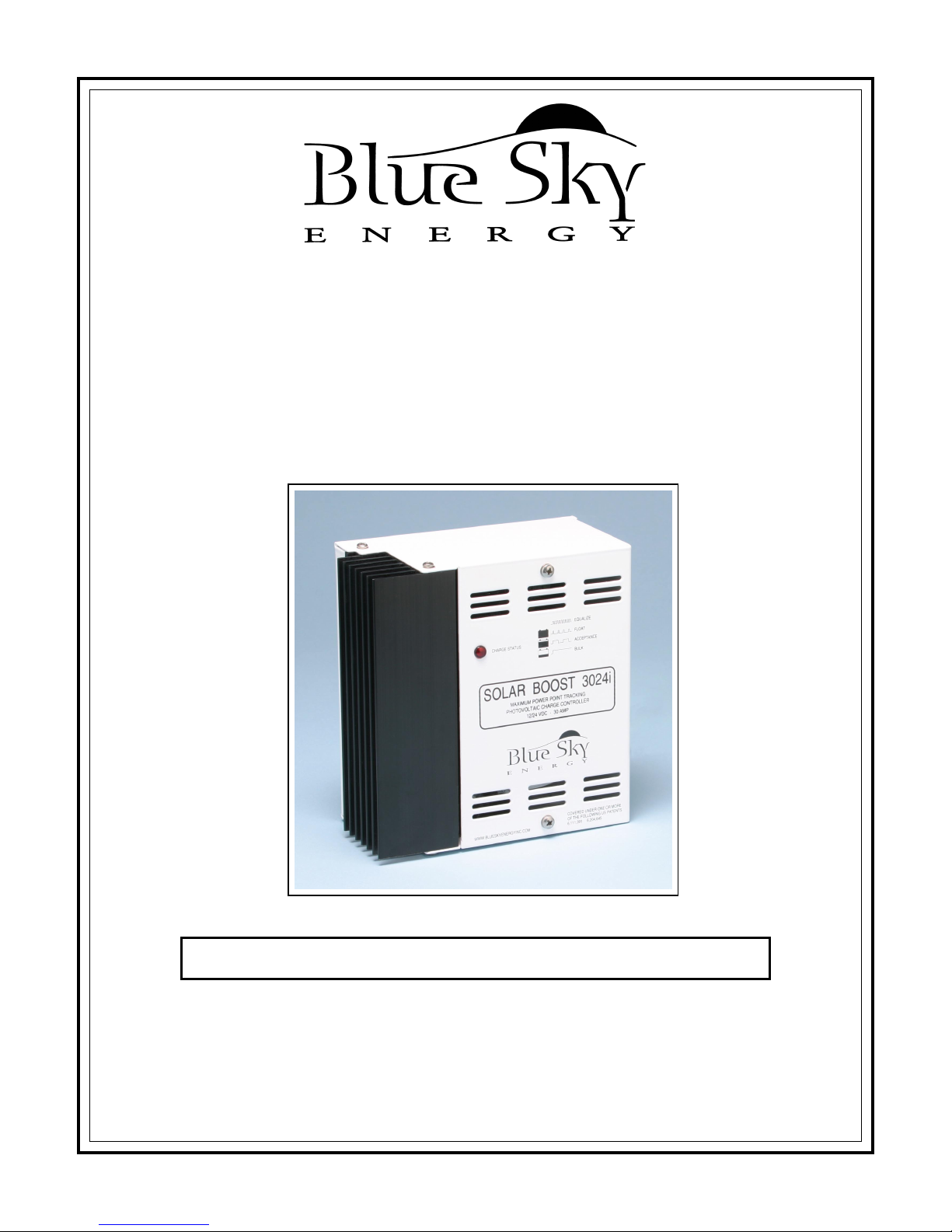

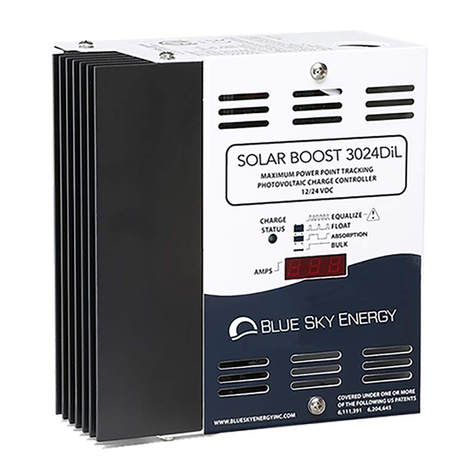

Blue Sky Energy SOLAR BOOST 3024i User manual

SOLAR BOOST™ 3024i

30AMP 12/24VDC MAXIMUM POWER POINT TRACKING

PHOTOVOLTAIC CHARGE CONTROLLER

INSTALLATION AND OPERATION

MANUAL

THIS MANUAL INCLUDES IMPORTANT SAFETY INSTRUCTIONS FOR

MODEL SB3024i. SAVE THESE INSTRUCTIONS.

COVERED UNDER ONE OR MORE OF THE FOLLOWING US PATENTS

6,111,391 •6,204,645

© Blue Sky Energy, Inc. 2005 430-0018 C

Blue Sky Energy - Solar Boost 3024i

1

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ............................................................................................. 2

PRODUCT DESCRIPTION .................................................................................................................. 3

Part Numbers and Options..................................................................................................... 3

OPERATION ........................................................................................................................................ 3

Optional Remote Displays...................................................................................................... 3

Charge Status Indicator ......................................................................................................... 4

Three Stage Charge Control .................................................................................................. 4

Bulk Charge........................................................................................................ 4

Acceptance Charge............................................................................................ 5

Float Charge....................................................................................................... ..5

Two Stage Charge Control..................................................................................................... 5

Equalization............................................................................................................................ 5

Equalize Time Accumulator ............................................................................... 5

Automatic Equalization....................................................................................... 5

Manual Equalization........................................................................................... 6

Optional Temperature Compensation.................................................................................... 6

Maximum Setpoint Voltage Limit............................................................................................ 6

Temperature and Output Power............................................................................................. 6

Maximum Power Point Tracking (MPPT)............................................................................... 6

How MPPT Works .............................................................................................. 7

Multiple Charge Controllers On The IPN Network ................................................................. 7

INSTALLATION ................................................................................................................................... 7

Over Voltage / Reverse Polarity Protection ........................................................................... 7

Electrostatic Handling Precautions ........................................................................................ 7

Solar Boost 3024i Setup ........................................................................................................ 8

Default Factory Settings..................................................................................... 8

Basic Settings..................................................................................................... 9

Advanced Settings ............................................................................................. 9

Restoring Default Settings ................................................................................. 9

Battery And PV Voltage...................................................................................... 9

Charge Mode...................................................................................................... 10

Acceptance Charge Voltage .............................................................................. 10

Float Charge Voltage ......................................................................................... 10

Acceptance Charge Time................................................................................... 10

IPN Network Address......................................................................................... 10

Battery and PV Wiring............................................................................................................ 11

24V Input / 12V Output........................................................................................................... 11

Battery Temperature Sensor.................................................................................................. 11

Auxiliary Output...................................................................................................................... 12

Auxiliary Battery Charge .................................................................................... 12

Load Controller................................................................................................... 12

Installing a Multi-Controller System ....................................................................................... 13

Multi-Controller Wiring And Setup...................................................................... 13

IPN Network ....................................................................................................... 13

Auxiliary Output In Multi-Controller Systems...................................................... 13

