Blakeslee D-18 Parts list manual

COD.: 3050E

Ed. 02 - 05/2016

APPLICARE ETICHETTA

MATRICOLA

Istruzioni per l'installazione, l'uso e la

manutenzione

IT

Instructions for Installation, Use and

Maintenance

HOOD-TYPE

D-18

USA

Thank you for choosing our appliance.

The installation, use and maintenance instructions given in this manual have been prepared

to ensure the long life and correct operation of your appliance.

Follow these instructions carefully.

We have designed and manufactured this appliance according to the latest technological

developments. Now, it is in your care.

Your satisfaction is our greatest reward.

USA

page 19

TRANSLATION OF THE ORIGINAL INSTRUCTION

WARNING: FAILURE TO COMPLY (EVEN PARTIALLY) WITH THE RULES GIVEN IN THIS MANUAL

WILL INVALIDATE THE PRODUCT WARRANTY AND RELIEVES THE MANUFACTURER OF ANY

RESPONSIBILITY.

READ THE INSTRUCTIONS CAREFULLY BEFORE INSTALLING THE MACHINE.

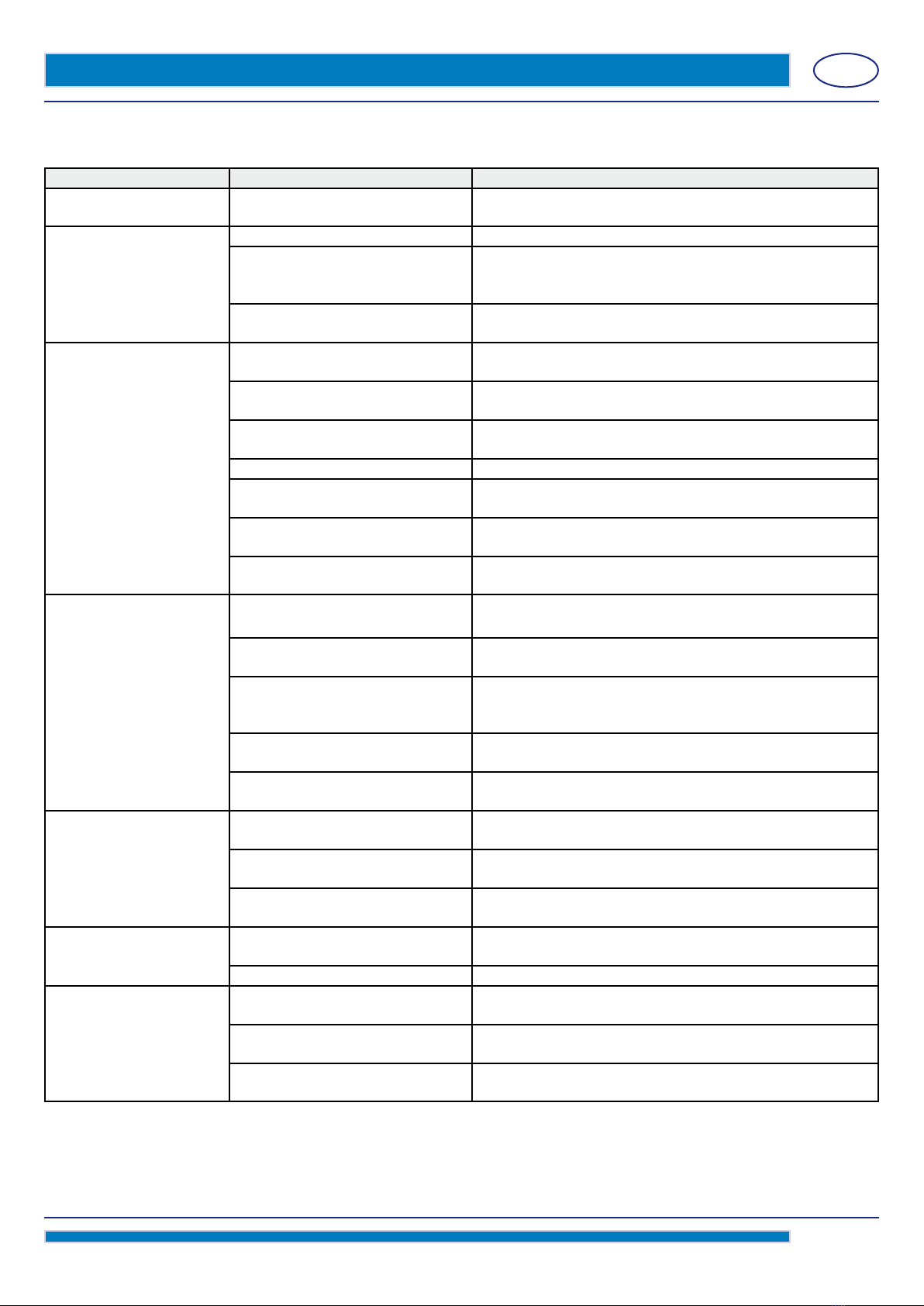

SUMMARY Page

IMPORTANT INFORMATION 20

1. SERIAL NUMBER DATA 22

INSTALLER SECTION

2. MACHINE INSTALLATION 23

2.1 Receiving the machine 23

2.2 Water connections 23

2.3 Electrical connection 24

2.4 Temperature adjustment 24

2.5 Rinse aid dispenser operation 24

3. DETERGENT DISPENSER INSTALLATION 26

3.1 Electrical connection 26

3.2 Water connection 26

3.3 Dispensing the detergent 26

4. TECHNICAL DATA AND USEFUL INFORMATION ON PUMPS 26

4.1 Drain pump (optional) 26

USER SECTION

5. CONTROL PANEL AND RELATIVE SYMBOLS 27

6. OPERATION 27

6.1 Cutlery and crockery loading 27

6.2 Detergent use 28

6.3 Rinse aid use 28

6.4 Compliance with hygiene regulations, H.A.C.C.P. and NSF 29

6.5 Drain pump (optional) 29

7. MAINTENANCE 29

7.1 Routine maintenance 29

7.2 Extraordinary maintenance 29

8. THE ENVIRONMENT 30

8.1 Packing 30

8.2 Disposal 30

9. ECOLOGICAL ASPECTS 30

9.1 Recommendations for optimal use of energy, water and additives 30

10.TROUBLESHOOTING 31

USA

page 20

IMPORTANT INFORMATION

Always keep this instruction manual near the dishwasher for future

consultation. If the appliance is sold or transferred to another User, make

sure this manual always remains with the machine to enable the new

owner to be informed about operation of the appliance and the relative warnings.

The dishwasher shall be installed in accordance with local codes, or in the absence

of local codes, installed in accordance with the applicable requirements in the

National Electrical Code, NFPA 70, Canadian Electrical Code (CEC), Part 1, CSA

C22.1, and Standard for Ventilation Control and Fire Protection of Commercial

Cooking Operations, NFPA 96.

These warnings are provided to safeguard the user in conformity with technical

standards UL 921 and NSF.

They must be read carefully before installation and use of the dishwasher.

• Theelectricalandplumbingconnectionsforinstallingthedishwashermustonly

bemadebyqualiedandauthorizedpersonwhowillcomplywithallavailable

Federal, State, and Local Health, Electrical, Plumbing and Safety codes.

• Thisdishwashermustbeusedbyadultsonly.Thisisaprofessionalmachinetobeused

byqualiedpersonnel,andinstalledandrepairedexclusivelybyaqualiedtechnical

assistance service. The Manufacturer declines any responsibility for improper use,

maintenance or repair.

• Theapplianceisnottobeusedbychildrenorpersonswithreducedphysical,sensoryor

mentalcapabilities,orlackofexperienceandknowledge,unlesstheyhavebeengiven

