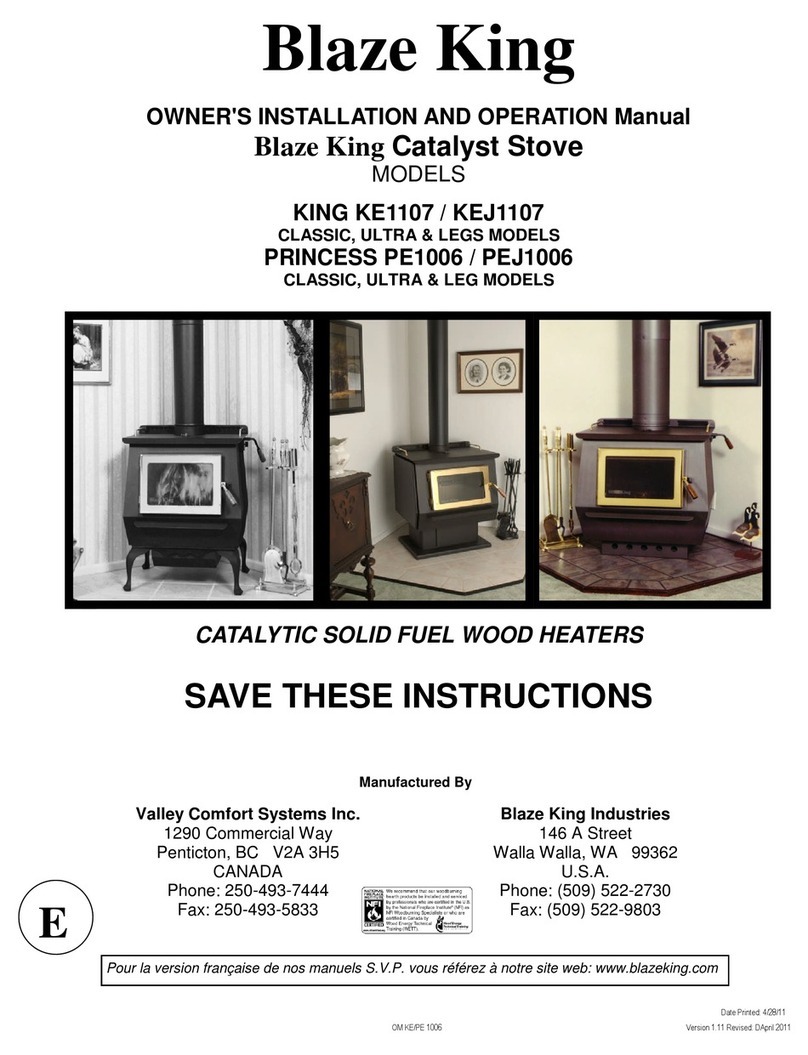

Superior Engineering

Blaze King®Classic Wood Stoves provide the optimum heating efficiency from solid wood fuel. When wood is initially burned in the firebox of your stove, as much as

one-third of the woods energy is released as gases and liquid/vapor materials. Blaze King®catalytic combustor stoves capture these gases and materials and “burns” them

instead of allowing this valuable energy source to escape up the chimney. This secondary burn capability means greater heat output and cleaner emissions from the wood

consumed. Your overall consumption of wood is reduced while your heat output is increased.

More Heat

Blaze King®Classic Wood Stoves have large fire boxes lined with thermo-reactive fire brick which radiates heat directly into the room. They have been tested and certi-

fied with an overall efficiency of 82.5% for both the PE1006 & KE 1107. For extended burn times, large logs can be used, and up to 90# of wood can be loaded (KE),

eliminating the hassle associated with the frequent reloading of smaller stoves.

Special Features

A large viewing glass door allows the fire to be seen from different angles in the room, creating an atmosphere of an open fireplace. The warmth and beauty of the fire

can be highlighted with the addition of the optional gold-plated door.

• Up to 90,000 Btu’s (see reverse side for details)

• Incredible 82.5% Efficiency

• Optional Gold Plated Doors

• 1400 Degree Ceramic Glass

• Optional Variable Speed Dual Fans

• Temperature Sensor Turns Fans off/on

• Mobile Home Approved (All Models)

• Limited-5 Year Warranty

PLUS 6 years on Catalytic Combustor

KE Scientific Burn Chart Offers The Proof! Burns Longer, Cleaner & More Efficiently!