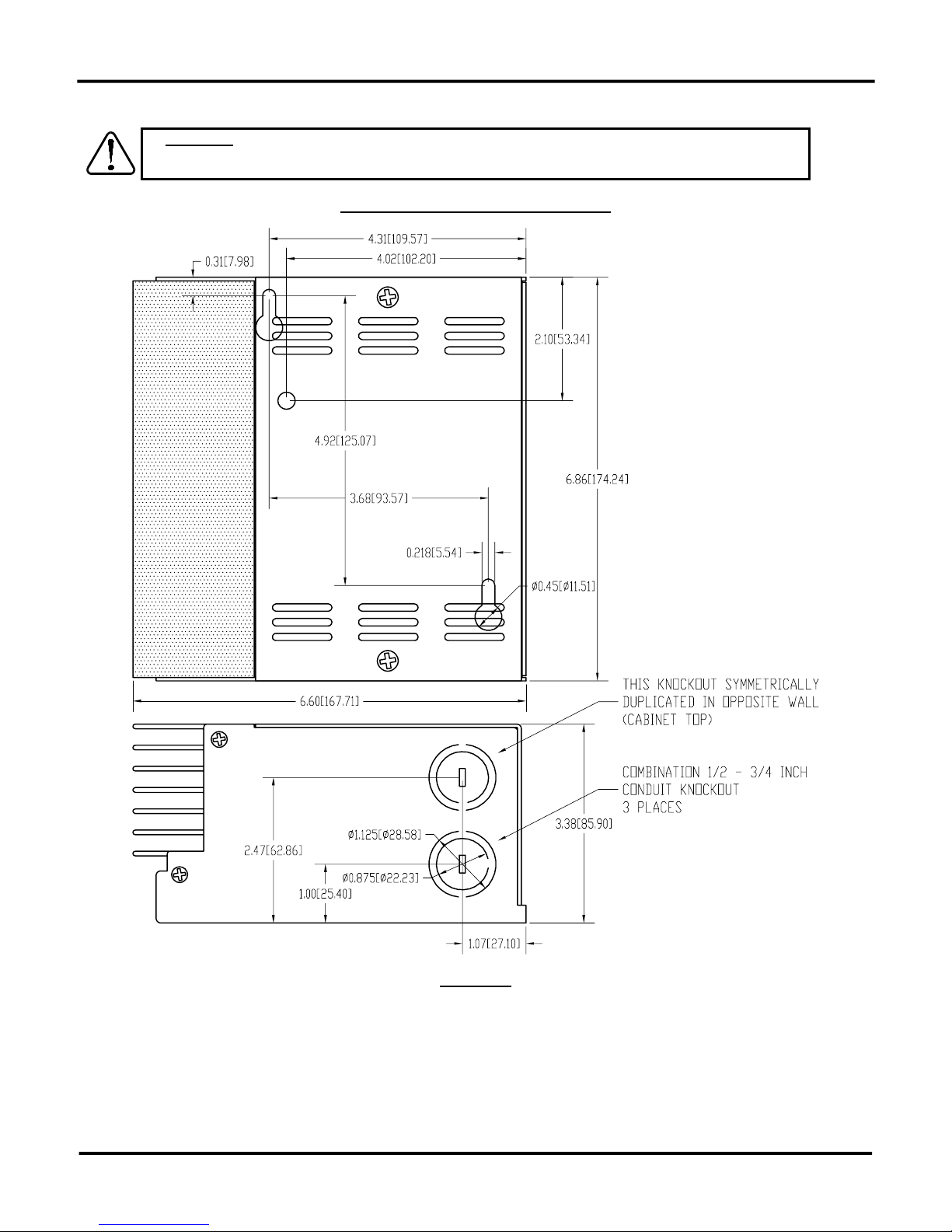

Mounting ................................................................................................................................ 14

TROUBLESHOOTING GUIDE............................................................................................................. 15

SPECIFICATIONS ............................................................................................................................... 17

TWO YEAR LIMITED WARRANTY..................................................................................................... 18

TABLES AND FIGURES

Table 1 Charge Status Indicator ..................................................................................... 4

Table 2 Maximum Conductor Length - 3% Voltage Drop................................................ 11

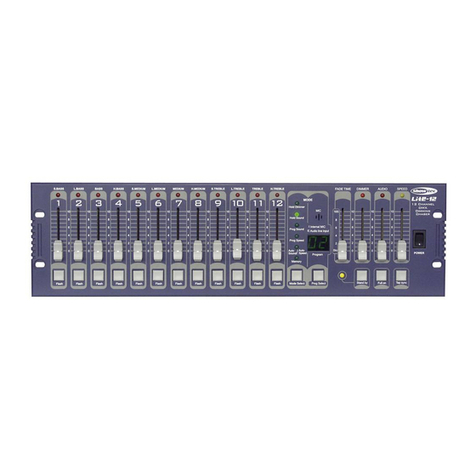

Figure 1 Front Panel and Remote Display Indicators....................................................... 4

