Blue Diamond 127006 User manual

Operation and Maintenance Manual

Heavy Duty

Tree Puller

888-376-7027 | BlueDiamondAttachments.com

Register your

WARRANTY

within 30 days

of purchase

Blue Diamond® Attachments2

Thank you for your decision to purchase a Blue Dia-

mond® Tree Puller. To ensure maximum performance

of your equipment, it is mandatory that you thoroughly

study the Operator’s manual and follow the recommen-

dations. Proper operation and maintenance are essential

to maximize equipment life and prevent personal injury.

Operate and maintain this equipment in a safe man-

ner and in accordance with all applicable local, state,

and federal codes, regulations and /or laws. Follow all

on-product labeling and instructions.

Make sure that all personnel have read this Operator’s

Manual and thoroughly understand safe and correct

operating, installation and maintenance procedures.

Blue Diamond is continually working to improve its

products. Blue Diamond reserves the right to make any

improvements or changes as deemed practical and pos-

sible without incurring any responsibility or obligation

to make any changes or additions to equipment sold

previously.

Although great care has been taken to ensure the

accuracy of this publication, Blue Diamond makes no

warranty or guarantee of any kind, written or expressed,

implied or otherwise with regard to the information

contained within this manual. Blue Diamond assumes

no responsibility for any errors that may appear in this

manual and shall not be liable under any circumstances

for incidental, consequential or punitive damages in con-

nection with, or arising from the use of this manual.

Keep this manual available for frequent reference. All

new operators or owners must review the manual before

using the equipment and annually thereafter. Contact

your Blue Diamond Attachments Dealer for assistance,

information, or additional copies of the manual. Contact

www.bluediamondattachments.com or call 888-376-

7027 for a complete list of dealers in your area.

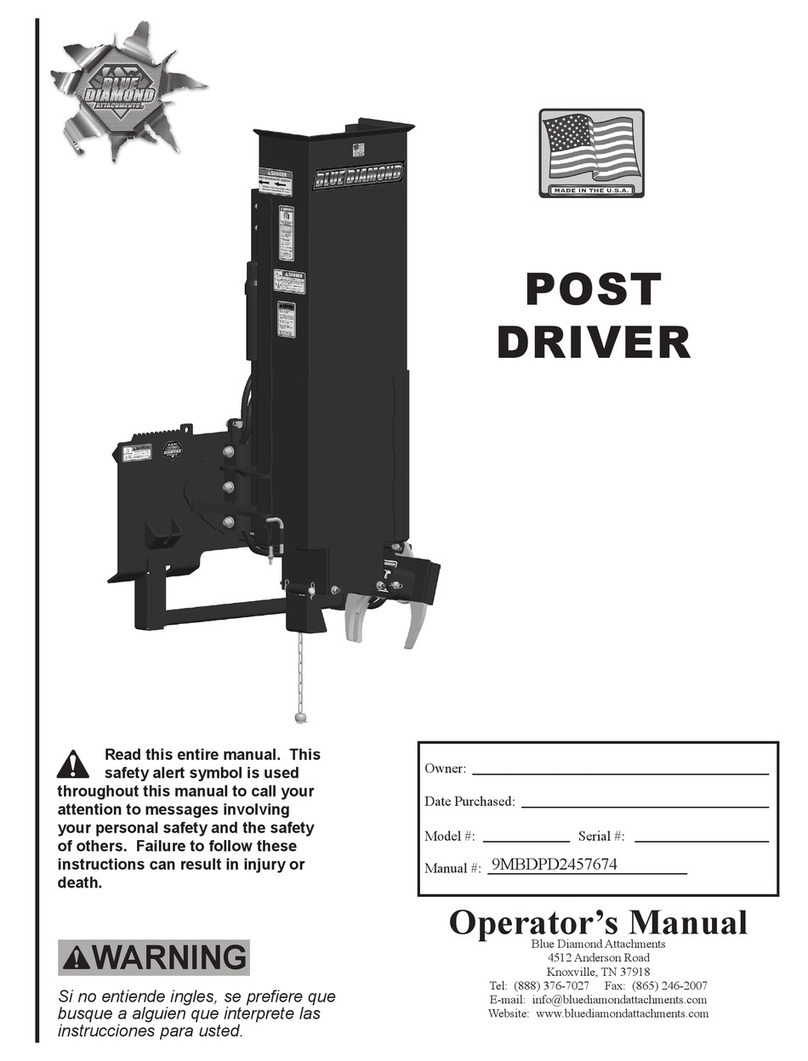

Serial Number Location:

Please record attachment information in the space pro-

vided for future reference.

