Blodgett 1400 SERIES Guide

Other Blodgett Oven manuals

Blodgett

Blodgett COS-20E Owner's manual

Blodgett

Blodgett XR8-G User manual

Blodgett

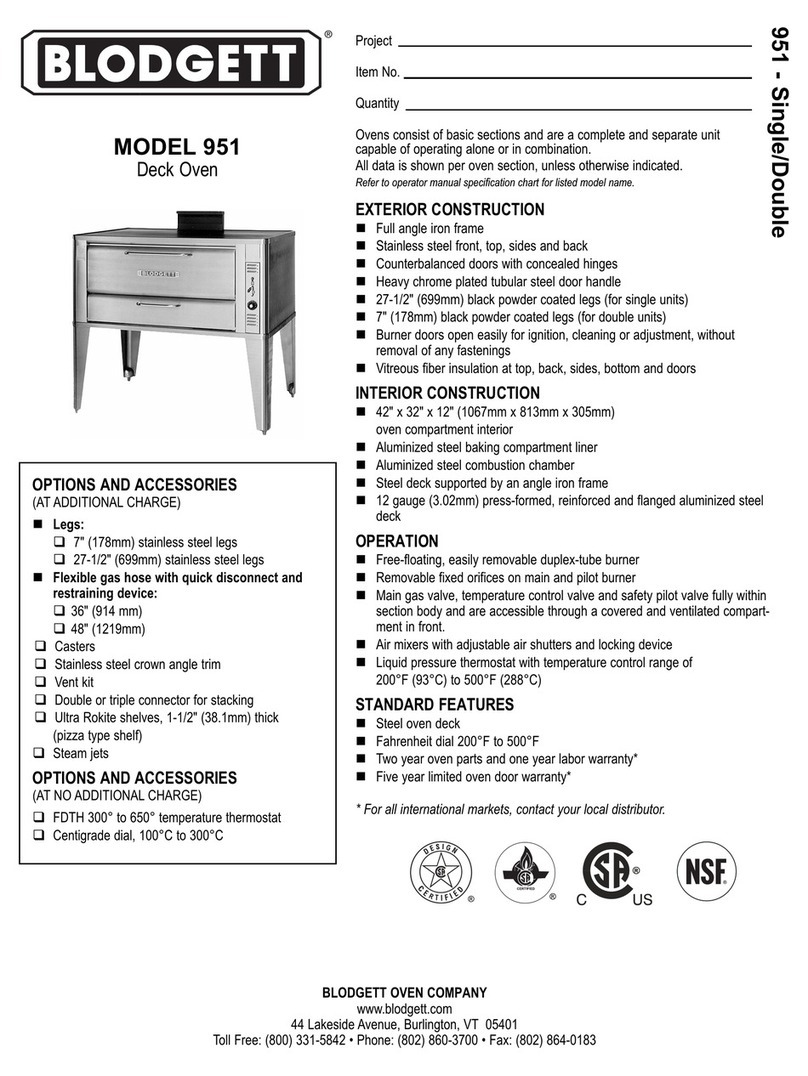

Blodgett 951 Base User manual

Blodgett

Blodgett BE2136 DOUBLE Manual

Blodgett

Blodgett BG2136 Double User manual

Blodgett

Blodgett CONVEYOR OVEN MT1820E Application guide

