Blue Sky Energy - Solar Boost 3024(D)iL

1Blue Sky Energy | USA | www.blueskyenergyinc.com

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS .................................................................................................................. 2

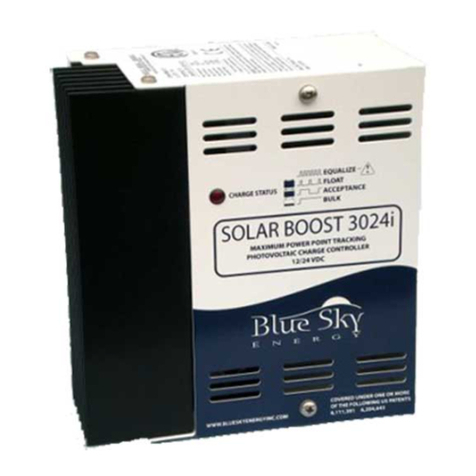

PRODUCT DESCRIPTION...................................................................................................................................... 3

Part Numbers and Options .................................................................................................................. 3

OPERATION ........................................................................................................................................................ 3

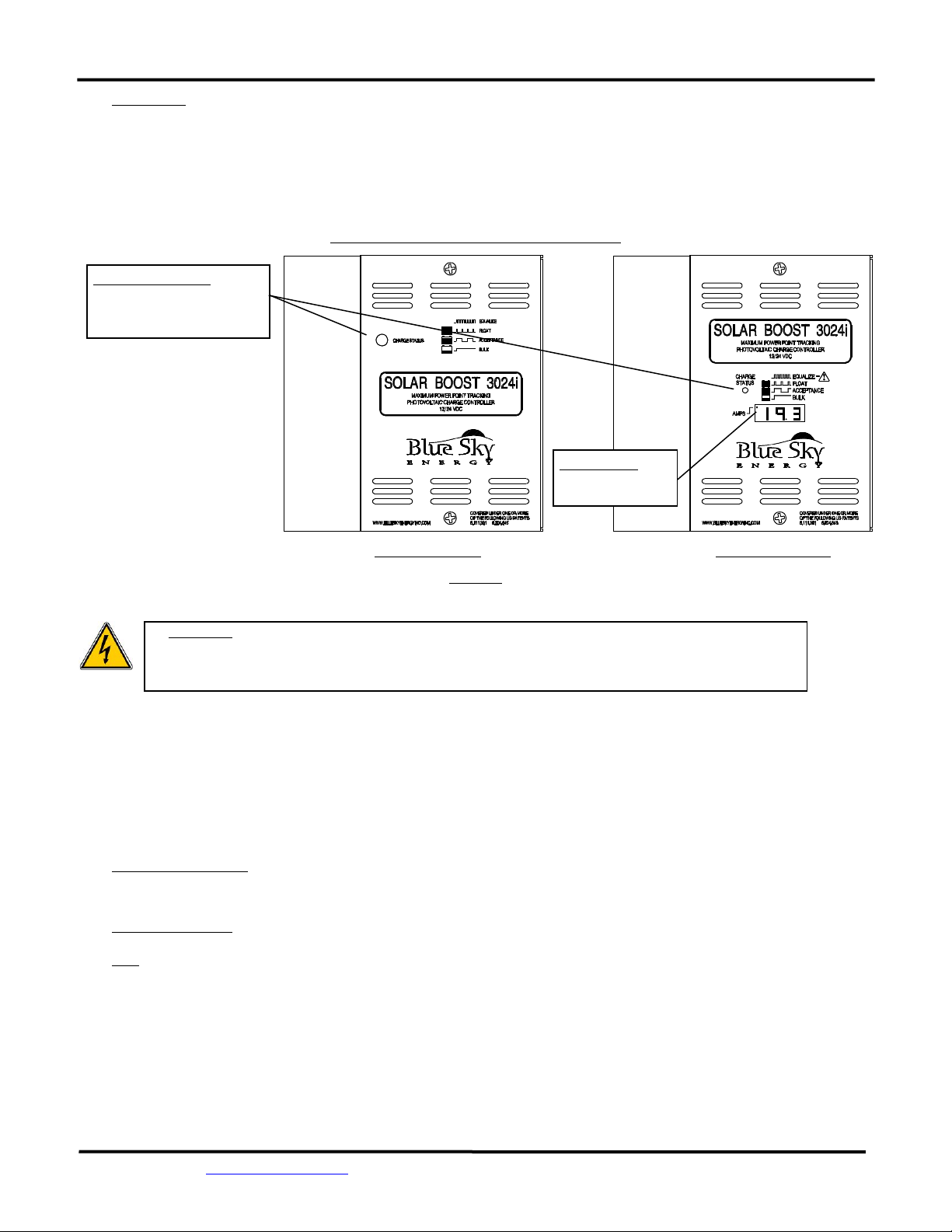

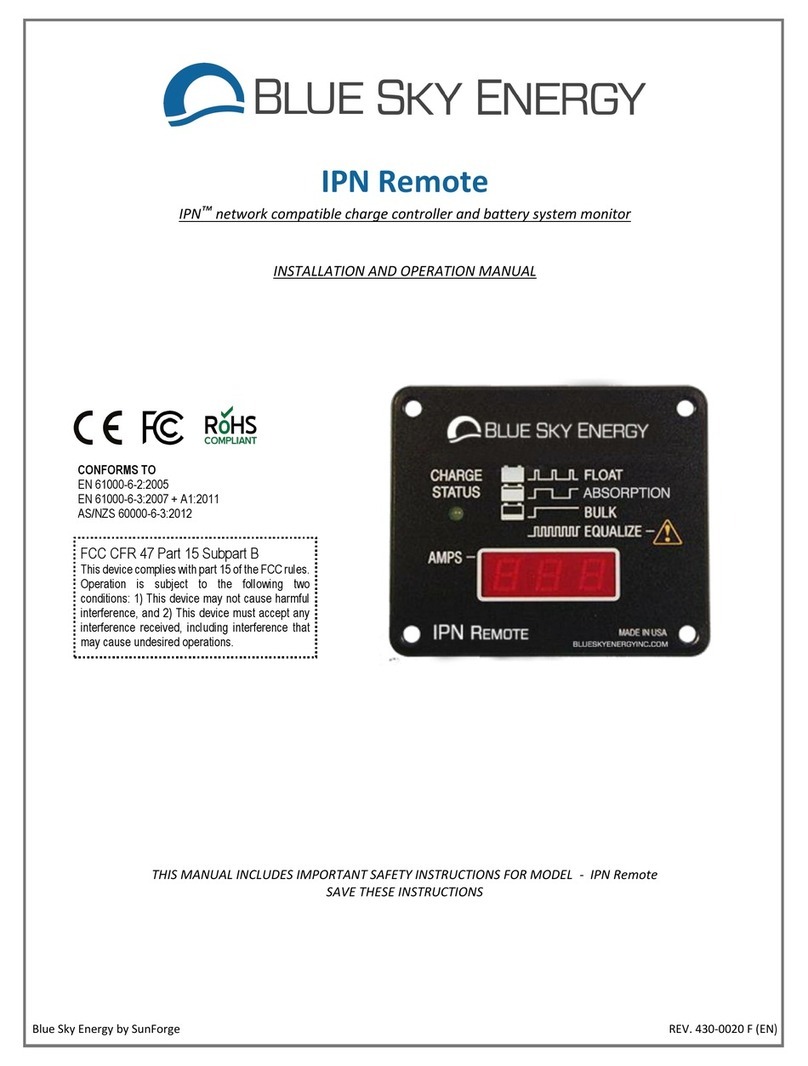

Charge Status Indicator........................................................................................................................ 4

Optional Digital Display........................................................................................................................ 3

Optional Remote Displays.................................................................................................................... 3

Multi-Stage Charge Control ................................................................................................................. 3

Bulk Charge .................................................................................................................... 3

Absorption (Acceptance) Charge ................................................................................... 3

Float Charge................................................................................................................... ..4

Equalization ......................................................................................................................................... 4

Automatic Equalization.................................................................................................. 4

Manual Equalization ...................................................................................................... 4

Current Limit........................................................................................................................................ 4

Temperature and Output Power ......................................................................................................... 4

Optional Temperature Compensation................................................................................................. 5

Maximum Setpoint Voltage Limit ........................................................................................................ 5

