Blue Giant EPJ-25 User manual

OPERATOR’S MANUAL

EPJ-25 ELECTRIC PALLET JACK

ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

WARNING

Do not operate or service this product unless you have read and fully understand

the entire contents of this manual. Failure to do so may result in property damage,

bodily injury or death.

ACTUAL PRODUCT MAY NOT APPEAR EXACTLY AS SHOWN

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

2ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

TABLE OF CONTENTS

DEALER INFORMATION

Name:

Contact:

Telephone:

1.0 SAFETY PROCEDURES 3

2.0 EXCLUSION OF LIABILITY 3

3.0 OWNER’S PURCHASE RECORD 4

4.0 WARRANTY 4

5.0 CHECK SHIPMENT BEFORE ASSEMBLY AND/OR USE 5

5.1 LOADING SPECIFICATION 5

5.2 MAXIMUM INCLINES OR DECLINE GRADES 5

5.3 SAFETY WITH TALL LOADS 5

6.0 EPJ-25 HAND PALLET TRUCK SPECIFICATIONS 6

7.0 NAME PLATE AND WARNING DECAL LOCATIONS 7

8.0 LOAD CAPACITY 8

9.0 BEFORE OPERATION 9

10.0 TROUBLESHOOTING GUIDE 10

11.0 INSTRUMENTS AND CONTROLS 11

11.1 OPERATION - DRIVING INSTRUCTIONS 12

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

3ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

1.0 SAFETY PROCEDURES

1. Do not operate this truck unless you have been trained and authorized

to do so.

2. Do not operate this truck until you have read and understood all of the

safety information and instructions contained herein and on the truck.

3. Do not operate this truck until you have checked its condition. Give

special attention to wheels, controls and lifting systems, including steering

mechanism, guards and safety devices.

4. Report the need for truck repairs to your supervisor immediately and

do not operate truck until repairs are made. Neglect may cause a minor repair to

become a major service problem and cause the truck to become unsafe.

5. Do not load truck beyond capacity shown on serial name plate on

truck.

6. Do not lift with the fork tips or one fork only.

7. This equipment is designed for evenly centered loads with forks

completely supporting the load. Off-centering of loads can result in a dangerous

operating condition and may cause damage or injury.

8. Always look in direction of travel. Use caution when visibility is

obstructed by load.

9. Extreme caution must be used when handling loosely stacked/

packaged loads.

10. Watch swing clearance when turning near walls, racks. pillars or other

obstacles.

11. Start, stop, change direction and travel smoothly. Slow down for turns

and on uneven or slippery surfaces that cause truck to slide or tip. Be aware that

the truck behaves differently without a load than with a load.

12. Observe applicable traffic regulations. Yield right of way to pedestrians.

13. Do not ride on this equipment.

14. Do not carry passengers or lift personnel.

15. Before you leave the truck, fully lower lifting mechanism.

2.0 EXCLUSION OF LIABILITY

The manufacturer assumes no liability for damage or injury to persons or

property which has occurred as a result of defects or faults in the hand pallet

trucks delivered or due to incorrect use. The manufacturer also assumes no

liability for lost profits, operating down times, or similar indirect losses which

the buyer has incurred. Damage to third parties, irrespective of its nature, is not

subject to compensation.

The operating instructions are not subject to notification of amendment.

The descriptions and illustrations included in our operating instructions and

replacement parts list are not binding.

In the interests of further development, we reserve the right to make any

changes at any time to the modules, components and accessories which we

deem to be expedient, or for technical reasons, while retaining the essential

features of the models described here.

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

4ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

4.0 WARRANTY

To validate warranty on recently purchased equipment, please

complete and submit your information with our online Warranty

Registration at

www.bluegiant.com.

For more information about Blue Giant Warranty Support, please contact your

local Blue Giant Equipment dealer, representative or authorized partner near

you. You may also visit

www.bluegiant.com or phone 1.905.457.3900.

* Note that failure to validate warranty at the time of receipt can seriously affect

the outcome of any claim.

3.0 OWNER’S PURCHASE RECORD

OWNER’S PURCHASE RECORD

Please record information for future inquiries and to validate warranty.

Dealer: Date in Service:

Number of Units:

Owner’s Name: Order Number:

Serial Number: Year of Construction:

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

5ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

5.0 CHECK SHIPMENT BEFORE ASSEMBLY AND/OR USE

The hand pallet truck is to be carefully checked at the manufacturer’s plant

before shipment. In order to ensure that no damage has occurred during

transport, the hand pallet truck should be checked upon receipt for transport

damage and to ensure correct operation. Damage due to transport is to be

listed on the signed copy on the freight document. The freight forwarder must be

notified of any damage within 48 hours. Damaged hand pallet trucks must not

be put into use.