Model Number:_____________________________

Serial Number: _____________________________

Dealer Name: ______________________________

Dealer Number:_____________________________

Date of Purchase:___________________________

The serial plate is located on the bottom center of the

attachment, on the front of the mounting frame.

Always use your serial number when requesting infor-

mation or when ordering parts.

NOTE: The directions left, right, front and rear, as

mentioned throughout this manual, are as viewed from

the operator’s position.

Introduction: Owner Information

Revision Date: 08.28.2023

3Blue Diamond® Attachments

Table of Contents

1. Introduction......................................................................................4

1.1 Attachment Identification.........................................................4

2. Safety ...........................................................................................5-7

2.1 General Safety Information.................................................... 5

3. Operation .................................................................................. 8-10

3.1 General Information................................................................. 8

3.2 Attachment Installation.......................................................... 9

3.3 Operating the Attachment ...................................................10

4. Maintenance .............................................................................11-13

4.1 Maintenance Safety.................................................................11

4.2 Service Schedule ...................................................................12

4.3 Storing the Attachment.........................................................13

5. Assembly....................................................................................... 14

5.1 Tree Puller Parts ...................................................................... 14

6. Specifications ..........................................................................15-16

6.1 Tree Puller Specifications......................................................15

6.2 Torque Specifications ...........................................................16

7. Warranty ......................................................................................... 17

Blue Diamond® Attachments4

1. Introduction

1.1 Attachment Identification

M F

P J H S

C

C

5Blue Diamond® Attachments

2. Safety

2.1 General Safety Information

NOTE: Notes are used to indicate important

information. This information may be repeated in

other areas of the manual.

Safe Operation Needs a Qualified Operator

Operator Training

• Check the rules and regulations at your

location. The rules may include an employer’s

work safety requirements. Regulations may

apply to local driving requirements or use

of a Slow Moving Vehicle (SMV) emblem.

Regulations may identify a hazard such as a

utility line.

• The new operator must start in an area without

bystanders and use all the controls until he or

she can operate the machine safely under all

conditions of the work area.

CAUTION

The signal word CAUTION on the machine and

in the manuals indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury. It may also be used to alert

against unsafe practices.

WARNING

The signal word WARNING on the machine and

in the manuals indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

DANGER

The signal word DANGER on the machine and

in the manuals indicates a hazardous situation

which, if not avoided, will result in death or serious

injury.

SAFETY ALERT SYMBOL

This SAFETY ALERT SYMBOL identifies important

safety messages on the equipment and in the

owner’s manual. When you see this symbol, be

alert to the possibility of personal injury and

carefully read the message that follows.

IMPORTANT

The signal word IMPORTANT identifies

procedures which must be followed to avoid

damage to the machine.

WARNING

AVOID SERIOUS INJURY OR DEATH

Operators must receive instructions before

operating the machine. Untrained operators can

cause serious injury or death. For an operator

to be qualified, he or she must not use drugs

or alcoholic drinks which impair alertness or

coordination while working. An operator who is

taking prescription drugs must get medical advice

to determine if he or she can safely operate a

machine and the equipment.

Blue Diamond® Attachments6

2. Safety

2.1 General Safety Information

Importance of Safety

Operating Safety

• Read and follow instructions in this manual

and the machine’s Operator’s Manual before

operating.

• This equipment is dangerous to persons

unfamiliar with its operation.

• Check for overhead and / or underground lines

before operating equipment (if applicable).

• In addition to the design and configuration

of equipment, hazard control and accident

prevention are dependent upon the

awareness, concern, prudence and proper

training of personnel involved in the operation,

transport, maintenance and storage of

equipment.

• Check that the attachment is securely fastened

to the machine.

• Make sure all the machine controls are in

NEUTRAL before starting the machine.

• Operate the equipment only from the

operator’s position.

• Operate the equipment according to the

Operator’s Manual.

• When learning to operate the equipment, do it

at a slow rate in an area clear of bystanders.

• DO NOT permit personnel to be in the work

area when operating the equipment.