Maximum Power Point Tracking (MPPT) ............................................................................................. 5

Multiple Charge Controllers On The IPN Network ............................................................................... 5

INSTALLATION..................................................................................................................................................... 5

Electrostatic Handling Precautions ...................................................................................................... 5

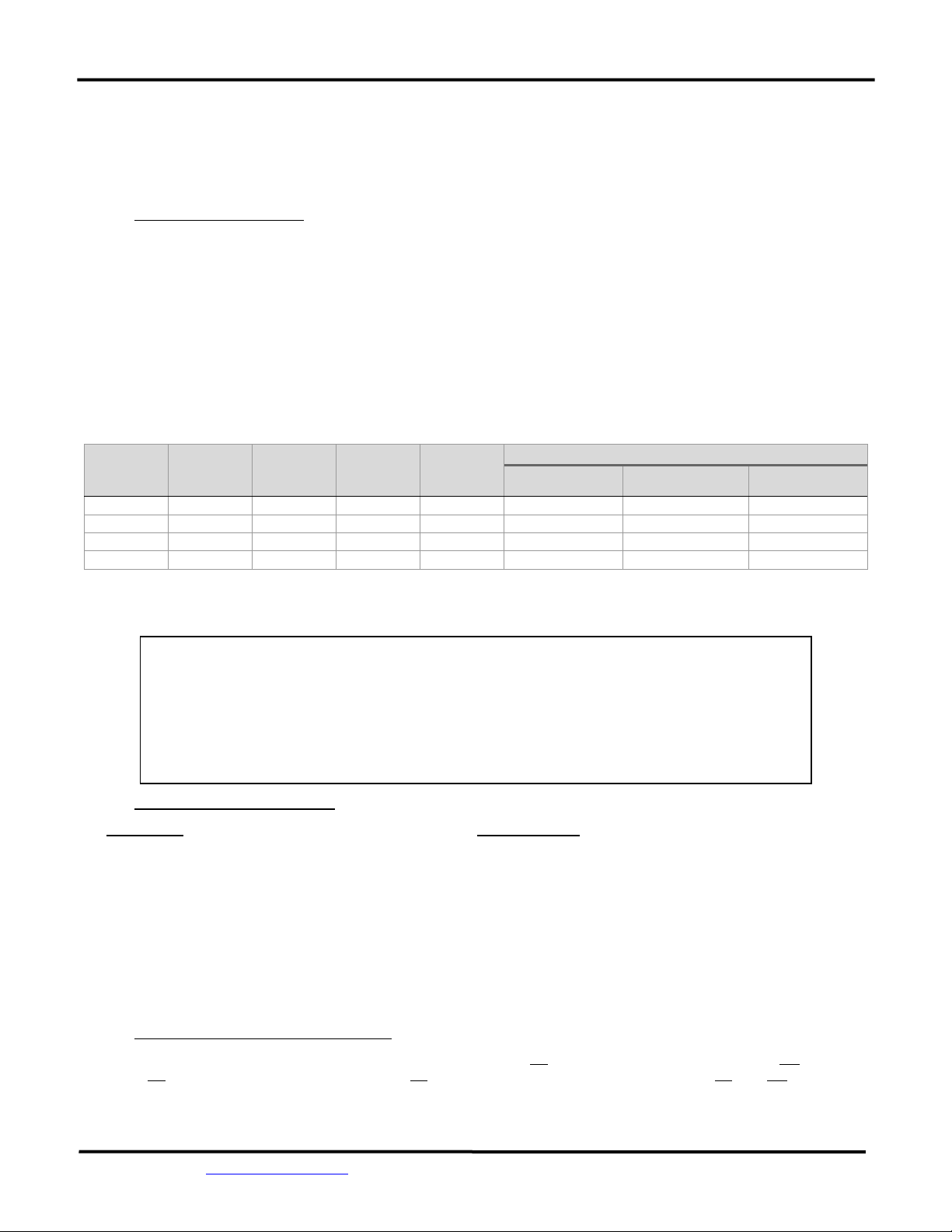

Selecting PV Modules .......................................................................................................................... 6

Solar Boost 3024i Setup....................................................................................................................... 6

