To order parts and supplies: 800.343.9353 >> eastwood.com 7

DRAINING FLUID

• Remove the Inlet Adapter from the Inlet/Spout at the top of the Evacuator by pushing in firmly

and turning 15° Clockwise to unlock the latch.

• Grasp Knob and pull out to remove.

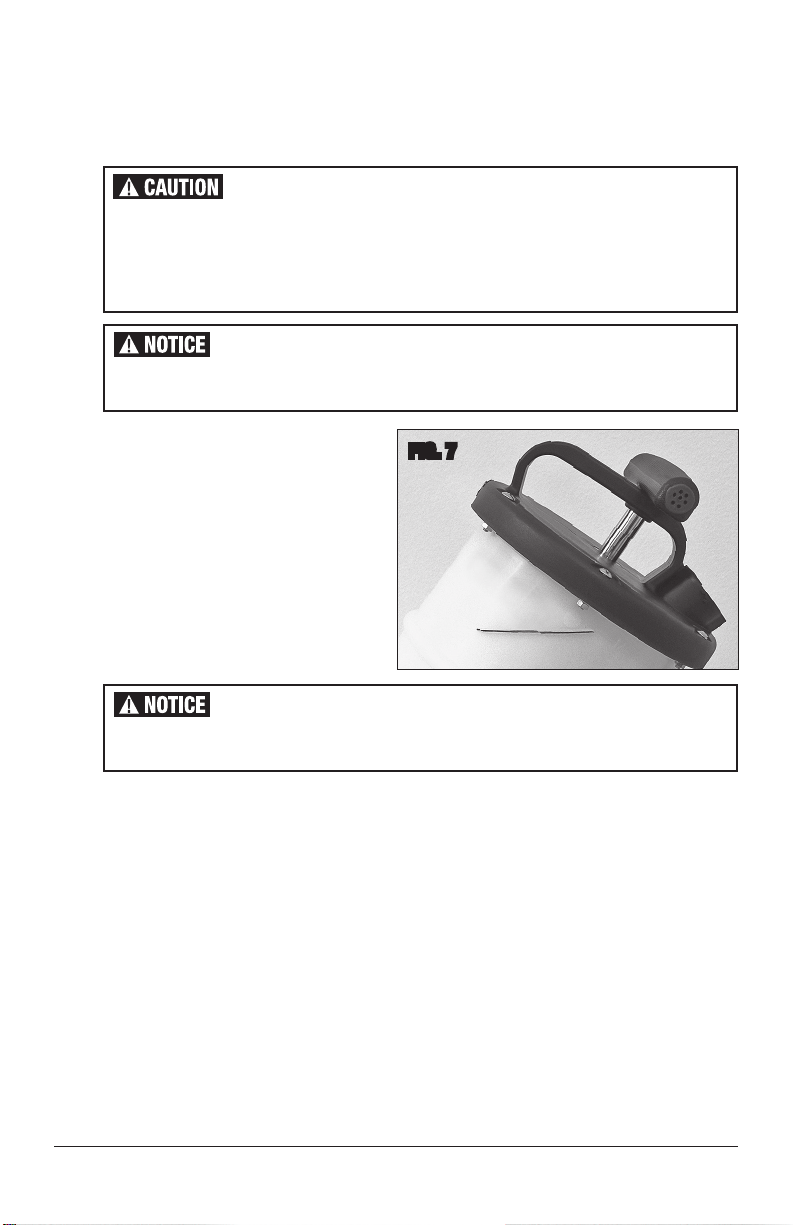

• Before proceeding to empty the Fluid

Canister, note the “Fluid Drain Limited

Line” molded into both sides of the Fluid

Canister (FIG 7). Allowing the fluid level

in the Canister to go above this line while

tilting the Canister to empty its contents

may allow fluid to escape through the

built-in Safety Valve.

• Tilt Evacuator Canister to allow accumu-

lated fluid to pour out of Spout.

MAINTENANCE

• DO NOT allow fluid to remain in Evacuator Canister.

• DO NOT use Evacuator Canister as a fluid storage vessel.

• Remove Nylon Tube or Silicone Hose when done, allow to drain fully then clean out by flushing

with a suitable solvent.

• If a clog in a Nylon Tube should occur, use the Tube Clog Clearing Wire by inserting into the end

of the tube and pushing until the material causing the clog is discharged.

EXPOSURE TO AUTOMOTIVE FLUIDS CAN BE A HEALTH HAZARD!

• Contents can splash into eyes. Be sure to follow all precautions listed

on fluid containers before using.

• Wear ANSI Z87.1 approved eye protection while using extractor.

• Wear appropriate chemical resistant gloves while handling fluids.

Used automotive fluids are hazardous materials and should be disposed of

in compliance with local regulations.

To avoid leakage from the built-in Safety Valve when draining fluid, DO NOT

allow fluid level in the Canister to exceed the “Fluid Drain Limited Line”.

FIG. 7