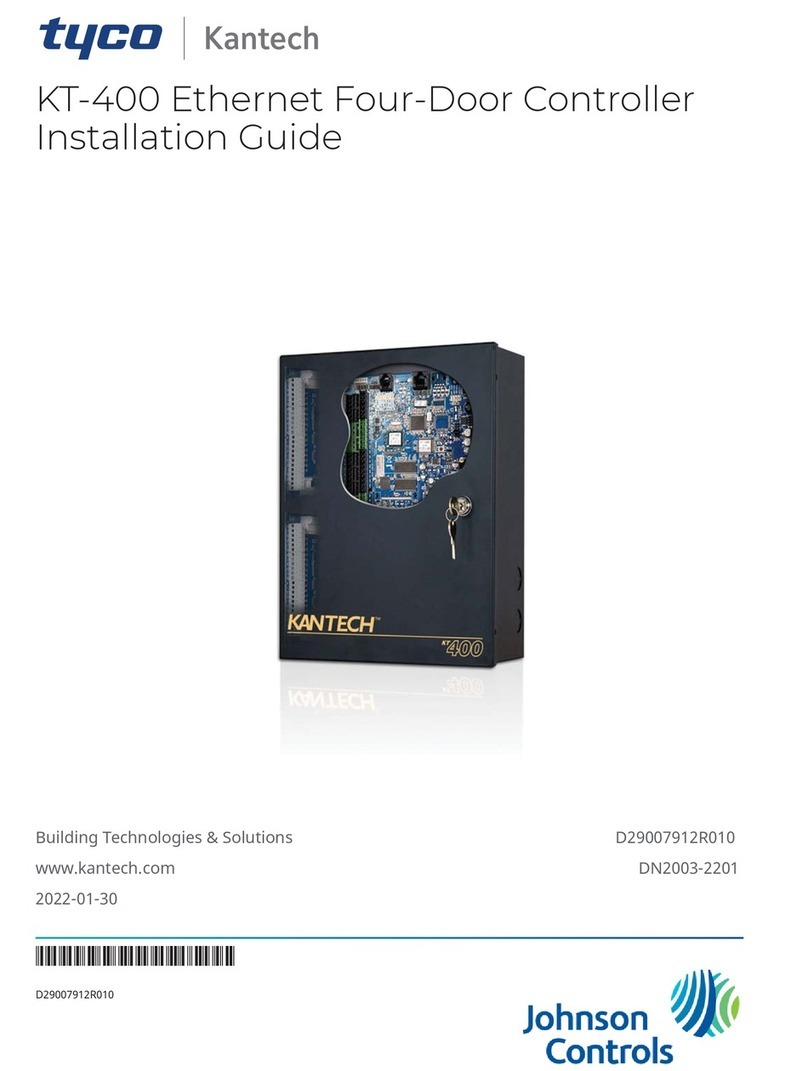

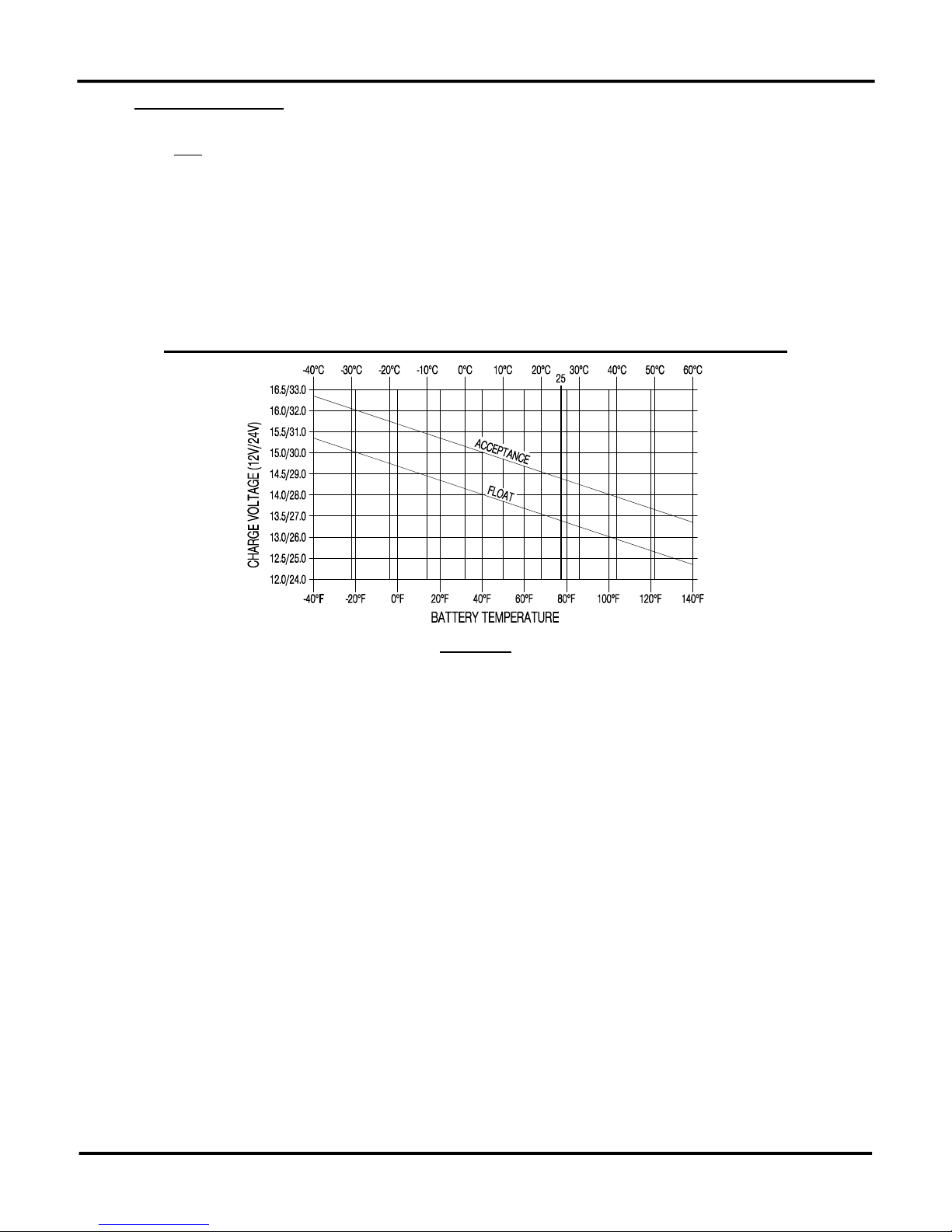

Figure 2 Factory Charge Voltage Setpoint -vs.- Battery Temperature............................. 6

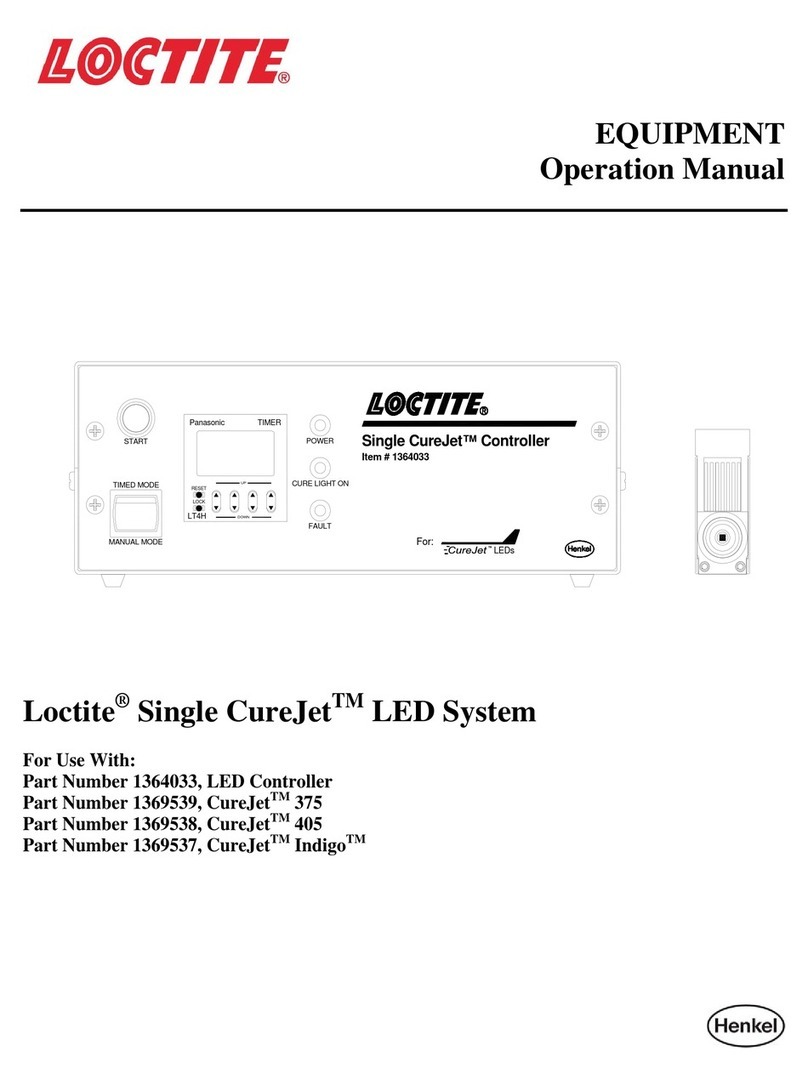

Figure 3 Setup and Wiring Diagram ................................................................................. 8

