Blodgett CTB SERIES Owner's manual

Other Blodgett Convection Oven manuals

Blodgett

Blodgett Mark V Owner's manual

Blodgett

Blodgett Zephaire FA-100 Installation and operating instructions

Blodgett

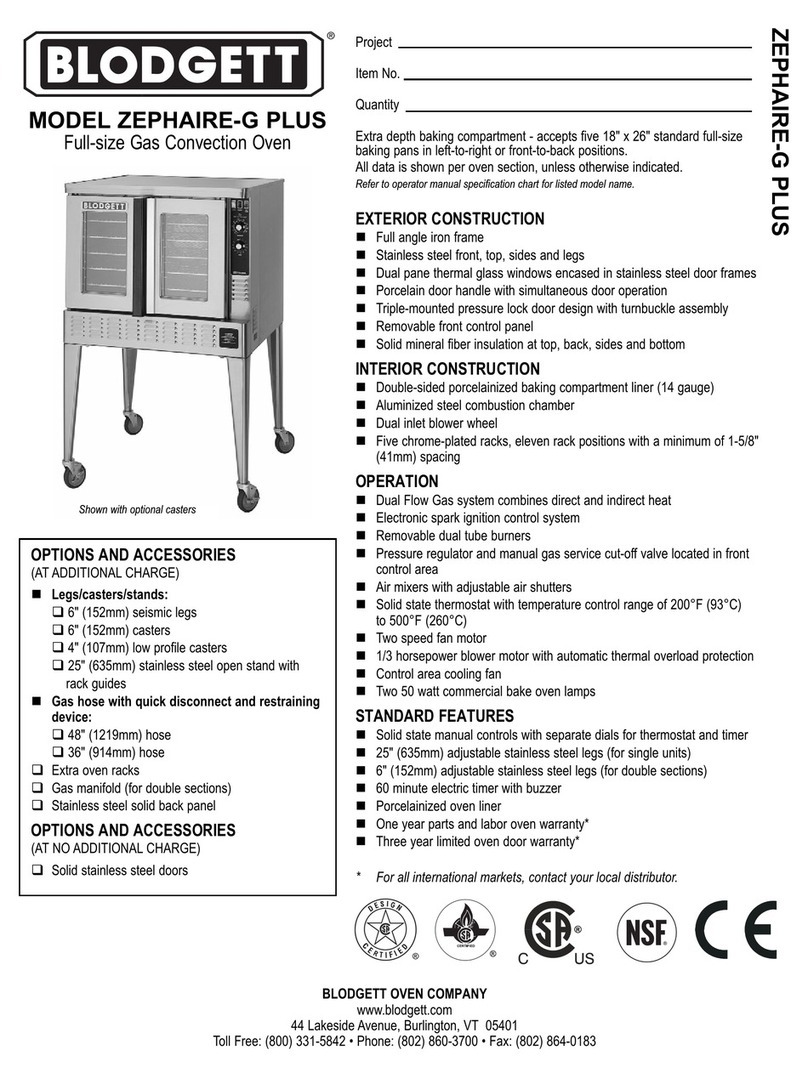

Blodgett ZEPHAIRE-G PLUS User manual

Blodgett

Blodgett Export Series User manual

Blodgett

Blodgett ZEPHAIRE-G PLUS User manual

Blodgett

Blodgett ZEPHAIRE-100-E Owner's manual

Blodgett

Blodgett Mark V Installation and operating manual

Blodgett

Blodgett SHO-100-E Owner's manual

Blodgett

Blodgett Zephaire FA-100 User manual

Blodgett

Blodgett DFG-100 Series User manual

Blodgett

Blodgett CBTR User manual

Blodgett

Blodgett DFG100-N Owner's manual

Blodgett

Blodgett DFG-100 Series User manual

Blodgett

Blodgett MARK V-100 XCEL Owner's manual

Blodgett

Blodgett AC-500 XCEL Owner's manual

Blodgett

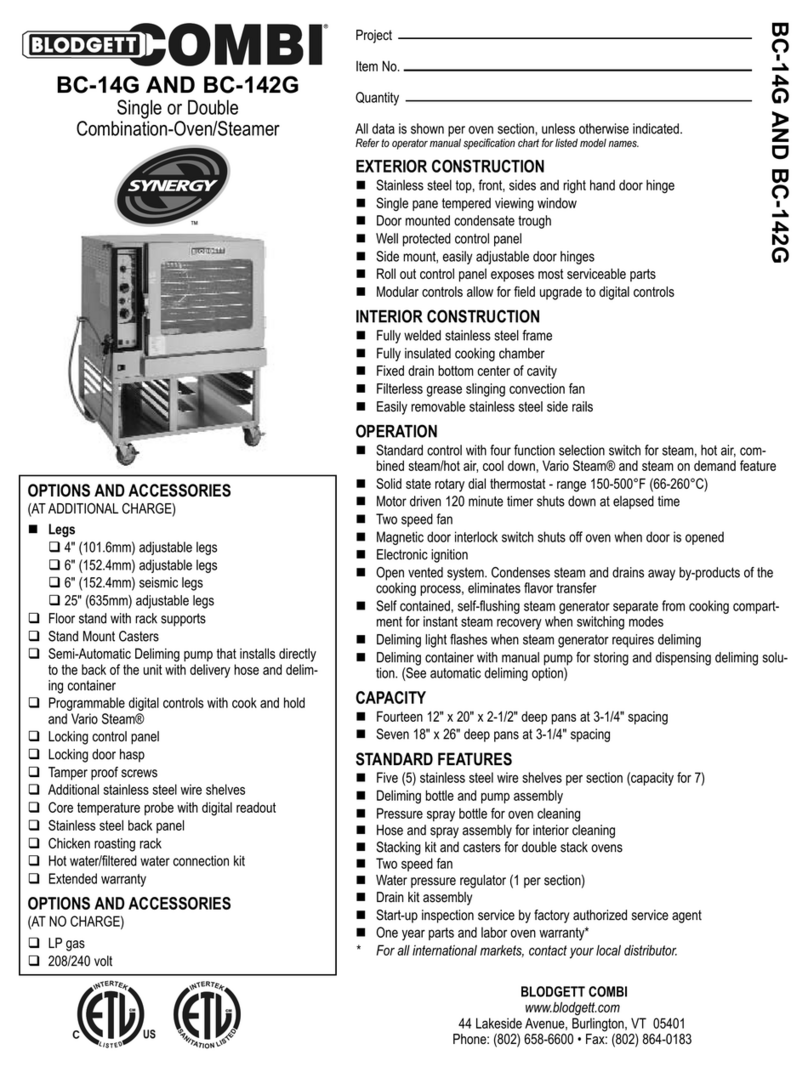

Blodgett Combi SYnergy BC14G Operating and safety instructions

Blodgett

Blodgett zephaire-240g plus Owner's manual

Blodgett

Blodgett AC-500 XCEL Owner's manual

Blodgett

Blodgett Mark V XCEL Owner's manual

Blodgett

Blodgett SHO-G Owner's manual