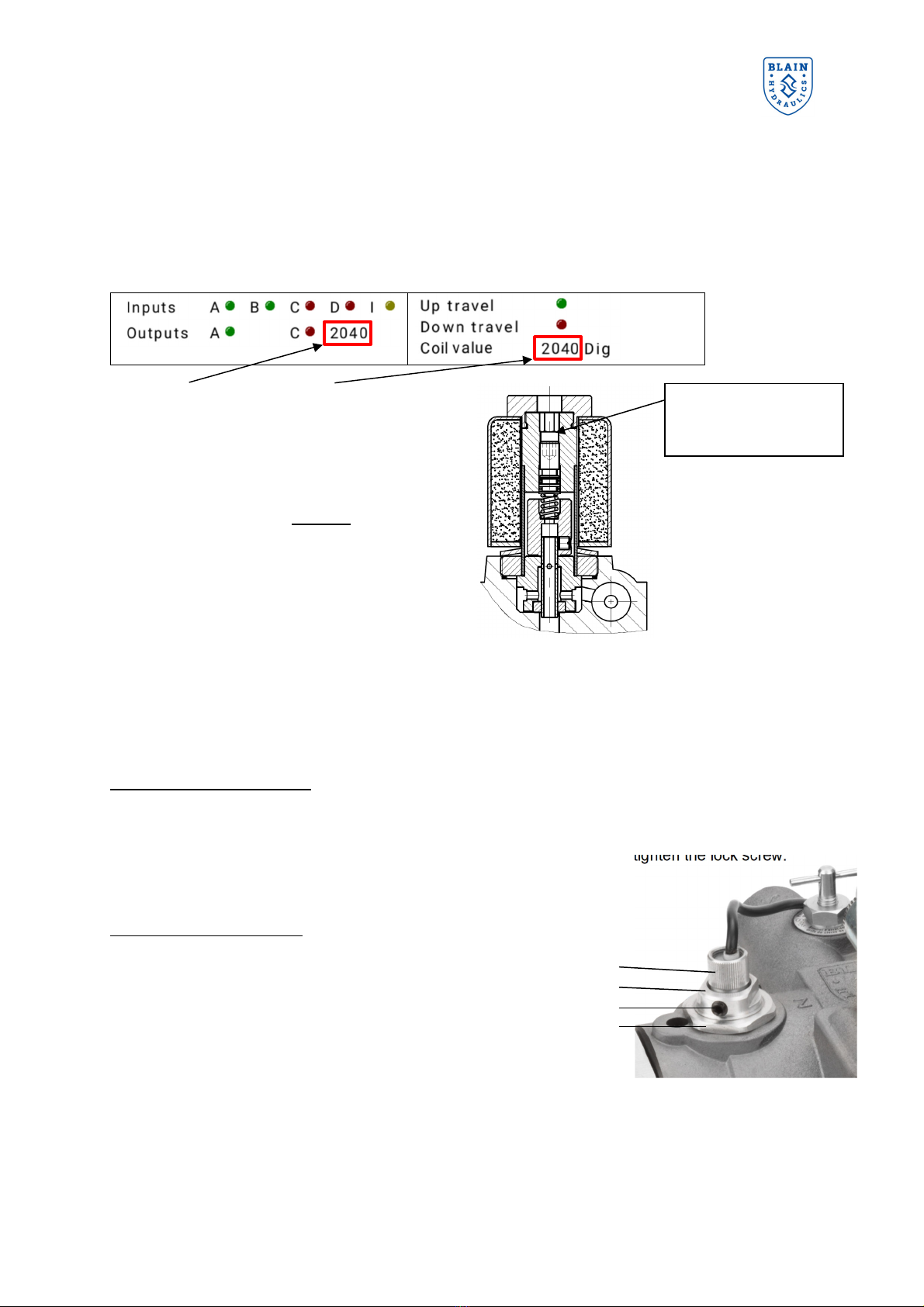

The “MAIN MENU” and the “Status” are

showing the digital value of the UP solenoid

(A) or DOWN solenoid (C) during an UP or

DOWN travel. Depending on travel direction,

the green LED for output signal A (Up) or red

LED for output signal C (Down) will e

illuminated. The digital value should e

around 2100 ± 200 during constant travel

while in full speed or slow speed. Setting up

this value is easier done while travelling with

slow speed since there is more time for

adjusting. To alter the value, turn the trim

screw in or out. Turn clockwise to increase

digital value. Turn counter clockwise to

decrease digital value.