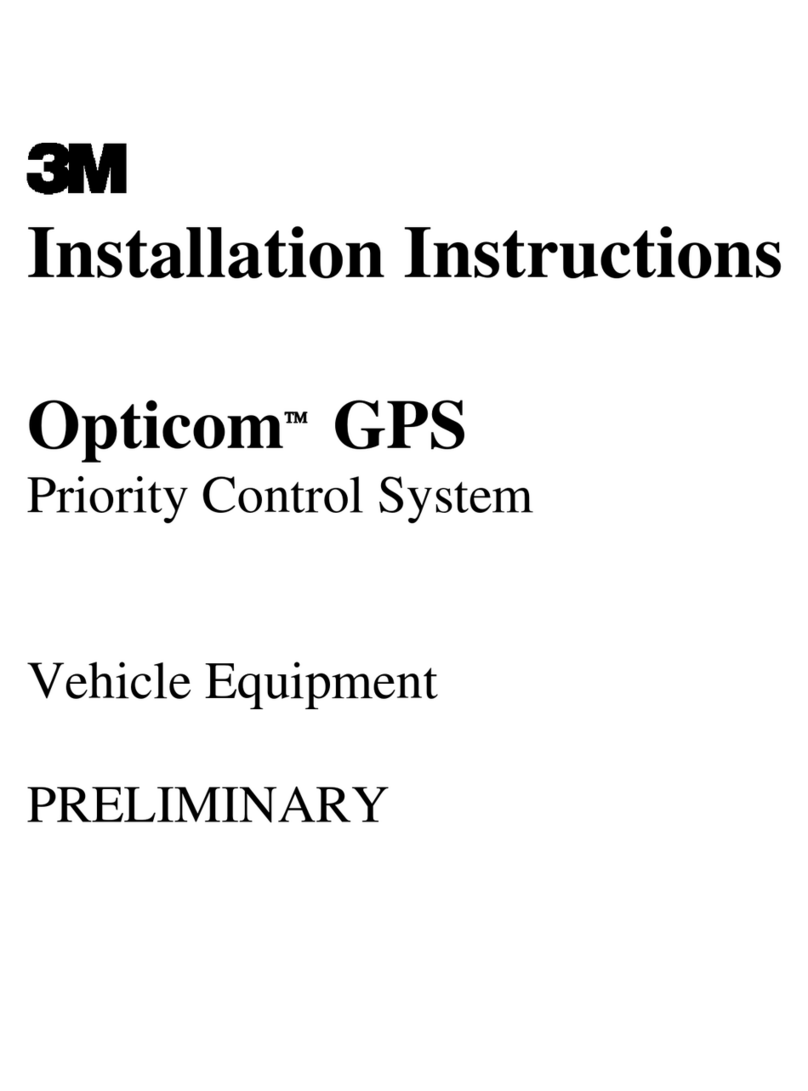

Figure 4 Auxiliary Output Wiring....................................................................................... 12

Figure 5 IPN Network Wiring ............................................................................................ 13

Figure 6 Detailed Dimensional Drawing ........................................................................... 13

Installation and Operation Manual

2

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important instructions for Model SB3024i

SAVE THESE INSTRUCTIONS

1. Refer installation and servicing to qualified service personnel. High voltage is present inside unit. Incorrect installation or use

may result in risk of electric shock or fire. No user serviceable parts in this unit.

2. To reduce the risk of electric shock, fire or personal injury, the following symbols are placed throughout this manual to indicate

dangerous conditions, or important safety or operational instructions.

WARNING CAUTION IMPORTANT

Indicates dangerous conditions or

electric shock potential. Use extreme

caution.

Indicates items critical to safe

installation or operation of the unit.

Follow these instructions closely for

proper operation of the unit

3. PERSONAL PRECAUTIONS

a) Working in the vicinity of lead-acid batteries is dangerous. Batteries produce explosive gasses during normal operation.

b) To reduce risk of battery explosion, follow these instructions and those published by battery manufacturer and manufacturer

of any equipment you intend to use in vicinity of battery.

c) Someone should be within range of your voice or close enough to come to your aid when you work near a lead-acid battery.

d) Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing or eyes.

e) Wear complete eye protection and clothing protection. Avoid touching eyes while working near battery.

f) If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters eye, immediately flood eye

with running cold water for at least 10 minutes and get medical attention immediately.

g) NEVER SMOKE or allow a spark or flame in vicinity of battery.

h) Be extra cautious to reduce risk of dropping metal tool onto battery. It might spark or short circuit battery or other electrical

part that may cause explosion.

i) Remove personal metal items such as rings, bracelets and watches when working with a lead-acid battery. A lead-acid

battery can produce a short circuit current high enough to weld a ring or the like to metal, causing a severe burn.

j) Remove all sources of power, photovoltaic and battery before servicing or installing.

4. CHARGER LOCATION & INSTALLATION

a) This unit is designed to charge flooded or sealed type lead-acid chemistry batteries. Follow battery manufacturers charging

recommendations when considering this unit for use with other battery chemistry, i.e., NiCd.

b) This unit employs components that tend to produce arcs or sparks. NEVER install in battery compartment or in the

presence of explosive gases.

c) This unit must be installed and wired in accordance with National Electrical Code, ANSI/NFPA 70.

d) Over current protection for the battery must be provided externally. To reduce the risk of fire, connect to a circuit provided

with 40 amperes maximum branch-circuit over current protection in accordance with National Electrical Code, ANSI/NFPA

70.

e) Over current protection for the auxiliary load control output or auxiliary battery charge output must be provided externally.

To reduce the risk of fire, connect to load or auxiliary battery with 25 amperes maximum over current protection in

accordance with National Electrical Code, ANSI/NFPA 70.

f) Insure that unit is properly configured for the battery being charged.

g) Unit is not water tight. Do not expose to rain or snow.

h) Insure all terminating connections are clean and tight. Battery and PV compression terminals are to be tightened to 45 in-lb

(5 nm). IPN Network and battery temperature sensor compression terminals are to be tightened to 2.1 in-lb (0.24 nm).

Auxiliary output compression terminals are to be tightened to 6 in-lb (0.67 nm).

i) Charging system must be properly installed as described in these instructions prior to operation.

j) Do not connect to a PV array capable of producing greater than 24 amps of short circuit current @ 25°C. Limit input short

circuit current to 12 amps if the 24V input 12V output mode is used.

5. PREPARING TO CHARGE

a) Never charge a frozen battery.

b) Be sure battery is mounted in a well ventilated compartment.

c) Add distilled water in each cell of a lead-acid battery until battery acid reaches level specified by battery manufacturer. This

helps purge excessive gas from the cells. Do not overfill. For batteries other than flooded lead-acid type, or sealed batteries

without cell caps, carefully follow manufacturers charging instructions.

Blue Sky Energy - Solar Boost 3024i

3

PRODUCT DESCRIPTION

Solar Boost™ 3024i a 30 amp 12/24 volt Maximum Power Point Tracking (MPPT) photovoltaic (PV) battery charge controller.

Through the use of patented MPPT technology, Solar Boost 3024i can increase charge current up to 30% or more compared to

conventional controllers. Solar Boost 3024i’s sophisticated three stage charge control system can be configured to optimize charge

parameters to precise battery requirements. The unit is fully protected against voltage transients, over temperature, over current,

reverse battery and reverse PV connections. An automatic current limit feature allows use of the full 30 amp capability without

worrying about overload or nuisance fuse blow from excessive current. An auxiliary output provides either voltage or amp-hour

based 20 amp load control, or can serve as a 2 amp auxiliary battery charger.

Series pass Pulse Width Modulation (PWM) charge voltage control combined with a multistage charge control algorithm leads

to superior charging and enhanced battery performance. The filtered PWM power control system uses highly efficient and reliable

power MOSFET transistors. The MOSFET’s are turned on and off at high frequency to precisely control charge voltage and MPPT.

An environmentally sealed high current high reliability relay is used to disconnect the PV array at night to prevent unwanted current

drain. A relay is used rather than blocking diodes for improved power conversion efficiency, current boost performance, and true

reverse battery polarity protection in an MPPT controller.

Fully automatic temperature compensation of charge voltage is available as an option to further improve charge control and

battery performance. The available battery temperature sensor is built for long term reliability. The sensor element is

environmentally sealed and encapsulated into a copper lug which mounts directly to the battery terminal.