supervision or instruction.

• Childrenbeingsupervisednottoplaywiththeappliance.

• Accompanythedoorinopeningandclosing.

• Makesurethedishwasherisnotrestingontheelectricalfeedcablesorthellingand

emptying pipes, otherwise adjust the feet of the appliance and make sure that it is perfectly

level.

• Donotusetheapplianceoranypartofitasastepladderormeansofsupportasithas

beendesignedexclusivelytobeartheweightofthedishrackcontainingdishestobe

washed.

• Thedishwasherisdesignedonlyand exclusivelyfor washing plates, glasses

andcrockeryingeneralwithresidualsoffoodstus.Neverwashanyunspecied

item, anything overly fragile or unable to withstand the washing process. Do not

use acidic corrosive chemical products or alkaline and solvents or chlorine based

detergents.

• Neveropenthedishwasherdoorandneverswitchitoduringoperation.Alwaysswitch

itobeforeaccessingtheinside.Thedishwasherhasasafetydevicewhichimmediately

stops it if the door is accidentally opened, preventing water spillage.

• Thismachinemustbedisconnectedfromthemainelectricalsupplyafteruseat

theendofthedayandforanyservice/maintenanceoperation.Switchothemain

USA

page 21

switch located on the wall, which shall be installed by a professional installer. Shut

the water supply valve(s). Disregarding the aforesaid prescriptions is a serious

misuse and can cause damages and injures to property an people, and will relieve

the manufacturer from whatever liability.

• Undernocircumstancesshouldtheuserattempttocarryoutrepairs.Contactaqualied

and authorized technician.

• Technical assistance for this dishwasher must only be carried out by qualied and

authorized operators.

Note: Only use original replacement parts. Otherwise the product warranty is

invalidated and the manufacturer is no longer responsible.

• Donotuseoldloadpipe,butonlynewones.

• Someimportantrulesmustbefollowedforusingthisappliance:

1) never touch the appliance with wet hands or feet

2) never use the appliance when barefoot

3)donotinstalltheapplianceinplacesexposedtowatersprays.

• Donotdipbarehandsintowatercontainingdetergent.Ifthisshouldoccur,washthem

immediately with plenty of water.

• Onlyfollowtheinstructionsgiveninthemanufacturer’sbookletforcleaningoperations

(chap. 7).

• Minimumroomtemperatureforoperationis50°F(10°C).

• Donotusewatertoputoutresonelectricalparts.

• Donotclogtheintakeordissipationgrids.

• Onlyqualiedpersonnelcanaccessthecontrolpanelafterpowerisswitchedo.

• ThemachinehasanIPX3ratingofprotectionagainstaccidentalsplashesofwater.It

is not protected against pressurized jets of water, so it is recommended that pressure

cleaning systems not be used.

NOTICE: This machine must be operated with an automatic detergent dosing pump

and, if applicable, an automatic chemical sanitizer dosing pump, including a visual

means to verify that detergents and sanitizers are delivered or a visual or audible

alarm to signal if detergents and sanitizers are not available for delivery to the

respective washing and sanitizing systems. Please see instructions for electrical

and plumbing connections located in this manual.

N.B.: The Manufacturer declines any responsible for damage or injury caused by

failure to follow the above rules.

IMPORTANT: WAIT AT LEAST 10 MINUTES AFTER THE MACHINE HAS

BEEN SWITCHED OFF BEFORE CLEANING INSIDE IT.

DO NOT INSERT HANDS AND/OR TOUCH THE PARTS AT THE BOTTOM

OF THE TANK WITH THE MACHINE ON AND/OR HOT.

