5. OPERATION

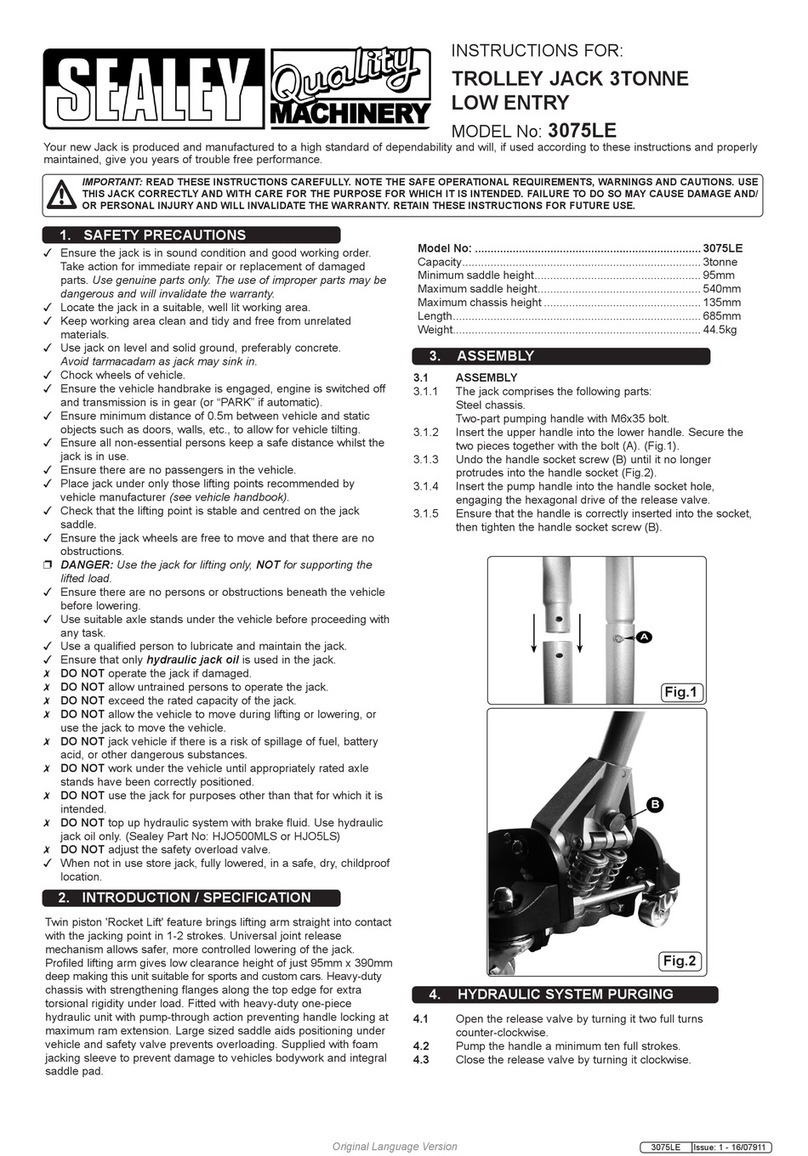

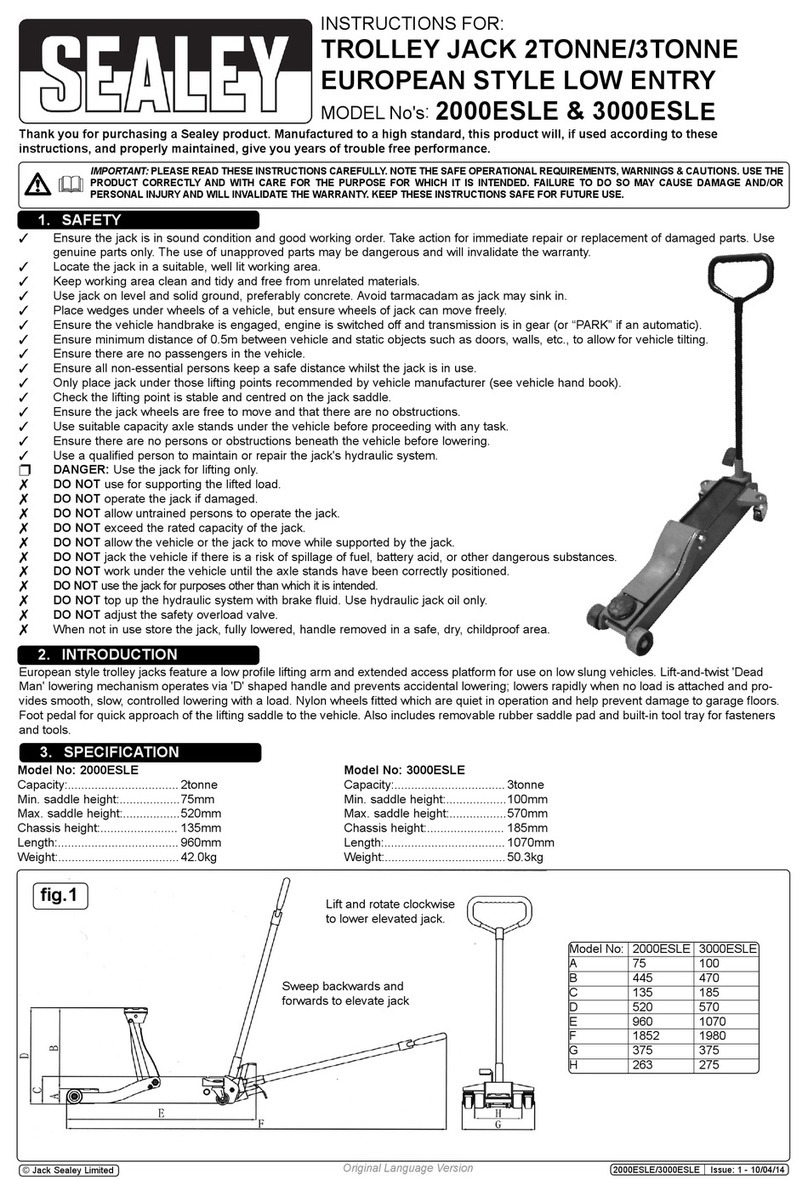