As Shipped Factory Default Settings............................................................................... 6

Restoring As Shipped Default Settings ........................................................................... 6

Battery And PV Voltage.................................................................................................. 7

Charge Voltage, Float Voltage & Charge Time ............................................................... 7

Output Current Display .................................................................................................. 8

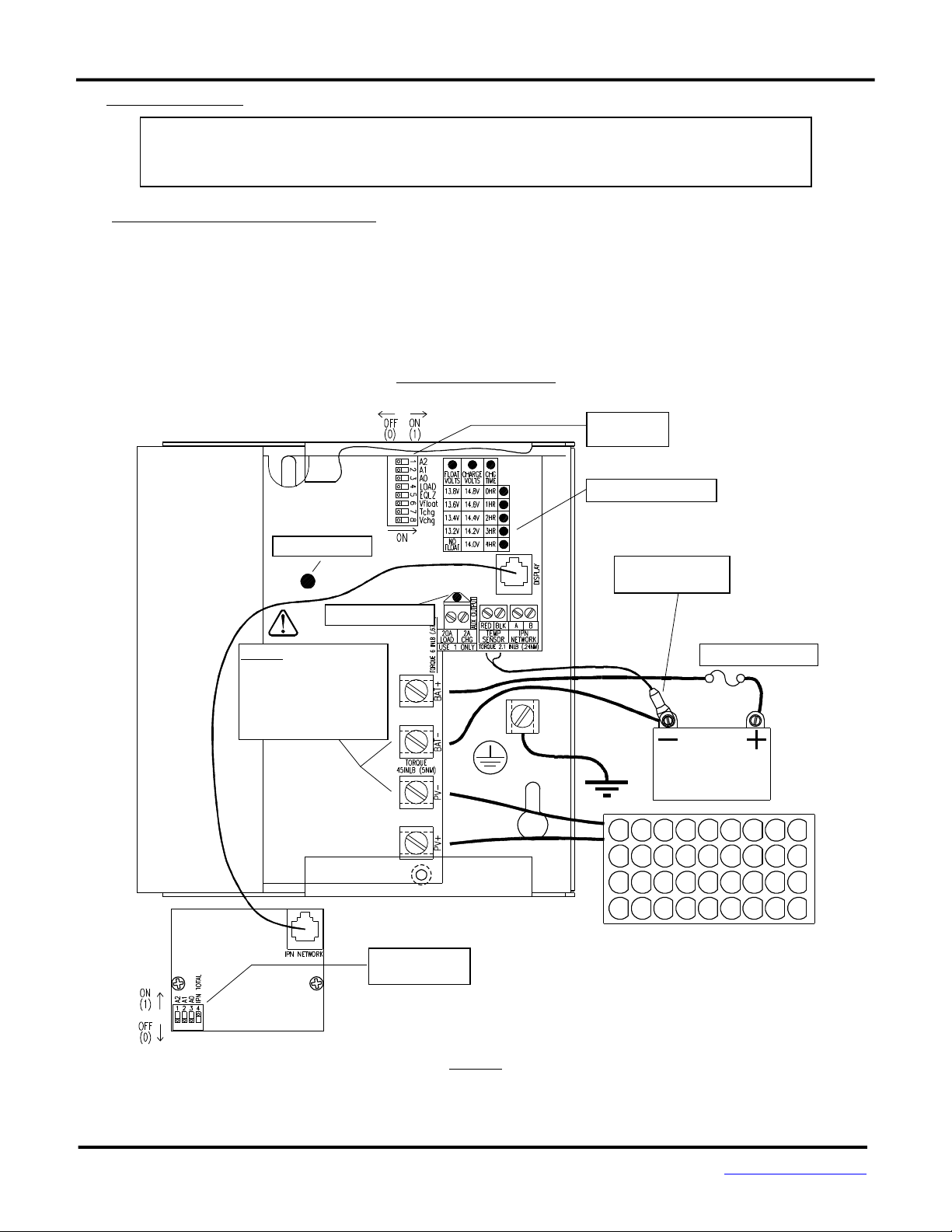

Battery and PV Wiring ......................................................................................................................... 8

Electromagnetic Compatibility............................................................................................................. 8

Battery Temperature Sensor ............................................................................................................... 8