The Solar Boost 3024i also includes an IPN Network interface. The IPN interface allows multiple IPN compatible charge

controllers to communicate with each other and operate as a single machine rather than separate charge controllers. The IPN

interface also provides connection to optional IPN compatible remote displays. The full featured IPN-ProRemote provides

enhanced charge controller setup, monitoring and control. It also provides a complete battery system monitor with amp-hour

counting and a highly accurate remaining battery capacity “fuel gage” type indicator.

PART NUMBERS AND OPTIONS

•SB3024i...............................Solar Boost 3024i controller

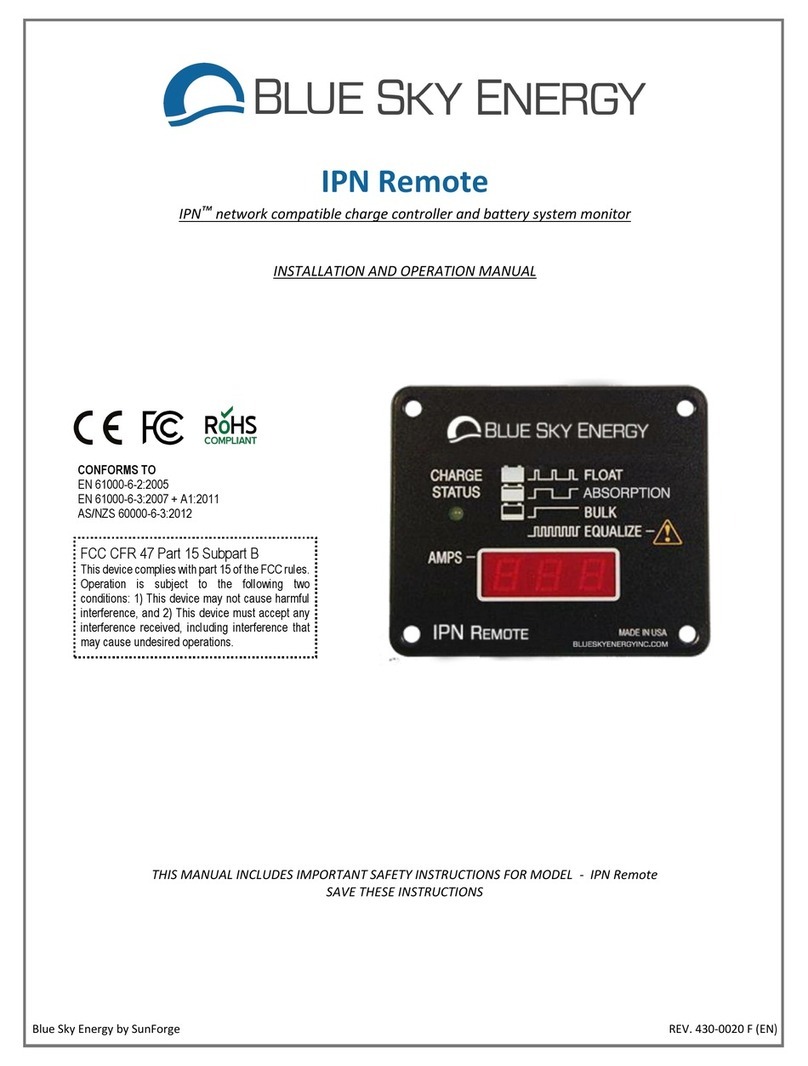

•IPNREMOTE.......................IPN-Remote, Low cost LED Bargraph IPN charge control monitor w/25’ cable

•IPNPRO ..............................IPN-ProRemote, Full featured IPN charge control and battery system monitor w/25’ cable

•IPNPRO-S...........................IPN-ProRemote with 500A/50mV current shunt

•CS-500 ................................500A/50mV current shunt

OPERATION

Once installed and configured, charge control and MPPT operations are fully automatic. Charge turns on whenever the PV

array is capable of producing ≈0.25 amps at 2V greater than battery voltage. When PV charge is on the Charge Status LED will

indicate the present charge mode, and indicate when the battery has become highly charged. At night when PV power

production stops, the PV array is disconnected from the battery to prevent unwanted current drain. Note that there is a 5 second

turn-on delay, and a 45 second turn-off delay.

¾The unit operates on battery power, not PV power. A battery must be connected with a minimum voltage

of 9V for the unit to operate.

OPTIONAL REMOTE DISPLAYS

Solar Boost 3024i uses an IPN compatible display which can monitor up to 8 charge controllers on a single IPN network.

There are two available displays, the very low cost IPN-Remote and the full featured IPN-ProRemote. The IPN-Remote is a basic

LED bargraph type voltage, current and charge mode display without setup or control capability.

The full featured IPN-ProRemote incorporates a multi-line backlit LCD display and three function keys to provide enhanced

setup and monitoring of IPN devices on an IPN network. The IPN-ProRemote provides the ability to access additional setup

parameters and adjust setup parameters to wider ranges that those available with the Solar Boost 3024i alone.

The IPN-ProRemote also provides complete battery system monitoring and eliminates the need for a separate battery

monitor. Some of the many displays provided include; battery voltage, net battery current, net battery amp-hours, highly accurate

battery capacity “fuel gage”, PV amp-hours, min/max battery voltage, auxiliary battery voltage, load control status and much more.

With the IPN-ProRemote, the Solar Boost 3024i can be configured to determine the end-of-charge based on net battery current

matched to battery capacity in amp-hours to provide the most highly optimized charge process.

