Blue Giant ML10 Series Operating instructions

ML10 SERIES

MECHANICAL VEHICLE RESTRAINT SYSTEM

DO NOT INSTALL, OPERATE OR SERVICE THIS PRODUCT UNLESS YOU HAVE READ AND

FULLY UNDERSTOOD THE ENTIRE CONTENTS OF THIS MANUAL. FAILURE TO DO SO MAY

RESULT IN PROPERTY DAMAGE, BODILY INJURY OR DEATH.

INSTALLATION & OWNER’S MANUAL

Mechanical Vehicle Restraint System Issue Date: October 26, 2009. (Part# 038-538E) Rev.2

ML10 SERIES

TABLE OF CONTENTS

1. ABOUT THE ML10 MECHANICAL VEHICLE RESTRAINT 1

1.1 Owner’s Purchase Record 1

2. INTRODUCTION 2

2.1 Exclusion of Liability 2

2.2 Manufacturer's Note 2

3. OPERATOR’S MANUAL SAFETY MESSAGE COLOR IDENTIFICATION 3

3.1 Identifying Safety Warning Labels And Serial Plate Specifications 3

4. INSTALLATION INSTRUCTIONS 4

4.1 Installation Inspection 4

5. OPERATING INSTRUCTIONS 5

5.1 Engage Restraint 5

5.2 Disengage Restraint 5

6. MAINTENANCE 6

6.1 Planned Maintenance 6

6.2 Operator Maintenance and Care 6

6.3 Operator’s Daily Checklist 7

7. TROUBLESHOOTING 8

8. MECHANICAL COMPONENTS- STANDARD 9

9. MECHANICAL COMPONENTS- OPTIONAL 10

ABOUT THE ML10 MECHANICAL VEHICLE RESTRAINT

The Blue Giant ML10 Mechanical Vehicle Restraint is a high performance yet low cost solution for loading

docks worldwide. Its many features and benefits include:

• A restraining power of 30,000 lbs (13,636 kg).

• A broad horizontal restraining range of 0” to 12” (305mm).

• Services transport vehicles with ICC bars from 11” to 29” (279 mm to 737 mm) above ground level.

• Restraint Arm constructed from 1” (25 mm) solid steel.

• Minimal maintenance requirements.

• Single detachable control rod allows dock attendant to operate the ML10 safely and efficiently.

The system can be upgraded to include an Automatic Lights Communications System for added safety at the

loading dock.

Dealer:

Date in Service:

Number of Units:

Serial Number(s):

Door # :

OWNER’S PURCHASE RECORD

Please record information for future inquiries

The manufacturer offers a full line of dock levelers, dock safety equipment, accessories, ergonomic and scissor lift

equipment, and industrial trucks. Concurrent with a continuing product improvement program, specifications are subject

to change without notice. Please contact the manufacturer for latest information. Some features illustrated may be

optional in certain market areas.

1. 1 OWNER’S PURCHASE RECORD

MECHANICAL VEHICLE RESTRAINT SYSTEM

1

Loading Dock Equipment Manufacturers

A Product Section of Material Handling Industry of America,

A Division of Material Handling Industry

8720 Red Oak Blvd., Suite 201, Charlotte, NC, 28217-3992

Telephone: (704) 676-1190 Fax: (704) 676-1199

ALSO MEMBERS OF :

American National Standards Institute (ANSI)

1430 Broadway

New York, NY 10018

(212) 642-4900

LOADING DOCK EQUIPMENT MANUFACTURERS

2. INTRODUCTION

The following is a quick reference to important procedures that must be followed while using the Vehicle Restraint

System. It is not intended to cover, or suggest that it does cover, all procedures necessary to ensure safe operation. All

operators should be aware of and abide by all workplace safety regulations applicable to the operation of the Vehicle

Restraint System. These laws and regulations include but are not limited to:

• The Occupational Safety and Health Act (USA)

• Occupational Safety and Health Acts for Individual States (USA)

• Canadian Material Handling Regulations

For additional information on these regulations as well as industry standards that may apply to this product, please

contact:

The manufacturer assumes no liability for damage or injury to persons or property which occur as a result of defects or

faults in or incorrect use of Vehicle Restraint System. The manufacturer also assumes no liability for lost profits,

operating downtimes, or similar indirect losses incurred by the purchaser. Injury to third parties, irrespective of its

nature, is not subject to compensation.