USA

page 22

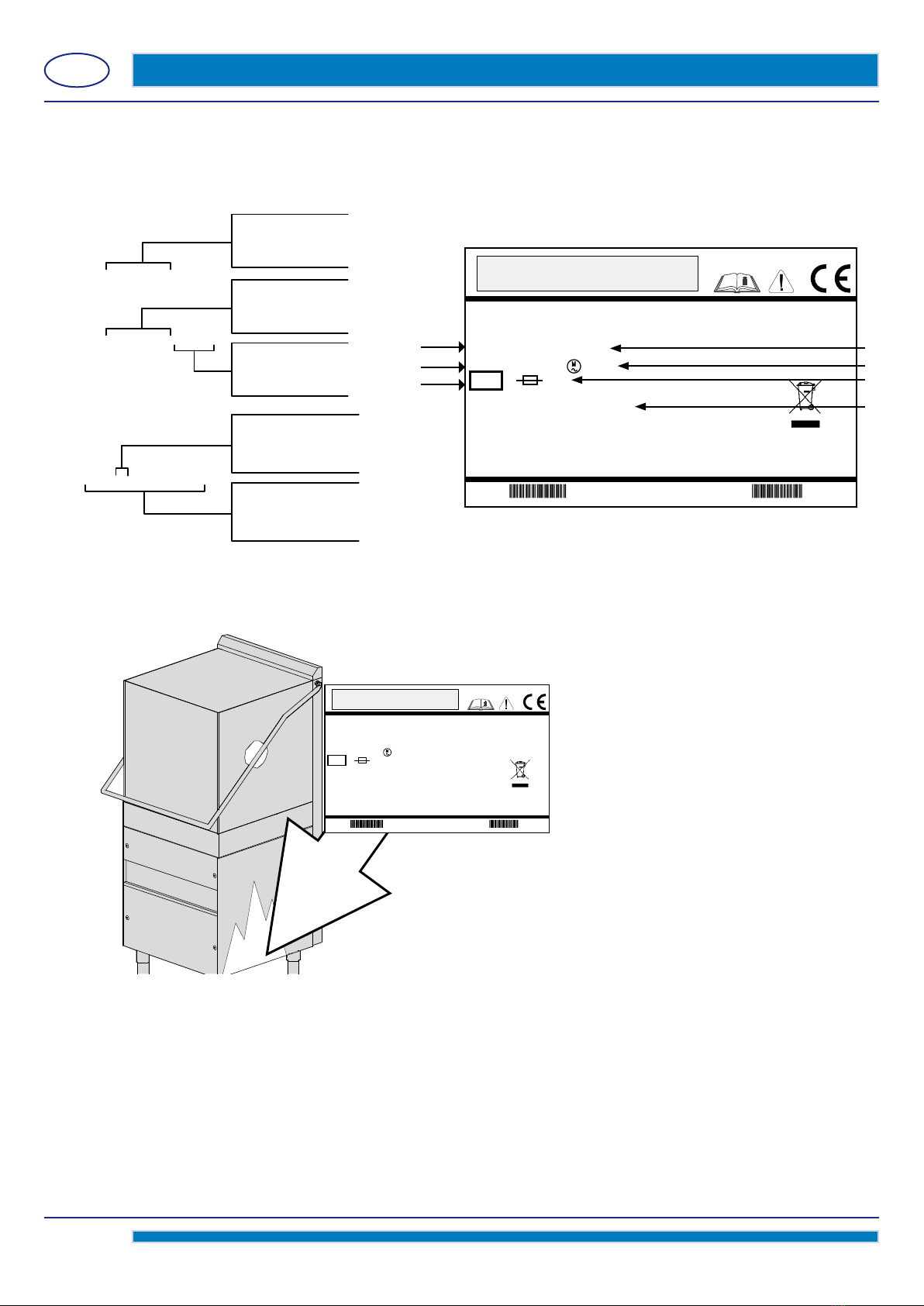

A Power source

B Total power installed

C Envelope protection degree

D Total electricity absorption

E Total motors power

F Electrical protection index

G Dynamic pressure

AD

E

F

G

B

C

S/N DW L 10XXXXX

ANNO

YEAR

ANNÉE

ANO

JAHR

NUMERO DI SERIE

SERIAL NUMBER

NUMÉRO DI SÉRIE

NUMERO DI SERIE

SERIENNUMMER

G=2012 - 2013

H=2013 - 2014

I=2014 - 2015

L=2015 - 2016

CODE DWXXXX

FAMIGLIA PRODOTTO

PRODUCT FAMILY

FAMILLE DU PRODUIT

FAMILIA PRODUCTO

FAMILIE DES PRODUKTES

CODE DWXXXX.YYYY

FAMIGLIA PRODOTTO

PRODUCT FAMILY

FAMILLE DU PRODUIT

FAMILIA PRODUCTO

FAMILIE DES PRODUKTES

CODICE MODELLO

MODEL CODE

CODE ARTICLE

CODIGO MODELO

KODE VON MODELL

Model S/N

Model DESCRIPTION

S/N DWL10XXXXX Type ..........

xx°C

200-500 kPa

xxxkpA

xxA

IPXX

MADE IN ITALY

ANNO PROD.: 2016

Temperatura massima acqua in ingresso

Température max eau à l'entrée

Maximum water-infeed temperature

Maximale Zulaufwassertemperatur

Pressione dinamica alimentazione idrica

Pression dynamique arrivée d'eau

Dynamic pressure water supply

Fließdruck Wasserzulauf

Pressione dinamica vapore saturo

Pression dynamique vapeur saturée

Saturated steam dynamic pressure

Dynamischer Dampfdruck

Code DWXXXX.YYYY CL/Part

xxxxW xxxW

400V 3N 50HZ xA

RoHS

1. SERIAL NUMBER DATA

Model S/N

Model DESCRIPTION

S/N DWL10XXXXX Type ..........