Installation and Operation Manual

4

FRONT PANEL AND REMOTE DISPLAY INDICATORS

FIGURE 1

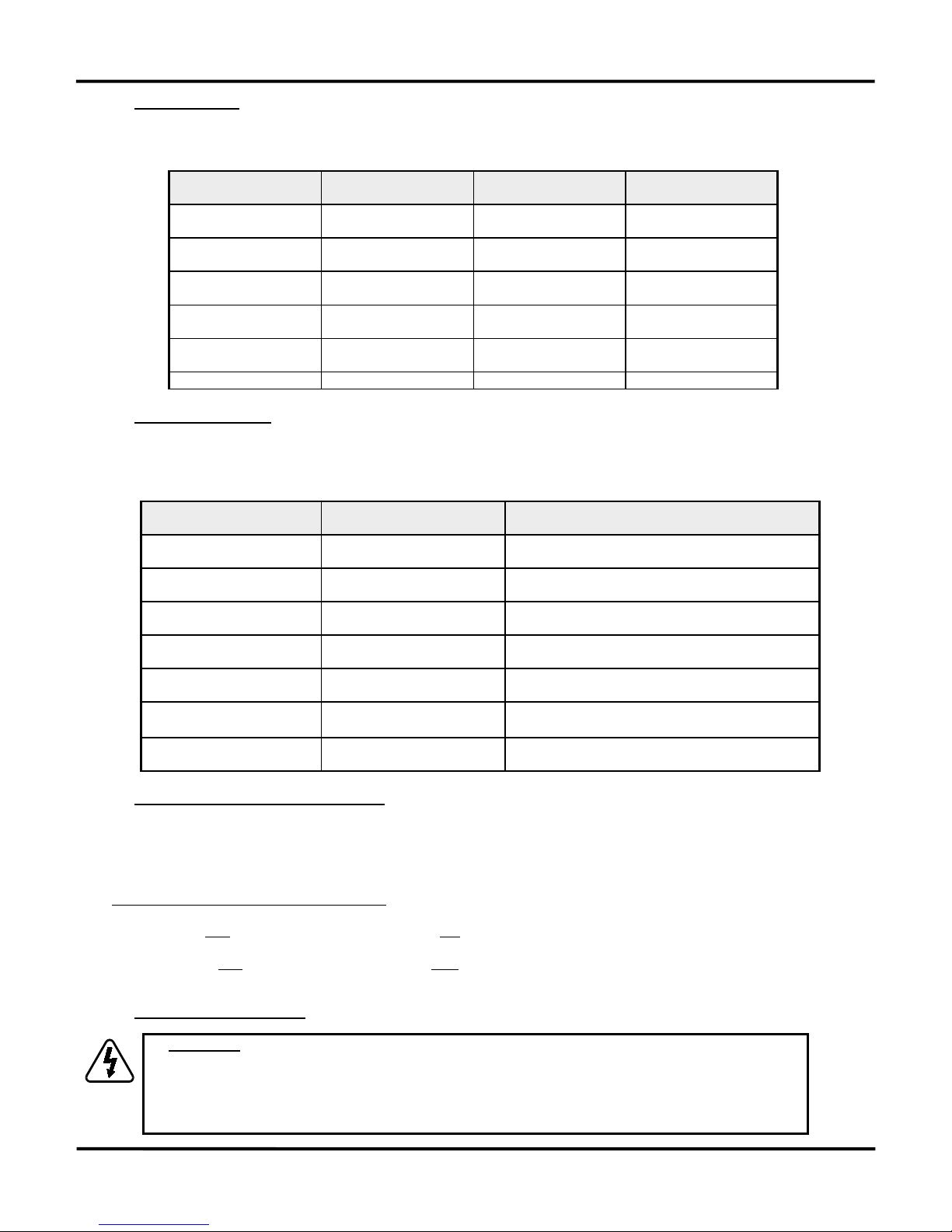

CHARGE STATUS INDICATOR

An LED charge status indicator is provided on the face of the unit, and on the IPN-Remote and IPN-ProRemote displays. The

LED will be off when the unit is not charging, and will be on solid or blinking when the unit is charging the battery. If the PV array is

capable of delivering greater than approximately 3 to 5 amps per 100 amp-hours of battery capacity, the charge status LED can

provide a rough approximation of battery state of charge as shown in the table below.

CHARGE STATUS INDICATOR

STATUS LED CHARGE MODE APPROXIMATE CHARGE LEVEL

OFF

[0]

CHARGE OFF NOT DISPLAYED

CONTINUOUSLY ON

[1]

BULK <70% FULL

BLINKING

1 SEC ON [1] / 1 SEC OFF [0]

ACCEPTANCE 70% - 95% FULL

BLINKING

0.1 SEC ON [1] / 1 SEC OFF [0]

FLOAT FULLY CHARGED

BLINKING RAPIDLY

0.1 SEC ON [1] / 0.1 SEC OFF [0]

EQUALIZE

TABLE 1

THREE STAGE CHARGE CONTROL

Solar Boost 3024i is typically configured for a three stage charging process, Bulk, Acceptance and Float. The three stage

charge process provides a somewhat higher charge voltage to charge the battery quickly and safely. Once the battery is fully

charged a somewhat lower voltage is applied maintain the battery in a fully charged state without excessive water loss. The

three stage charge process charges the battery as quickly as possible while minimizing battery water loss and maintenance.

Bulk Charge

When charge starts the Solar Boost 3024i attempts to apply the Acceptance charge voltage to the battery. The system will

switch to Bulk charge if the battery is sufficiently discharged and/or insufficient charge current is available to drive the battery up to

the Acceptance voltage setpoint. During the Bulk charge stage the unit delivers as much charge current as possible to rapidly

recharge the battery. Once the charge control system enters Acceptance or Float, the unit will again switch to Bulk charge if

Blue Sky Energy - Solar Boost 3024i

5

battery voltage drops below the present charge voltage setpoint. Fully automatic electronic current limit prevents the possibility of

overload by limiting output current to 30 amps regardless of PV input current or power.

Acceptance Charge

As the battery charges in Bulk, battery voltage slowly rises as the battery recovers charge. When sufficient charge has been

recovered for battery voltage to reach the Acceptance voltage setpoint, the unit changes to a constant voltage mode where the

Acceptance voltage is applied to the battery. The Acceptance voltage is factory set to 14.4/28.8V. In Acceptance the battery is

typically between 70% to 95% charged depending on battery size and available charge current.

The battery remains at the Acceptance voltage until it is fully charged and switches to Float as determined by either;

1. Battery voltage has been continuously at (or above) the Acceptance voltage setpoint for the Charge Time period.

(factory default = 2 hours)

– OR –

2. With the IPN-ProRemote display, net battery charge current drops below the Float Transition Current while the

battery is at (or above) the Acceptance voltage setpoint. (factory default = 1.5A per 100 amp-hours)

Float Charge

Once the battery is fully charged the unit switches to Float where the Float voltage is applied to the battery to maintain it in

a fully charged state without excessive water loss. The Float voltage is factory set to 13.4/26.8V. During Float a healthy fully

charged lead-acid battery will draw approximately 0.1–0.2 amps per 100 amp-hours of battery capacity.

TWO STAGE CHARGE CONTROL

Certain battery types or system configurations may require two stage charge control. Solar Boost 3024i can be configured for

a two stage bulk-acceptance charge to accommodate these batteries or systems. Two stage charge is selected by setting the Float

charge voltage setting to No Float. Refer to the Solar Boost 3024i Setup section to configure two stage charge.

EQUALIZATION

¾WARNING: Not all batteries can be safely equalized. Equalization should only be performed on

vented liquid electrolyte lead-acid batteries. Follow battery manufacturers recommendations pertaining

to equalization.

The Solar Boost 3024i can perform equalization manually or automatically. Since each cell of a battery is not identical,

repeated charge/discharge cycles can lead to an imbalance in the specific gravity of individual cells and electrolyte stratification.

Equalization is essentially a controlled overcharge which brings all battery cells up to the same specific gravity and eliminates

stratification by heavily gassing the battery. While equalization parameters are adjustable with the IPN-ProRemote, factory default

parameters of 15.2/30.4V for 2 hours every 30 days are suitable for most applications. Note that for proper equalization a minimum

net charge current of approximately 3 amps per 100 amp-hours of battery capacity is required. If insufficient current is available

equalization may have to be canceled manually since the equalization time accumulator may not be able to complete count down.

¾CAUTION: Equalization is a controlled over charge of the battery at a relatively high voltage

producing heavy battery gassing. While the Solar Boost 3024i can be configured for manual or

automatic equalization it is strongly recommended that a qualified operator always plan and monitor the

process. The operator should ensure that connected equipment can tolerate the high equalization

voltage which is factory set to 15.2/30.4V. Since the Equalization voltage is temperature compensated,

the voltage can be quite high at cool temperatures if temperature compensation is used.

Equalize Time Accumulator

The equalize time period is not a simple timer but rather a “time at voltage” time accumulator. The equalization timer will not

count down unless the battery is at (or above) the equalization voltage setpoint for the required time period to assure that a proper

equalization cycle has taken place. This is particularly beneficial on systems where the battery or loads are large relative to

available charge current. The equalize time accumulator counts in 3 minute increments. If battery voltage reached the equalization

voltage setpoint during a given 3 minute period, that period is considered good. Unless manually disabled, the unit will stay in

equalize for as long as it takes to accumulate the required time at voltage. This may take hours or even days. If equalize does not

complete by the time the charging day ends, it will pick up where it left off when the next charging day begins.

Automatic Equalization

If DIP switch #5 is turned ON prior to the application of battery power, automatic equalization is enabled. From then on the

unit will perform automatic equalization after the set number of days has elapsed (factory default = 30 days).