Blodgett

Blodgett BC-20E Owner's manual

Blodgett

Blodgett COS-8E User manual

Blodgett

Blodgett 981 BASE User manual

Blodgett

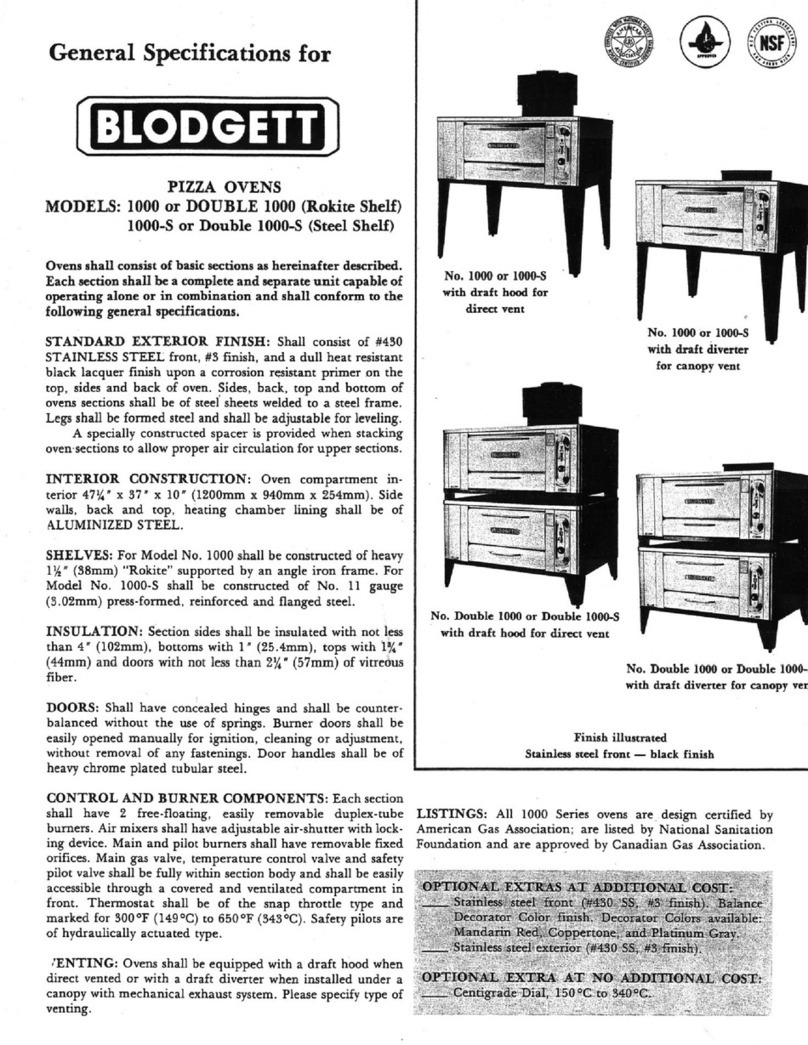

Blodgett Double 1000 User manual

Blodgett

Blodgett 966 User manual

Blodgett

Blodgett MT3870 User manual

Blodgett

Blodgett RE Series Owner's manual

Blodgett

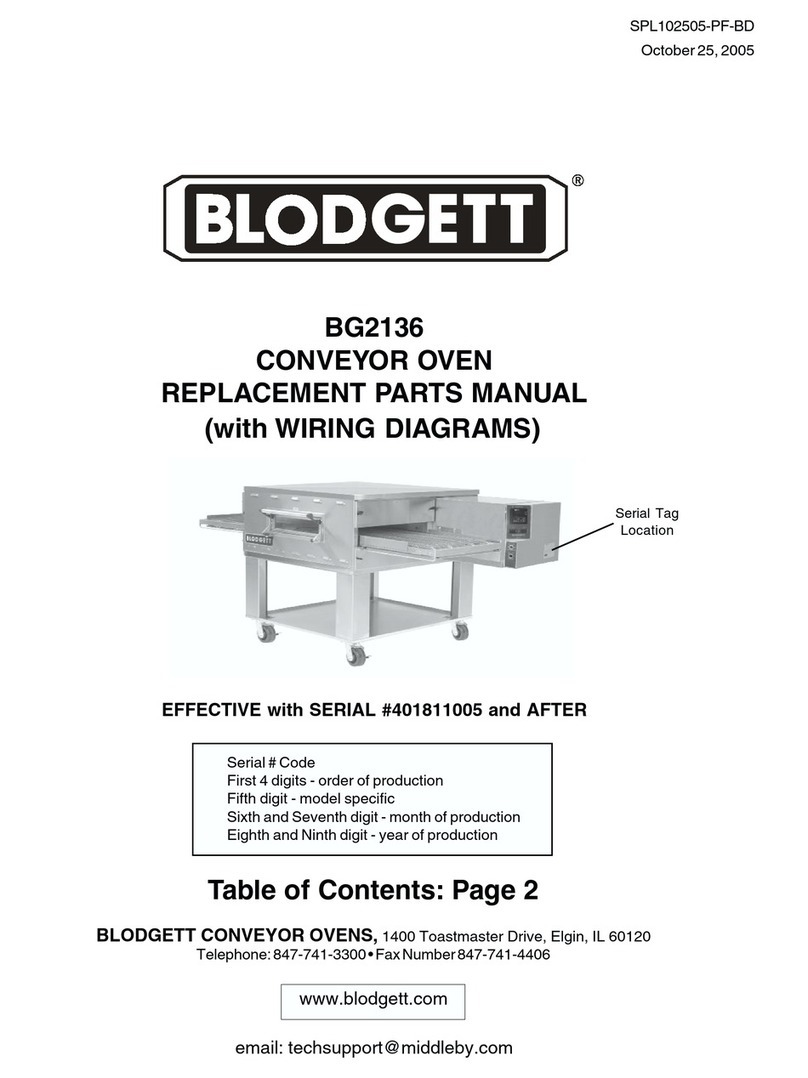

