Blue Giant STRONGARM ML10 User manual

OWNER’S MANUAL

STRONGARM™ ML10 VEHICLE RESTRAINT

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

WARNING

Do not operate or service this product unless you have

read and fully understand the entire contents of this

manual. Failure to do so may result in property damage,

bodily injury or death.

ACTUAL PRODUCT MAY NOT APPEAR EXACTLY AS SHOWN

STARTING FROM AUGUST, 2013 / SERIAL # 376630

2

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

TABLE OF CONTENTS

1.0 ABOUT THE STRONGARM™ ML10 WITH OPTIONAL TLC24 CONTROLS 3

1.1 OWNER’S PURCHASE RECORD 3

2.0 INTRODUCTION 4

2.1 WARRANTY INFORMATION 4

2.2 EXCLUSION OF LIABILITY 4

2.3 MANUFACTURER’S NOTE 4

2.4 OWNER’S RESPONSIBILITY 5

3.0 SAFETY MESSAGE COLOR IDENTIFICATION 6

3.1 OPERATIONAL SAFETY WARNINGS 6

4.0 LOCKOUT / TAGOUT PROCEDURE AND RULES 7

5.0 OPERATING INSTRUCTIONS - STANDALONE STRONGARM™ ML10 8

5.1 FUNCTIONAL DESCRIPTION 8

5.2 PRIOR TO USE: EQUIPMENT IN HOME POSITION 9

5.3 TRAILER AT BAY 9

5.4 ENGAGING RESTRAINT 9

5.5 RELEASING THE RESTRAINT ARM 10

6.0 PLANNED MAINTENANCE (PM) CHECK LIST – VEHICLE RESTRAINT – BASED ON CYCLES 11

7.0 RECOMMENDED SPARE PARTS 12

7.1 STANDARD OPERATIONAL COMPONENTS 12

7.2 PROTECTIVE COMPONENTS 13

7.3 TLC24 COMPONENTS (OPTIONAL) 13

8.0 DECAL IDENTIFICATION AND LOCATION 14

9.0 EQUIPMENT COMPONENT ILLUSTRATIONS 15

9.1 COMPONENTS AS SHIPPED CHECK LIST 15

9.2 MECHANICAL ASSEMBLY - 52-011130 16

9.3 GENERAL DIMENSIONS 17

10.0 OPERATING INSTRUCTIONS - STRONGARM™ ML10 WITH TLC24 CONTROLS (AUTOMATIC & MANUAL) 18

10.1 PRIOR TO USE: EQUIPMENT IN HOME POSITION 18

10.2 TRAILER AT BAY 18

10.3 ENGAGING RESTRAINT 19

10.4 RELEASING THE RESTRAINT ARM 19

10.5 MANUAL OVERRIDE MODE (TLC24-A) 20

10.6 TLC24 CONTROLS 21

11.0 OPERATING INSTRUCTIONS - STRONGARM™ ML10 WITH BLUE GENIUS™ CONTROLS 22

11.1 TRAILER AT BAY 22

11.2 ENGAGING RESTRAINT 22

11.3 RELEASING THE RESTRAINT ARM 23

11.4 MANUAL OVERRIDE MODE 23

11.5 BLUE GENIUS™ CONTROLS 24

12.0 EXTERIOR TRAFFIC LIGHT / MIRROR IMAGE SIGN 25

13.0 VEHICLE RESTRAINT TROUBLESHOOTING 26

14.0 WIRING DIAGRAMS 28

14.1 WIRING DIAGRAM—TLC24-A 115V AND 230V SINGLE PHASE 28

14.2 WIRING DIAGRAM—TLC24-M 115V AND 230V SINGLE PHASE 29

14.3 WIRING DIAGRAM— BLUE GENIUS™ 115V SINGLE PHASE 30

3

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

1.0 ABOUT THE STRONGARM™ ML10 WITH OPTIONAL TLC24 CONTROLS

The manufacturer offers a full line of dock levelers, dock safety equipment, accessories, ergonomic and scissor lift equipment, seals and

shelters, and industrial trucks. Concurrent with a continuing product improvement program, specifications are subject to change without

notice (see section 2.2 of this manual). Please contact the manufacturer for latest information. Some features illustrated may be optional

in certain market areas.

1.1 OWNER’S PURCHASE RECORD

OWNER’S PURCHASE RECORD

Please record information for future inquiries and to validate warranty. (See Section 2.1 for warranty validation)

Dealer: Date in Service:

Number of Units:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

Serial Number: Door #:

The StrongArm™ ML10 Mechanical Vehicle Restraint is a high-performance yet low-cost solution for loading docks worldwide. With a

vertical restraining range of 11" to 26" (279 mm to 660 mm) above ground and horizontal reach of 13" (330 mm), the ML10 is compatible

with virtually all modern trucks and trailers, even those with air-ride suspension systems. 30,000 lb (13,636 kg) of restraining force

prevents premature truck departure during loading and unloading. Easy and ergonomic to operate, the unit is engaged and released by

a single detachable control rod.

This manual also incorporates operating instructions for the TLC24-A (automatic) and TLC24-M (manual) lights communication

packages, which are optional and recommended add-ons to the ML10. Both control stations feature a keyed selector switch, red and

green indicator lights, high-visibility LED traffic lights, and mirror-image driver warning signs.

See section 8.0 Decal Identification and Location, item #4 for serial number location.

NOTICE

4

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

2.0 INTRODUCTION

The following is a quick reference to important procedures that

must be followed while using the Vehicle Restraint System. It is

not intended to cover, or suggest that it does cover, all procedures

necessary to ensure safe operation. All operators should be aware

of and abide by all workplace safety regulations applicable to

the operation of the Vehicle Restraint System. These laws and

regulations include but are not limited to:

• TheOccupationalSafetyandHealthAct

• CanadaOccupationalHealthandSafetyRegulations

• Occupational Safety and Health Acts for Individual States

(USA)

For additional information on these regulations as well as industry

standards that may apply to this product, please contact:

American National Standards Institute (ANSI)

1430 Broadway

New York, NY 10018

Telephone: 212.642.4900

www.ansi.org

Also a member of:

Loading Dock Equipment Manufacturers

A Product Section of Material Handling Industry of America

A Division of Material Handling Industry

8720 Red Oak Blvd, Suite 201

Charlotte, NC, 28217-3992

Telephone: 704.676.1190

www.mhi.org/lodem

2.2 EXCLUSION OF LIABILITY

The manufacturer assumes no liability for damage or injury to

persons or property which occur as a result of defects or faults in

or incorrect use of the Vehicle Restraint System. The manufacturer

also assumes no liability for lost profits, operating downtimes, or

similar indirect losses incurred by the purchaser. Injury to third

parties, irrespective of its nature, is not subject to compensation.

The manufacturer reserves the right to make changes at any time

to the modules, components, and accessories, concurrent with

its continuing product improvements and development program.

Specifications, operating instructions, and illustrations included in

this manual are subject to change without notice. Please contact

manufacturer for the latest information.

2.3 MANUFACTURER’S NOTE

The Vehicle Restraint has been carefully inspected and tested at

the manufacturer’s plant prior to shipment, but should be checked

upon receipt for transport damage. Any observed transport

damage is to be listed on the signed copy of the freight document.

Notify the freight forwarder of any damage WITHIN 48 HOURS.

2.1 WARRANTY INFORMATION

Thank you for purchasing Blue Giant products. We appreciate your

business, and are confident that our product will serve you for

many years to come. In the event that you experience a problem

with our product, our Warranty Center is here to support the

Blue Giant Product(s) that you have purchased.

To validate warranty on recently purchased equipment,

please complete and submit your information with our

online Warranty Registration at www.BlueGiant.com.

For more information about Blue Giant Warranty Support, please

contact your local Blue Giant Equipment dealer, representative or

authorized partner near you. You may also visit www.BlueGiant.

com or phone 1.905.457.3900.

DEALER INFORMATION

Name:

Contact:

Telephone:

* NOTE that failure to validate warranty at the time of receipt can

seriously affect the outcome of any claim.

5

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

2.4 OWNER’S RESPONSIBILITY

1. The owner should recognize the inherent danger of the

interface between the dock and the freight carrier. The owner

should, therefore, train and instruct operators in the safe use

of the dock equipment and accessories in accordance with the

manufacturer’s recommendations.

2. The owner should thoroughly familiarize themselves with

the following procedures and specifications, and request

immediate replacement of all manufacturer-supplied

documents that are missing, damaged, or otherwise illegible.

