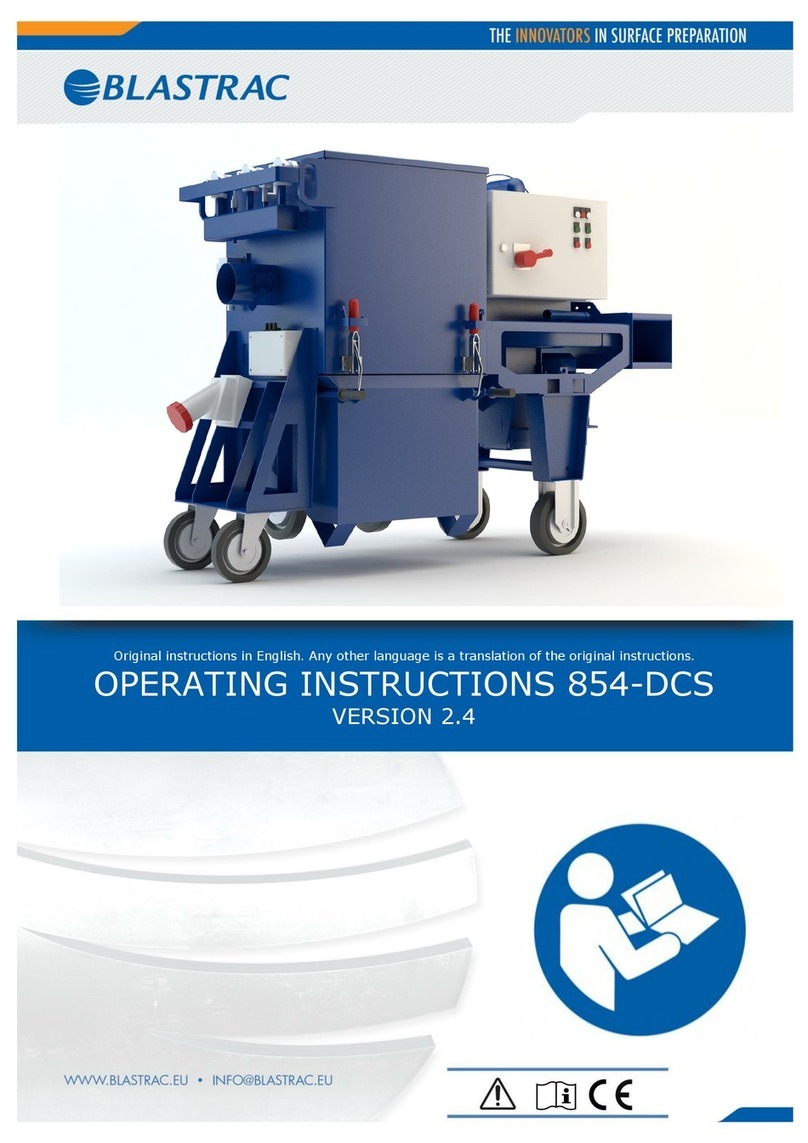

Operating Instructions EBE 500 S

Safety instructions

The Operating Instructions must be supplemented by instructions

including the duty to supervise and report relating to particular

working practices, for example work organisation, work procedures

and personnel allocation.

Personnel entrusted with working with the machine must have read

the Operating Instructions before starting work, in particular the

Safety Instructions chapter. To read these instructions during work

is too late. This particularly applies to incidental activities such as

setting up the equipment, carrying out maintenance work or training

staff to work with the machine.

From time to time the working practices of the staff are to be checked

regarding awareness of safety and hazards.

Personnel must tie back long hair and not wear loose clothing or

jewellery including rings. There is a risk of injury through getting stuck

or being drawn into moving machinery.

Use personnel protection equipment if necessary or required by

regulations! Take notice of all safety and hazard notices on the

machine!

All safety and hazard notices at or on the machine must be kept

complete and legible!

If safety-critical changes occur to the machine or its working

method, the machine must be shut down immediately! The cause of

the fault must be established immediately!

Changes, add-ons or conversions to the machine which might impair

safety must not be undertaken without the manufacturer’s

permission!

This applies in particular to the fitting and adjustment of safety

devices as well as to welding on load-bearing parts.

Spare parts must comply with the technical requirements specified

by the manufacturer. This is always guaranteed if original spare

parts are used.

Intervals for recurring checks and inspections specified in these

Operating Instructions must be complied with!

4