Blodgett BG2136 Double Manual

Blodgett

Blodgett S1820E User manual

Blodgett

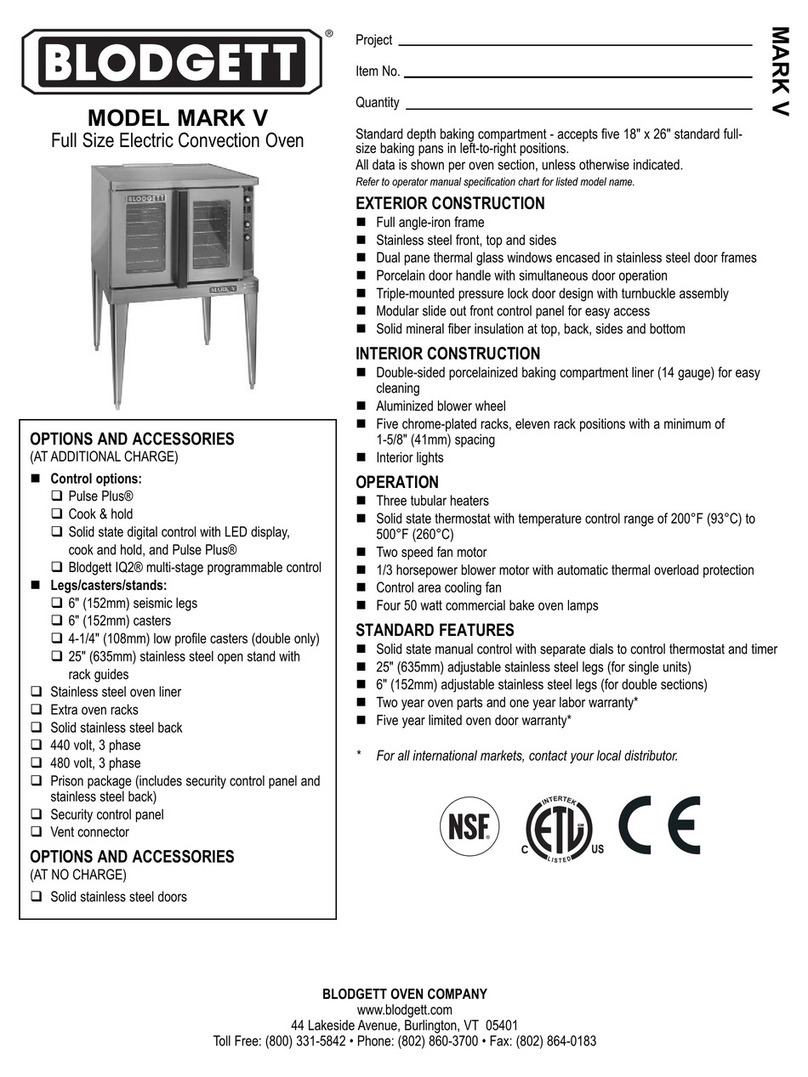

Blodgett Mark V User manual

Blodgett

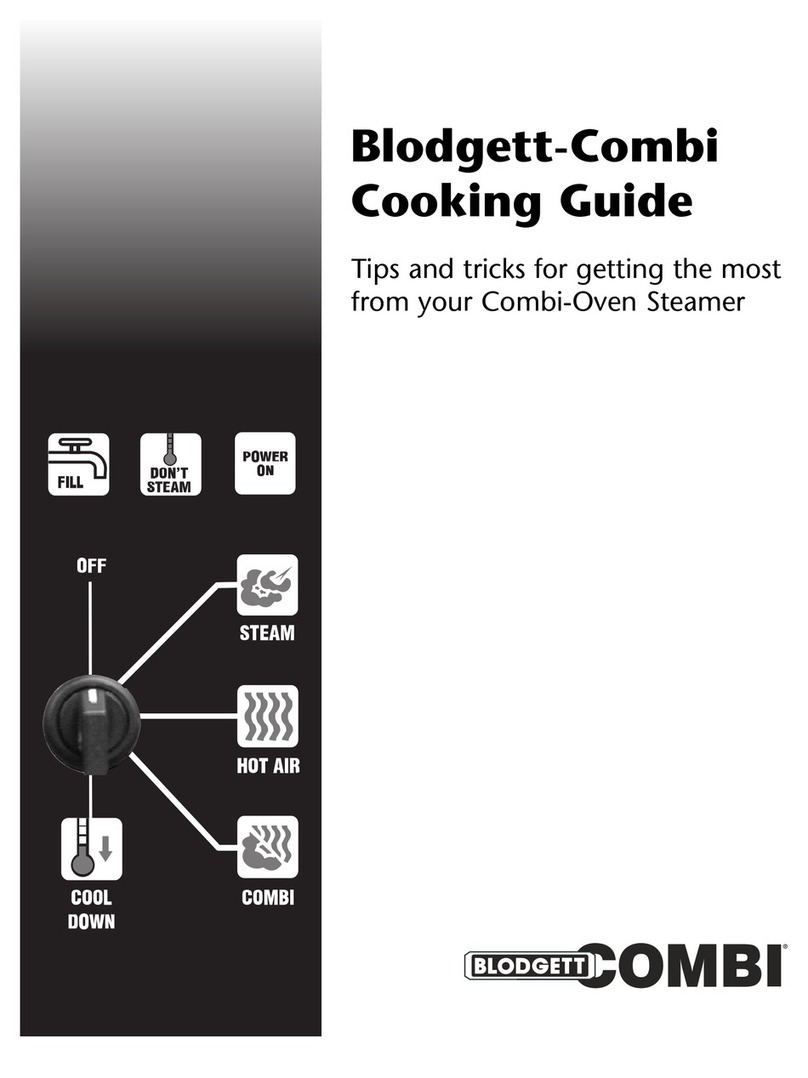

Blodgett Combi Use and care manual

Blodgett

Blodgett Mark V User manual

Blodgett

Blodgett 951 Base User manual

Blodgett

Blodgett S1820 Owner's manual