• Installationinstructions

• Operatinginstructions

• Plannedmaintenanceprocedures

• Inspectionsprocedures

• Replacementpartslists

Upon receipt of any newly purchased dock equipment, the

owner shall verify the presence of owner’s manuals, operating

placards, and any other documentation necessary for

training dock personnel how to use the equipment safely and

effectively.

3. Manufacturer’s recommended periodic maintenance and

inspection procedures shall be followed, and written records

of the performance of these procedures should be kept as per

warranty guidelines.

4. Dock equipment that is structurally damaged, experiencing

performance irregularities, or has been potentially

compromised (i.e. sudden loss of support due to premature

truck departure) shall be removed from service until a trained

and authorized manufacturer’s representative can conduct an

inspection and perform any necessary repairs.

5. As with any piece of machinery, dock equipment requires

routine maintenance, lubrication, and adjustments. Your

local Blue Giant®representative offers owners the option

of a Planned Maintenance Program (P.M.P.). As part of this

service, your local Blue Giant®representative will do all routine

maintenance, lubrication, and adjustments.

6. The owner shall ensure that all nameplates, caution/

instruction markings or labels are in place and legible, and

that the appropriate operating/maintenance manuals are

provided to authorized users. Replacement name plates,

caution/instruction labels, and manuals containing operating

and maintenance instructions are available through the

Blue Giant Aftermarket Department.

7. Modifications or alterations of dock equipment shall be made

only with written permission of the original manufacturer. These

changes shall also satisfy all safety recommendations of the

original equipment manufacturer for the particular application

of the dock equipment.

8. The owner or a trained and authorized representative shall

verify that all freight carrier brakes have been applied and a

vehicle restraint and/or wheel chocks properly engaged before

cross-docking procedures such as loading and unloading

begin.

9. Unless specifically agreed to in writing by Blue Giant

Equipment Corporation at the time of order (and prior to

manufacture), all Blue Giant Dock equipment is sold as a

complete offering, and must not be altered or added to in

any manner (which includes configuration and function)

without written permission from an authorized manufacturer’s

representative.

10. If, at the request of the owner, Blue Giant does not supply

all or some of the dock equipment power unit and/or control

station components, the owner shall assume responsibility for

any and all operational and safety issues associated with the

resulting configuration.

PELIGRO

6

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

DANGER

DANGER

DANGER

DANGER

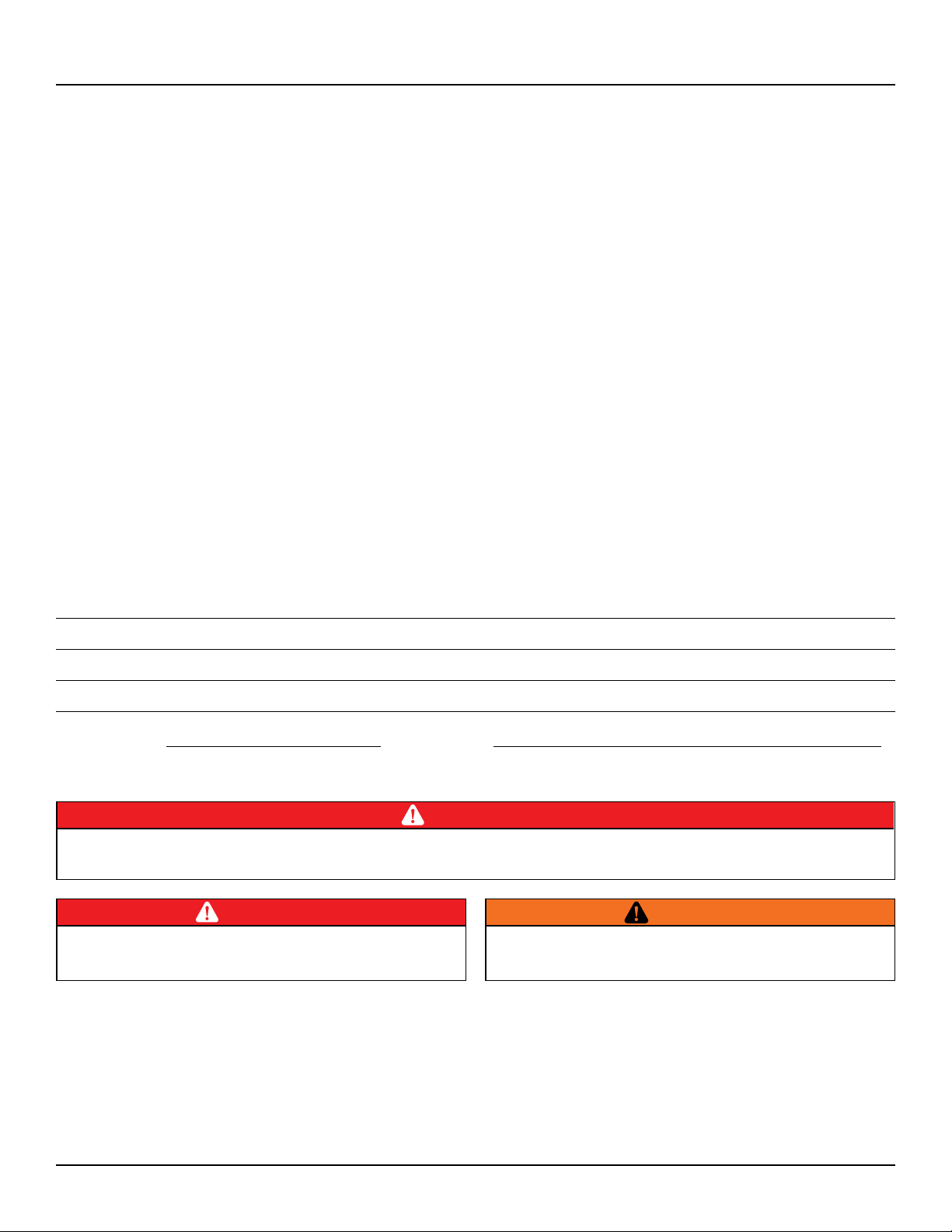

3.0 SAFETY MESSAGE COLOR IDENTIFICATION

This manual includes color-coded safety messages that clarify instructions and specify areas where potential hazard exists. To prevent

the possibility of equipment damage and serious injury or death, please observe strictly the instructions and warnings contained in

the messages. If warning decals become damaged or missing, replace them immediately. Avoid accidents by recognizing dangerous

procedures or situations before they occur.

Serious injury or death will likely occur if the

instructions are not followed.

Serious injury or death may occur if the

instructions are not followed.

Procedures marked notice must be followed in order

to prevent damage to machinery.

Instructions marked caution concern safe operating procedure.

Failure to comply may result in personal injury.

3.1 OPERATIONAL SAFETY WARNINGS

1. Installation must be performed only by trained and authorized personnel.

2. Prior to installation, place adequate barriers to prevent vehicle traffic from entering the work area.

3. During installation, anchors must be properly torqued to achieve the necessary anchoring strength. DO NOT USE IMPACT DRIVERS.

4. Any electrical work must be performed by qualified personnel only.

5. Do not remove the wheel chocks until loading /unloading is finished and the truck is cleared for departure or the vehicle restraint has been

released and the lights have changed to RED inside and GREEN outside.

WARNING

DANGER 1. Do not operate the dock equipment while anyone is standing in its path.

2. Lift the dock equipment with suitable hoisting equipment only. Do not

stand under the dock equipment or any heavy object while it is being

hoisted.

3. BEFORE BEGINNING ANY SERVICE PROCEDURES:

Disconnect the power and follow all lockout / tagout procedures outlined

in this manual.

Keep hands and feet away from operating space of the

restraint apparatus.

CRUSH

HAZARD

1. Only trained personnel should operate or service this equipment.

2. Do not operate the dock equipment until the transport vehicle is parked against the dock bumpers.

3. Always park the dock equipment after use.

4. Conduct routine inspections and maintenance. Failure to do so could cause equipment damage and or personal injury.

5. Always call your authorized service representative or manufacturer immediately if a malfunction occurs.

6. Always return the restraint arm to the parked position after use.

1. Do not ground welding equipment to any electrical components.

2. Do not allow the drill to go too deeply into the control box, as damage may occur to the control systems.

3. Never use air to blow debris from the control box. Use a vacuum to perform any necessary cleaning.

4. Do not connect green ground lead into control box or junction box until all welding has been completed.

5. If an extension plate / box is required, securely mount it on the restraint with hardware provided before shimming and drilling.