• The equipment must be used ONLY on

approved machines.

• DO NOT modify the equipment in any way.

Unauthorized modification may impair the

function and / or safety and could aect the

life of the equipment. Warranty may also be

aected or voided.

• DO NOT make any adjustments or repairs on

the equipment while the machine is running.

• Keep shields and guards in place. Replace if

damaged.

• DO NOT operate equipment in poor visibility

conditions such as fog, darkness, or any

conditions that limit clear visibility less than

300 feet (100 m) in front of and to the sides of

the equipment.

• DO NOT operate in a work area that has

not been inspected for foreign debris and

obstacles.

• Remove any foreign objects and clearly mark

any objects that cannot be removed.

• Wear safety glasses, gloves, hearing protection

and other protective clothing when required.

Fire Prevention Safety

• Flammable debris (leaves, grass, etc.) must

be removed regularly. If flammable debris

is allowed to accumulate, it can cause a fire

hazard. Clean often to avoid this accumulation.

• All fuels, most lubricants and some coolant

mixtures are flammable. Flammable fluids that

are leaking or spilled onto hot surfaces or onto

electrical components can cause a fire.

Transporting Safety

• Comply with state and local laws governing

highway safety and movement of machinery on

public roads.

• Check local laws for all highway lighting and

marking requirements.

• Never allow riders on either machine or

equipment.

• If transporting the attachment on a truck or

trailer, make sure it is properly secured to the

transport vehicle.

Hydraulic System

• Check hydraulic tubes, hoses and fittings for

damage and leakage. Never use open flame

or bare skin to check for leaks. Hydraulic tubes

and hoses must be properly routed and have

adequate support and secure clamps. Tighten

or replace any parts that show leakage.

• Always clean fluid spills. Do not use gasoline or

diesel fuel for cleaning parts. Use commercial

nonflammable solvents.

7Blue Diamond® Attachments

3. Operation

3.1 General Information

Pre-Operation Inspection

Before operating the Tree Puller for the first time

and each time thereafter, use the following list as a

guideline during equipment inspection.

• Lubricate the attachment per the schedule

outlined in the Maintenance Section. See

“Service Schedule” on page 12.

• Check the tree puller mounting frame for

damage or cracks.

• Check that all shields and guards are in place.

• Check for loose bolts and tighten them if

necessary.

• Check all welds on the attachment for wear

and damage each time the attachment is

removed from the machine.

• Check for damaged or missing safety decals.

Replace if necessary.

• Inspect the machine’s mounting frame. (See

the machine’s Operator’s Manual for inspecting

the mounting frame). Replace any parts

that are damaged, bent or missing. Keep all

fasteners tight. Look for cracked welds.

• Check condition of all hydraulic components

for leaks. Repair as required.

NOTE: Do not operate with hydraulic leaks.

• Verify that the tree puller is properly connected

to the machine.

WARNING

AVOID SERIOUS INJURY OR DEATH

• Disengage machine’s auxiliary hydraulics,

engage the machine’s parking brake, stop the

engine and make sure all rotating components

are completely stopped before connecting,

disconnecting, adjusting or cleaning

equipment.

• Always keep shields and all guards in place

when using the equipment.

• Disengage machine’s auxiliary hydraulics for

road travel.

• Keep hands, feet and clothing away from

rotating parts.

WARNING

Leaking fluids under pressure can enter the skin

and cause serious injury or death. Immediate

medical attention is required. Wear goggles. Use

cardboard to check for leaks.

Blue Diamond® Attachments8

3. Operation

3.2 Attachment Installation

Entering the Operator’s Position

Use the attachment safety treads, handles and

steps (on the machine) to enter the operator’s

position.

When in the operator’s position, lower safety seat

bar, fasten the seat belt, start the engine and

release the parking brake.

Leaving the Operator’s Position

Park the machine / attachment on a flat level

surface. Place all controls in neutral, engage

the park brake and stop the engine. Leave the

operator’s position.

Connecting Attachment to the Machine

Before connecting to the attachment, inspect the

machine’s mounting plate. (See the machine’s

Operator’s Manual for inspecting the mounting

frame).

(See the machine’s Operator’s Manual for

inspecting the mounting frame).

Enter the operator’s position. See “Entering the

Operator’s Position” on page 8.

Drive the machine slowly forward, until the top

edge of the machine’s mounting plate is under the

top flange of the attachment mounting frame.