Auxiliary Output................................................................................................................................... 8

Auxiliary Battery Charge................................................................................................. 9

Load Controller .............................................................................................................. 9

Dusk-to-Dawn Lighting Control...................................................................................... 9

Installing a Multi-Controller System .................................................................................................... 10

Multi-Controller Wiring And Setup ................................................................................ 10

IPN Network................................................................................................................... 10

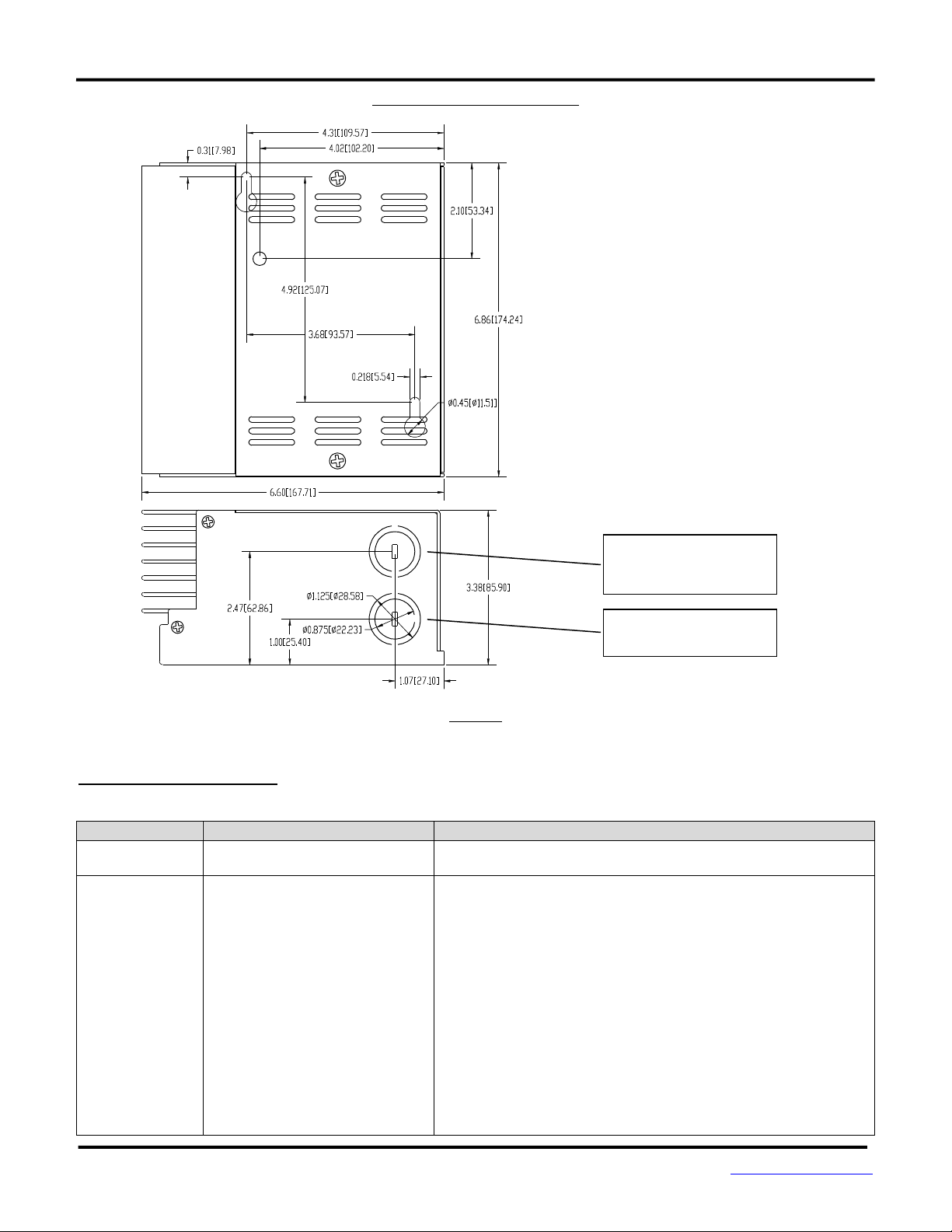

Mounting ............................................................................................................................................. 11