6. Improper adjustments and / or lubrication may cause operational problems with equipment.

DANGER NOTICE

CAUTIONWARNING

DANGER

NOTICE

CAUTION

1. Installation must be performed only by trained and authorized personnel.

2. Prior to installation, place adequate barriers to prevent vehicle traffic from entering the work area.

3. During installation, anchors must be properly torqued to achieve the necessary anchoring strength. DO NOT USE IMPACT DRIVERS.

4. Any electrical work must be performed by qualified personnel only.

5. Do not remove the wheel chocks until loading /unloading is finished and the truck is cleared for departure or the vehicle restraint has been

released and the lights have changed to RED inside and GREEN outside.

XXXXXXXXXXXX

XXXXXXXXXXX

OPERATE

DO NOT

7

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

WARNING

Always lockout and tagout any power source before performing any

work on any electrical devices or electrical controls according to

OSHA regulations and approved local electrical codes.

Approved way to lockout / tagout.

4.0 LOCKOUT / TAGOUT PROCEDURE AND RULES

In accordance with the rules and regulations of the Occupational

Safety and Health Administration (OSHA), all affected employees

must be notified that the machine or equipment will be shut down

and locked out to perform repair or maintenance work. The work

area must be checked to ensure that all personnel have been

removed or safely repositioned. The machine or equipment power

supply shall be locked in the OFF position or disconnected from

the energy source. Blue Giant® strongly recommends that only

OSHA-approved lockout devices and procedures be utilized.

The energy isolating device must bear a prominent warning tag

indicating that work is being done on the equipment and the

name of the authorized employee responsible for the lockout. It is

mandatory that tagout notices not be susceptible to deterioration

or illegibility due to weather conditions or exposure to chemicals

and moisture.

8

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

5.0 OPERATING INSTRUCTIONS - STANDALONE STRONGARM™ ML10

ML10 operation placard—part # 038-759E.

WARNING

5.1 FUNCTIONAL DESCRIPTION

The StrongArm™ ML10 mechanical vehicle restraint is used to

restrain a trailer at the loading dock. When engaged, it secures

a vehicle’s under-ride guard (ICC bar), restricting forward

movement caused by vehicle creep or unscheduled departure.

It is mechanically engaged and disengaged using a control rod

(782-371). For added safety, Blue Giant recommends the use

of a lights communication package (TLC24-A or TLC24-M) in

conjunction with the ML10.

Do not operate this vehicle restraint unless you have been trained and

authorized to do so, and have read and understood all of the safety

information and instructions contained in this manual.

Do not operate this restraint until you have checked its condition.

Report the need for repairs to your supervisor immediately and do not

operate the unit until repairs are made.

Never try to lift or move any part of the vehicle restraint manually. Keep

hands and feet clear of vehicle restraint pinch points.

It is the responsibility of the owner / operator of truck / vehicle to

(whenever possible) exhaust the air from air-ride suspension systems

prior to performing loading or unloading.

Because ICC bars differ in strength and construction, review the need

to use wheel chocks in conjunction with the vehicle restraint.

This vehicle restraint is designed for rear impact guards (RIG)

and rear impact protection (ICC Bar) that follow the Federal

Motor Carrier Safety Administration guidelines (FMCSA

section 571.223 and 571.224) + NHTSA (National Highway

Traffic Safety Administration) guidelines.

Truck / Vehicle Dock Bumper Dock Leveler (Typical)

Vehicle

ICC Bar Dock Face

Vehicle Restraint

(Arm Released)

WARNING

TLC24-A TLC24-M

OUTSIDE TRAFFIC

LIGHT STATUS

INSIDE COMMUNICATION

LIGHTS & CONTROL STATION

ENGAGE RESTRAINT

Activate the ML10 by using the control rod to

press down on the engagement arm until the

restraint arm is in the fully vertical position,

holding the ICC bar in place.

TLC24-A: The control station light will turn

GREEN and the outside trafc light will turn

RED.

TLC24-M: Turn the key switch to the

‘Interlocked’ position (green LED). The

outside trafc light changes to RED while

GREEN light on the control station comes on.

TLC24-A TLC24-M

OUTSIDE TRAFFIC

LIGHT STATUS

INSIDE COMMUNICATION

LIGHTS & CONTROL STATION

OPPOSITE

SIDE

NOTE: The truck / trailer is NOT restrained if the arm is not fully vertical and

the communication lights do not change colour as described above. Do a visual

inspection to conm that the ICC bar is securely restrained before proceeding with

loading / unloading.

OPERATING INSTRUCTIONS

Only for the ML10 and TLC24-A (Automatic) or TLC24-M (Manual)

1. Only trained and authorized personnel may operate this vehicle

restraint.

2. Read, understand, and follow the instructions on this document and

included manual

3. Prior to using the vehicle restraint:

• Ensure that the vehicle restraint is free and clear of all debris, snow,

and ice.

• Ensure that all personnel near the vehicle restraint are aware that it

is being operated.

• Operate the vehicle restraint through one complete cycle to conrm

that it is functioning properly. If the vehicle restraint is equipped with

a communications package, conrm that the lights are working as

required.

• Inspect unit for signs of structural damage or mechanical

malfunction. If damage is observed or the restraint fails to operate

properly, remove it from service and notify maintenance personnel

immediately.

4. Before attempting to restrain a transport vehicle:

• Ensure that the vehicle is parked rmly against the dock bumpers.

• If the dock leveler is equipped with a light communication package,

load and unload on green only.

• Do not exceed the rated capacity as indicated on the serial plate.

• Do not leave equipment or material unattended on the dock leveler.

• Keep a safe distance from both edges.

• If either the dock leveler or vehicle restraint fail to operate as

outlined in the accompanying manual’s operating instructions, refer

to the Troubleshooting section.

5. If service or maintenance is required:

• Only authorized service personnel shall maintain or service the

units.

APPLIES TO ALL DOCK LEVELER AND VEHICLE RESTRAINT

COMBINATIONS

RELEASE RESTRAINT

After loading / unloading has been completed

and the dock leveler is safely parked, release

the restraint arm by pulling up on it quickly

and rmly using the control rod. The arm will

return to the parked position.

TLC24-A: The control station light will turn

RED and the outside trafc light will turn

GREEN.

TLC24-M: Turn the key switch to the ‘No

Trafc’ position (red LED). The outside trafc

light changes to GREEN and the control

station light turns RED.

038-759Ewww.BlueGiant.com

NOTE: If the ICC bar is applying pressure to the restraint arm, it may be necessary

to have the driver back up the vehicle before releasing the arm.