5.1 LOADING SPECIFICATION

The hand pallet truck is designed for the horizontal transportation of loads on

a level, fixed base. The load must be evenly distributed on pallets or similar

receptacles. The ideal loading mode is that the gravity center of heavy goods is

at the central position of the fork. The maximum load-carrying capacity is shown

on the appropriate designation plate and on the load sticker on the hand pallet

truck. When there exists deflective load, the rated carrying capacity shall be

reduced. If the load on the forks is one sided, there is a risk of the forks bending

or the load slipping off. Supporting or shifting the load with the fork tips is to

be avoided in all cases as this results in damage to the appliance. In order to

preserve the wheels and chassis the hand pallet truck must not be driven over

very uneven ground.

5.2 MAXIMUM INCLINES OR DECLINE GRADES

The hand pallet truck is equipped with a permanently set pressure-limiting valve

which permits a maximum load of 5 % of the nominal load. The screw plug on

the pressure control valve is secured so as to avoid inappropriate manipulation

from the operating personnel. In order to avoid damage to the goods being

transported and the means of transport, the load must be supported evenly.

If the load is unevenly distributed the pressure limiting valve will not function.

When driving on down-grades the load is to be secured to prevent it from

slipping or sliding off the hand pallet truck, (e.g. additional operating personnel).

In addition to this, only hand pallet trucks with a service and parking brake are

to be used on down-grades up to approx 6 %. Journeys on inclines or down-

grades of more than 6 % are always to be avoided. Safe transport cannot be

guaranteed when the center of gravity of the load has altered.

5.3 SAFETY WITH TALL LOADS

Transporting with tall loads, (e.g. machines) changes the center of gravity of

the load so unfavorably that the complete hand pallet truck including the load,

goes out of control and may overturn on a curve. Loading, (e.g. onto a truck

or mobile loading ramps) should be regarded in particular as likely occasions

for accidents. During such activities the hand pallet truck is to be secured with

particular care. Conveying persons or using the hand pallet truck as a form of

roller skate is not permissible. Foodstuffs are only to be transported in packed

form. Direct contact with the hand pallet truck is to be avoided. The accident

prevention regulations for industrial trucks and the safety regulations and

accident prevention regulations applicable to the user are also to be complied

with.

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

6ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

6.0 EPJ-25 HAND PALLET TRUCK SPECIFICATIONS

The following data must always be specified to ensure correct processing of

your spare parts order:

A) Truck type (capacity)

B) Serial number of the truck

C) Complete Part Number

ASSEMBLY DRAWINGS:

Handle and Pump Assembly

Frame Assembly

WEIGHT:

160 lbs (72.575 kg)

CAPACITY:

5,500 lbs (2,300 kg)

FORK LENGTH:

48" (1,220 mm)

Please fill in Owner’s Purchase Record (Section 3.0) with the following details:

- Serial Number(s)