Adjustment of flow sensor

Attention!

Flow sensor is already factory adjusted. Readjusting should only e necessary when replacing sensors.

Vertical sensor adjustment

If the sensor value [mA] under static condition is not etween 4,8 and 5,3 mA, close the all valve and open

manual lowering to make the valve pressure-less, loosen up the lock screw of the sensor and turn the

knurled sensor-head in or out until the value is etween 4,8 and 5,3 mA. Re-tighten the lock screw.

Adjusting the sensor value elow 4.5 mA may cause the sensor to

press against the flow meter

.

Radial sensor adjustment

For radial adjustment of the sensor loosen the ushing lock

nut (4), without turning the sensor ushing (2). Operate the

elevator to run Up and Down at leveling speed. Measure

the speed with stop watch or tachometer. Levelling speeds

for oth directions should have the same value. If Down

leveling speed is slower than Up leveling speed, rotate the

ushing (2) clockwise y 15° and re-measure the leveling

speeds. If Down leveling speed is faster than Up leveling

speed, rotate the ushing (2) counter-clockwise y 15° and

re-measure the leveling speeds.

Repeat the process of rotating the ushing in clockwise or

anti-clockwise as required to set the Up and Down leveling

speeds to e practically the same. Re-tighten the ushing

lock nut once the setup is finished.

1 Sensor head

2 Sensor ushing

[19 mm (3/4”) spanner]

3 Sensor lock screw

(3mm Allen key)

4 Bushing lock nut

[32 mm (1 1/4”) spanner]

1

2

3

4

Trim screws AT and

CT at solenoids A and

C (3mm Allen key)

SEV User Manual

Version: 02/2020

15

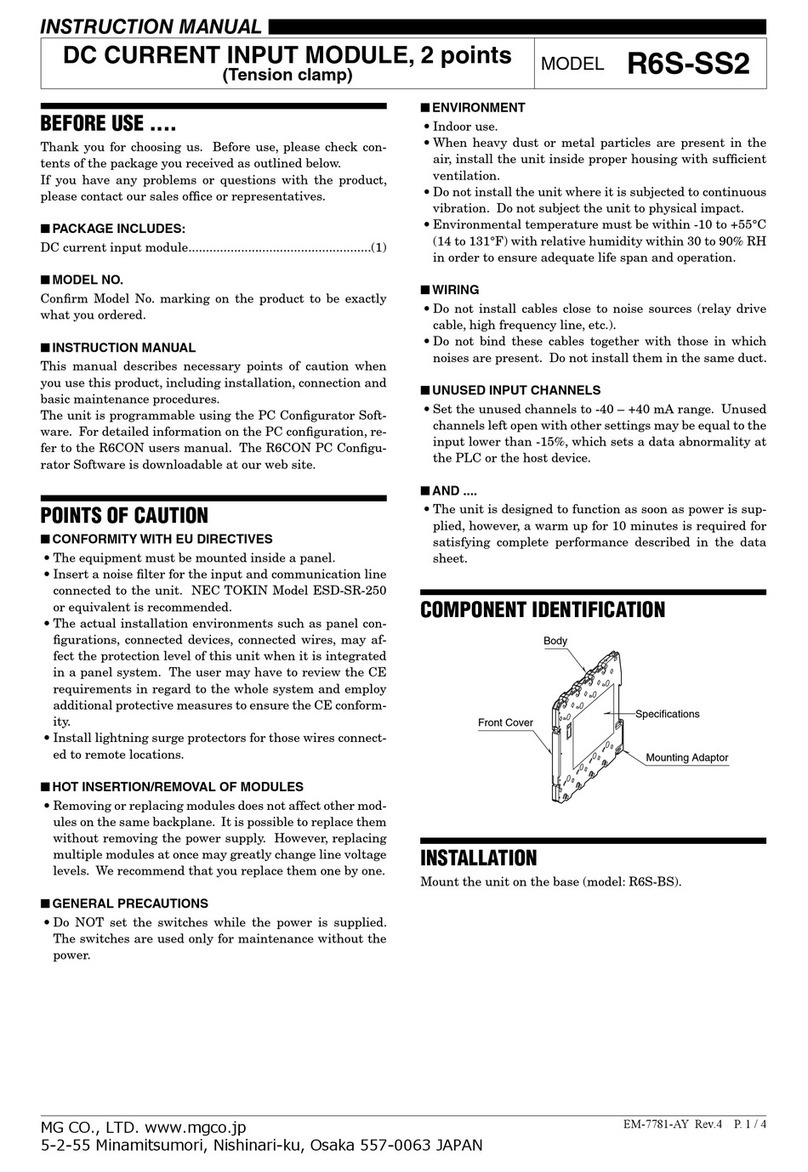

. WI-FI CONNECTIVITY & SECURITY

The SEV electronic card uses the IEEE Standard 2.4GHz, 802.11 /g/n connectivity protocols. Generally, all