9

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

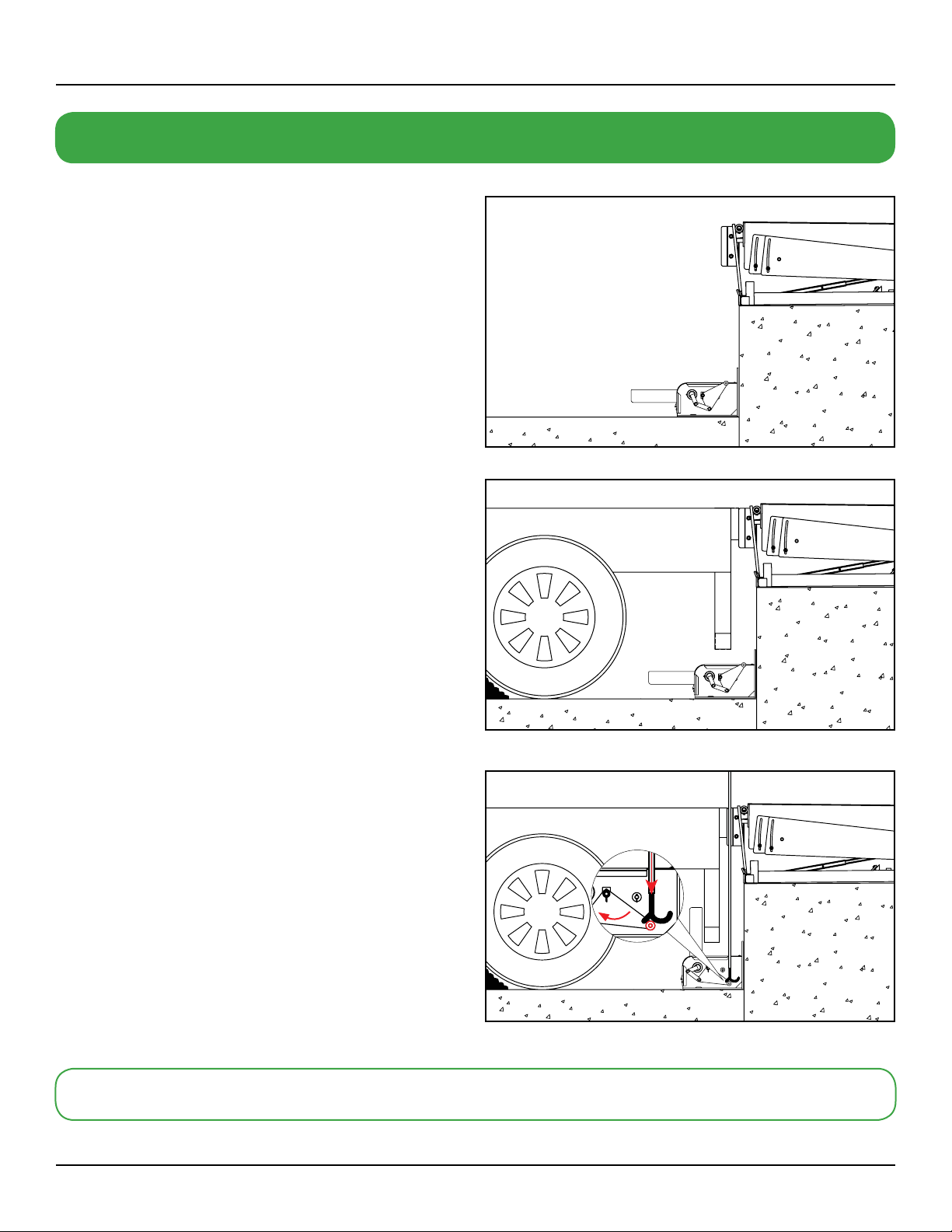

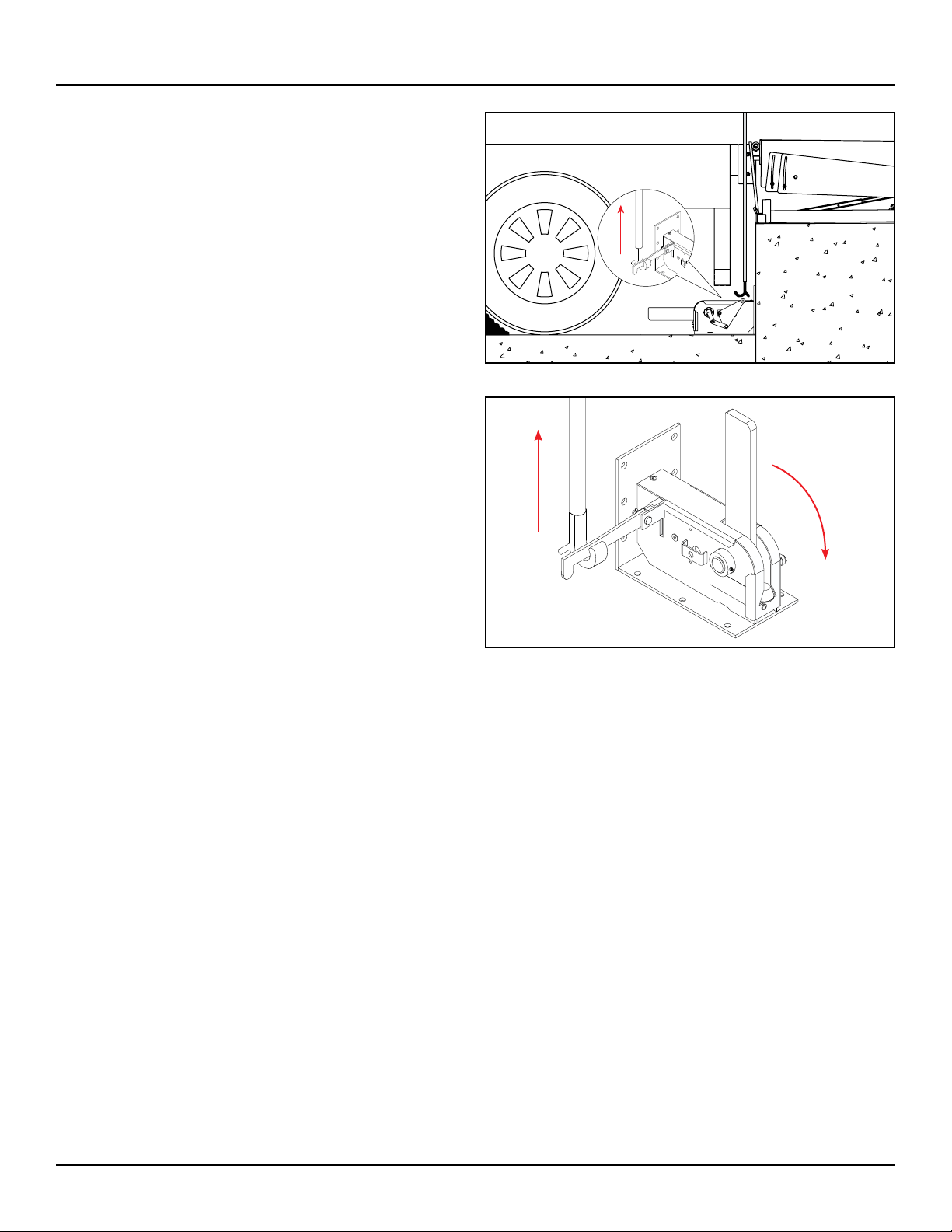

5.3 TRAILER AT BAY

The truck reverses into position against the dock leveler bumpers.

After the truck is correctly parked, chock wheels securely.

STANDARD OPERATION PROCEDURES

5.4 ENGAGING RESTRAINT

Activate the ML10 by using the control rod (Blue Giant part

# 782-371) to press down on the engagement arm until the

restraint arm is in the fully vertical locked position, which now

holds the ICC bar in place.

NOTE: The truck / trailer is NOT restrained if the arm is not fully

vertical. Do a visual inspection to confirm that the ICC bar is

securely restrained before proceeding with loading / unloading.

RESTRAINT

ARM IN HOME

POSITION

5.2 PRIOR TO USE: EQUIPMENT IN HOME

POSITION

The restraint apparatus is in the home position and the dock leveler

lip is parked safely in the lip keepers.

PERFORM LOADING AND UNLOADING

10

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

5.5 RELEASING THE RESTRAINT ARM

After loading / unloading has been completed and the dock leveler

is safely parked, release the restraint arm by pulling up on it quickly

and firmly using the control rod (Blue Giant part # 782-371). The

arm will return to the parked position.

NOTE: If the ICC bar is applying pressure to the restraint arm, it

may be necessary to have the driver back up the vehicle before

releasing the arm.

Control rod (part # 782-371) releasing the restraint arm.

11

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

INSPECTED BY: DATE:

Forward checklist to the person responsible for Vehicle Restraint maintenance.

6.0 PLANNED MAINTENANCE (PM) CHECK LIST – VEHICLE RESTRAINT – BASED ON CYCLES

INSTRUCTIONS FOR USE: Photocopy this page and indicate “OK for USE” with a check mark in the appropriate box of each

inspection point.

EVERY DAY:

Remove any debris that may have accumulated inside the restraint.

Check that the operating hazards placard is present and legible.

Verify complication-free operation of the restraint and the interior and exterior lights system.

Check for missing or damaged dock bumpers.

Verify complication-free operation of the TLC24-A / TLC24-M and exterior lights (if applicable).

EVERY THREE MONTHS:

Lubricate all bushings.

Check wall or floor anchors.

Check safety warning decals and replace if necessary.

Explain faults briefly in the space provided below:

DANGER WARNING

DANGER

DANGER

Prior to repairs, place adequate barriers to prevent unauthorized

personnel and vehicle traffic from entering the work area.

All repairs and maintenance work are to be conducted by trained

and authorized personnel ONLY.

When repairing or conducting maintenance procedures on electrical components, perform lockout / tagout steps according to OSHA

regulations and approved electrical codes.

