706304/060515/ES-90 7

NOTE: Primary line voltage must not be greater or less than 8%

of rated voltage listed on voltage tap. For example, Tap 120 volt

(110 – 130 voltage range is acceptable) for excessively low line

voltage, a buck boost transformer maybe required. (Supplied by

others).

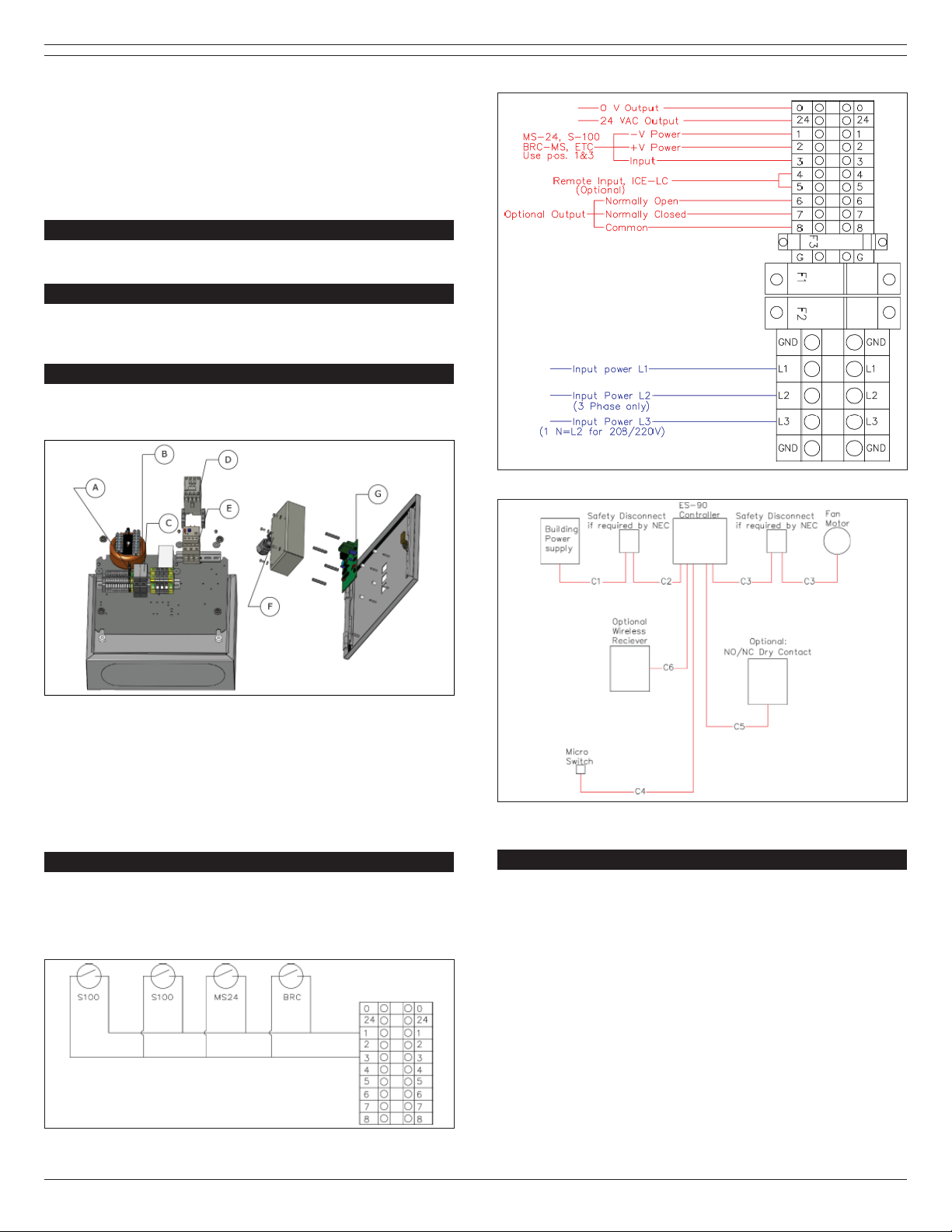

4.3.2 Primary Voltage Wiring

On the right side of the terminal block is the first terminal block

marked GND (green ground). Here you will connect your ground

wire (properly sized per NEC). In the second terminal block

marked L1, you will connect your first power wire. In the third

terminal block marked L2, you will connect your second power

wire. For the fourth terminal block (when applicable), marked

L3, you will connect your third power wire.