xx°C

200-500 kPa

xxxkpA

xxA

IPXX

MADE IN ITALY

ANNO PROD.: 2016

Temperatura massima acqua in ingresso

Temperature max eau a l'entre

Maximale Wasseranschluss temperatur

Maximum Water temperature infeed

Pressione Dinamica alimentazione idrica

Pression dynamique arrivée d'eau

Dynamic pressure water supply

Dynamischer Druck Wassereinlauf

Pressione dinamica vapore saturo

Pression dynamique vapeur saturée

Dynamischer Druck gesattigter Dampf

Saturated steam dynamic pressure

Code DWXXXX.YYYY CL/Part

xxxxW xxxW

400V 3N 50HZ xA

RoHS

USA

page 23

INSTALLER SECTION

ATTENTION:

Attheendofinstallationmakesuretoremovethepartsofthisbookletrelevanttotheinstaller,forfutureconsultation.

2. MACHINE INSTALLATION

2.1 Receiving the machine

Afterunpacking,makesurethemachinehasnotbeendamagedduringtransportation.Ifso,donotifythe

sellerimmediatelyabouttheproblem.Ifthedamagemightquestionthemachinesafety,donotinstallit.

Doublecheckthermtightnessofallhose-clampsonpiping,nuts,boltsandelectricalconnection

that might have come loose during transportation, to prevent water dripping leakages, or other

damages, during the machine operation.

Seechap.8 for disposing the packing material.

2.2 Water connections

Connectthemachine'swatersupplywithaninterruptvalvecapableofquicklyandcompletelyshuttingowaterintake.

TheWatersystemmusthavecharacteristicsbetweentheparametersspeciedintable1.

Ifitislessthan30Psidynamicpressure(200kPa)apressurepumpmustbeinstalledtoguaranteeoptimalmachineoperation.

If,however,thewatersupplypressureisgreaterthan60Psi(400kPa),apressurereducingdevicemustbeinstalled.

Forwaterwithaveragehardnessgreaterthan10°f,awatersoftenermustbeused.Thiswillresultincleanerdishesand

longer life of the appliance.

Eachmachineisprovidedwitharubbertubewitha¾"threadedattachmentforwaterlling.

Itisadvisabletoconnectthehosetoawatersupplynotabove150°F(65,5°C),ifconnectedtothehotwater.

Connecttheemptyingtube,suppliedwiththeappliance,totheunionelbowlocatedunderthetubsothatwaterowsfreely.

Ifitisnotpossibletoemptythewateratalevellowerthanthedrainoftheappliance,itisadvisabletoinstallanemptying

pump, which can be provided by request.

The emptying tube should always be connected to a siphon to prevent odor back-up from the screen.

Pressure table Min. Max.

Psi (kPa) Psi (kPa)

StaticPressure 30 (200) 60(400)

DynamicPressure 30 (200) 50 (350)

Water Hardness 2°f 10°f

table 1

H2O supply temperature table

H2O Hot

140°F≤t≤150°F

60°C≤t≤65.5°C

table 2

max 19

11/16

inches

(500 mm)

pict. 1

USA

page24

INSTALLER SECTION

2.3 Electrical connection

The electrical connection must be made according to current technical standards.

Ensure that the mains voltage corresponds to the value given on the machine dataplate.

Installasuitableomnipolarthermalmagneticcircuitbreaker,dimensionedaccordingtoabsorption,withopeningcontact,

in according to current standards.

Thiscircuitbreakermustbeexclusivelyusedforthispurposeandinstalledintheimmediatevicinity.

Themachinemustbeturnedowiththisswitch.

Make sure that the electrical systems are suitably earthed.

On the back of the appliance there is a terminal marked with the symbol which is provided for equipotential connection

betweendierentappliances.Thespecialdataplategivesthemax.powervalueinwatts(W),amperes(A)andfuse,for

dimensioning of the line, cable and switches.

The dealer/importer/installer must adapt the power cable insulation class according to the work environment, in

conformitywithcurrentTechnicalStandards.

Cable characteristics: Usecoppercablesonly,correctlydimensionedfortheamperageindicatedonthemachine

andmadetooperateatminimum167°F(75°C).

Warning:someversionsofthismachinecandissipatemorethan10mAtoearth.

Ifthemachineisttedwithathree-phasepump,checkcorrectmotorrotation(directionofarrowsonthe

casing-seepict.2).Theproblemdoesnotexistifthepumpissingle-phase(standard).

2.4 Temperature adjustment

Ifnecessary,thewatertemperatureofthewashandrinsecyclescanbeadjustedbymeanstherespective

thermostats.

Therecommendedtemperaturesare160°F(71°C)forthewashcycle(tub)and185°F(85°C)forthe

rinse cycle (boiler).