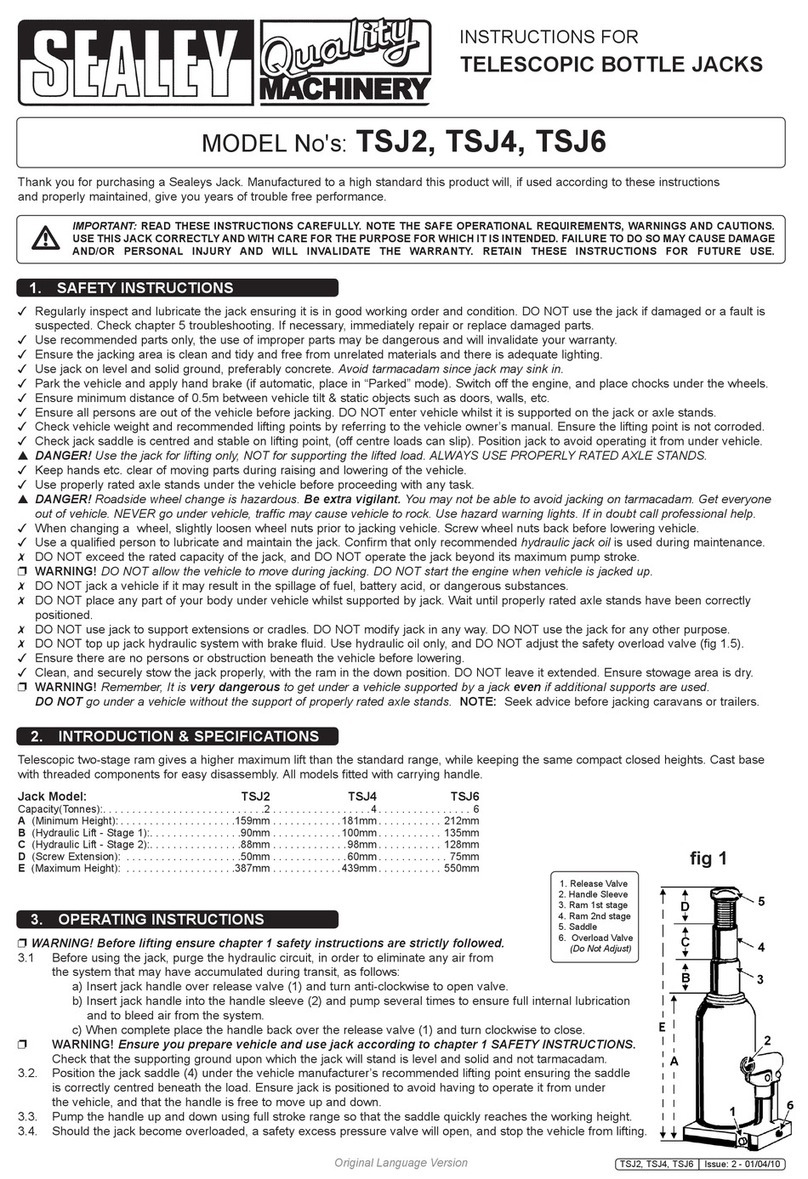

Refer to attached parts diagram.