- Dealer Name

- Date in-Service

- Owner’s Name

- Order Number

- Year of Construction

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

7ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

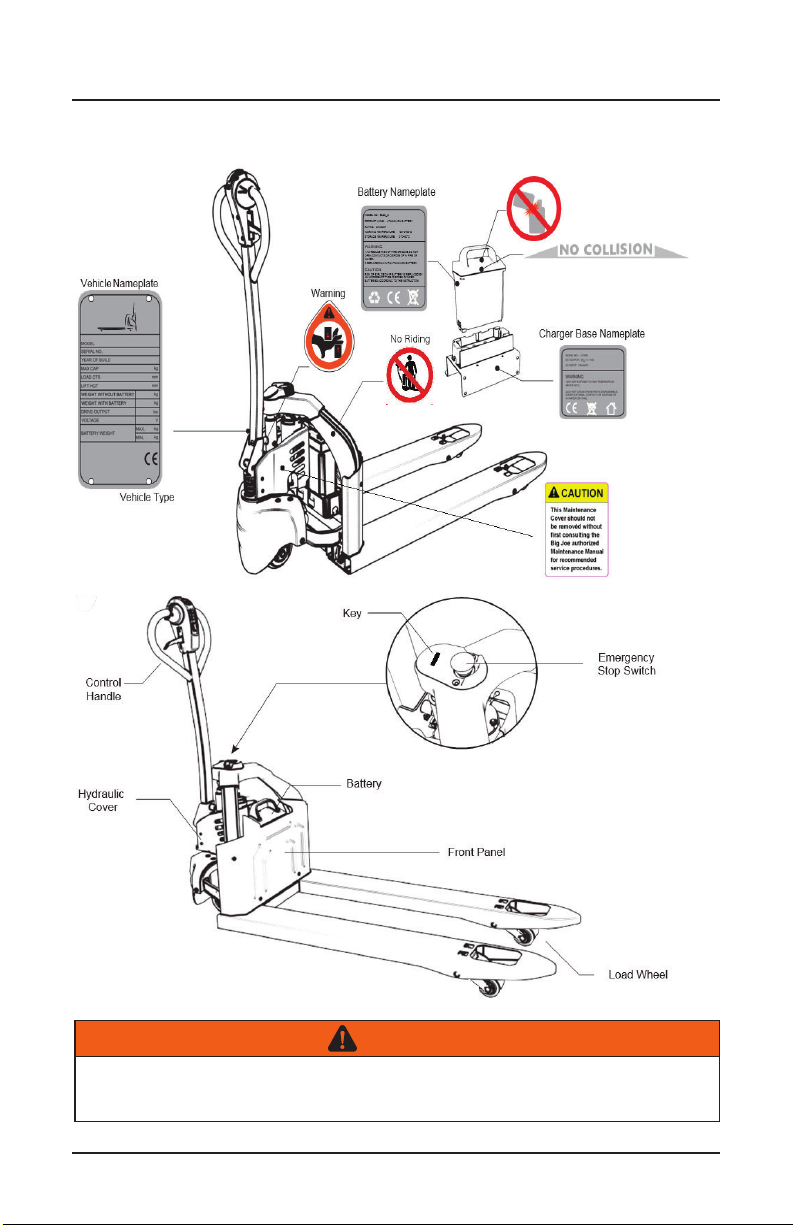

7.0 NAME PLATE AND WARNING DECAL LOCATIONS

This truck is equipped with a battery. Read and heed the following

warning plus any other warnings located near or on the battery.

WARNING

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

8ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

8.0 LOAD CAPACITY

Do not overload truck. Check name plate for load weight capacity and load center

information.

The load capacity depends on the load center. The load maximum capacity listed

on the capacity plate assumes a uniform load whose center is at 1/2 the length of

the fork and centered between the forks. The maximum load capacity is reduced

when the load center exceeds 1/2 the length of the forks or is not centered be-

tween the forks. The fork length and wheelbase must be adequate for the skid or

bin to be handled.

Note that a truck undergoing speed changes is less stable than a standing truck.

If you are not sure that the truck can lift a certain load, consult your supervisor or

the designated authority.

Load Center

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

9ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

9.0 BEFORE OPERATION

The table on page 10 covers important inspection points on trucks which should

be checked prior to operation. Depending on use, some trucks may require ad-

ditional checks.

The illustration below shows a sample format for an Operator Checklist.

Periodic maintenance of this truck by a qualified service

technician is required.

A qualified service technician should check the truck monthly for proper

lubrication, proper fluid levels, brake maintenance, motor maintenance

and other areas specified in the parts and service manual

maintenance section.

If the truck is found to be unsafe and in need of repair, or contributes to

an unsafe condition, report it immediately to the designated authority.

Do not operate it until it has been restored to a safe operating condition.

Do not make any unauthorized repairs or adjustments. All service must

be performed by a qualified service technician.

WARNING

DATE: OPERATOR:

VEHICLE NUMBER: MODEL NUMBER:

DEPARTMENT: SHIFT:

HOUR METER READING - DRIVE: HOIST:

CHECK O.K.

NEED MAINTENANCE

Tires

Load Wheels

Horn

Lift / Lower Control

Attachment Operation

Forward and Reverse Controls

Steering

Electrical Brakes

Hydraulic Leaks, Cylinders, Valves,

Hoses, etc.