The manufacturer reserves the right to make changes at any time to the modules, components, and accessories,

concurrent with its continuing product development program. Specifications, operating instructions, and illustrations

included in this manual are subject to change without notice. Please contact manufacturer for the latest information.

MANUFACTURER’S NOTE

The Vehicle Restraint has been carefully inspected and tested at the manufacturer’s plant prior to shipment, but should

be checked upon receipt for transport damage.Any observed transport damage is to be listed on the signed copy of the

freight document. Notify the freight forwarder of any damage WITHIN 48 HOURS.

2.2 EXCLUSION OF LIABILITY

2.3 MANUFACTURER’S NOTE

Thank you for purchasing Blue Giant products. We appreciate your business, and are confident that our product will

serve you for many years to come. In the event that you experience a problem with our product, our Warranty Center

is here to support the Blue Giant Product(s) that you have purchased.

To validate warranty on recently purchased equipment, please complete and submit your information with our on-line

Warranty Registration at www.BlueGiant.com.

For more information about Blue Giant's Warranty Support, please contact your local Blue Giant Equipment dealer,

representative or authorized partner near you. You may also visit www.BlueGiant.com or phone 1-905-457-3900.

* Note that failure to validate warranty at the time of receipt can seriously affect the outcome of any claim.

2.1 WARRANTY INFORMATION

MECHANICAL VEHICLE RESTRAINT SYSTEM

2

3.1 OPERATIONAL SAFETY WARNINGS

.

3. OPERATOR’S MANUAL SAFETY MESSAGE COLOR IDENTIFICATION

CRUSH HAZARD.

Keep Hands and Feet away from

operating space of the Restraint Arm.

This manual includes color-coded safety messages that clarify instructions and specify areas where potential hazard

exists. To prevent the possibility of equipment damage and serious injury or death, please observe strictly the

instructions and warnings contained in the messages. If warning decals become damaged or missing, replace them

immediately. Avoid accidents by recognizing dangerous procedures or situations before they occur.

Serious injury or death will likely occur if the instructions are

not followed. Procedures marked IMPORTANT must be followed in order to

prevent damage to machinery.

Serious injury or death may occur if the instructions are not

followed. Instructions marked CAUTION concern safe operating

procedure. Failure to comply may result in personal injury.

1. Installation must be performed only by trained and

authorized personnel.

2. Prior to installation, place adequate barriers to prevent

vehicle traffic from entering the work area.

3. Use caution when unbanding the Vehicle Restraint.

Keep hands and feet clear of pinch points and wear

appropriate safety attire.

4. During installation, anchors must be properly torqued to

achieve the necessary anchoring strength. DO NOT USE

IMPACT DRIVERS.

5. Any electrical work must be performed by qualified

personnel only.

6. Do not remove the wheel chocks until loading /unloading

is finished and the truck is cleared for departure or the

Vehicle Restraint has been released and the lights have

changed to RED inside and GREEN outside.

1. Do not ground welding equipment to any electrical

components.

2. Do not allow the drill to go too deeply into the control

box, as damage may occur to the control systems.

3. Never use air to blow debris from the control box. Use a

vacuum to perform any necessary cleaning.

4. Do not connect green ground lead into control box or

junction box until all welding has been completed.

5. If an extension plate / box is required, securely mount it

on the Restraint with hardware provided before shimming

and drilling.

6. Improper adjustments and / or lubrication may cause

operational problems with equipment.

1. Only trained personnel should operate or service this equipment.

2. Do not operate the Restraint until the transport vehicle is parked against the dock bumpers.

3. Always return the Restraint Arm to the released position after use.

4. Conduct routine inspections and maintenance. Failure to do so could cause equipment damage and or personal injury.

5. Always call your authorized service representative or manufacturer immediately if a malfunction occurs.

1. Do not operate the Vehicle Restraint while anyone is standing in its path.

2. Lift the Vehicle Restraint with suitable hoisting equipment only. Do not stand under

the Restraint or any heavy object while it is being hoisted.

MECHANICAL VEHICLE RESTRAINT SYSTEM

3

4. INSTALLATION INSTRUCTIONS

1. Installation must only be performed by trained and authorized personnel.

2. Prior to installation, place adequate barriers to prevent vehicle traffic from entering the work

area.