8

5

46

7 9

1 2 3

12

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

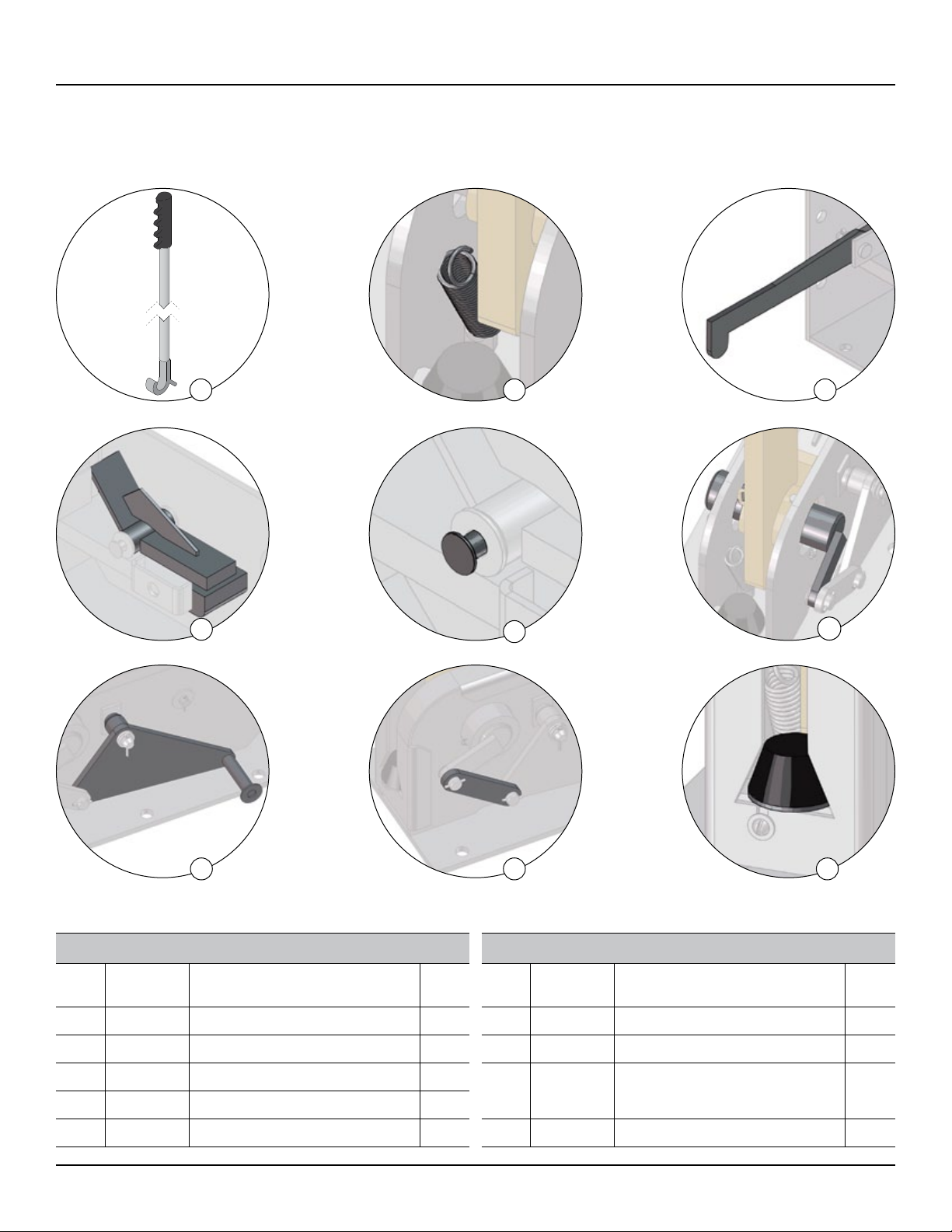

7.0 RECOMMENDED SPARE PARTS

7.1 STANDARD OPERATIONAL COMPONENTS

RSP FOR ML10 – STD OPERATIONAL COMPONENTS

ITEM

NO. PART NO. DESCRIPTION QTY

REQ’D

1 782-371 Control Rod 1

2 017-012 Return Spring 1

3 522-0000 Arm, Release Lever 1

4522-5001 Lock Weldment 1

5 210-0005 Pin, Lock Weldment 1

RSP FOR ML10 – STD OPERATIONAL COMPONENTS

ITEM

NO. PART NO. DESCRIPTION QTY

REQ’D

6 522-5005 Arm, Pivot Shaft Assembly 1

7 522-5006 Arm, Engagement Lever 1

8 522-0010 Arm Engagement Link

1 1/4" x 5 5/8" (32mm x 143 mm) 1

9 091-041 Bumper 1

3

6

4 5

1 2

10

13

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

7.2 PROTECTIVE COMPONENTS

RSP FOR ML10 – PROTECTIVE COMPONENTS

ITEM NO. PART NO. DESCRIPTION QTY

REQ’D

10 52-011187 Top Cover 1

7.3 TLC24 COMPONENTS (OPTIONAL)

RSP FOR TLC24

ITEM

NO. PART NO. DESCRIPTION QTY

REQ’D

4 026-G206 24V Monoblock LED Indicator- Green 1

5026-G014-

1115

Traffic Lights Controller Board

(1PH 115V TLC) 1

6026-G014-

1230

Traffic Lights Controller Board

(1PH 230V TLC) 1

RSP FOR TLC24 COMPONENTS (OPTIONAL)

ITEM

NO. PART NO. DESCRIPTION QTY

REQ’D

1 026-G202 Normal-Open Contact Block 1

2 026-G203 Normal-Closed Contact Block 1

3 026-G205 24V Monoblock LED

Indicator- Red 1

BLUE GIANT EQUIPMENT

CORPORATION

MODEL/

MODELO

SERIAL NO./

NO. DE SERIE

TEST LOAD/

PRUEBA DE CARGA

MFG / FAB

COMPLIES WITH ANSI MH30.3

“REFER TO SAFETY AND OPERATING

INSTRUCTIONS IN YOUR OWNERS

MANUAL” /

“A SEGURESE DE HABER LEIDO LAS

PROVISIONES DE OPERACION Y

SEGURIDAD EN EL MANUAL DEL

PROPIETANO.”

lbs.

kg.

www.BlueGiant.com

MADE IN CANADA

HECHO EN CANADA

038-299ES

ML10

371381

01/14

22,500

10,206

(MM / YYYY)