NOTE: Ensure all Safety Instructions in Section 1 are read and understood and carried out before use and save the instructions

and warnings for future reference.

WARNING! Before operating the pump slacken the vent screw/filler cap (fig 3) by turning it counter clockwise.

5.1. SAFETY LOCKING LEVER

5.1.1. As an extra safety feature the jacking beam has two locking positions, controlled by the safety locking lever (fig 3).

5.1.2. When operating the jacking beam the safety locking lever will engage at two predetermined heights to prevent instant collapse,

which may cause personal injury.

5.1.3. To lower the jacking beam beyond these points, raise the jacking beam slightly, by pressing the right hand end of the control lever

(fig 3). Turn the safety locking lever (fig 3) clockwise. Then press the left hand end of the control lever (fig 3), to fully lower the

jacking beam (fig 4).

5.2. TO JACK A VEHICLE

5.2.1. Raise the ramp or pit inspection runners to the desired height (fig 2).

5.2.2. Position the jacking beam as described in section 4.2.

5.2.3. Ensure that the jacking beam is at it’s lowest position (fig 4), and is located under the vehicle manufacturer’s designated jacking

points (fig 6).

NOTE: The majority of lift applications require the use of two saddles.

5.2.4. Determine which saddle pair combinations are best suitable for the application, saddles or adjustable end saddles (fig 2).

NOTE: The end saddles can be adjusted, up or down to suit (fig 2).

5.2.5. Adjust the telescopic arms (fig 2) to line up the saddles (fig 2) with the jacking points of the vehicle (fig 6).

5.2.6. Ensure that the saddles are centred on the jacking points.

5.2.7. Attach the airline hose to the connector (fig 3) on the pneumatic pump (fig 2).

WARNING! Ensure there is sufficient slack in the air hose route from the compressor and that it does not constitute a trip hazard.

5.2.8. Raise the jacking beam in short increments by pressing the right hand end of the control lever (fig 3).

5.2.9. If satisfied with the stability of the set up, continue to jack the vehicle to the required height (fig 6).

5.2.10. At the required height place the vehicle on axle stands (fig 7), not supplied.

WARNING! Ensure the locking lever is engaged (fig 3).

5.2.11. On completion of operations remove the axle stands (fig 7) and store in a safe, clean, dry location.

5.2.12. To lower the jacking beam follow instruction point 5.1.3.

WARNING! When raising or lowering the jacking beam ensure that the air hose does not become trapped between the ramp and

the jacking beam and/or the jacking beam and the vehicle.

5.2.13. When operations are complete remove the airline hose from the pump and secure in a safe, clean, dry location.

5.2.14. With the assistance of another person remove the jacking beam, using the lifting handles (fig 2), from the pit or inspection runners

and store in a safe, clean, dry location.

WARNING! DO NOT raise or lower the ramp or pit inspection runners with the air line still attached to the jacking beam.

6. MAINTENANCE

Replace any labels on the jacking beam should they become unreadable. This applies in particular to any warning or operation

instruction labels. If replacement labels are required, contact your Sealey stockist.

NOTE: Only fully qualified personnel should attempt maintenance or repairs.

6.1. Disconnect the jacking beam from the air supply before changing parts, servicing or performing any maintenance.

6.2. When not in use, the beam should be stored in the lowest position, to minimise corrosion and disconnected from the air supply.

6.3. Keep the beam clean and lubricate all moving parts on a regular basis.

WARNING: DO NOT use brake fluid, or any fluid other than a good quality jack oil, such as SEALEY HYDRAULIC JACK OIL, as this

may cause serious damage to the jack and will invalidate the warranty!

6.4. To check the fluid level and to top up, fully unscrew the vent screw/filler cap and remove. Place in a secure location. Check the fluid

level either directly or using a dipstick. The level should be just below the vent, top up if necessary. Replace the vent screw/filler cap.

DO NOT overfill as this will affect the smooth operation of the beam.

6.5. Before each use check for broken, cracked, bent, or loose parts, or any visible damage to pump, saddles, lifting arms, frame and all

parts including nuts, bolts, pins and other fasteners. If any suspect item is found, remove beam from service and take action to

remedy the problem. DO NOT use the beam if it is believed to have been subjected to abnormal load or shock load. Inspect and take

appropriate action.

6.6. Periodically check the pump piston and the ram for signs of corrosion. Clean exposed areas with a clean oiled cloth.

SJBEX200A Issue 1 05/10/21

Original Language Version

© Jack Sealey Limited

fig.6 fig.7