Installation and Operation Manual

6

Manual Equalization

If DIP switch #5 is turned OFF, equalization is completely disabled. A manual equalize can be performed by turning DIP

switch #5 ON, after battery power is applied and the unit initializes. After the manually initiated equalization cycle completes,

turn DIP switch #5 OFF. If DIP switch #5 is left ON automatic equalize is enabled. Fully manual equalization can also be

performed from the IPN-ProRemote.

OPTIONAL TEMPERATURE COMPENSATION

The charge voltage required by batteries changes with battery temperature. Temperature compensation of charge voltage

enhances battery performance and life, and decreases maintenance. Automatic temperature compensation can be provided

using the optional battery temperature sensor (BSE p/n 930-0022-20). The default compensation factor of –5.00mV/°C/cell is

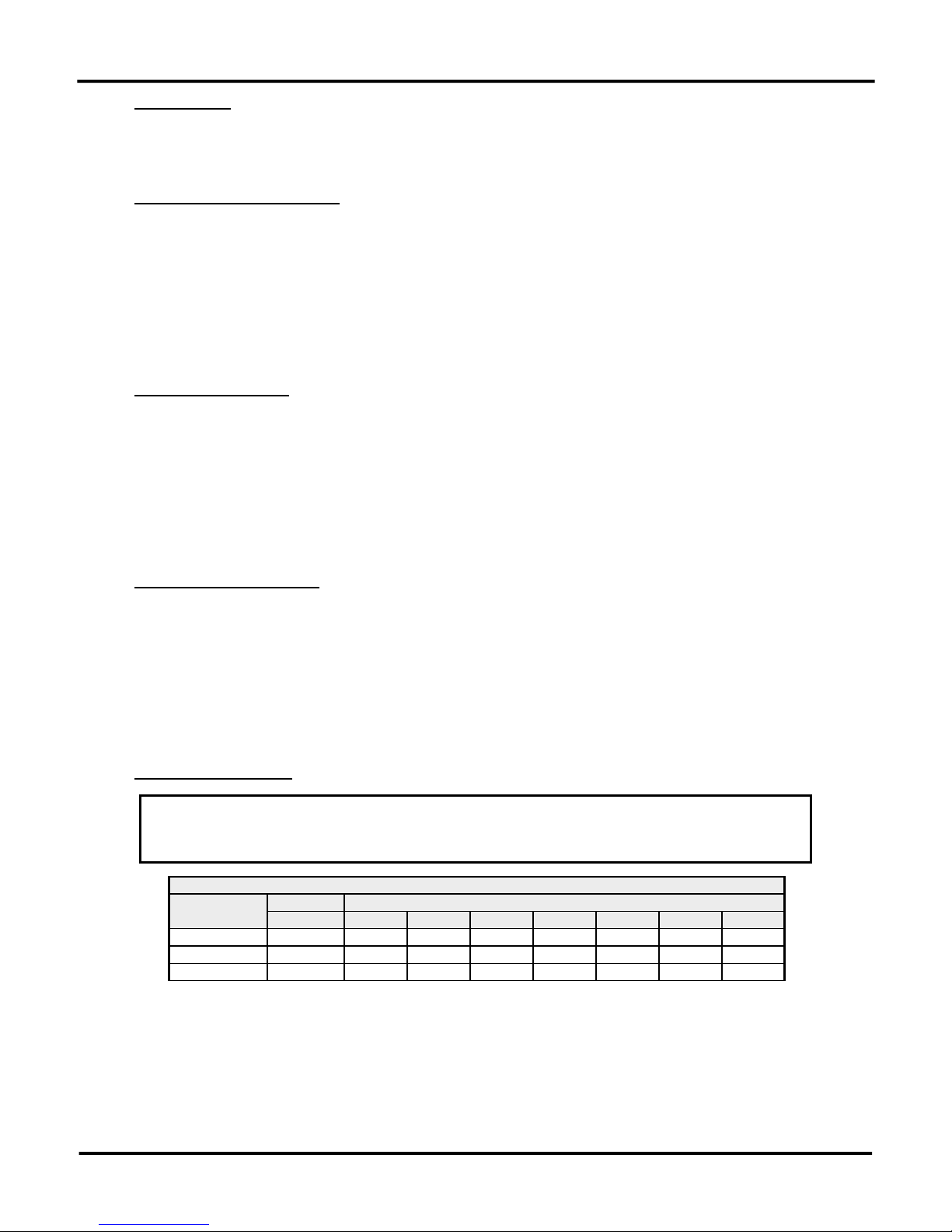

appropriate for most lead-acid batteries. The graph of Figure 2 shows charge voltage vs. battery temperature for factory default

Acceptance and Float voltage setpoints. The temperature compensation factor can be changed using the IPN-ProRemote.

FACTORY DEFAULT CHARGE VOLTAGE SETPOINT -VS.- BATTERY TEMPERATURE

FIGURE 2

MAXIMUM SETPOINT VOLTAGE LIMIT

Very cold batteries combined with high charge voltage setpoints can produce voltages high enough to disrupt or damage

other equipment connected to the battery. To minimize possible damage a maximum voltage setpoint limit feature is provided.

The factory defaults of 15.5/31.0V can be changed using the IPN-ProRemote. Regardless of what setpoint values are entered

by the user or result from temperature compensation, the Solar Boost 3024i will never attempt to apply a charge voltage greater

than the maximum voltage setpoint limit value.

TEMPERATURE AND OUTPUT POWER

Over temperature protection is provided to protect the unit from damage due to high output power at high ambient

temperatures. When mounted vertically as described in the installation section, the unit can deliver full output in a temperature of

up to 40°C (104°F). If an over temperature condition exists, the unit will cycle on/off, reducing average power delivery to within safe

limits. During thermal shutdown the Charge Status Indicator will display an “off” condition. Over temperature shutdown occurs when

the heatsink temperature reaches 75°C. Actual heatsink temperature for can be displayed on the IPN-ProRemote.

MAXIMUM POWER POINT TRACKING (MPPT)

MPPT and associated current boost operation is fully automatic and will function whenever sufficient PV voltage and current

are available. The percent increase in output charge current relative to PV current is variable, and will change with operating

conditions. When conditions are such that insufficient PV power is available to produce an increase in output current, the unit will

stop it’s internal DC-DC power conversion and operate as a series pass PWM controller with very low forward voltage drop.

The principal operating conditions which affect current boost performance are PV array temperature and battery voltage. At

constant solar intensity available PV power changes with PV temperature. A PV array’s power vs. temperature characteristic is

such that a cool PV array can produce a higher voltage and more power, than a hot PV array. When PV voltage is sufficiently high

for MPPT to operate, a constant power output is delivered to the battery. Since output power is constant while MPPT is operating, a

decrease in battery voltage produces corresponding increase in charge current. This means that the greatest current increase

occurs with a combination of cool ambient temperature and low battery voltage. The unit delivers the greatest charge current

Blue Sky Energy - Solar Boost 3024i

7

increase when you need it most, in cold weather with a discharged battery. Additionally, anything that can be done to lower PV

array temperature will also lead to increased charge current by increasing PV power production. In cool/comfortable temperatures

and typical battery states of charge, most systems see about 10 – 20% increase. Charge current increase can go to zero in hot

temperatures, whereas charge current increase can easily exceed 30% with a discharged battery and freezing temperatures.

HOW MPPT WORKS

A PV module is a constant current type device. As shown on a typical PV module voltage vs. current curve, current remains

relatively constant over a wide range of voltage. A typical 75 watt module is specified to deliver 4.45 amps @ 17 volts @ 25°C cell

temperature. Conventional PV controllers essentially connect the PV array directly to the battery when battery is discharged. When

a 75 watt module is connected directly to a battery charging at 12 volts, the module still provides approximately the same current.