WARNING

AVOID SERIOUS INJURY OR DEATH

• Always park on a flat level surface.

• Lower lift arms and place attachment flat on

the ground.

• Place all controls in NEUTRAL.

• Engage the park brake.

• Stop the engine and remove the key.

• Wait for all moving parts to stop.

SEE MACHINE’S OPERATOR’S MANUAL FOR

ADDITIONAL INFORMATION.

IMPORTANT

See the machine’s Operator’s Manual for detailed

information on operating the loader.

WARNING

CRUSH HAZARD

• Before moving the machine, look in all

directions and make sure no bystanders,

especially small children are in the work area.

• Do not allow anyone between the machine

and attachment when approaching the

attachment for connecting.

• Keep fingers and hands out of pinch points

when connecting and disconnecting the

attachment.

9Blue Diamond® Attachments

3. Operation

3.2 Attachment Installation

Connecting Attachment to the Machine

(Cont’d)

Slowly tilt the machine’s mounting plate back until

the attachment mounting frame fully contacts the

front of the machine’s mounting plate.

Leave the operator’s position. See “Leaving the

Operator’s Position” on page 8.

Engage attachment locking levers / wedges (See

the machine’s Operator’s Manual for detailed

information).

Connecting Hydraulic Hoses

Remove dirt or debris from the male and female

couplers. Visually inspect the couplers for

corroding, cracking, damage, or excessive wear.

Connect the attachment hydraulic hoses to

the machine. Pull on each hose to verify full

connection is made.

Disconnecting Hydraulic Hoses

Relieve auxiliary hydraulic pressure. (See

the machine’s Operator’s Manual for correct

procedure.)

Disconnect attachment hydraulic hoses from the

machine.

Disconnecting Attachment from the

Machine

Relieve auxiliary hydraulic pressure. (See

the machine’s Operator’s Manual for correct

procedure.)

Park the machine and attachment on a flat level

surface.

Lower the tree puller flat on the ground.

Leave the operator’s position. See “Leaving the

Operator’s Position” on page 8.

Disconnect attachment hydraulic hoses from the

machine. Connect the hydraulic couplers together

or install plugs or caps on the couplers.

Disengage locking pins / wedges. (See the

machine’s Operator’s Manual for correct

procedure.)

Enter the operator’s position. See “Entering the

Operator’s Position” on page 8.

WARNING

AVOID SERIOUS INJURY OR DEATH

The locking pins / wedges must extend through

the holes in the attachment mounting frame.

Failure to secure locking pins / wedges can allow

attachment to come o.

SEE MACHINE’S OPERATOR’S MANUAL FOR

ADDITIONAL INFORMATION.

IMPORTANT

Throughly clean the quick couplers before

making connections. Dirt can quickly damage the

hydraulic system.

WARNING

AVOID BURNS

Hydraulic fluid, tubes, fittings, and quick couplers

can get hot during operation. Be careful when

connecting and disconnecting hydraulic hoses.

Blue Diamond® Attachments10

3. Operation

3.2 Attachment Installation

Disconnecting Attachment from the

Machine (Cont’d)

Slowly tilt the machine’s mounting plate forward

until the attachment mounting frame is free from

the machine’s mounting plate.

Drive the machine slowly backward, away from the

attachment.

3.3 Operating the Attachment

Machine Requirements

The tree puller attachment can be used for pulling

up to 8” trees and shrubs. Some wood types may

be more dicult — not all 8” trees will be easily

pulled.

• Only use tree puller on compatible loaders.

• Refer to the machine’s operator’s manual for

flow and pressure specifications.

Operating the Tree Puller

Install the Tree Puller onto the loader. (See

the machine’s operator’s manual for correct

procedure).

Open the cylinder, and clamp tree or bush as near

to the attachment plate as possible.

Pull upward until roots are clear of the ground

taking caution to keep the prime mover balanced.

Depending on the diculty, taking a new grip from

a dierent direction or shaking the tree or bush

may help.

WARNING

Never allow riders on the tree puller.

MAX P

3200 PSI

11Blue Diamond® Attachments

4. Maintenance

WARNING

AVOID SERIOUS INJURY OR DEATH

Never operate the machine in a closed building.

Proper ventilation is required when operating

the machine under all circumstances.