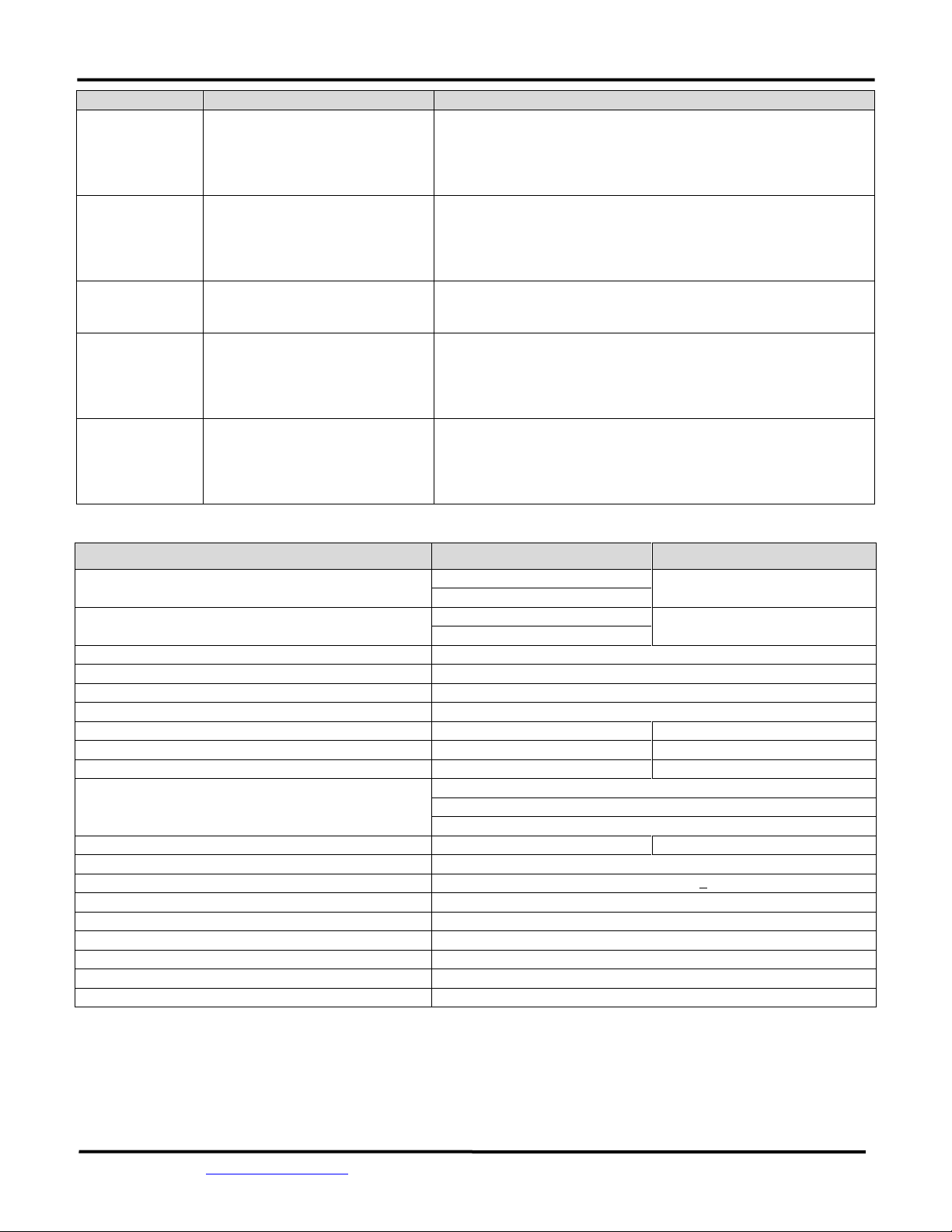

TROUBLESHOOTING GUIDE ................................................................................................................................ 12

SPECIFICATIONS .................................................................................................................................................. 14

TWO YEAR LIMITED WARRANTY ........................................................................................................................ 15