Automatic Thermostat

Eliminates need for constant

adjustment of draft controls associated

with ordinary manual wood stoves. It

automatically compensates for the natur-

al uneven burning of wood.

Dual Jet Air Fan System

Radiant heat is stopped by anything in its

path. Blaze King solves this problem by

using a dual fan system to move air over

the firebox surface and circulate it into

your home.

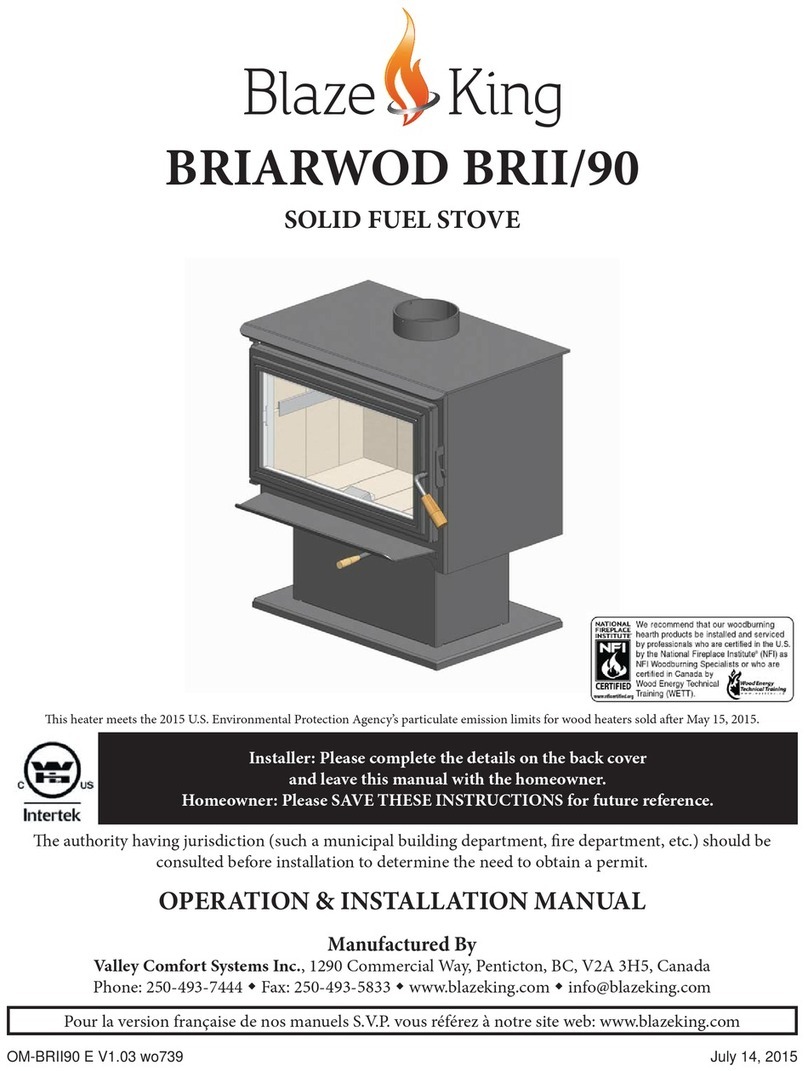

Both the KE1107L& PE1006L Feature Parlor Legs. PicturedAbove

With Optional Ash Drawer, Dual Fans & Gold Door.