3

4

038-240

VehicleRestraint

1

1

2

4

3

2

14

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

ITEM # QTY PART NO. DESCRIPTION

1 1 038-859E Decal - BG StrongArm™ ML10

2 1 038-240 Decal - StrongArm™ - Vehicle Restraint

3 1 038-243E Decal - Crush Hazard

4 1

038-299EF Decal - Serial Plate - English / French

038-299ES Decal - Serial Plate - English / Spanish

8.0 DECAL IDENTIFICATION AND LOCATION

Keep Hands and Feet away

from operating space of the

Restraint Arm. CRUSH HAZARD

038-243E

CAUTION

3

1‡

2*

5

4

15

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

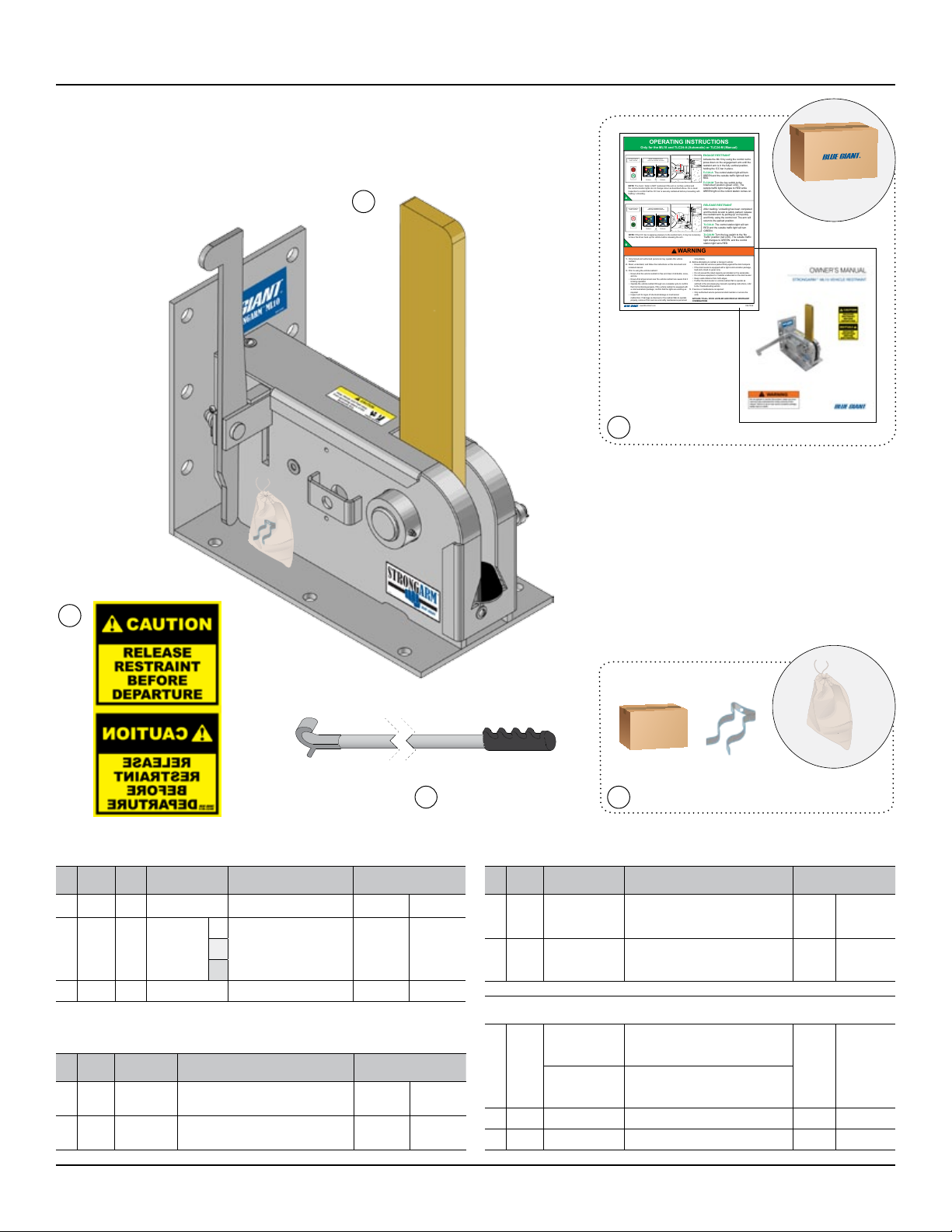

9.0 EQUIPMENT COMPONENT ILLUSTRATIONS

9.1 COMPONENTS AS SHIPPED CHECK LIST

MOUNTING

BRACKET

‡ NOTE: The arm is shown in the shipping

position and will need to be installed correctly.

ANCHORS

ITEM QTY PART NO. DESCRIPTION APPROX. WEIGHT

1 1 52-011130 ML10 Body 150 lb 68 kg

2 1 038-224/5

EExterior Driver Warning

Sign (English / French /

Spanish)

0.7 lb 0.32 kgF

S

3 1 782-371 Control Rod 7 lb 3.2 kg

ITEM # 5 - CONTROLS (OPTIONAL)

1

TLC24-A

See Sec 10.0

Automatic Lights Communication

Package (optional)

5 lb 2.27 kg

TLC24-M

See Sec 10.0

Manual Lights Communication

Package (optional)

1032-461 Exterior Traffic Light (optional) 1.3 lb 0.6 kg

1038-759E Operation Placard — —

ITEM # 4 - HARDWARE INCLUDED:

QTY PART NO. DESCRIPTION APPROX. WEIGHT

6010-108 5/8" dia. x 6" / 152mm Anchor

Wedge .15 lb .06 kg

1035-288 Mounting Bracket — —

ITEM # 5 - COMPONENTS

QTY PART NO. DESCRIPTION APPROX. WEIGHT

1038-538E ML10 Owner's Manual — —

1038-759E Operation Placard — —

OPTIONAL

CONTROLS

*NOTE: For sign specifications, see section 7.7

WARNING

TLC24-A TLC24-M

OUTSIDETRAFFIC

LIGHTSTATUS

INSIDECOMMUNICATION

LIGHTS& CONTROL STATION

ENGAGE RESTRAINT

Activate the ML10 by using the control rod to

press down on the engagement arm until the

restraint arm is in the fully vertical position,

holding the ICC bar in place.

TLC24-A: The control station light will turn

GREEN and the outside trafc light will turn

RED.

TLC24-M: Turn the key switch to the

‘Interlocked’ position (green LED). The

outside trafc light changes to RED while

GREEN light on the control station comes on.

TLC24-A TLC24-M

OUTSIDETRAFFIC

LIGHTSTATUS

INSIDECOMMUNICATION

LIGHTS& CONTROL STATION

OPPOSITE

SIDE

NOTE: The truck / trailer is NOT restrained if the arm is not fully vertical and

the communication lights do not change colour as described above. Do a visual

inspection to conm that the ICC bar is securely restrained before proceeding with

loading / unloading.

OPERATING INSTRUCTIONS

Only for the ML10 and TLC24-A (Automatic) or TLC24-M (Manual)

1. Only trained and authorized personnel may operate this vehicle

restraint.

2. Read, understand, and follow the instructions on this document and

included manual

3. Prior to using the vehicle restraint:

• Ensure that the vehicle restraint is free and clear of all debris, snow,

and ice.

• Ensure that all personnel near the vehicle restraint are aware that it

is being operated.

• Operate the vehicle restraint through one complete cycle to conrm

that it is functioning properly.If the vehicle restraint is equipped with

a communications package, conrm that the lights are working as

required.

• Inspect unit for signs of structural damage or mechanical

malfunction. If damage is observed or the restraint fails to operate

properly,remove it from service and notify maintenance personnel

immediately.

4. Before attempting to restrain a transport vehicle:

• Ensure that the vehicle is parked rmly against the dock bumpers.

• If the dock leveler is equipped with a light communication package,

load and unload on green only.

• Do not exceed the rated capacity as indicated on the serial plate.

• Do not leave equipment or material unattended on the dock leveler.

• Keep a safe distance from both edges.

• If either the dock leveler or vehicle restraint fail to operate as

outlined in the accompanying manual’s operating instructions, refer

to the Troubleshooting section.

5. If service or maintenance is required:

• Only authorized service personnel shall maintain or service the

units.

APPLIES TO ALLDOCK LEVELER AND VEHICLE RESTRAINT

COMBINATIONS

RELEASE RESTRAINT

After loading / unloading has been completed

and the dock leveler is safely parked, release

the restraint arm by pulling up on it quickly

and rmly using the control rod. The arm will

return to the parked position.

TLC24-A: The control station light will turn

RED and the outside trafc light will turn

GREEN.

TLC24-M: Turn the key switch to the ‘No

Trafc’ position (red LED). The outside trafc

light changes to GREEN and the control

station light turns RED.

038-759Ewww.BlueGiant.com

NOTE: If the ICC bar is applying pressure to the restraint arm, it may be necessary

to have the driver back up the vehicle before releasing the arm.