modern-day smart devices (phone/ta let/laptop) can communicate with the Wi-Fi access point on the card

using these protocols. The SEV card is delivered using the default settings as shown in the picture elow.

Switch 1 - The Wi-Fi switch in ON position allows

communication with the electronic card using a smart

phone. The on- oard Wi-Fi access point is availa le for

accepting connections.

Switch 2 – OFF position allows ackward compati ility of

the electronic card to e used for the older version of the

SEV valve. Certain functions related to pressure and

temperature measurements are not availa le.

Switch 3 & 4 – Reserved for Blain Hydraulics.

To connect with the SEV card using your smart device,

ensure the switch 1 to e in ON position. The Blue

LED will flash during the process of esta lishing a Wi-

Fi connection. Once a sta le connection is esta lished,

the LED would stop flashing and remain ON.

Getting connected

1

2

3

4

Identify and connect

with the BLAIN-SEV

Wi-Fi from your smart

device.

Provide the password to

get connected. The

default password is

12345678

Once connected, tap on

the Wi-Fi to get into the

configuration. Tap on

“Manage router” to enter

the on- oard APP on

the access point in your

preferred rowser

(Firefox recommended).

Alternatively open your

preferred rowser and

provide the IP address

192.168.4.1 in the

navigation ar.

Once the authentication

is completed, a loading

screen will appear and

confirm the successful

connection. Once

loading is completed the

MAIN MENU can e

seen.

During the time the smart device is connected

with the SEV card, no internet connectivity or

other network connections are possible.

In order to safeguard unauthorized access to the

i-Fi and the electronic card, the i-Fi should

be switched OFF on completion of setup /

configuration / monitoring.