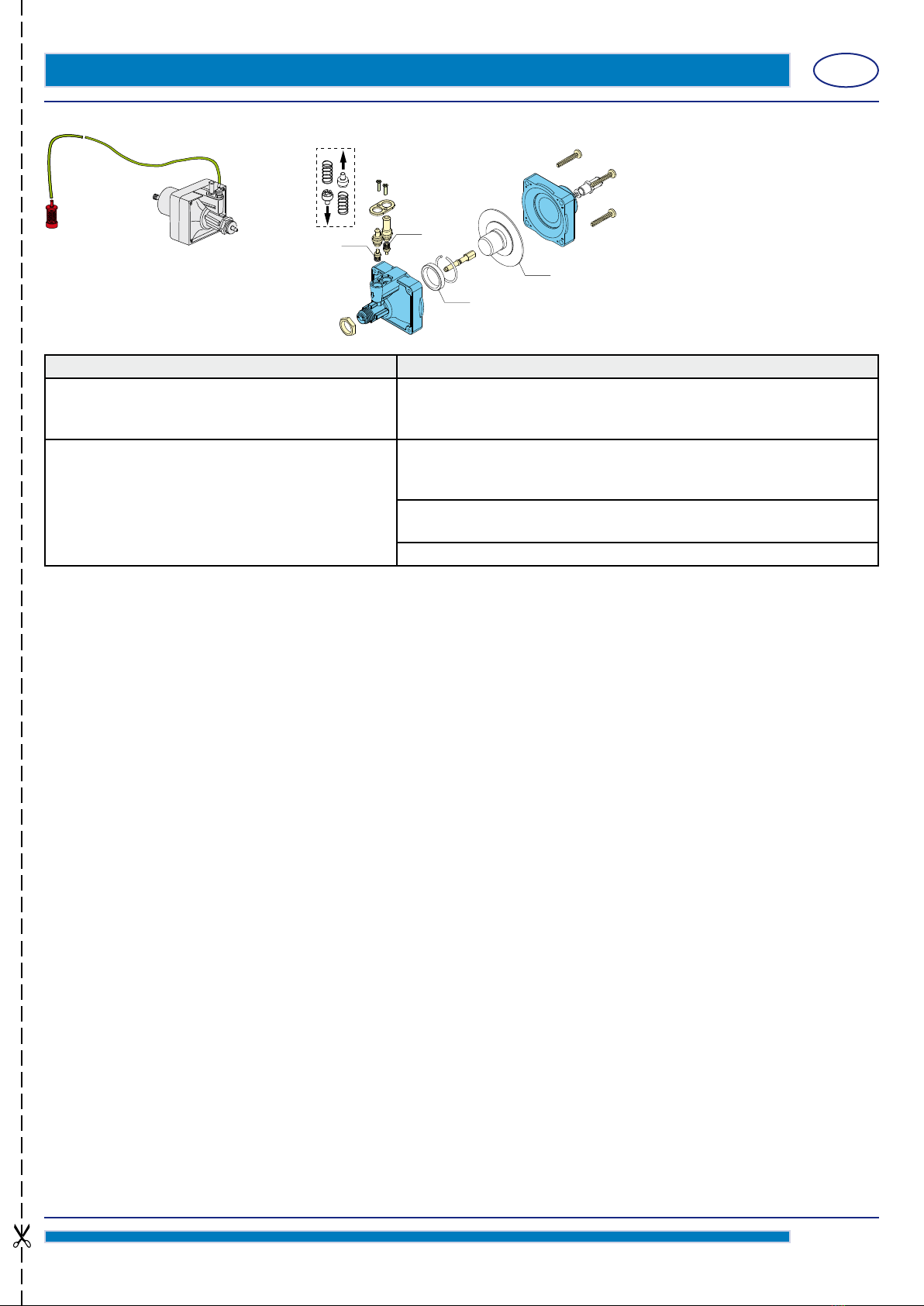

2.5 Rinse aid dispenser operation

Technical characteristics:

Operation: it utilizes the wash pump starting pressure and the water circuit pressure in the rinse phase. Min. water pressure

30Psi(200kPa).

Water connection:

1)ConnectthedispensertubettingAto the pump, by means of the rubber tube installed in the appliance (pump pressure).

2)ConnectthesmallblackrubbertubebythebrassdeliveryttingBto the connection near the boiler (injector).

3)MakesurethatthegreenproductsuctiontubeisinsertedonthespecialttingCandthatthesmalllterandtheballast

are inserted in the rinse aid tank.

Priming: To carry out priming, start the machine and carry out a few complete wash and rinse cycles. To speed up restoration

press the adjustment screw Dduring the wash cycle and open the hood; press pin Dagain and close the hood; press pin

Dagain and close the hood for a few seconds, open the hood again and press pin Dagain and close the hood. Repeat this

operationuntilthegreentubeiscompletelylled.

Adjustment: Witheveryrinsethedispenserdrawsaquantityofrinseaidadjustablefrom0to2cubicinches(from0to4

cm3), equivalent to a length of 0 to 11 inches (from 0 to 30 cm).

Min. delivery is obtained by turning the adjustment screw Dclockwisealltheway,whereasmax.deliveryisobtainedby

turningtheadjustmentscrewapprox.20turnsanticlockwise.

For the right amount of product see the paragraph Rinse aid use.

Note:foreveryturnofthescrewtheamountofrinseaiddrawninthetubevariesby5/8inches(1,6cm)equalto13/16cubic

inches/run (0,2 cm3/turn-approx0,01onces/run-0,21gr/turnwithrinseaiddensityof0,60onces/cubicinches-1,05g/cm3).

Therinseaiddispensercannotworkcorrectlyifthedierenceinlevelbetweenthebottomofthemachineandthetankis

morethan31inches(80cm).

THEDISPENSERSAREPRESETFORDRAWING2"(5cm)FOLLOWINGAFUNCTIONALCHECKDURINGTHETESTING

PHASE.THISVALUEMUSTALWAYSBEMODIFIEDACCORDINGTOTHETYPEOFRINSEAIDANDTHEHARDNESS

OFTHEWATER.

pict. 2

USA

page 25

INSTALLER SECTION

code 10799

C

D

B

A

10807

10806

10805

10805

10805

PROBLEMS CAUSES AND SOLUTIONS

Waterexitsfromtherinseaidsuctiontube Thesuctionvalves10805anddeliverydonotsealduetoforeignbodies

intheclosingseats.Cleanthevalves10805,checkthattherinseaid

suctionlterispresent,andlterthewaterenteringthedishwashwer

The dispenser does not draw rinse aid a)Thedeliveryvalve10805doesnotsealduetoforeignbodiesinthe

closingseats.Cleanthevalve10805,checkthattherinseaidsuction

lterispresentandlterthewaterenteringthedishwasher

b)Thepistonseal10806doesnotholdbecauseitisdamaged.