3. Use caution when unbanding the Vehicle Restraint. Keep hands and feet clear of pinch points

and wear appropriate safety attire.

1. Prior to installation, clear away all debris and dirt from the

driveway and dock face where installation is to take place,

and perform a visual inspection of both areas.

2. To ensure maximum strength, install the Vehicle Restraint

on a poured concrete dock face and driveway. If

installation will be performed on cement block construction

or a poor concrete dock face, contact the manufacturer for

custom lag plates and/or lag anchors. Damaged asphalt

driveways should be replaced by a 6” (150mm) deep

concrete pad.

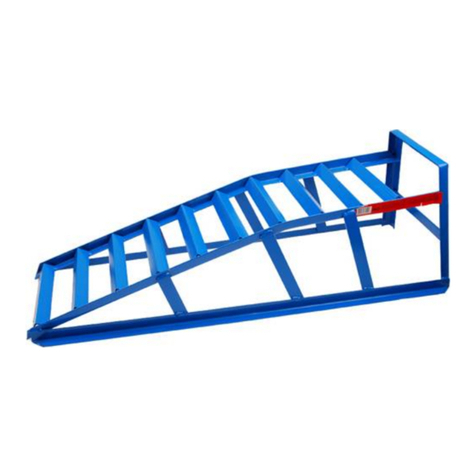

3. Using proper hoisting equipment, position the ML10 square

against the dock face and centered with the door opening.

4. Keep the Vehicle Restraint base-plate at a 90 degree angle

to the dock face and place a sufficient density of shims (not

supplied) between the driveway surface and the outer

edge of the base-plate. (See illustration at the bottom of

this page.) Shims must be a minimum 13” (326mm) x 6”

(150mm) in size and must be permanently welded together

to the base-plate. Note: If an extension plate / box is

required, securely mount it onto the ML10 with hardware

provided before shimming and drilling.

5. With the ML10 properly positioned, and using back-plate

as a template, drill six holes 5/8" dia. X 6" (15mm x 150mm)

deep, in the dock face concrete. After cleaning out the

holes, insert and permanently install anchors and lag bolts

supplied with the unit. Tighten securely.

6. When optional light package is included, mount the control

station c/w operating switch and communication lights

permanently onto an interior wall adjacent to the doorway

opening, at approx. 50" (1270mm) above floor level.

7. Mount the exterior signs (and communication lights, if

applicable) permanently onto the exterior wall

adjacent to the doorway at approx. 84" (2134mm)

above the driveway.

8. Securely mount the Operating Hazards placards

permanently onto an interior wall adjacent to the

control station in a location approx. 6 feet (1800mm)

above floor level. Confirm that the placard is clearly

legible to the operator.

9. When optional light package is included and conduits

were not poured-in with the concrete, install 1/2" dia.

(13mm) rigid conduit for (surface mounted) electrical

wires from the ML10 along the dock face, up and

through the wall, and up to the control station.

10. Install 1/2" dia. (13mm) rigid conduit from the control

station, through the wall to the exterior

communication lights.

11. Complete the electrical hook-up between the ML10

and control station, and exterior lights to control

station.

12. Remove the Release Arm from its vertical shipping

position on the ML10 and using the removed pin -

spacers - cotter pin, remount horizontally into the

same brackets in its working position.

13. Mount Hanger Bracket for Control Rod in the

appropriate location on interior wall adjacent to

ML10. Place the Control Rod in the bracket.

14. Review Installation Instructions and verify that all

work has been performed.

Clean up the entire work area and apply touch-up

paint to all welds, scratches and burns. Ensure that all

fasteners have been tightened and locked. Check that

all electrical conduits and wires are mechanically

protected against damage and are adequately

secured. Cycle test the ML10 several times. Ensure

that the lock is fully engaged when the Restraint Arm

is fully raised (vertical). Test operate theAutomatically

Actuated Communication Lights System (if

applicable). Replace all wiring diagrams into the

control box. Leave these instructions with the ML10

for use by the operator.

IMPORTANT

If an extension plate / box is required,

securely mount it on the hardware

provided before shimming and drilling.

Do not attempt to lift the ML10 without

suitable hoisting equipment. The

approximate weight of the Vehicle

Restraint is 180 lbs.