• Always keep the work area clean and dry.

• Always use personal protection devices such

as eye, hand and hearing protection when

performing any service or maintenance.

• A fire extinguisher and first aid kit should

be readily accessible while performing

maintenance on this machine.

• Before working or doing maintenance on this

machine, shut o the engine and remove

the key. Make sure the machine’s wheels are

blocked.

• Never work under the machine or attachment

unless the machine or equipment is blocked or

supported securely.

• Disconnect the battery (both terminals) before

welding on any part of the machine. Failure

to do so may cause damage to electrical

components.

• When working around batteries, remember

that all of the exposed metal parts are “live”.

Never lay a metal object across the terminals

because a spark, short circuit, explosion or

personal injury may result.

• Battery posts, terminals and related

accessories contain lead and lead compounds.

Wash hands after handling.

• Always relieve hydraulic system pressure

before repairing, adjusting or disconnecting.

Never search for leaks with your hands.

• When replacement parts are necessary,

genuine factory replacement parts must be

used to restore your equipment to original

specifications. Blue Diamond will not be

responsible for injuries or damage caused by

use of unapproved parts and / or accessories.

General Maintenance

To ensure ecient operation, you should inspect,

lubricate, and make necessary adjustments

and repairs at regular intervals. Keep good

maintenance records and adequately clean your

machine after each use.

Proper Maintenance and lubrication is important.

Follow instructions in the service schedule.

NOTE: Repair or replace any damaged parts.

4.1 Maintenance Safety

WARNING

AVOID SERIOUS INJURY OR DEATH

Never operate the machine in a closed building.

Proper ventilation is required when operating

the machine under all circumstances.

Blue Diamond® Attachments12

4. Maintenance

4.2 Service Schedule

WARNING

AVOID SERIOUS INJURY OR DEATH

Never work under the machine or attachment

unless the machine or equipment is blocked or

supported securely.

IMPORTANT

Fluid such as hydraulic fluid, coolants, grease,

etc. must be disposed of in an environmentally

safe manner. Some regulations require that

certain spills and leaks on the ground must be

cleaned in a specific manner. See local, state

and federal regulations for the correct disposal.

WARNING

AVOID SERIOUS INJURY OR DEATH

Before servicing the attachment:

• Always park on a flat level surface.

• Lower lift arms and place attachment flat on

the ground.

• Place all controls in NEUTRAL.

• Engage the park brake.

• Wait for all moving parts to stop.

• Stop the engine and remove the key.

SEE MACHINE’S OPERATOR’S MANUAL FOR

ADDITIONAL INFORMATION.

NOTE: Check tree puller for correct function after adjustments, repairs or service.

DESCRIPTION

SERVICE PROCEDURES

Check Clean Lube Change

Daily Maintenance (or every 8 hours)

Hydraulic Fittings •

Hydraulic Hoses •

All Hardware •

Tree Puller Frame • •

Pivot Pins •

Hydraulic Cylinder •

13Blue Diamond® Attachments

Storage

Sometimes it may be necessary to store your tree

puller for an extended period of time. Below is a

list of items to perform before storage.

• Make sure the hydraulic hose couplers are

capped, plugged, or connected to each other.

• Thoroughly wash the tree puller before storing

the tree puller for long periods.

• Lubricate the tree puller.

• Coat the exposed portion of the cylinder rod

with grease.

• Check for loose hardware, missing guards, or

damaged parts.

• Check for damaged or missing decals. Replace

if necessary.

• Replace worn or damaged parts.

• Place the attachment in a dry protected shelter.

• Place the attachment flat on the ground.

NOTE: In muddy conditions or to prevent the

attachment from freezing to the ground, put the

attachment on planks or blocks before removing

the attachment from the machine.

Return to Service

After the tree puller has been in storage, it is

necessary to follow a list of items to return the tree

puller to service

• Lubricate the tree puller.

• Install and operate the tree puller and check

for correct function.

• Check for leaks. Repair as needed.