TABLES AND FIGURES

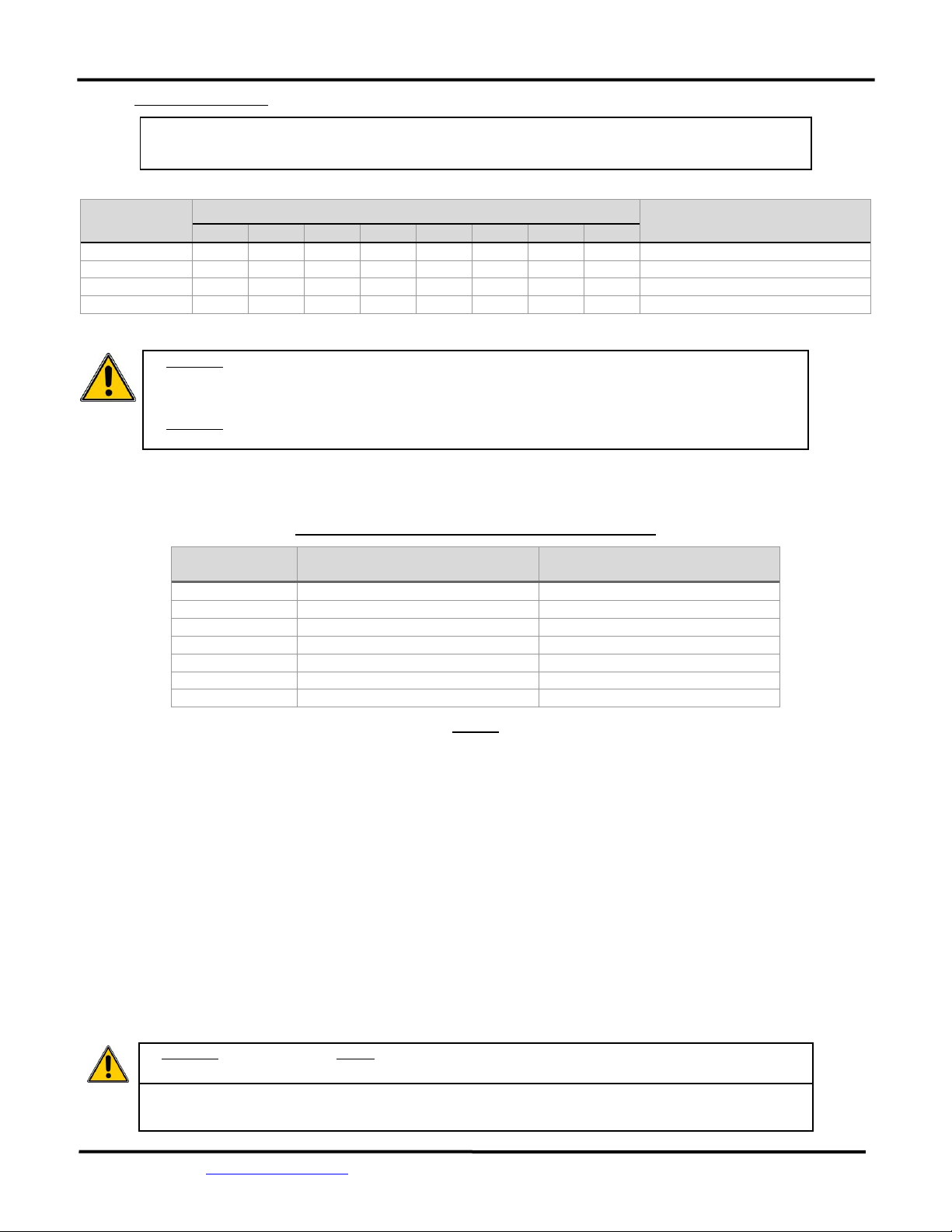

Table 1 Charge Status Indicator.................................................................................................. 3

Table 2 Maximum Conductor Length - 3% Voltage Drop............................................................ 8

Figure 1 Front Panel and Remote Display Indicators ................................................................... 4

Figure 2 Factory Charge Voltage Setpoint -vs.- Battery Temperature ......................................... 5

Figure 3 Setup and Wiring Diagram ............................................................................................. 7

Figure 4 Auxiliary Output Wiring.................................................................................................. 9

Figure 5 IPN Network Wiring ....................................................................................................... 10

Figure 6 Detailed Dimensional Drawing....................................................................................... 11