NOTE: The line supply voltage from your building, which will

supply your motor, shall be connected directly to L1, L2 for

single phase and L1, L2, and L3 for 3-phase. Re-check that rated

voltage corresponds with supply voltage to avoid damage to

electrical components or control wiring.

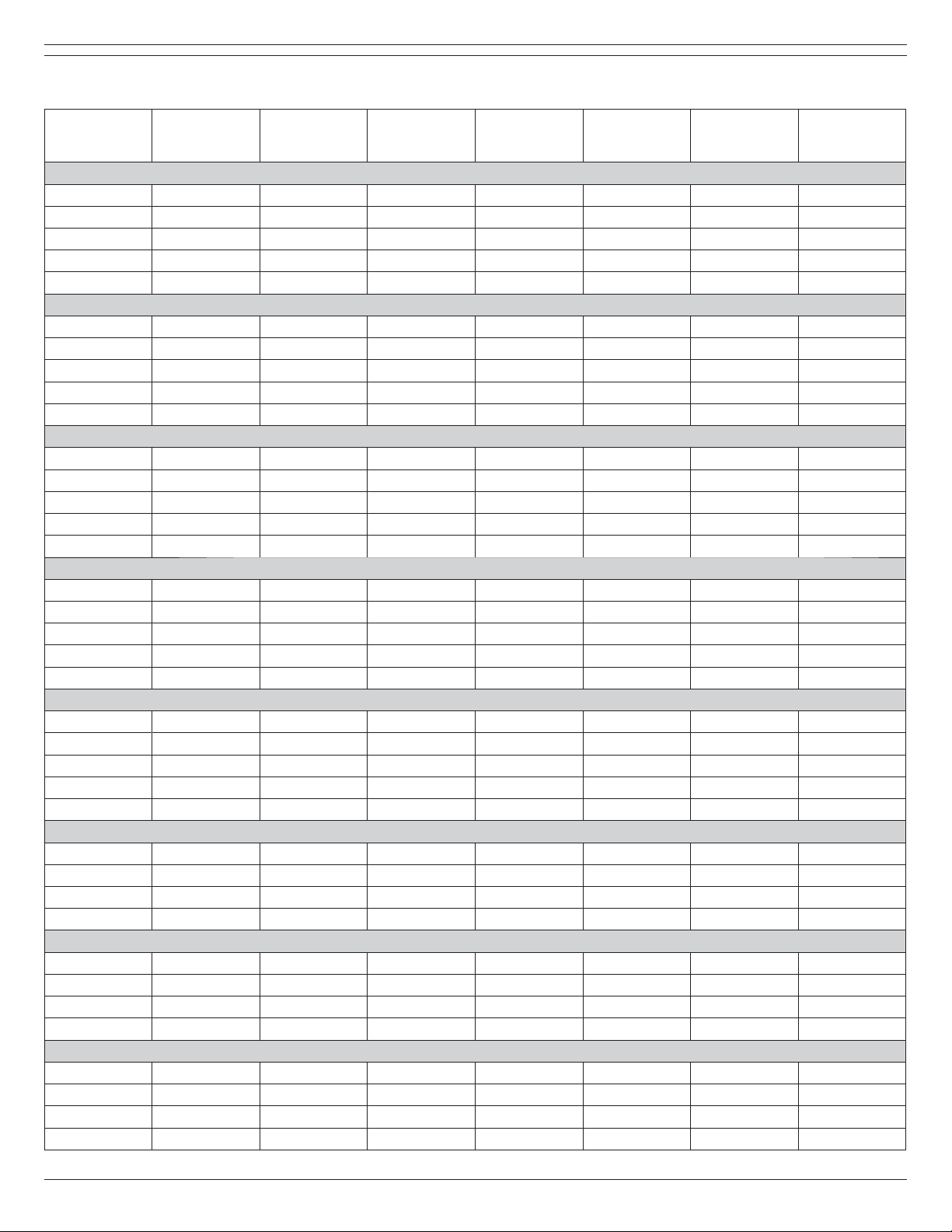

Table 2A on page 12 and Table 2B on page 13 show the fan

component sizing charts.