4.3 Storing the Attachment

4. Maintenance

Blue Diamond® Attachments14

5. Assembly

5.1 Tree Puller Parts

ITEM PART NUMBER DESCRIPTION QTY

1 227000 Main Weldment 1

2 227001 Pivot Jaw 1

3 206343 Pin 1.25x5.25 3

4 227015 Pin 1.25x6.75 1

5 227003 Cylinder Cover - Outer Tree Puller HD 1

6 227002 Cylinder Cover - Inner Tree Puller HD 1

7 227004 Hydraulic Cylinder - 2 1/2” Bore x 8” (1.5” Retracted) 1

8 206246 2-Line Hose Clamp 1

9 224006 Coupler, Male Flat Face Style 1/2” Body, 1/2” Pipe Thread 1

10 224005 Coupler, Female Flat Face Style 1/2” Body, 1/2” Pipe Thread 1

11 295030-M06JIC-M08NPT -6 37° Flare JIC to -8 NPT 2

12 295010-M06JIC-M04ORB 1/4 ORB to 3/8” JIC straight fitting 2

13 227010 Tree Puller Hoses No Couplers (3/8” x 84” & 94”) 1

NS 299329 Pin Retaining Bolt 4

NS 208550 Pin Retaining Nut 4

1

3

23

5

6

7

4

8

12

1

10

9

13

15Blue Diamond® Attachments

6. Specifications

6.1 Tree Puller Specifications

DESCRIPTION TREE PULLER

OVERALL WIDTH 50 1/2 in.

OVERALL LENGTH 30 1/2 in.

OVERALL HEIGHT 20 1/2 in.

CLAMP LENGTH 19 in.

CLAMP OPENING 10 in.

MAXIMUM TREE SIZE 8 in.

WEIGHT 415 lbs.

MAX PRESSURE 3200 PSI

Blue Diamond® Attachments16

6. Specifications

6.2 Torque Specifications

Standard Hardware, Lock & Nuts

BOLT

TYPE SAE GRADE 5 SAE GRADE 8 LOCK NUTS

Nominal

Size

Plated or

Unplated

Silver

Plated W/

ZnCr

Gold

Plated or

Unplated

Silver

Plated W/

ZnCr

Gold

Plated or

Unplated

Silver

Plated W/

ZnCr

Gold

W/ Grade

5 Bolt

W/ Grade

8 Bolt

1/4 55 ft / lb

(6.2 N•m)

72 ft / lb

(8.1 N•m)

86 in / lb

(9.7 N•m)

112 in / lb

(12.6 N•m)

121 in / lb

(13.6 N•m)

157 in / lb

(17.7 N•m)

61 in / lb

(6.9 N•m)

86 in / lb

(9.8 N•m)

5/16 115 ft / lb

(13 N•m)

149 ft / lb

(17 N•m)

178 ft / lb

(20 N•m)

229 ft / lb

(26 N•m)

250 ft / lb

(28 N•m)

325 ft / lb

(37 N•m)

125 ft / lb

(14 N•m)

176 ft / lb

(20 N•m)

3/8 17 ft / lb

(23 N•m)

22 ft / lb

(30 N•m)

26 ft / lb

(35 N•m)

34 ft / lb

(46 N•m)

37 ft / lb

(50 N•m)

48 ft / lb

(65 N•m)

19 ft / lb

(26 N•m)

26 ft / lb

(35 N•m)

7/16 27 ft / lb

(37 N•m)

35 ft / lb

(47 N•m)

42 ft / lb

(57 N•m)

54 ft / lb

(73 N•m)

59 ft / lb

(80 N•m)

77 ft / lb

(104 N•m)

30 ft / lb

(41 N•m)

42 ft / lb

(57 N•m)

1/2 42 ft / lb

(57 N•m)

54 ft / lb

(73 N•m)

64 ft / lb

(87 N•m)

83 ft / lb

(113 N•m)

91 ft / lb

(123 N•m)

117 ft / lb

(159 N•m)

45 ft / lb

(61 N•m)

64 ft / lb

(88 N•m)

9/16 60 ft / lb

(81 N•m)

77 ft / lb

(104 N•m)

92 ft / lb

(125 N•m)

120 ft / lb

(163 N•m)

130 ft / lb

(176 N•m)

169 ft / lb

(229 N•m)

65 ft / lb

(88 N•m)

92 ft / lb

(125 N•m)

5/8 83 ft / lb

(112 N•m)

107 ft / lb

(145 N•m)

128 ft / lb

(174 N•m)

165 ft / lb

(224 N•m)

180 ft / lb

(244 N•m)

233 ft / lb

(316 N•m)

90 ft / lb

(122 N•m)