SEV User Manual

Version: 02/2020

16

8. SETUP PROCEDURE

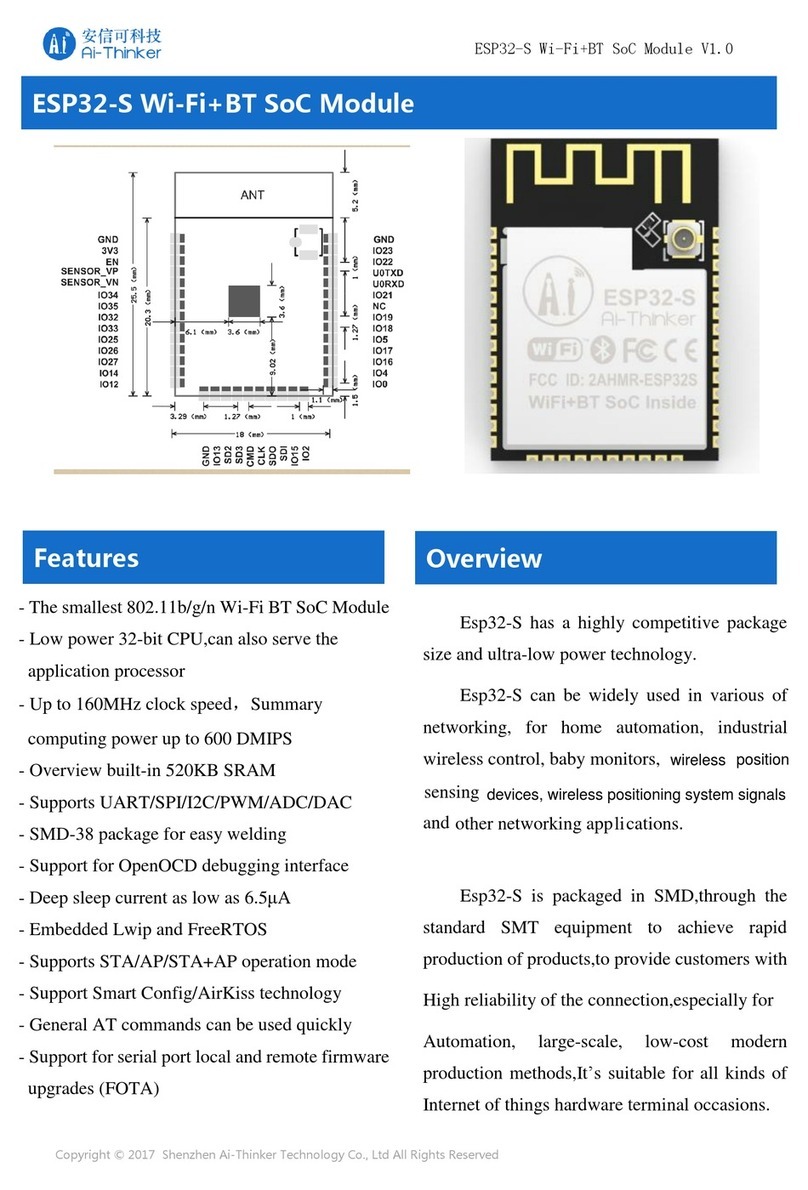

8.1 SOFTWARE MENU OVERVIEW

Language

1. German

2. English

3. Spanish

Settings

1. Date / Time Set date and time

2. Units SI

Imperial

3. Valve settings

Gain value

Dither amplifier

Speed mode

Pressure relief valve

4. Factory settings

Reset elevator data

Reset travel data

Reset all data to

factory settings

5. Wi-Fi settings

IP Adress

SSID

Password

6. Pro

Save factory setting

Sensor cali ration

Sensor ta le

Device ID

Hardware ID

State

Notifications

1. State

2. Notifications

3. Update

Install wizard

1. Welcome screen

Introduction

2. Cylinder data

Transmission

No. of cylinders

Piston type / diameters

3. Pump data Performance

Efficiency

4. Weight &

pressure

Empty ca in

Payload

Min. pressure

Max. pressure

5. Up travel data

Speed

Acceleration

Soft stop

6. Down travel data

Speed

Acceleration

7. Inspection travel

data

Up travel

Down travel

8. Final screen Final information

Data collection

1. Elevator data

Cylinder data

Pump data

Weight

Pressure

2. Travel data

Up travel

Down travel

Inspection travel

3. Teach run /

speed adjustment

Teach values

Standard values

R10 Test

4. Log ook Last runs

Reset counters

5. Trou le shooting

General error

Error Up travel

Error Down travel

Ⅱ

Ⅰ

Ⅳ

Ⅴ

Ⅲ

SEV User Manual

Version: 02/2020

17

8.2 MAIN MENU

The language of the software can e changed y

pressing the flag in the upper left corner. From the

main menu the easy to use “Install wizard” for

assisting during initial setup, the “Data collection”,

“Settings” and “State/Notifications” su menus

can e accessed.

Once the preferred language has een selected, go

to “Settings” to set the date and time and choose

your units for setting up the valve. In order to set up

the valve, please follow the instructions. Use the

“Main Menu utton” (highlighted) to get ack to the

“

MAIN MENU

”.

The following chapter of this installation manual descri es how to set up and service the valve with the help

of the software. The most important points of navigating the menu will e covered and the su menus “Install

wizard”, “Data collection”, “Settings” and “State / Notifications” will e explained in detail.

As the software for interacting with the SEV card resides on the we server and on the card itself, no additional

software installation on the smart device is necessary. This unique feature allows the user to use any smart

device; independent of the operating system or software architecture. It is highly recommended to use Mozilla

Firefox for Android or Safari for iOS as we rowsers.

Before the installation wizard is started it is highly recommended that all technical data of the lift is readily

available and that the input unit is correctly selected. The choice for unit’s selection between Metric and

Imperial can be made from the “Settings” menu > units from the home screen.

I II

Main Menu utton

SEV User Manual

Version: 02/2020

18

The “MAIN MENU” allows access to the “Install wizard”, the “Data

collection”, the “Settings” and the “State/notifications” su menus.

The “Install wizard” is eing used to assist during valve setup and

serves as a step y step guide to help users entering the complete and

correct necessary elevator data.

The “Data collection” gives an overview a out all entered data to

make changes if necessary and it gives access to the “Logbook” and

the “Trouble shooting” sections.