Please refer to local codes and requirements. These will take

precedence over the supplier wiring chart at the back of this

manual.

4.3.3 Field Power Wiring of Control Box, Safety

Disconnect and Fan Motor

The primary wiring of the electrical system must be rated for the

maximum amps and HP rating of the fan motor load as well as

the wiring voltage drop, which is calculated for the distance, you

are running. See Plymovent Wiring Chart in the back of this

manual as a guide for wiring. It is critical to always follow local

code requirements for selecting wire in instances where they

differ from Plymovent published recommendations.

NOTE: Field wiring, power supply panel and electrical safety

disconnect are provided by others. Plymovent assumes no

liability for any electrical installation and all national and local

codes and standards should be followed.

4.4 Primary Wiring Procedures (Control Wiring)

4.4.1 Control Voltage Wiring

The terminal blocks 0, 24V and 1 through 8 are used for low

voltage control wiring of optional wireless control system,

remote mounted activation devices for starting functions. An

optional remote alarm relay connection is available for

connection to Building Automation Systems (BAS).

MSR-24/2

Optional MSR-24/2 is a single throw double pole micro switch

that is installed on the exhaust hose reel. When the hose is

lowered the MSR-24/2 will activate the ES-90 and turn the fan

on. Auxiliary contact can be used to control an automatic

damper.

BRC-MS

Optional BRC-MS is a single throw double pole micro switch that

attaches to the BRC-450 spring balancer on fixed and boom

extractors. When the hose is pulled down to connect to the

vehicle, the BRC-MS will activate the ES-90 and turn the fan on.

Auxiliary contact can be used to control an automatic damper.

A maintained manual switch can also be placed in parallel in this

circuit for remote starting of the system.

NOTE: Control wires must be a minimum of 16 AWG/1.29 mm².

Smaller wire sizing will result in improper system operation.

4.4.2 Remote Alarm (optional)

Terminals 6, 7, and 8 are a relay dry contact connection for a

Building Automation System (BAS). Terminal block 8 provides

the common connection, terminal 7 provides a normally closed

contact connection and terminal 6 provides a normally open

contact connection.

NOTE: Relay output is a dry contact potential free and will

require additional control equipment depending on its use.

4.5 Transformer Wiring Procedure

4.5.1 Multi-tap Control Transformer

Designed by Plymovent to allow the field electrician the ability to

select the primary voltage of his/her choice. This voltage

selection ranges from 120 volt through 600 volt VAC. The

transformer has been designed to operate in both 50 and 60 Hz

environments.

NOTE: Primary line voltage must not be greater or less than 8%

of rated voltage listed on voltage tap. For example, Tap 120 volt

(110 – 130 voltage variant acceptable) for low line voltage, a

buck boost transformer maybe required (supplied by others).

4.5.2 Primary Voltage Connection

On the top right side of transformer you will find a terminal block

with 8 points of connection. Common black wire is connected to

the top terminal block (black to yellow wire) and will always

remain in this position regardless of the voltage adjustment that

you will be making. The voltage adjusting gray wire is preset for

the voltage ordered. You may be required to reposition the

voltage adjusting wire to the line supply voltage present at your

installation/facility. For example, adjusting to 120 volt line

voltage, move the voltage adjusting wire to wiretap second from

the top of terminal block (black to white). View yellow label for

correct wiretap color for each available voltage.

NOTE: Improper wiring will result in damage of other electrical

components. Re-check that rated voltage corresponds with

supply voltage to avoid damage to electrical components.

Always ensure power is off and all required procedures for

facility (such as lock out tag out) are properly followed before

making any adjustments to the control system.

WARNING!

Procedures which, if not carried out with the

necessary caution, may damage the product and/or

cause serious personal injury.

4.5.3 Secondary Voltage Connection

A 24VAC power supply is available using terminals labeled 0 and

24. This can be used to power an optional wireless control

system or automatic dampers.