Replacetheseal10806withanoriginal

c)Checkthediaphragm10807

USA

page 26

INSTALLER SECTION

3. DETERGENT DISPENSER INSTALLATION

3.1 Electrical connection

Follow the wiring diagram attached to the machine.

3.2 Water connection

a)Removethecapfromtheholeandtthedeliveryconnection.

b) Correctly mount the injector Cusingtheappropriatextures.

c)Connectthesuctiontubetothesuctionattachmentofthedispenser(seepict.4-pointA).

d)Connectthedeliverytubetotheotherattachmentofthedispenser,andthedeliverytting(seepict.4

point B).

e)Insertthesuctiontubewithlterinthedetergenttank.

f)Primethedetergentandproceedtodispense.

3.3 Dispensing the detergent

The detergent dispenser capacity can be adjusted using a screwdriver as shown in picture 3.

Every 13/16 (2 cm) of product drawn into the tube corresponds to 1/64 cubic inches (0,25 cm³) equivalent to 0,01

oz (0.3 g - th a concentration of 1/16 oz/cubic inches - 1,2g/cm³). For proper dispensing see paragraph 6.2.

IMPORTANT: DO NOT INVERT THE TUBES INTHE PRODUCTS; IF THIS

OCCURS IT WOULD RUINTHE METERING PUMPSAND COMPROMISE

DISHWASHEROPERATION.

4. TECHNICAL DATA AND USEFUL INFORMATION ON PUMPS

4.1 Drain pump (optional)

When installing, pay particular attention to the position of the emptying tube (see pict. 5).

Max.drainheight <39 inches (<1mt), there must be a trap downstream of the drain.

For the electrical connection see the wiring diagram notes.

max 39 inches (1 mt)

pict. 5

g.3

A

B

C

min1"1/4

(3 cm)

PuntoB

CONNECTION DIAGRAM

pict. 4

USA

page 27

USER SECTION

5. CONTROL PANEL AND RELATIVE SYMBOLS

6. OPERATION

• Inserttheoverowpipeinthespecialseatinsidethetank.

Makesurealltheltersareproperlyttedintheirseats.Theltersmustbecleanedevery40-50washcyclesandwhenever

necessary.

Donotoperatethemachinewithoutlters,andinparticularthepumpsuctionlters.

• Openthewatervalve.

• Turnonthemainwallswitchandputtheselectoron (it is not a total disconnecting switch).

• Insertthespecialgreenrinseaiddispensertubeintheliquidrinseaidcontainerandcheckthatthequantityissucient

for the daily requirement.

• Makesurethattheselectorison .

• Usingthehandle,lowerthemachinehoodandthetankllingphaseautomaticallystarts.Theautomaticelectricdetergent

dispenser supplies to the dosage of the detergent.

• Afterlling,themachineautomaticallystartstheheatingphase.

• Themachinewillbereadyforwashingonlywhentheboilerthermometer4and tank thermometer 5indicate that the

requiredtemperatureshavebeenreached,whichare185°F(80-85°C)forboilerand160°F(71°C)forthetank.

• Selectthewashtimewiththeselector3.

Pos.1=short

Pos.2=long(NSF)

Thisinmachinesequippedwiththermostop,inordertoguaranteetheexactrinsetemperature,thewashingtimecan

increasetoallowtheboilerwatertemperaturetoreachthesettemperature(185°F/80°-85°C)

• Insertthebasketwithdishesorvariousarticlestobewashedandclosethehood(seepar.6.1). The wash cycle starts

automatically, immediately followed by the rinse cycle. The cycle is signalled by the indicator 2.

• Thecycleisnishedwhentheindicatorgoeso.

• Theapplianceisreadyforanothercycle.

Note:Itisadvisabletochangethetankwater,bymeansofanotherlling,atleastevery40-50washesortwiceaday.

Clean the machine at the end of the day (see chap. 7 Maintenance).

Positiontheselector3on the position 0.

Switchthemachineoandclosethewatervalve.

N.B.: therstcyclecarriedoutafterchangingthetimewiththemechanicaltimerwillnotyetbeliketheonesetpreviously:

thetimerrequiresacompletewashingcycleinordertorealignthecamsaccordigntothesettime.Selecting the cycle

won’tstartbyclosingthehood.

6.1 Cutlery and crockery loading

Beforecutleryandcrockeryloadinginthemachine,coarselycleanthemfromtheleftoverfood.

Itisn'tnecessarytorinsethecutleryancrockeryunderwater.

ATTENTION: Do not wash articles polluted with petrol, paint, chips of steel or iron, ash, sand, wax, lubricant grease.

These substances damage the machine. Do not wash fragile objects or material not resistant to the washing process.

CONTROLS INDICATORS

Cycle indicator

Cycle time selector

0=o

=loadingonly

1=120s

2=180s(NSF)

Boilerthermometer

Tank thermometer

Manual-automatic

draining button

(optional)

USA

page28

USER SECTION

Note the following recommendations:

•Crockeryandcutleryshouldnotbeinsertedinsideoneanother,coveringeachother.

•Placethecrockeryinordertoallsurfacescanbereachedbywater;otherwisethedishesarenotwashed.

•Makesureallthecrockeryareinastablepositionandthatthehollowcontainersdon'toverturn(cups,

glasses, bowls, etc.) .