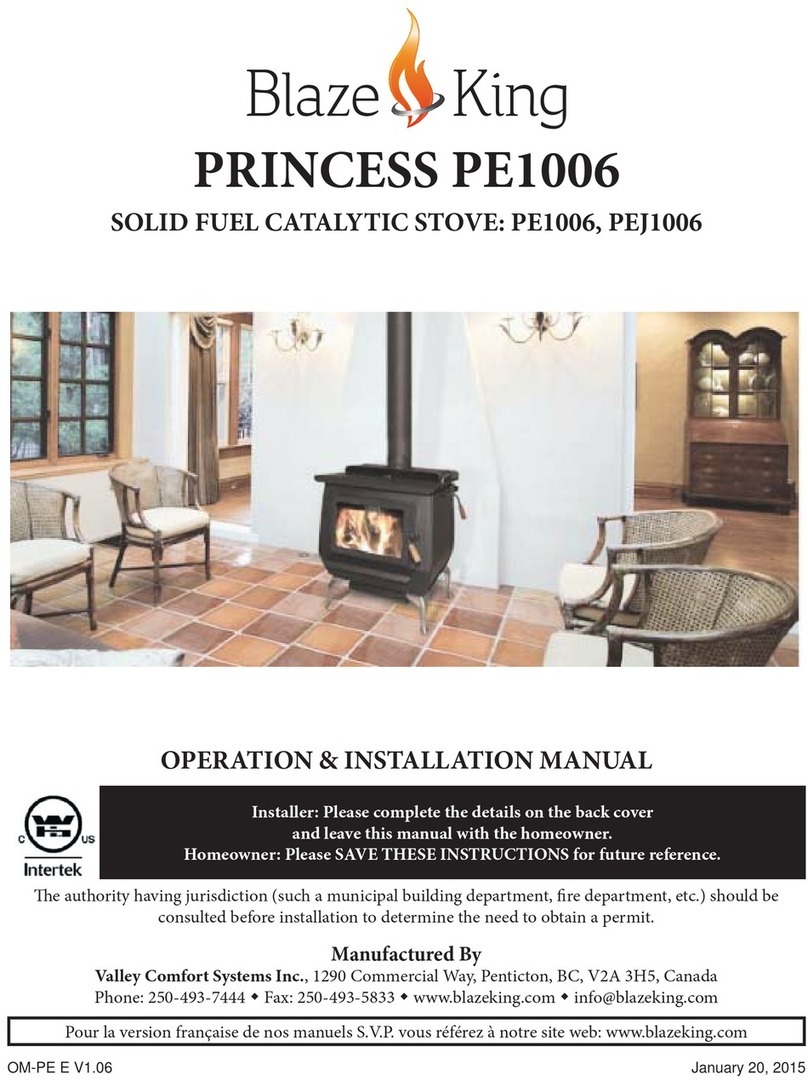

The PE1006 Classic Shown Above with Painted Door and

Optional Dual Fans.

12345 6 7 8910 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

Hours

1350 o

1200 o

1050 o

900 o

750 o

600 o

450 o

300 o

150

40#

45#

50#

35#

30#

25#

20#

15#

10# o

Blaze King®

It burns cleaner and burns longer

than any ordinary wood stove!

This graph plots the results of a test run by Blaze King Industries, Inc. in its

Research and Development laboratory on Friday,August 23, 2002. The test, of a

Blaze King®KE 1107, was run according to WHA(Wood HeatingAlliance) stan-

dards for indirect measurement of the heating performance of wood-fired, closed

combustion chambered, heating appliances. The lines on this graph trace the tem-

peratures recorded by thermocouple sensors within the catalytic combustor and

centered in the flue pipe 48” above the stove top. The fuel level was also charted.

With a hot fire burning and 54-pound load of Douglas

Fir in the firebox, the thermostat was closed down to a

low setting. Time Friday afternoon 3:30 p.m. Temperatures

at the sensing locations immediately begin to drop, in

response to the thermostat setting. Although the flue temper-

ature soon drops below 200 degrees, indicating a slow burn,

the catalyst remains lit, actively consuming the smoke and

pollutants which would otherwise be exhausted up the stack.

Saturday,August 24, 6:00 a.m., 27+ hours at low

burn and 22 pounds of fuel remain. Average fuel

consumption so far 1.02 pounds per hour. Assuming a

useful BTU/Pound from the Tamarack of 8,450 and an

EPAweighted average overall heating efficiency of

82.5% for the model KE 1107, we get an average heat

output of more than 7000 BTU per hour over the 27

hour period of low, clean burn.

Peaks like this result from the burning wood collapsing, stir-

ring up sparks and smoke (which sets off a flurry of combus-

tor activity), and exposing unburned wood to the fire, resulting in

rising firebox temperatures. Note how the thermostat responds to

this increase, controlling the air intake to the fire, and automatically

lowering the combustion to its previous operating level.

After more than 47 hours of clean burning, the catalytic combustor finally

goes out, having simply run out of fuel. The remaining volatiles are being

consumed within the firebox, before they can reach the combustor. The fire itself

is not completely out. A bed of hot coals remains, continuing to produce heat for

more than an additional 7 hours! Adding more fuel during that time would

recharge the fire and relight the combustor. That’s more than 47 hours of contin-

uous heating, with an instant potential for continuing the burn almost indefinitely.

Note too, how the flue temperature remains

right around 200 degrees for nearly the entire

47 -hour burn. The stoves heat is being put

into the room, not wasted up the stack!

Flue Temperature

Catalyst Temperature

Fuel Level

D

D

C

AAB

BC