1 611222120 1612

4

3

25

23

18

18

26

27

19

24

20 21

7

8

13

5

17

2

14

15

9

10

23

29

28

16

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

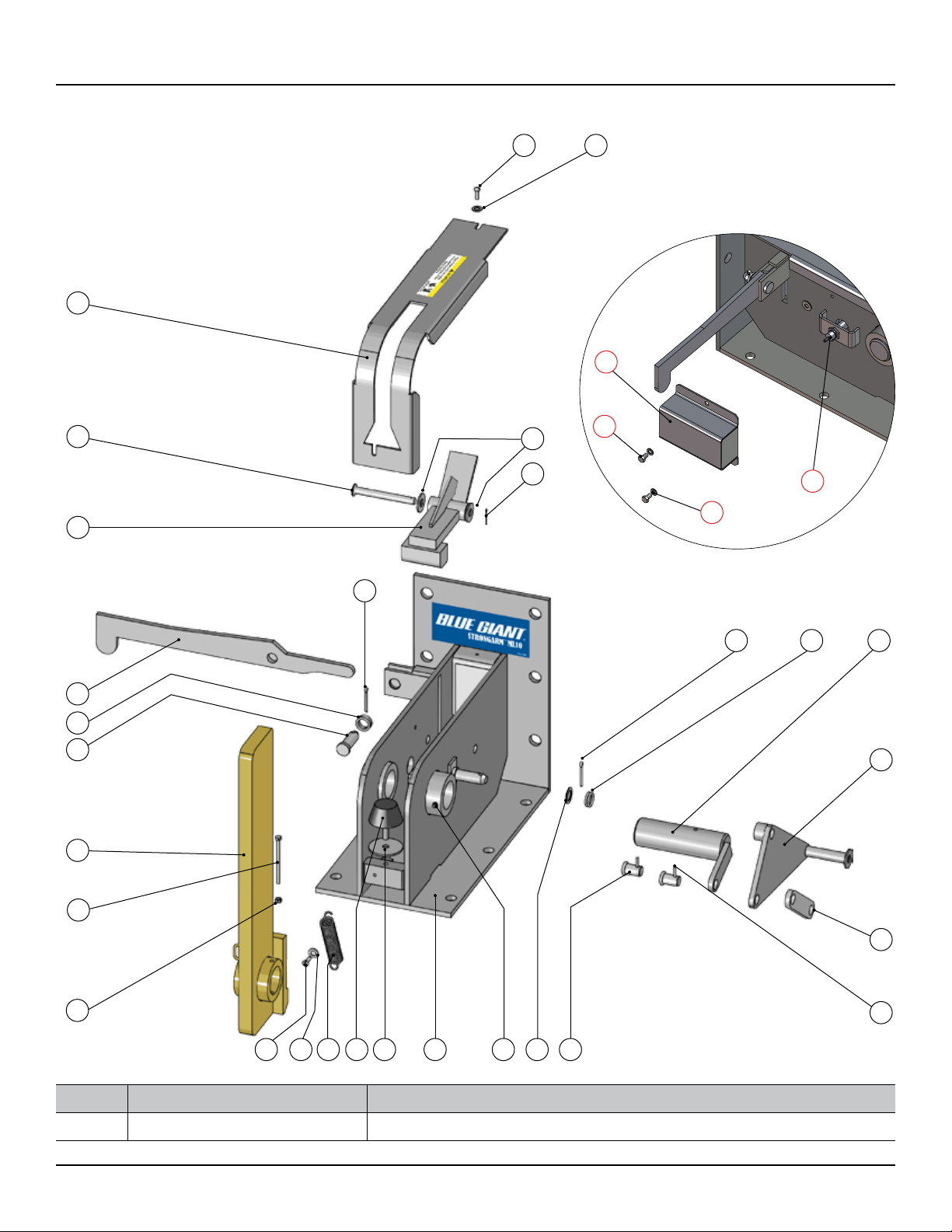

9.2 MECHANICAL ASSEMBLY - 52-011130

OPTIONAL: AUTOMATIC LIGHT PACKAGE

NOTE PART NO. DESCRIPTION

52-011131 Automatic light package includes parts highlighted

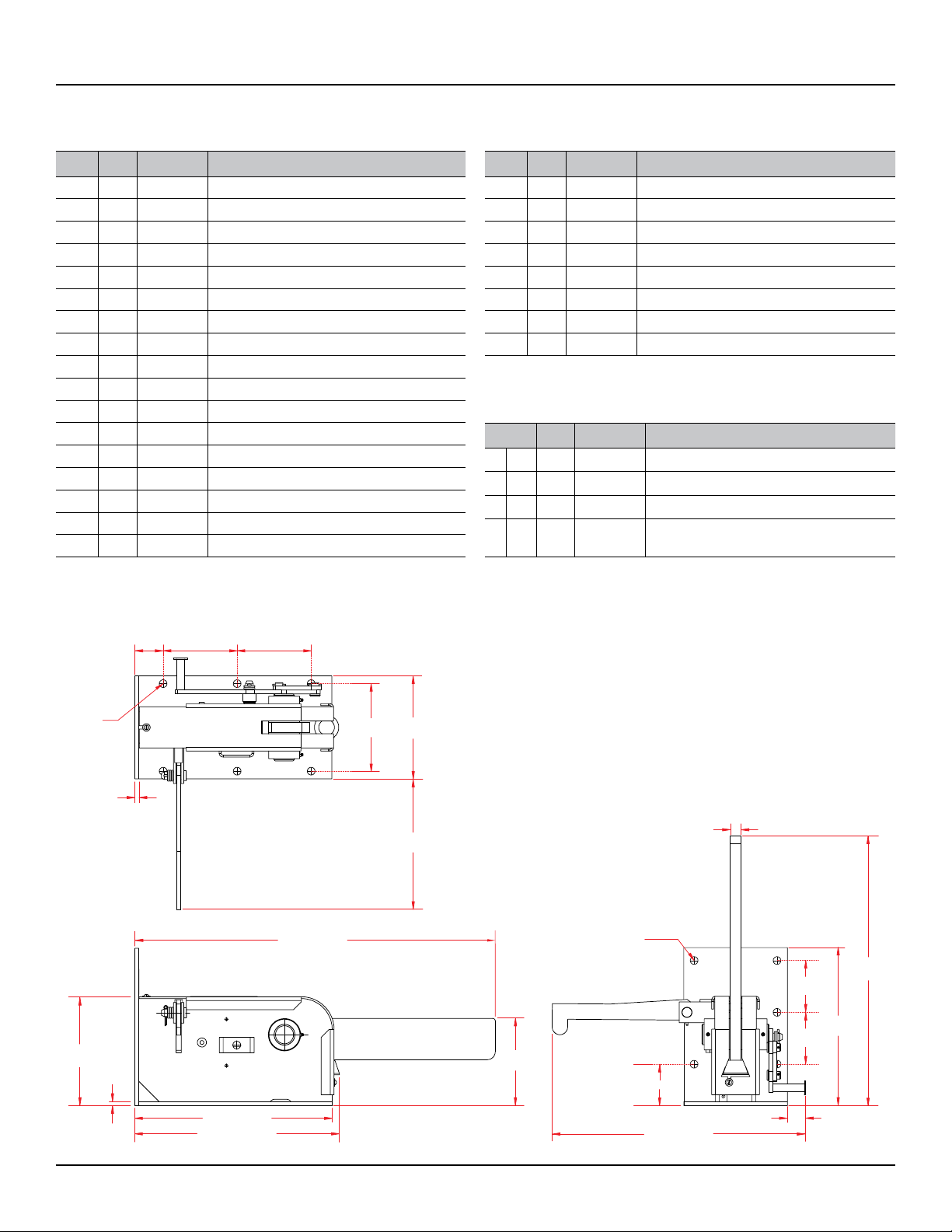

8 3/8"

(213mm)

10 1/2"

(267mm)

19 13/16" (503mm)

19 1/8" (486mm)

3/8"

(10mm)

33 5/8" (854mm)

15 1/4"

(387mm)

26"

(660mm)

5"

(127mm)

4" (101mm)

1" (25.4mm)

24.3" (618mm)

6 x 3/4" Ø

(19mm)

5"

(127mm)

10"

(254mm)

8 1/2"

(216mm)

12 3/4"

(323mm)

3/8"

(10mm)

2 3/4"

(70mm)

7 3/16"

(183mm)

6 x 3/4" Ø

(19mm)

7 3/16"

(183mm)

1 1/2"

(38mm)

17

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

9.2 MECHANICAL ASSEMBLY - 52-011130

AUTOMATIC LIGHT PACKAGE MECHANICAL

ASSEMBLY - 52-011131 (INCLUDES PART # 52-011130)

ITEM QTY PART NO. DESCRIPTION

18 2 013-025 Cotter Pin 3/16" x 1 ½" (38mm)

19 1 013-018 Cotter Pin 3/32" x 1" (25mm)

20 2 011-020 Round Head Slotted Screws (U.S.)