•Placeintherackallthehollowcontainerssuchascups,glass,etc.upside-down.

•Placethecrockerywithdeephollowwithupperfacedownwards,sothatwatercanowout.

•Makesurethesmallercrockerydonotfallfromtherack.

•Checkallthewasharmsrunsfreelyandtheyarenotblockedbytootallortooprominentcrockery.

Eventually, run a manual rotation of the arms to check it.

Somefoods,suchascarrots,tomatoes,andothers,maycontainsomenaturaldyessubstances,thatin

large amounts, can alter the crockery and plastic parts colors.

Anydiscolorationdoesnotmeanthattheplasticisnotheatresistant.

Crockery and cutlery not suitable for dishwasher

Not suitable for dishwasher:

•Woodencrockeryandcutleryorwithwoodenparts;waterathightemperaturecausesdeformationto

wood.Alsotheadhesivesusedarenotsuitablefortreatmentinthedishwasher;aconsequencecould

be the handles detachment.

•Crafts,preciousvasesordecoratedglasses.

•Notheat-resistantplasticcrockery.

•Copper,brass,pewteroraluminumobjects:theymaybecomediscoloredoropaque.

•Thedecorationsonglass,afteracertainnumberofwashes,canlosegloss.

•Fragileglassesorcrystalitems,ifoftenwashed,canbecomeopaque.

Werecommendtobuyexclusivelycrockeryandcutlerysuitablefordishwashing.

Afterseveralwashes,theglasscanbecomeopaque.

It is mandatory to repeat the washing cycle if at the end of the cycle the crockery are not well clean or if there are

washing residues (glasses, cups, bowls, etc. with liquid inside).

6.2 Detergent use

ThedetergentshallbetheNOFOAMtype,suitableforindustrialdishwashers.Theuseofgoodqualityliquid

detergents is recommended.

Putthedetergentdirectlyinthetub.Followthemanufacturer’srecommendationsforchemicaldosage.By

request, the dishwasher can be equipped with an electric detergent dispenser .

3/8inches (1cm) of the product drawn into the tube is equal to about 3/32 Dramme(0,15g).Acorrectamountof

detergent is very important for a successful wash.

Thismachinemustbeoperatedwithanautomaticdetergentdosingpump.Verifythecorrectoperationbycheckingthe

detergentowinthetransparentsuctionhosefromthedetergentcanister.Makethecheckduringthetankllingorrinsephase.

6.3 Rinse aid use

The machine is equipped with a rinse aid dispenser. The machine automatically draws the product. The amount

dispensedcanberegulatedbyoperatingthene-adjustmentscrewonthedispenser.Reducetheamountby

turning the screw clockwise, increase by turning it anticlockwise.

The recommended amount is 7/8- 1 15/16 inches (2-5cm) of product measured on the suction tube.

3/8inches (1cm) of the product drawn into the tube is equal to about 1/16 Dramme(0,13g).Acorrectamountof

rinse aid is very important for a quick and clean drying.

N.B.: toomuchproduct,orfoam,reducestheeciencyofthewashpump.

DETERGENT

RINSE AID

USA

page 29

USER SECTION

6.4 Compliance with hygiene regulations, H.A.C.C.P. and NSF

• Themachinesareequippedwithatemperatureindicatortoindicatetheboilerandtanktemperature.Waituntiltheset

temperaturesarefullyreached:atleast160°Fforthewashingtuband185°Ffortherinse.Verifythatthepressureofthe

rinsingisbetween15and25Psi.

• Removesolidsformthecrockery,notcloglters,nozzlesandpipes.

• Drainthewashtanksandcleantheltersatleasttwiceaday.

• Checkthatdetergentandrinseaiddosingiscorrect(asrecommendedbythesupplier).Beforestartingthemachine

makesuretheamountofchemicalsinthetanksissucientforthedailyrequirement.

• Keepthetablessurfacesclean.

• Removethebasketfromthemachinewithcleanhandsorgloves,nottocontaminatethecutlery.

• Donotdryorpolishthecrockerywithunsterilecloths,brushesorrags.

6.5 Drain pump (optional)

Toemptythetank:removetheoverowandleavethehoodopen,thenpressthekey6to start the automatic total emptying

time.

Foranotherload,inserttheoverowandswitchthemachineonagain.

Duringthewash-rinsecycletheexcesswaterisautomaticallydischarged.

7. MAINTENANCE

7.1 Routine maintenance

ATTENTION: The machine is not protected against pressure water jets, therefore do not use such

cleaning systems on the cabinet.

It is also advisable to contact cleaning product dealers for detailed information on methods and

products for periodical sanitizing of the machine.

Donotusebleachorchlorine-baseddetergentstocleanthedishwasher.

Perfectmachineoperationdependsoncarefulcleaning,whichmustbecarriedoutatleastonceaday,inthefollowingway:

• TurnotheON/OFFswitchto0.

• Turnothewatervalve.

• Drainthewaterremovingtheoverowpipe.

For appliances provided with emptying pump, see par. 6.5.

• Removetheltersandcleanthemwithabrushunderastrongjetofwater.

• Removetheimpellersbyundoingthexingscrewsandcarefullycleanthenozzles,washarms,andrinseunderrunning

water.

• Retallthepartsandarrangetheimpellersintheirseats,securingthemwiththerelativexingscrew.

• Carefullycleanthetank;donotusechlorine-baseddetergents.

• Attheendofthedayitisadvisabletoleavethemachinehoodopen.

Note:Itisadvisabletochangethetankwater,bynewlling,atleastevery40-50washesortwiceaday.

Do not use metal scouring pads and/or corrosive products for cleaning the dishwasher.