Stacker

Daily Operator Check List

July 17, 2017

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

10 ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

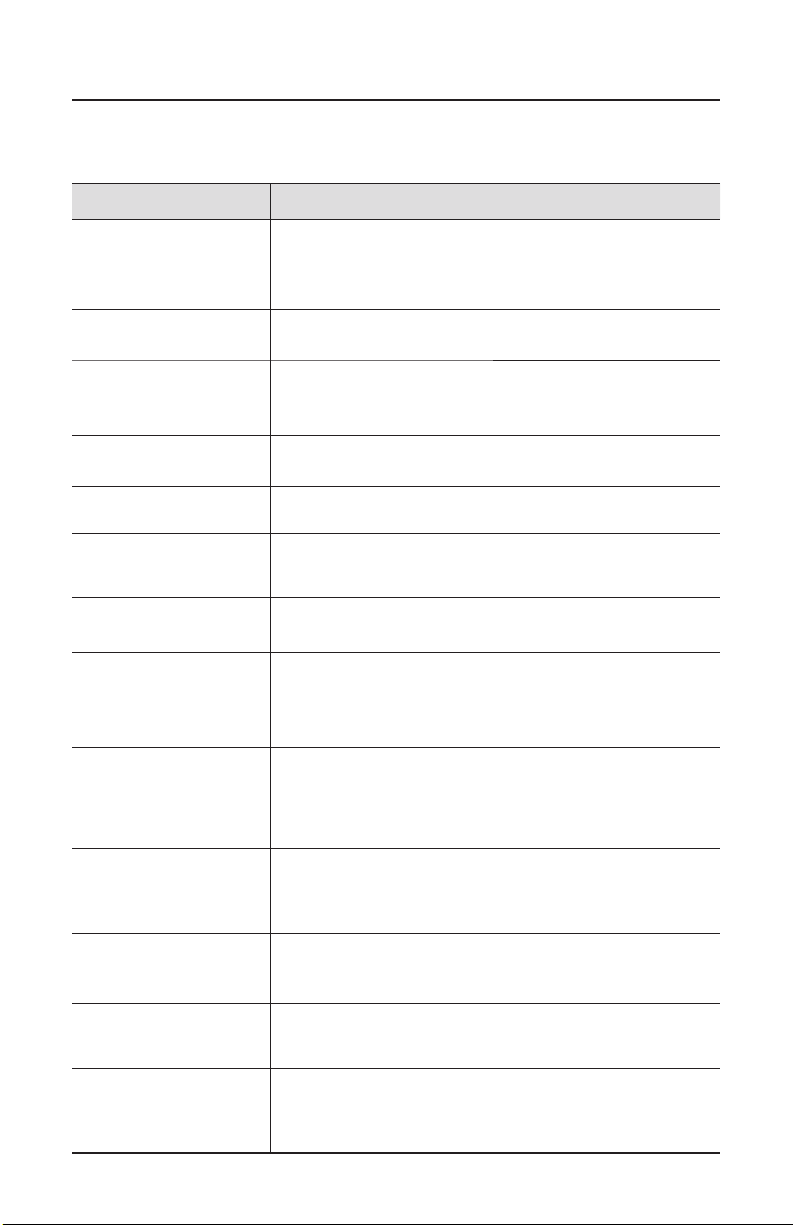

10.0 TROUBLESHOOTING GUIDE

CONDITION ACTION

Transmition and

hydraulic systems

Check for signs of fluid leakage and/or abnormal

noise.

Forks and frame Check for cracks and damage.

Guards and load

backrest

Check that safety guards are properly secured and

not damaged.

Safety signs Check that warning labels, nameplate, etc., are in

good condition and legible.

Horn Check that horn soundswhen operated.

Steering Check binding or looseness in steering arm when

steering.

Tiller switch/Parking

brake

Check that steering arm raises to upright position

when released and brake applies.

Brakes

Check that brakes actuate when steering arm is

raised to upright positon, and when lowered to

horizontal position.

Travel controls

Check that speed controls on control handle operate

in all speed ranges in forward and reverse and that

belly button switch

functions.

Wheels

Check drive wheel for cracks or damage.

Move truck to check load wheels for freedom of

rotation.

Hydraulic controls Check operation of lift and lower to their maximum

positions. Check the oil levels.

Electrical Check that there no damage to the cables on the

truck and that the horn and lift buttons work.

Battery disconnect

Check that battery can be disconnected and

reconnected.

Check for connector damage.

