Lit. No. 40388, Rev. 00 5 May 15, 2008

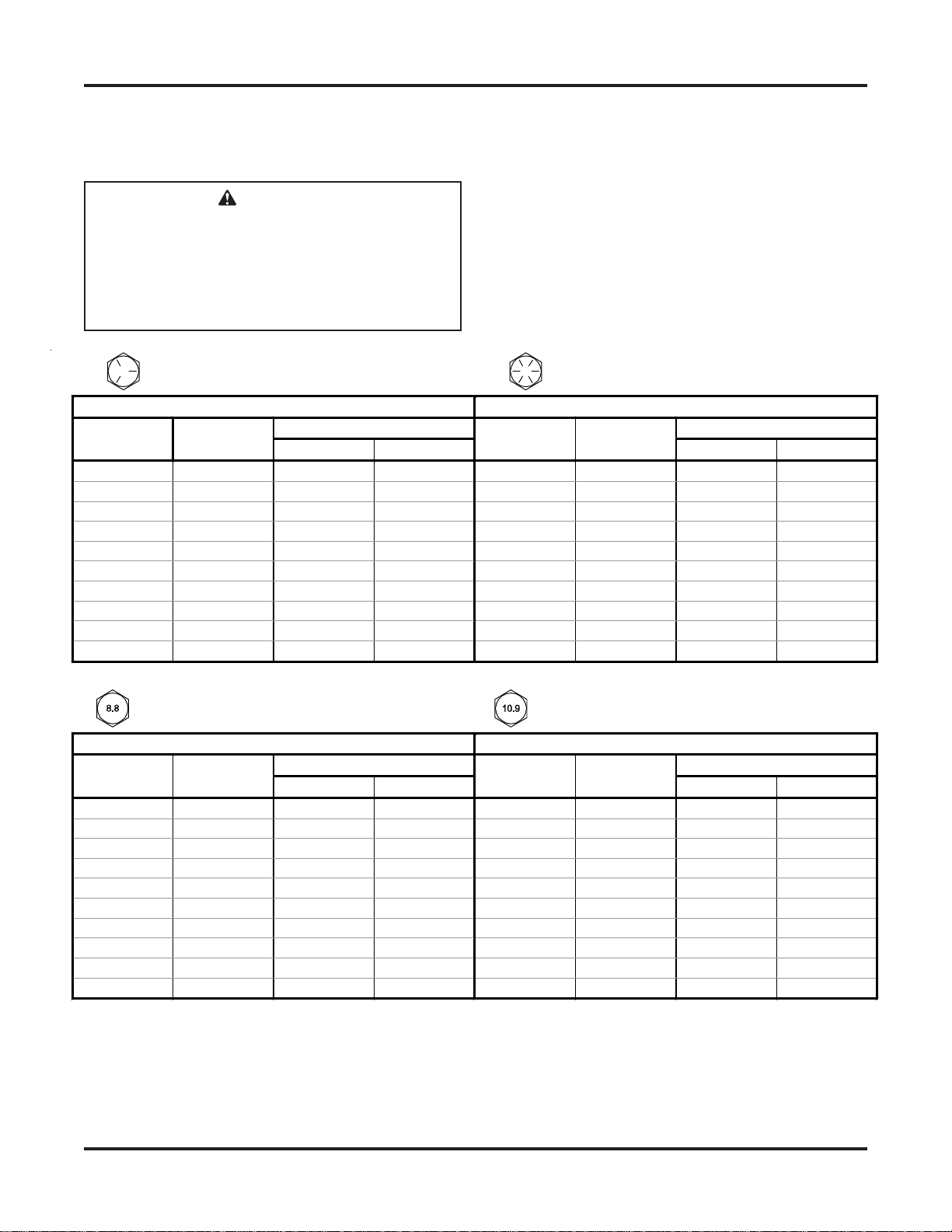

Grade Identification for J429–Grade 5 Bolt Grade Identification for J429–Grade 8 Bolt

SAE J429 Grade 5 Torque Values SAE J429 Grade 8 Torque Values

Tightening Torque Tightening Torque

Nominal

Thread Size Clamp Loads

(lb) "Lubricated" "Dry" Nominal

Thread Size Clamp Loads

(lb) "Lubricated" "Dry"

1/4-20 2,000 6 ft-lb 8 ft-lb 1/4-20 2,850 9 ft-lb 12 ft-lb

5/16-18 3,350 13 ft-lb 18 ft-lb 5/16-18 4,700 18 ft-lb 25 ft-lb

3/8-16 4,950 23 ft-lb 31 ft-lb 3/8-16 6,950 32 ft-lb 44 ft-lb

7/16-14 6,800 37 ft-lb 50 ft-lb 7/16-14 9,600 53 ft-lb 70 ft-lb

1/2-13 9,050 57 ft-lb 75 ft-lb 1/2-13 12,800 80 ft-lb 107 ft-lb

9/16-12 11,600 82 ft-lb 109 ft-lb 9/16-12 16,400 115 ft-lb 154 ft-lb

5/8-11 14,500 113 ft-lb 151 ft-lb 5/8-11 20,300 159 ft-lb 211 ft-lb

3/4-10 21,300 200 ft-lb 266 ft-lb 3/4-10 30,100 282 ft-lb 376 ft-lb

7/8-9 29,435 321 ft-lb 430 ft-lb 7/8-9 41,550 454 ft-lb 606 ft-lb

1-8 38,600 482 ft-lb 640 ft-lb 1-8 54,540 680 ft-lb 900 ft-lb

Grade Identification for Metric–Grade 8.8 Bolt Grade Identification for Metric–Grade 10.9 Bolt

Metric Class 8.8 Torque Values Metric Class 10.9 Torque Values

Tightening Torque Tightening Torque

Diameter

(mm) Clamp Loads

(lb) "Lubricated" "Dry" Diameter

(mm) Clamp Loads

(lb) "Lubricated" "Dry"

5 1,389 3 ft-lb 5 ft-lb 5 1,987 5 ft-lb 7 ft-lb

6 1,965 6 ft-lb 8 ft-lb 6 2,812 8 ft-lb 11 ft-lb

7 2,826 10 ft-lb 13 ft-lb 7 4,044 14 ft-lb 19 ft-lb

8 3,579 14 ft-lb 19 ft-lb 8 5,121 20 ft-lb 27 ft-lb

10 5,672 28 ft-lb 37 ft-lb 10 8,116 40 ft-lb 53 ft-lb

12 8,243 49 ft-lb 65 ft-lb 12 11,796 70 ft-lb 92 ft-lb

14 11,246 77 ft-lb 103 ft-lb 14 16,092 111 ft-lb 148 ft-lb

16 15,882 125 ft-lb 167 ft-lb 16 21,970 173 ft-lb 231 ft-lb

18 19,423 172 ft-lb 229 ft-lb 18 26,868 238 ft-lb 317 ft-lb

20 24,784 244 ft-lb 325 ft-lb 20 34,284 338 ft-lb 450 ft-lb

TORQUE SPECIFICATIONS

CAUTION

Read instructions before assembling.

Fasteners should be finger tight until

instructed to tighten according to the torque

chart. Use standard methods and practices

when attaching snowplow including proper

personal protective safety equipment.

TORQUE CHART