127 ft / lb

(172 N•m)

3/4 146 ft / lb

(198 N•m)

189 ft / lb

(256 N•m)

226 ft / lb

(306 N•m)

293 ft / lb

(397 N•m)

319 ft / lb

(432 N•m)

413 ft / lb

(560 N•m)

160 ft / lb

(217 N•m)

226 ft / lb

(306 N•m)

7/8 142 ft / lb

(193 N•m)

183 ft / lb

(248 N•m)

365 ft / lb

(495 N•m)

473 ft / lb

(641 N•m)

515 ft / lb

(698 N•m)

667 ft / lb

(904 N•m)

258 ft / lb

(350 N•m)

364 ft / lb

(494 N•m)

1213 ft / lb

(289 N•m)

275 ft / lb

(373 N•m)

547 ft / lb

(742 N•m)

708 ft / lb

(960 N•m)

773 ft / lb

(1048 N•m)

1000 ft / lb

(1356 N•m)

386 ft / lb

(523 N•m)

545 ft / lb

(739 N•m)

MANUFACTURER’S LIMITED WARRANTY

BLUE DIAMOND®ATTACHMENTS, a manufacturer of quality attachments, warrants new BLUE DIAMOND®

ATTACHMENTS products and/or attachments at the time of delivery to the original purchaser, to be free

from defects in material and workmanship when properly set up and operated in accordance with the

recommendations set forth by BLUE DIAMOND®ATTACHMENTS, LLC.

BLUE DIAMOND®ATTACHMENTS liability for any defect with respect to accepted goods shall be limited to

repairing the goods at a BLUE DIAMOND®ATTACHMENTS designated location or at an authorized dealer

location, or replacing them, as BLUE DIAMOND®ATTACHMENTS shall elect. The above shall be in accordance

with BLUE DIAMOND®ATTACHMENTS warranty adjustment policies. BLUE DIAMOND®ATTACHMENTS obligation

shall terminate twelve (12) months for the Heavy Duty Tree Puller after the delivery of the goods to original

purchaser.

This warranty shall not apply to any machine or attachment which shall have been repaired or altered

outside the

BLUE DIAMOND®ATTACHMENTS factory or authorized BLUE DIAMOND®ATTACHMENTS dealership

or in any way so as in BLUE DIAMOND®ATTACHMENTS judgment, to aect its stability or reliability, nor which has

been subject to misuse, negligence or accident beyond the company recommended machine rated capacity.

WARRANTY CLAIM

To submit a warranty claim, a claim must be filed with BLUE DIAMOND®ATTACHMENTS before work is performed.

The BLUE DIAMOND® PRODUCT SUPPORT TEAM will advise repairs and applicable parts exchanges. Tampering

with the failed part may void the warranty. This warranty does not include freight or delivery charges incurred

when returning machinery for servicing. Dealer mileage, service calls, and pickup/delivery charges are the

customers’ responsibility.

EXCLUSIONS OF WARRANTY

Except as otherwise expressly stated herein, BLUE DIAMOND®ATTACHMENTS makes no representation or

warranty of any kind, expressed or implied, AND MAKES NO WARRANTY OF MERCHANTABILITY IN RESPECT

TO ITS MACHINERY AND/OR ATTACHMENTS ARE FIT FOR ANY PARTICULAR PURPOSE. BLUE DIAMOND®

ATTACHMENTS shall not be liable for incidental or consequential damages for any breach or warranty, including

but not limited to inconvenience, rental of replacement equipment, loss of profits or other commercial loss.

Upon purchase, the buyer assumes all liability for all personal injury and property resulting from the handling,

possession, or use of the goods by the buyer.

No agent, employee, or representative of BLUE DIAMOND®ATTACHMENTS has any authority to bind BLUE

DIAMOND®ATTACHMENTS to any armation, representation, or warranty concerning its machinery and/or

attachments except as specifically set forth herein.

This warranty policy supersedes any previous documents.

NOTE: Blue Diamond®Attachments is a trademark of BLUE DIAMOND®ATTACHMENTS

Warranty

QUALITY | DEPENDABILITY | INTEGRITY

Blue Diamond® Attachments

4512 Anderson Road, Knoxville, TN 37918

888-376-7027

Other manuals for 127006

1

This manual suits for next models

1

Table of contents

Other Blue Diamond Industrial Equipment manuals