21 2 012-211 Flat Washer Type B Narrow 3/8"

22 1 017-012 Tension Spring

23 5 106-046 Ring, Split

24 3 012-212 Washer, Zinc-Plated ½"

25 1 105-879 Flat Washer ¾" x 1-3/16" x 1/16"

ITEM QTY PART NO. DESCRIPTION

26 1 52-011115 Sensor Cover

27 2 010-036 Cap Screw 5/16-18 x 1/2 HH GR. 5 ZC

28 2 012-200 Spring Lock Washers 5/16"

29 1 028-212 Proximity Sensor 18mm w/ 5m cable + 2

jamb nuts

ITEM QTY. PART NO. DESCRIPTION

1 1 52-011160 Body Weldment

2 1 52-012731 Restraint Arm 26" (660mm)

3 1 522-5005 Shaft Arm Pin

4 1 522-5006 Engagement Arm Weldment

5 1 522-0010 Actuator Linkage

6 2 119-278 Pivot Pin

7 1 522-5001 Lock Weldment

8 1 210-0005 Lock Roller Pin Assembly

9 1 522-0000 Release Arm

10 1 107-196 Clevis Pin

11 1 107-046 Washer Spacer

12 1 091-041 Rubber Bumper

13 1 52-011187 Truck Latch Cover

14 1 011-141 Cap Screw ¼" - 20 x 3 ½"(89mm) HH

15 1 011-506 Nuts Hex ¼" - 20 PLTD

16 2 019-500 Nipple Straight Grease ¼"

17 2 013-066 5/32" dia. Spring Pin 5/32" x 1 1/4" (32mm)

9.3 GENERAL DIMENSIONS

18

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

RESTRAINT

ARM IN HOME

POSITION

TLC24-A

TLC24-A

TLC24-M

TLC24-M

DOCK LEVELER

LIP PARKED

10.0 OPERATING INSTRUCTIONS - STRONGARM™ ML10 WITH TLC24 CONTROLS (AUTOMATIC & MANUAL)

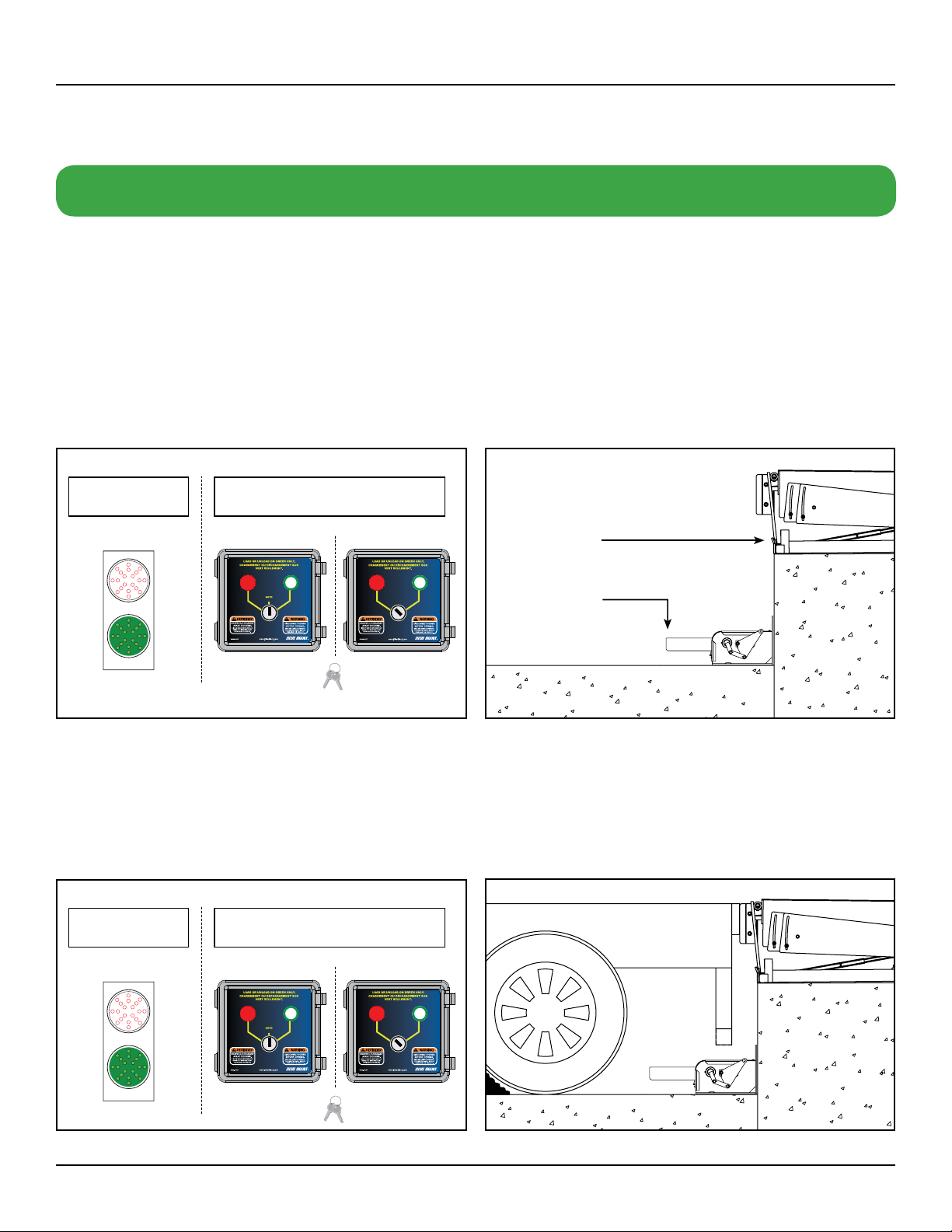

10.1 PRIOR TO USE: EQUIPMENT IN HOME

POSITION

The restraint apparatus is in the home position and the dock leveler

lip is parked safely in the lip keepers.

OUTSIDE TRAFFIC

LIGHT STATUS

OUTSIDE TRAFFIC

LIGHT STATUS

INSIDE COMMUNICATION

LIGHTS & CONTROL STATION

STANDARD OPERATION PROCEDURES

INSIDE COMMUNICATION

LIGHTS & CONTROL STATION

AUTOMATIC MANUAL

The TLC24-M has interior and exterior LED light signals (red / green) that are manually controlled to communicate safety conditions to

both dock workers and truck drivers. The TLC24-A, when operating in automatic mode, detects the position of the interlocked restraint

or dock lip via a sensor, allowing the lights to automatically change according to the relevant safety conditions. It may also be operated

in manual mode if necessary.

10.2 TRAILER AT BAY

The truck reverses into position against the dock leveler bumpers.

The outside traffic light is GREEN and the control station light

is RED. Chock the wheels and release the air from the air ride

suspension system (if applicable).

19

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

10.3 ENGAGING RESTRAINT

Activate the ML10 by using the control rod to press down on

the engagement arm until the restraint arm is in the fully vertical

position, holding the ICC bar in place.

TLC24-A: The control station light will turn GREEN and the outside

traffic light will turn RED in auto mode.

TLC24-M: Turn the key switch to the 'Interlocked' position (green

LED light). The outside traffic light changes to RED while GREEN

light on the control station comes on.

NOTE: The truck / trailer is NOT restrained if the arm is not fully

vertical. Do not switch the TLC24-M to green until you have

confirmed the restraint arm is fully deployed and locked in.

TLC24-A TLC24-M

OUTSIDE TRAFFIC

LIGHT STATUS

INSIDE COMMUNICATION

LIGHTS & CONTROL STATION

PERFORM LOADING AND UNLOADING

10.4 RELEASING THE RESTRAINT ARM

After loading / unloading has been completed and the dock leveler

is safely parked, release the restraint arm by pulling up on it quickly

and firmly using the control rod. The arm will return to the parked

position.

TLC24-A: The control station light will turn RED and the outside

traffic light will turn GREEN in auto mode.

TLC24-M: turn the key switch to the 'No Traffic' (red LED light)

position. The outside traffic light changes to GREEN and the

control station light turns RED.

NOTE: If the ICC bar is applying pressure to the restraint arm, it

may be necessary to have the driver back up the vehicle before

releasing the arm.

TLC24-A TLC24-M

OUTSIDE TRAFFIC

LIGHT STATUS

INSIDE COMMUNICATION

LIGHTS & CONTROL STATION

OPPOSITE SIDE

20

STRONGARM™ ML10 VEHICLE RESTRAINT—OWNER’S MANUAL

ISSUE DATE: SEPTEMBER 29, 2014 REV.0 (PART # 038-538E)

OVERRIDE FEATURES

OUTSIDE TRAFFIC

LIGHT STATUS

INSIDE COMMUNICATION

LIGHTS & CONTROL STATION

LEVELER PARKED

IN HOME POSITION

Under these circumstances, a supervisor or designated authority

may operate the TLC24-A in manual override mode by using the

key switch to operate the lights manually.

10.5 MANUAL OVERRIDE MODE (TLC24-A)

Situations may arise that require the TLC24-A to be operated

manually. For example:

• ThetruckICCbarisbent,damaged,ormissing

• Theinterlocksensorisbrokenorotherwiseinoperable

REASON AND OPERATION OF KEYS

• Supervisorusage

• Automodeisstandard

• Keysrequiredtoswitchselectortoanyothermode/position

Table of contents

Other Blue Giant Jack manuals