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

11ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

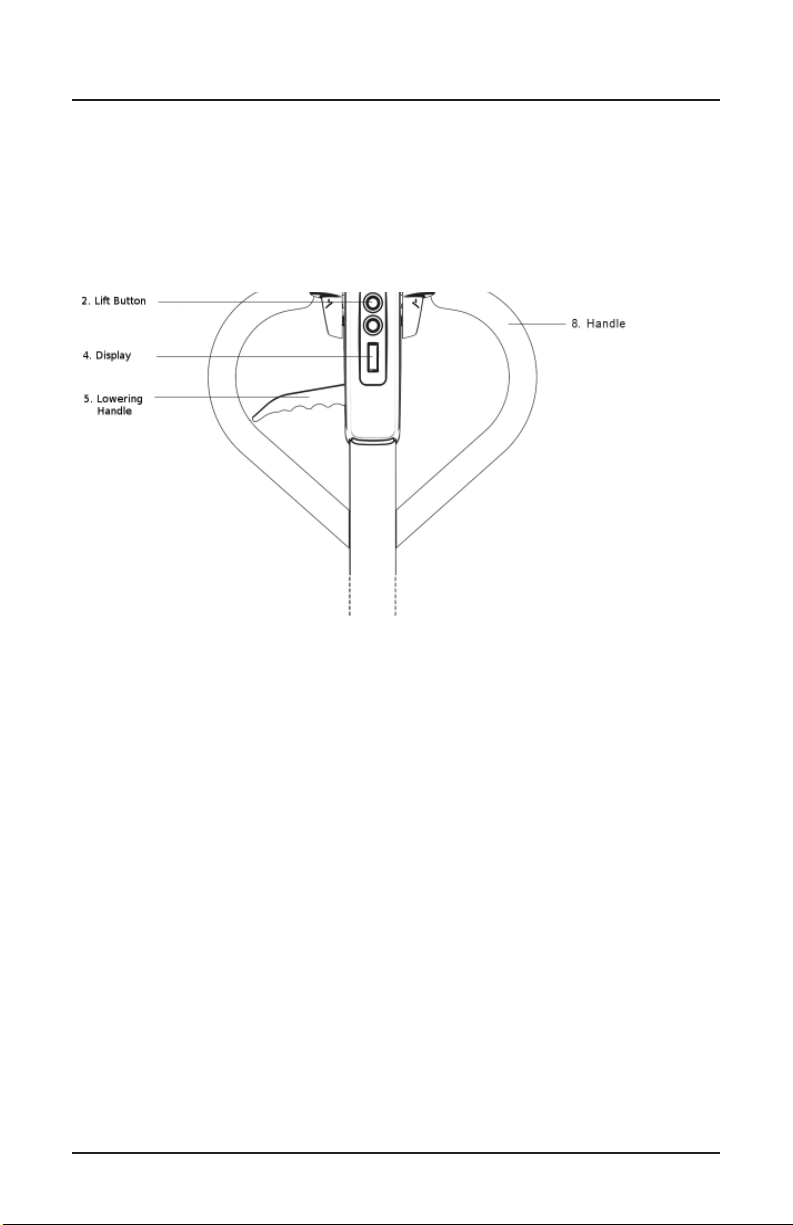

11.0 INSTRUMENTS AND CONTROLS

The steering arm and control handle provide controls for steering, forward and

reverse speed control, braking, raising and lowering the forks, and horn. Control

handles on all models have a “belly-button” reversing switch which reverses the

direction of the truck upon contact with the operator.

On the EPJ-25 pushing the red disconnect plunger removes all power from the

truck circuits in the event of an emergency.

CONTROL HANDLE

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

12 ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

11.1 OPERATION - DRIVING INSTRUCTIONS

Control Handle

All directional and speed controls are located on the control handle. Forward

and reverse are controlled by rotating the speed control lever as shown. The

lever is spring loaded to return to neutral when released. Further rotation in

either direction will progress the truck from slow to maximum travel speed.

To change directions or to stop the truck, rotate the speed control lever in the

opposite direction. The truck will come to a stop and then, unless the controls

are returned to the center neutral position, accelerate in the opposite direction.

Steering

Moving the control handle (which connects to the steering arm) right or left will

turn the truck right or left. When maneuvering around corners, make square

turns and be sure there is adequate clearance.

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

13ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

Stopping

Stop the truck as gradually as possible. Unnecessary rapid stopping could be

hazardous. Load could become unstable.

To stop the truck’s movement (forward or reverse), raise the control handle to

the up position or push the control handle all the way down. In both positions,

the brake will apply. To release the brake, just move the control handle to the

operating position.

NOTE: The steering arm gas spring automatically raises the steering arm to the

upright position when the steering arm is released.

Parking

When parking the truck, do not obstruct traffic lanes or aisles.

1. Park the truck in its designated parking area.

2. Raise the steering arm until vertical to apply the parking brake.

3. Fully lower forks.

4. Remove the key from the keyhole.

5. On the EPJ-25 push the red disconnect plunger to remove all power from

the truck circuits.

If the control handle does not raise immediately to the vertical position

when released, the truck should be placed “OUT OF SERVICE” until it can

be inspected by a qualified service technician.

CAUTION

Steering Arm Braking Positions

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

14 ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

Load Handeling

Handle only loads arranged for stability and always use caution. Raise and lower

the load smoothly to prevent the load from falling.

1. Approach the load slowly.

2. Move the truck slowly into position so that the forks are within pallet or skid,

and the load is centered over the forks and as far back as possible.

3. Push the button to raise the forks and lift the load.

4. Lead the truck by the control handle with the load trailing except when in

confined areas. Ramps should be traveled with operator uphill of truck when

empty, or operator downhill of truck with load on forks standing off to side of

truck.

5. Always look in the direction of travel. Move slowly and check clearances

when approaching obstructions.

6. Do not make sudden starts and stops. Operate truck smoothly and gradu-

ally.

7. Travel slowly and squarely around corners. Remember that the trailing load

wheels do not follow the turn path of the drive wheel. Instead they tend to

cut the corner.

8. Line up the truck with the unloading area.

9. Stop the truck and check the load alignment with surrounding objects.

10. Be careful not to damage or move adjacent loads and objects.

11. Lower the forks by pulling the lowering lever until the load is resting on its

own.

12. Move the truck back until the forks are clear of the pallet.

Moving a Disabled Truck

Do not attempt to move a disabled truck; notify your supervisor or proper

authority.

Always be sure the load and load center are within the capacity of the

truck. If in doubt check the nameplate.