In the “Settings” menu you can change units, valve and Wi-Fi settings

or reset settings to factory settings if desired.

The “State/notifications” shows the status of the system and allows

for possi le updates.

The “Access” utton gives the user the possi ility to enter and change

passwords necessary for accessing the features of the software.

Furthermore the “MAIN MENU” acts as the first tool for analyzing and

setting up the valve. Values for pressure, temperature and flow are

displayed. In case of no readings the connections need to e

rechecked or the sensors changed. LEDs for input and output give

feed ack for diagnostics.

While traveling constantly in full speed or levelling speed in Up or

Down direction, the highlighted digital value should stay in the range of

2100 ± 200. The green check marks should show up ehind the digital

values of the solenoids giving feed ack of the correct starting values.

←Left

After starting the install wizard and

reading the welcome screen, you

are asked to enter the necessary

cylinder data. Pressing the uttons

for the different piston types will

ring up a dialogue field (screen on

the right), where the desired values

can e entered. To change

transmission ratio or num er of

cylinders, press the corresponding

values.

The effective piston diameter is

eing calculated depending on the

entered data. Changing its value

will override all other data. Press

confirm to continue the setup.

Right→

Select a piston type and enter its

diameters y touching the values.

Use the confirm utton on the

ottom right to get ack to the

screen on the left.

I

IV.2 IV.2c

DIGITAL VALUE

CHECK MARKS

SEV User Manual

Version: 02/2020

19

←Left

Enter the pump performance data

provided y the manufacturer. Due

to changes in load and oil viscosity

the pump will not always deliver its

full flow. Furthermore some flow is

needed y the SEV to regulate and

provide constant speed and travel

time. 90 % efficiency is an

approximated value.

Right→

Provide the static weight of your

elevator system and the pay load

data. Alternatively the values for

minimum and maximum pressure

can e entered. Please note that

entering the weight would

automatically calculate the pressure

and vice versa.

←Left and Right→

Enter your desired speeds,

acceleration and deceleration times

of the Up travel as well as the Down

travel.

Your full speed in Up direction is

already eing calculated ased on

the entered piston and pump data.

Speed in Down direction is limited to

196,85ftm (1m/s). Values shown in

imperial units are displayed after

eing converted from Metric system

and therefore vary slightly from the

input value.

The soft stop setting controls the

final stopping into the landing zone

in the Up direction. Making it too soft

which means choosing a smaller

value may cause the elevator to

continue traveling and surpassing

the floor level.

IV.3 IV.4

IV.5 IV.6

IV.7 IV.8

SEV User Manual

Version: 02/2020

20

←

Left

The inspection travel speed for Up

and for Down direction can e set

here. Inspection speed is

sometimes referred to as the

second slow speed, which can e

used for inspections or short floor

distances. Press continue to

proceed further.

Right→

Once you reach the final screen,

the install wizard ends, confirming

that the entered data has een

saved successfully on the

electronic card. In order to review

all entered data, you can run the

install wizard again or check the

“Data collection”. Changes can e

made in the “Data collection” su

menu as well.

←Left

The “Data collection” su menu of

the software provides an overview

of the existing data stored on the

card. Data can e entered here

when selecting “Elevator data” or

“Travel data”. In addition there is

access to the “Teach run” menu,

the “Log book” as well as the

“Trouble shooting”. The “Teach

run” menu cali rates the flow

sensor while the “Logbook”

provides an overview of travel logs

with the option of looking at the

travel graph. “Troubleshooting”

offers help on general errors and

errors in Up and Down direction.

Right→

Within the “Elevator data” menu

section you can check the data for

your piston, pump, weight and

pressures and change them if

desired.

V V.1

IV.7 IV.8

Other manuals for SEV

1

Table of contents

Other Blain Hydraulics Control Unit manuals

Blain Hydraulics

Blain Hydraulics EV4 User manual

Blain Hydraulics

Blain Hydraulics SEV User manual

Blain Hydraulics

Blain Hydraulics R10 User manual

Blain Hydraulics

Blain Hydraulics L10 User manual

Blain Hydraulics

Blain Hydraulics EV100 Series User manual

Blain Hydraulics

Blain Hydraulics KV1P Guide

Blain Hydraulics

Blain Hydraulics SEV07 User manual

Blain Hydraulics

Blain Hydraulics EV100 Series User manual

Blain Hydraulics

Blain Hydraulics EV Series User manual