4.1 Final Inspection

MECHANICAL VEHICLE RESTRAINT SYSTEM

4

5. OPERATING INSTRUCTIONS

1. When the freight carrier reverses into position firmly

against the dock bumpers, activate the ML10 by using the

Control Rod to press down on the Engagement Arm until the

Restraint Arm is in the fully vertical position. Vehicle is not

restrained if the Restraining Arm is not fully vertical. If

Restraint is unusable, tires MUST be manually chocked.

2. Do a visual inspection to confirm that the vehicle under

ride guard is securely restrained before proceeding with

loading / unloading operation. For added safety, use wheel

chocks in addition to the Vehicle Restraint when operating in

manual override mode .

3. With vehicle secured, perform loading / unloading

operation.

1. When the loading / unloading operation is completed and all

personnel and equipment are clear of the vehicle, release the

ML10 by quickly and firmly by pulling up on the Release Arm

with the Control Rod. The RestrainingArm will return to the fully

lowered, horizontal position. (If the freight carrier is applying

pressure to the Restraining Arm, it may be necessary to have

the driver back up before the Restraining Arm can be

released.)

2. The vehicle departs and normal cycle is completed.

1

2

5.1 Engage Restraint

5.2 Disengage Restraint

MECHANICAL VEHICLE RESTRAINT SYSTEM

5

6. MAINTENANCE

PLANNED MAINTENANCE

In addition to the daily operator inspection, Blue Giant recommends (and government regulations may require) that a

planned maintenance and safety inspection program (PM) be performed by a trained and authorized mechanic on a

regular basis to keep your equipment in safe operating condition. The PM will provide an opportunity to make a thorough

inspection of the Vehicle Restraint’s operating condition.

Necessary adjustments and repairs can be done during the PM, which will keep components in good operating form,

reduce unscheduled downtime and increase safety. The procedures for a periodic planned maintenance program that

covers inspections, operational checks, cleaning, lubrication, and minor adjustments are outlined in this manual.

This manual is intended to be readily available. Keep it near the Vehicle Restraint as a ready reference for anyone who

may operate or service it.

OPERATOR MAINTENANCE AND CARE

It is the operator’s responsibility to check the Vehicle Restraint’s condition before use and make sure that it is safe to

operate. Perform a visual inspection of the Restraint and its major components. This includes the Light Communications

System, if used in conjunction with the Restraint.

If damage or maintenance problems are observed, either during an inspection or while operating the Vehicle Restraint,

a report must be made to a supervisor and repairs completed by qualified personnel before the unit is put back into

service.

6.1 Planned Maintenance

6.2 Operator Maintenance and Care

MECHANICAL VEHICLE RESTRAINT SYSTEM

6

INSTRUCTIONS FOR USE: Indicate “OK for Use” with a check mark ( ) in the

appropriate box of each inspection point.

Visually inspect the Vehicle Restraint and take note of obvious damage that may

have been caused by operation during the last shift.

Check that the Operating Hazards Placard is present in correct location and is

legible.

Inspect for damaged or missing parts, rust, corrosion, bent parts, cracks, etc.

Inspect operating controls to assure they are not missing, damaged or broken.

Clean away all foreign material such as parts of broken skids, etc. from area in

which the Vehicle Restraint is located.

Check for missing or damaged dock bumpers mounted on dock face.

Visually inspect the Vehicle Restraint for signs of structural damage or mechanical

malfunction as you operate the Vehicle Restraint throughout the day. Be alert to

abnormal sounds or operation.

Explain faults briefly in the space provided below.

INSPECTED BY: DATE:

Forward checklist to the person responsible for Vehicle Restraint maintenance.

6. MAINTENANCE

6.3 Operator’s Daily Checklist

MECHANICAL VEHICLE RESTRAINT SYSTEM

7

7. TROUBLESHOOTING

Do not attempt to install, make repairs or adjustments. Only a trained and authorized

service technician should perform the installation process.

Contact your local dealer or distributor for assistance.

PROBLEM CAUSE

PROBLEM

Restraining Arm will not

raise when the operator

pushes down on the

Actuating Arm.

1. Damaged Actuating Arm or Linkage.

2. Foreign material preventing movement of actuating arm or linkage.

3. Lack of lubrication at pivot points.

4. Operator needs to push down with more force.

Restraining Arm is not

reaching fully vertical

position.

1. Foreign material is preventing full movement of the actuating linkage.

2. ICC Bar on the transport vehicle is bent forward or otherwise undetectable by the

sensor.