WARNING

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

15ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

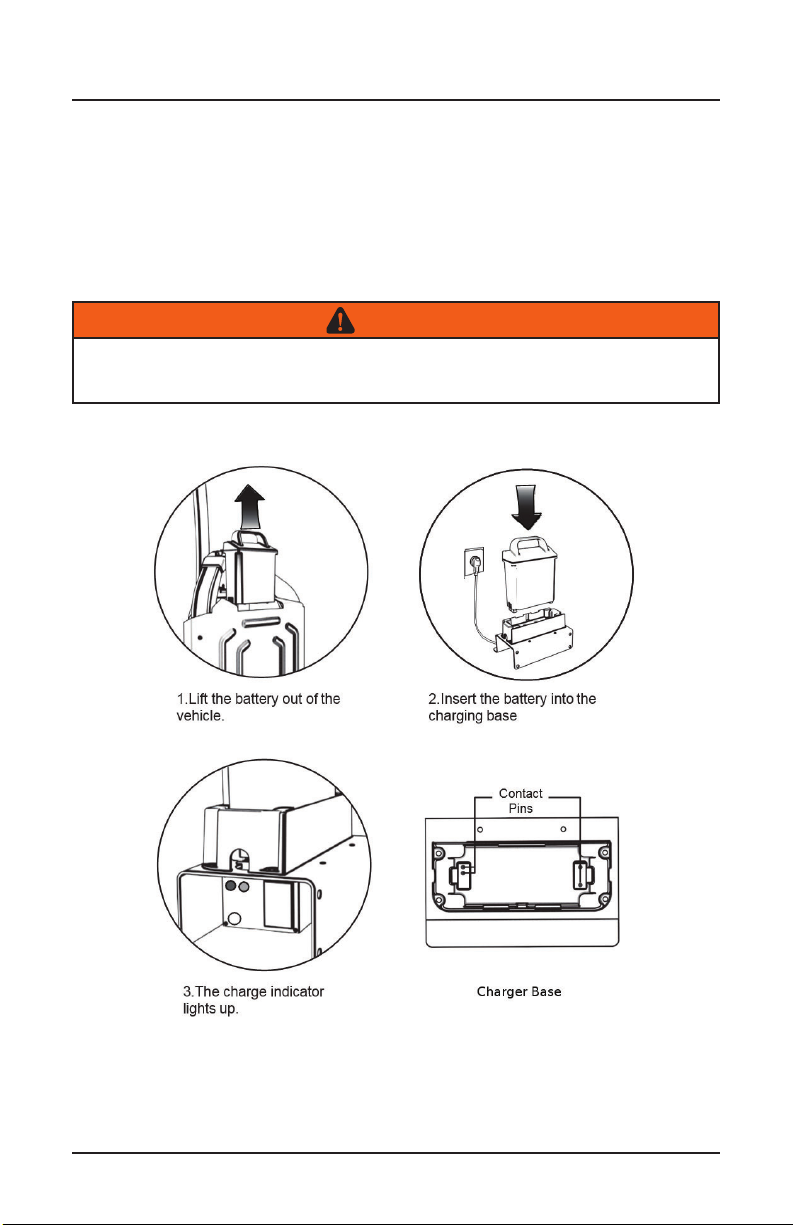

Before removing the battery make sure that the truck is completely

powered down.

WARNING

Battery Charging

When 1 Green + 1 Red LEDs are lit up charging is in progress. When the 2 Red

LEDs are lit up charging is complete.

The figure below shows the top view of the charger base contact pins, make

sure you plug in the battery accordingly. If the battery is not fully charged after

more than 5 hours contact your local dealer.

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

16 ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

Before installing the battery make sure that the truck key is not on.

WARNING

When plugging in the battery on the truck make sure that the contact pins on the

battery match those on the truck.

With a lithium battery it is possible to have some atten uation when used in a low

temperature environment. The operating temperature for the lithium battery is

between 14°F - 113°F.