7.2 Extraordinary maintenance

Onceortwiceayearhavethemachinecheckedbyaqualiedtechnician,to:

1Cleanthesolenoidvalvelter;

2 Remove scale from the heating elements;

3 Check the tightness of seals;

4Checktheintegrityand/orwearofcomponents;

5 Check the functionality of the dispensers.

6HavetheelectricalconnectionterminalstightenedatleastonceayearbyTechnicalAssistance.

USA

page 30

USER SECTION

8. THE ENVIRONMENT

8.1 Packing

The packing consists of the following:

•awoodenpallet

•anylon(LDPE)bag

•amultilayercardboardbox

•polystyrenefoam(PS)

•polypropylene(PP)straps.

Please dispose of the materials listed above, according to the current regulations.

8.2 Disposal

The machine must be disposed of according to current regulations: contact the Municipalized Firm responsible

for collection of urban solid waste.

Beforedisposingoftheappliance,disconnectallwaterandelectricalconnections.

Cut the electrical cable in such a way as to prevent further use.

Asallmetalpartsarestainlesssteel,theyarethereforerecyclable.

Recyclableplasticpartsareidentiedbytheplasticsymbol.

9. ECOLOGICAL ASPECTS

9.1 Recommendations for optimal use of energy, water and additives

Usethemachinefullyloadedwhenpossible

This shall prevent detergent, rinse aid, water and energy waste.

Detergent and rinse-aid

Usedetergentand rinse-aid chemicalswith high biodegradability, torespectthe environment best.Verify the

properdosageinrelationtowaterhardnessatleastonceayear.Excessofproductpollutesriversandseaswhile

aninsucientdosingwillcauseunsatisfactorydishwashingand/orhygiene.

Tank and boiler temperatures

The tank and boiler temperatures are set by the manufacturer in order to obtain the best washing results with detergents on

the market. These may be re-set by the installer according to your detergent (see paragraph 2.5).

Cleaningo

Carefullyremovesolidsothekitchenwareusingwateratroomtemperaturesoastomakeremovalofanimalfatseasier.

To remove encrusted matter, soaking in hot water is recommended.

Notes:

Washtheobjectsassoonaspossibleinordertopreventthedepositsfromdryingandjeopardizingtheeectivenessofthe

washing.Togetanecientwash,itisadvisabletoregularlycleanandmaintainthemachine(seechap.7).

Disregarding the points listed above and any information contained in this manual can cause energy, water and

detergent waste with a subsequent increase in running costs and/or performance reduction.

USA

page 31

USER SECTION

10. TROUBLESHOOTING

Type of problem Possible causes Cure

The machine does not

turn on

Main switch not ON. Turn switch ON.

The machine does not

load water.

Water valve shut. Open the water valve.

The spray arm nozzles or the

solenoid lter are clogged and/or

caked with lime deposists

Cleantherinsingarmnozzles,thepipesandthelter.Check

thatthewaterhardnessis<10°f.Equipthemachinewith

anexternalwatersoftener

Faulty pressure switch Replacethepressureswitch(calltheTechnicalAssistance

service)

Washing results are

unsatisfactory.

The washing nozzles are obstructed

or the rack does not rotate.

Unscrewand clean the nozzles and the rotationshaft

carefully,retthemcorrectlyintheirseats

Filters are dirty. Removelters,cleanwithbrushunderajetofwaterand

replace in original position.

Presenceoffoam Useanon-foamingdetergentorreducetheamountofthat

used. Check the rinse aid dispenser

Fats or starches are not removed Detergent concentration too low

Check the tank temperature (it

mustbeabout160°F-71°C)

Adjustthe thermostat or check correct heating element

operation

Lengthofwashingcycleinadequate

for type of grime build-up

Choose a longer cycle if possible, otherwise repeat wash

cycle

Wash water too dirty Emptywaterfromthetank,cleanlters;rellthetankand

correctlyretthelters

Glassesordishesarenot

completely dried

Insucientrinseaid Increasetheamountofrinseaidbyturningthescrewon

the dispenser (see paragraph Rinse aid use)

The rack is unsuitable for the

glasses and dishes

Useasuitablerackenablingthedishestobetiltedsowater

canruno

The dishes have been too long in

the tank

Assoon as the wash cycle is nished, pull the rack out

immediately, allowing the air to dry the glasses and dishes

more quickly

Rinse water temperature is less

than185°F(85°C)

Check the temperature of the booster thermostat. Call the

TechnicalAssistanceservicetoadjust

Surfaceofdishesandglassestoo

rough or porous for material wear.

Replace type of dishes and glasses used

Streaks and spots on

glasses and dishes.

Too much rinse-aid chemical. Reduce the rinse aid amount by turning the micrometric

dispenser screw (see par Rinse aid use)

Too hard water. Check the water quality. Water must not exceed 10°f in

hardness.Equipthemachinewithanexternalwatersoftener

Saltpresentindishwashertub Thoroughly clean and rinse the appliance, and avoid spilling

saltwhenllingthecontainer.

The machine suddenly

stops during the cycle

The machine is connected to an

overloaded circuit

Connect the machine separately (call the Technical

Assistanceservice)

Asafetydevicehasbeenactivated Checksafetydevices(calltheTechnicalAssistanceservice)

During wash cycle the

machine stops and draws

water

Water from the previous day has

not been replaced

Emptythetankandrellit

Faulty pressure switch HavetheTechnicalAssistanceservicecheckthethermostat

and the pressure switch

The overflow tube is incorrectly

positioned

Removetheoverowtubeandcorrectlyrepositionit

Note For any other problems, contact the Technical Assistance service.

The manufacturer reserves the right to alter the technical characteristics without prior notice.

Table of contents

Other Blakeslee Kitchen Appliance manuals