Blaupunkt MVP 01 User manual

Other Blaupunkt DVD Player manuals

Blaupunkt

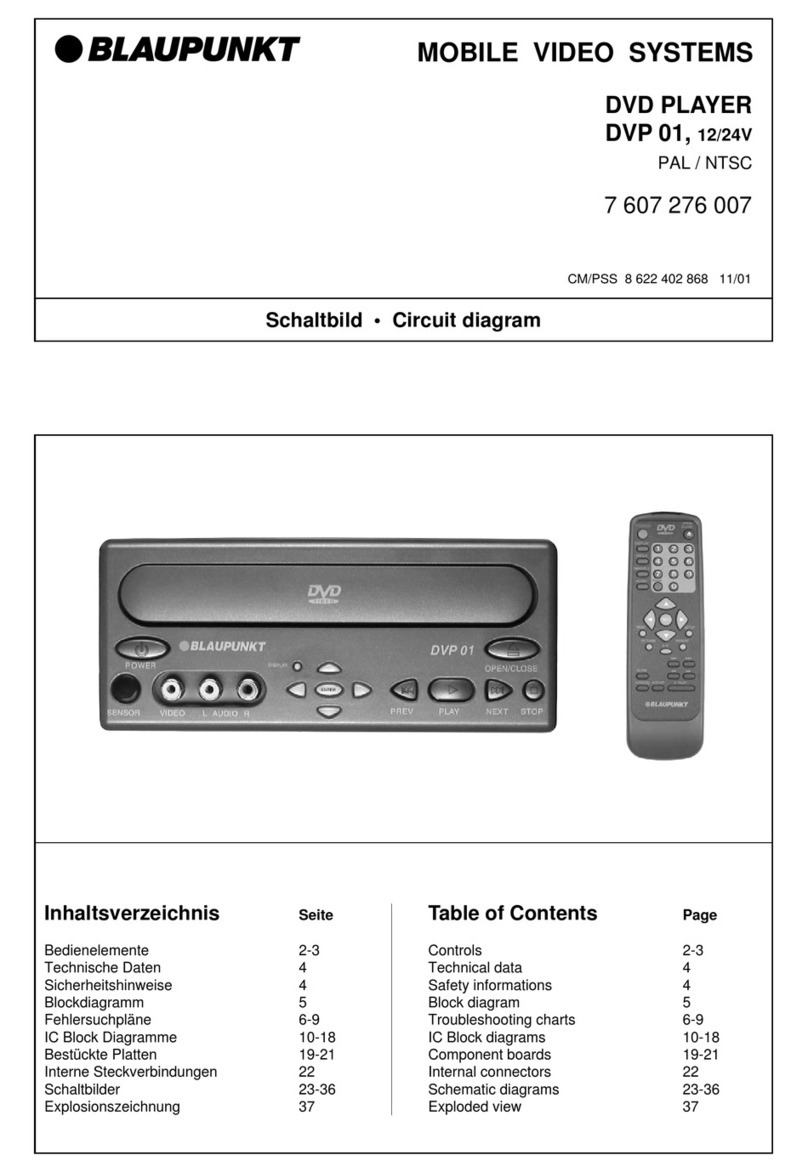

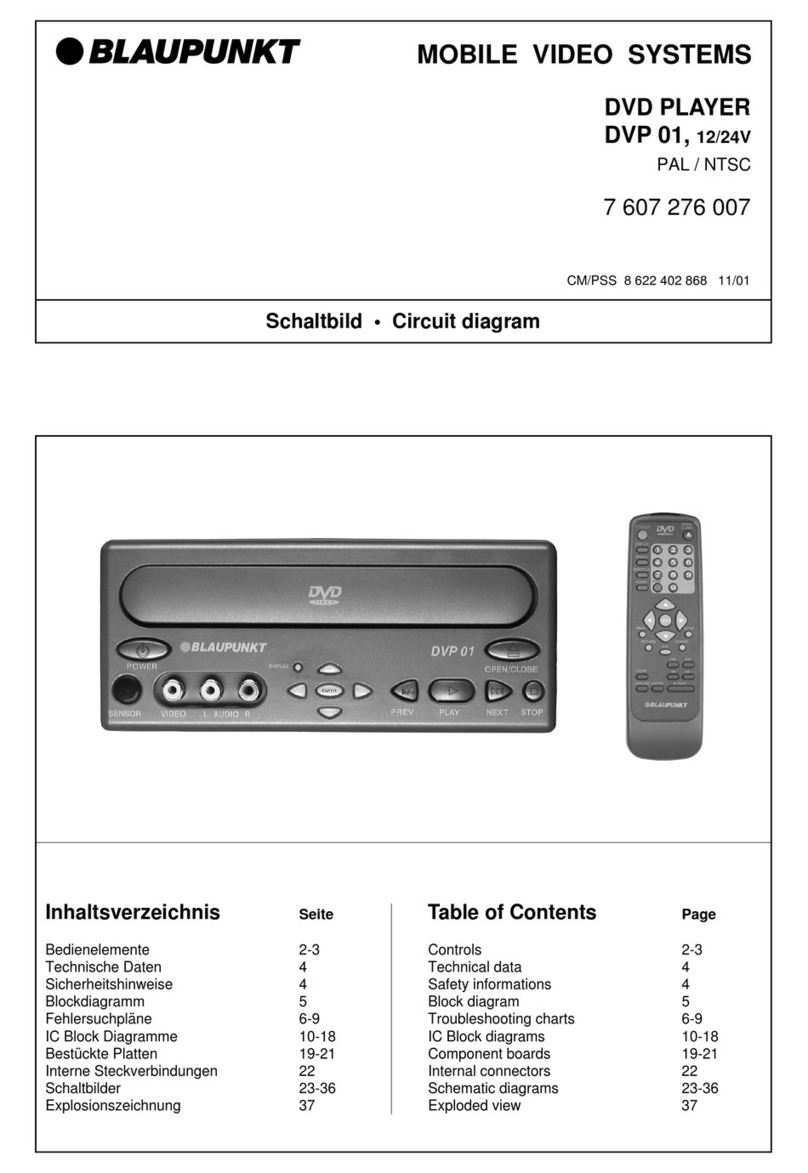

Blaupunkt DVP 01 User manual

Blaupunkt

Blaupunkt DVD-ME1 User manual

Blaupunkt

Blaupunkt DVD-ME1 User manual

Blaupunkt

Blaupunkt BDVD20H User manual

Blaupunkt

Blaupunkt DVP 01 User manual

Blaupunkt

Blaupunkt DVP 01 User manual

Blaupunkt

Blaupunkt TEV-501 User manual

Blaupunkt

Blaupunkt BDVD5200H User manual