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

17ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

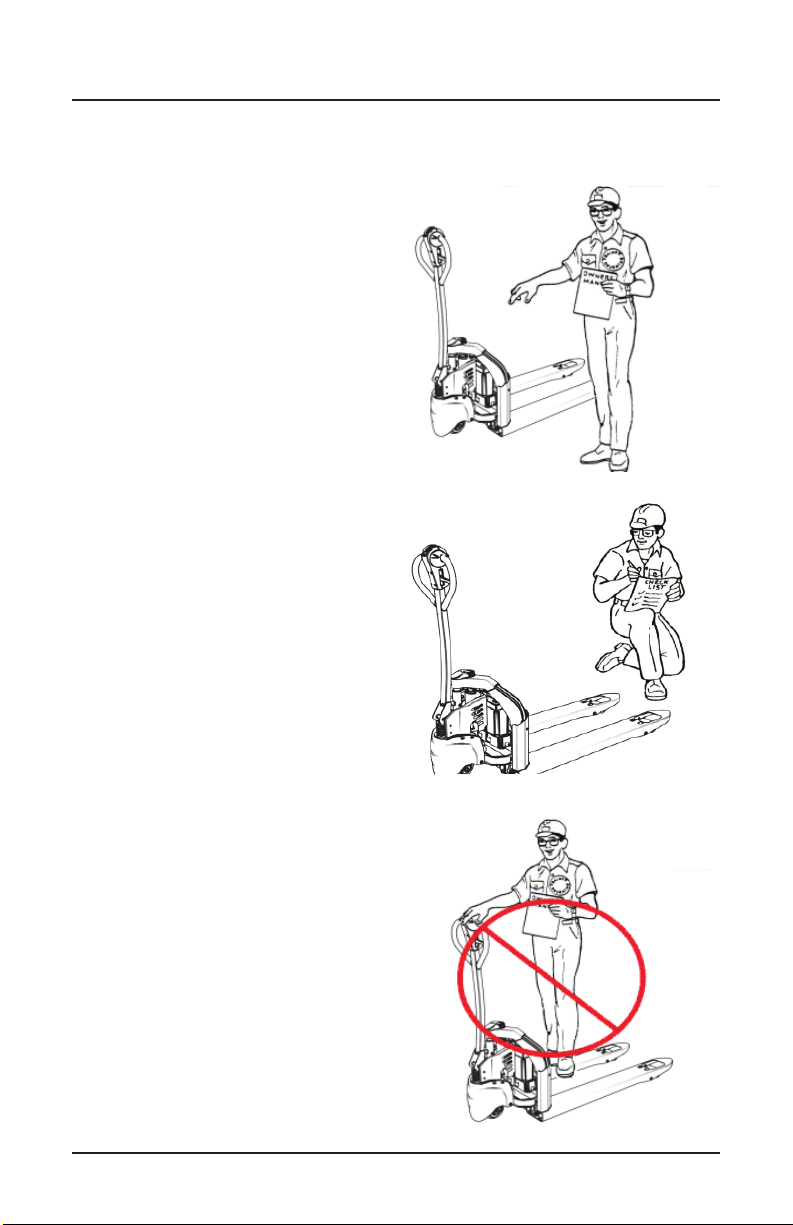

Do not operate this truck unless you

have been trained and authorized to do

so, and have read and understand all

warnings and instructions contained in

this operator’s manual and on this truck.

Do not operate this truck until you have

checked its condition. Give special

attention to wheels, horn, battery,

controller, lift systems, brakes, steering

mechanism, guards and safety devices.

If you have any questions, notify your

supervisor or proper authority.

Walkie Pallet Trucks: Operate truck only

from walking position.

The following operating instructions appear on the truck warning

decal, which is located near the steering arm.

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

18 ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

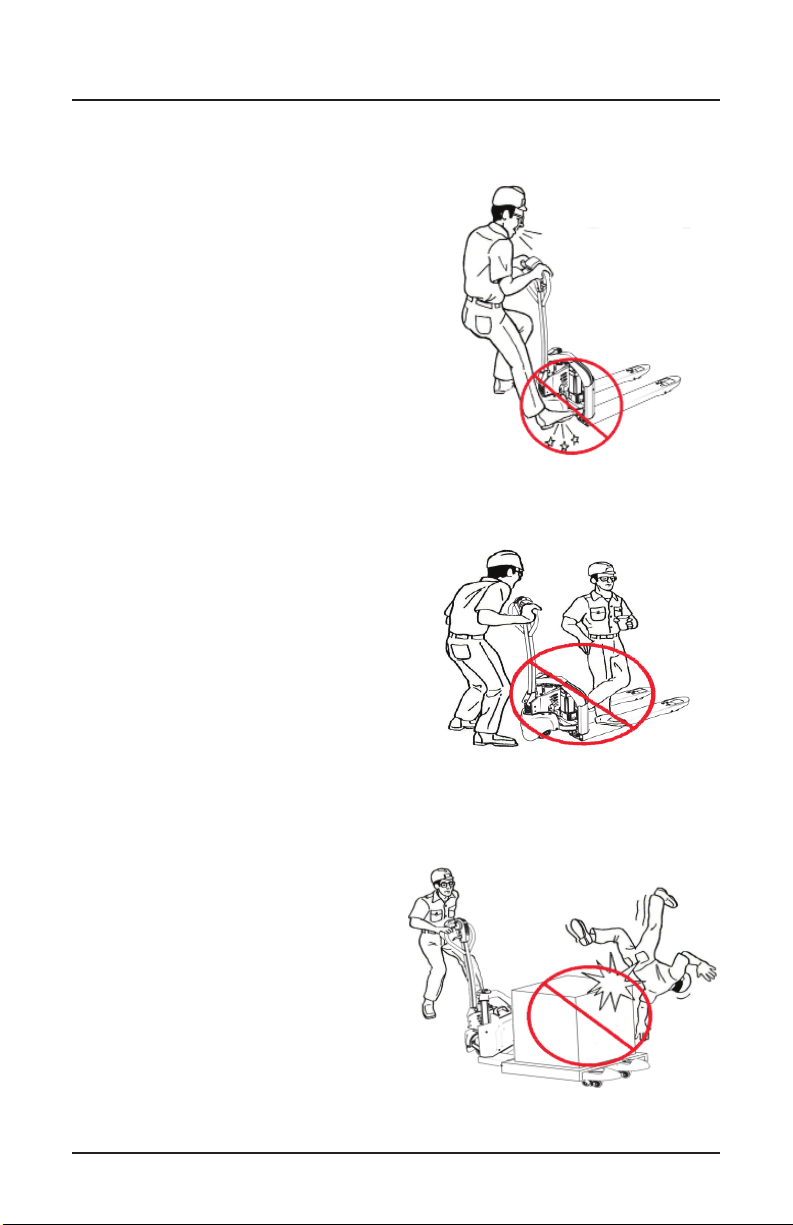

Wear foot protection and keep feet clear

of truck.