3. The truck is not parked firmly and squarely against dock bumpers, causing the

Restraint Arm to contact the ICC Bar.

4. Damaged Actuating Arm or Linkage.

5. Lack of lubrication at pivot points.

6. Operator needs to push down with more force.

Restraining Arm raises to

full vertical position, but

does not lock.

1. Lock (internal component) is not lowering into its locked position. Foreign material

inside enclosure may be preventing normal movement of the lock.

Restraining Arm will not

lower when the operator

raises the Release Arm.

1. Lock is not released when Release Arm is raised. Pull the Control Rod up quickly

and sharply.

2. The freight carrier is applying pressure against the Restraint Arm and lock. Reverse

the vehicle firmly against the dock bumpers, and then operate the release arm quickly

and sharply.

3. Foreign material may be lodged inside enclosure, preventing lock from raising.

4. Damaged or broken actuating linkage may be preventing the Restraint Arm from

lowering.

5. Damaged or broken springs.

6. Lack of lubrication.

MECHANICAL VEHICLE RESTRAINT SYSTEM

8

9. MECHANICAL COMPONENTS- STANDARD

31

ITEM QTY PART NO. DESCRIPTION

1 1 522-5003C BODY WELDMENT

2 1 522-5004C LOCKING ARM ASSEMBLY

3 1 522-5005A SHAFT ARM ASSEMBLY

4 1 011-141 ¼-20 UNC. X 3.5 LG. HEX HEAD CAPSCREW

5

1

011-506

¼-20 UNC HEX NUT

6

1

091-041

BUMPER

7

2

019-500

¼” STRAIGHT GREASE NIPPLE

8

2

013-066

5/32” DIA. X 1-1/4’ SPRING PIN

9

2

013-025

3/16 DIA. X 1-1/2” LG. COTTER PIN

10

1

013-018

3/32 DIA. X 1” LG. COTTER PIN

11 1 522-5001A LOCK WELDMENT

12 1 017-012 TENSION SPRING

13 1 522-0000A RELEASE ARM

14 1 107-196 CLEVIS PIN

15 6 105-880 WASHER, SPACER ¾ X 1/8

16

1

782-391A

LOCK ROLLER SHAFT ASSEMBLY

17

1

522-0010

ACTUATOR LINKAGE

18

1

522-0010A

ACTUATING ROD

19

2

119-278

CLEVIS PIN

20

1

119-409A

BODY COVER

21

2

012-211

5/16 DIA. FLAT WASHER

22 2 011-020 ¼-20 UNC. X ¾ R/H SLOT MACHINE SCREW

23 1 038-064 DRIVER WARNING SIGN

24 1 107-046 WASHER

25 1 012-239 ½ I.D. X 1” O.D. X 1/8” WASHER

28 1 028-200 PROXIMITY SENSOR

29

1

52-003236

PROXIMITY HOLDER

30

1

52-003245

WAND CAM

31

1

782-371

CONTROL ROD

OPTIONAL FOR INTERLOCK SWITCH *

OPTIONAL FOR INTERLOCK SWITCH *

OPTIONAL FOR INTERLOCK SWITCH *

NOT SHOWN

NOT SHOWN

NOT SHOWN

NOT SHOWN

NOT SHOWN

MECHANICAL VEHICLE RESTRAINT SYSTEM

9

9. MECHANICAL COMPONENTS- OPTIONAL

ITEM QTY PART NO. DESCRIPTION

28 1 028-200 Proximity Sensor

29

30 1 52-003245 Wand Cam

32

PROTECTIVE COVER REMOVED FOR CLARITY

1119-722 Protective Cover (not shown)

28

29

30

152-003236 Proximity Holder

MECHANICAL VEHICLE RESTRAINT SYSTEM

10

NOTES

MECHANICAL VEHICLE RESTRAINT SYSTEM

11

NOTES

MECHANICAL VEHICLE RESTRAINT SYSTEM

12

NOTES

MECHANICAL VEHICLE RESTRAINT SYSTEM

13

85 Heart Lake Road South

Brampton, Ontario, Canada L6W 3K2

Phone : 905-457-3900 Fax : 905-457-2313

www.BlueGiant.com

BLUE GIANT EQUIPMENT CORPORATION

©2012 Blue Giant Equipment Corporation

if calling within North America:

Phone: 1-800-668-7078 Fax: 1-888-378-5781

Table of contents