Do not carry passengers.

Observe applicable traffic regulations.

Yield right-of-way to pedestrians. Slow

down and sound horn at cross aisles

and wherever vision is obstructed.

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

19ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

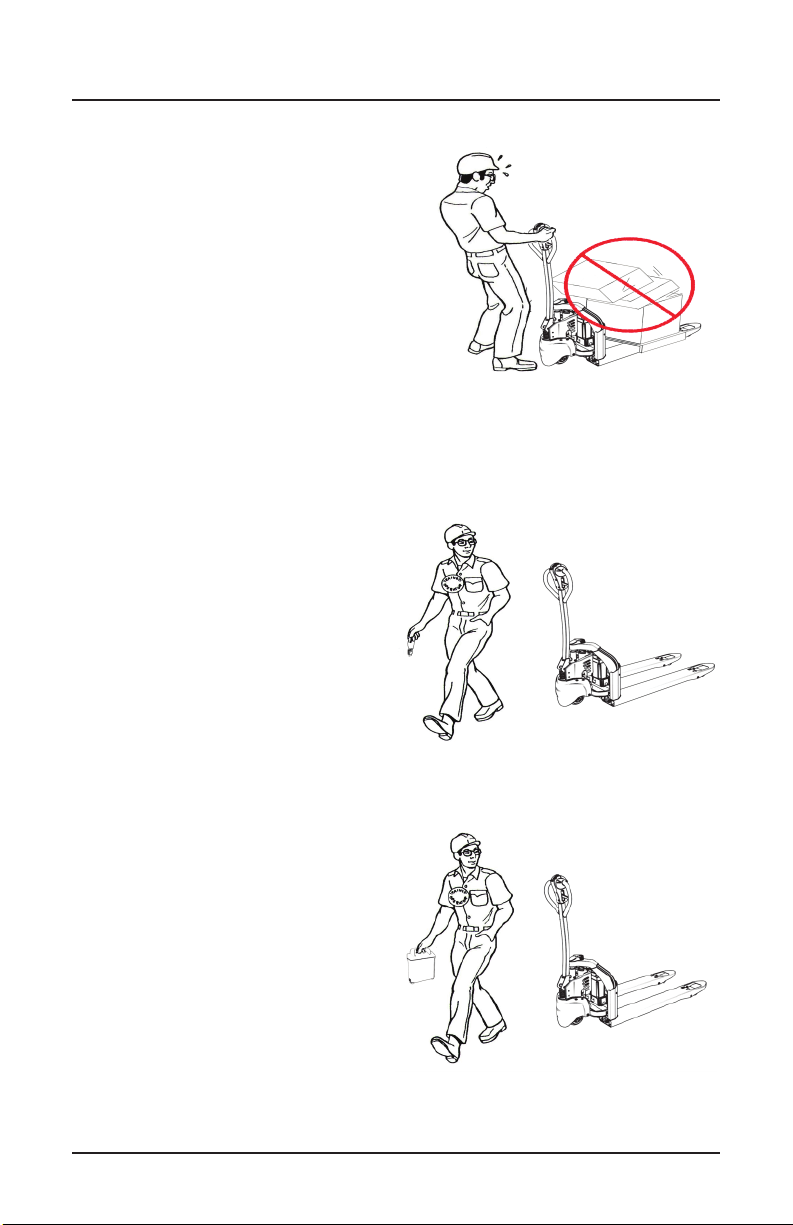

Start, stop, travel, steer and brake

smoothly. Slow down for turns and on

uneven or slippery surfaces that could

cause truck to slide or overturn. Use

special care when traveling

without load as the risk of overturn may

be greater.

Always look in direction of travel. Keep

a clear view, and when load interferes

with visibility, travel with load or lifting

mechanism trailing except when

climbing ramps.

Use special care when operating on

ramps; travel slowly, and do not angle

or turn. Travel with lifting mechanism

downhill.

EPJ-25 ELECTRIC PALLET JACK—OPERATOR’S MANUAL

20 ISSUE DATE: DECEMBER 7, 2020 REV. 1.0 (PART # 038-1074E)

Do not handle loads which are higher

than load backrest or load backrest

extension unless load is secured so that

no part of it could fall backward.

When leaving truck neutralize travel

control. Fully lower lifting mechanism

and set brake. When leaving truck

unattended also shut off power.

When leaving the truck for an extended

period of time remove the battery.

Table of contents

Other Blue Giant Jack manuals