But, because output voltage is now at 12 volts rather than 17 volts, module power production is artificially limited and the 75W

module only delivers 53 watts. This wastes 22 watts of available power.

Solar Boost 3024i’s patented MPPT technology operates in a very different fashion. Under these conditions Solar Boost 3024i

calculates the maximum power voltage (VMP) at which the PV module delivers maximum power, in this case 17 volts. It then

operates the module 17 volts which extracts maximum available power from the module. Solar Boost 3024i continually recalculates

the maximum power voltage as operating conditions change. Input power from the maximum power tracking controller, in this case

75 watts, feeds a switching type power converter which reduces the 17 volt input to battery voltage at the output. The full 75 watts

which is now being delivered at 12 volts would produce a current of 6.25 amps. A charge current increase of 1.8 amps or 40% is

achieved by converting the 22 watts that would have been wasted into useable charge current. Note that this example assumes

100% efficiency to illustrate the principal of operation. In actual operation, boost will be somewhat less.

MULTIPLE CHARGE CONTROLLERS ON THE IPN NETWORK

A key advantage of the IPN network architecture is the ability for multiple charge controllers operate as a single machine.

Up to 8 IPN compatible charge controllers can reside on a single IPN network charging a common battery. An single optional

display monitors all chargers on the network, and a single battery temperature sensor serves all chargers on the network and

temperature related functions of the IPN-ProRemote. Charge controllers can be added to grow a small system into a large

system and have this large system operate from the users standpoint as a single large charge controller. If any charge controller

in a multi controller system has input power available, the charge control system will start and charge the battery based on

charge control parameters set in the master.

INSTALLATION

¾WARNING: Read, understand and follow the Important Safety Instructions in the beginning of this

manual before proceeding. To reduce the risk of fire, connect only to a circuit provided with 40 amperes

maximum branch-circuit over current protection installed and wired in accordance with National Electrical

Code, ANSI/NFPA 70. To reduce risk of electric shock, remove all sources of power, PV and battery before

installing. Adjustments or connections other than those shown in Figures 3, 4 and 5 void the limited

warranty. Note that Figures 3, 4 and 5 show generalized connections only and are not meant to show all

wiring, circuit protection and safety requirements for a photovoltaic electrical system.

OVER VOLTAGE / REVERSE POLARITY PROTECTION

Solar Boost 3024i is fully protected against reverse polarity and high voltage transients for both the PV and the battery

connections. If the battery is connected reverse polarity, Solar Boost 3024i will not operate. If the PV array is connected reverse

polarity the charge control system will not turn on or provide output current. Should high PV current be available during reverse PV

connection the heatsink will become quite warm but no damage to the unit will result.

¾CAUTION: The unit is protected against reverse battery and reverse PV polarity, but is not protected

against reverse battery to the PV terminals. Additionally, transient voltage protection devices on the battery

and PV terminals are designed to absorb static electric discharges, or other high voltage transients and can

dissipate up to 1.5KW for 1ms. Steady state voltage in excess of 57V on either the battery or PV terminals

will damage the unit. Damage of this type will void the limited warranty.

ELECTROSTATIC HANDLING PRECAUTIONS

All electronic circuits may be damaged by static electricity. To minimize the likelihood of electrostatic damage, discharge

yourself by touching a water faucet or other electrical ground prior to handling the unit and avoid touching components on the

circuit boards. The risk of electrostatic damage is highest when relative humidity is below 40%.

Installation and Operation Manual

8

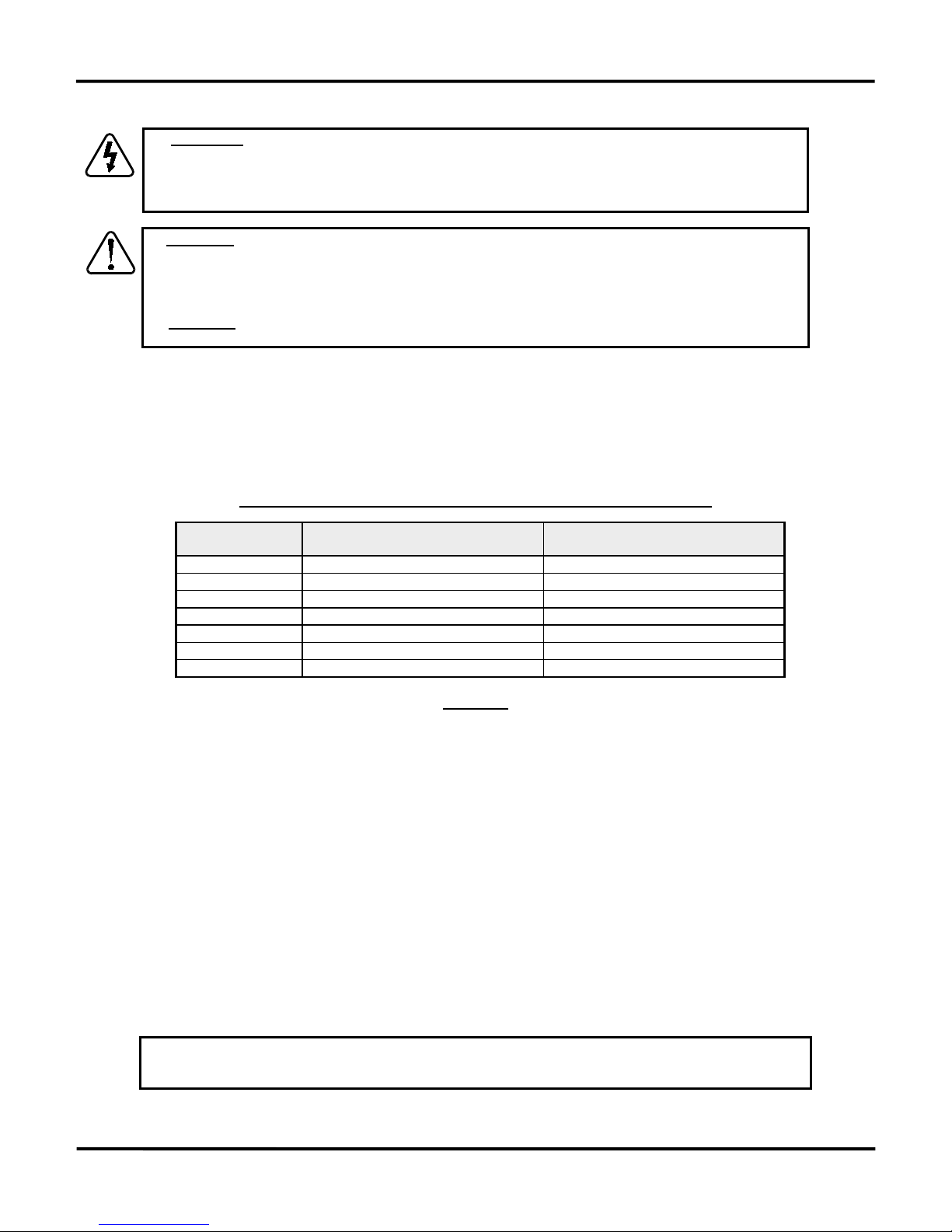

SETUP AND WIRING DIAGRAM

FIGURE 3

SOLAR BOOST 3024i SETUP

¾Solar Boost 3024i has various setup parameters all of which are preconfigured at the factory. Most

installations require no changes other than configuring the Auxiliary Output if used, and enabling

Equalization if desired. Default settings are typically suitable for most flooded lead-acid batteries.

--------------------------------------------------------------------

¾Setup parameters are divided into two categories, Basic and Advanced. Basic parameters can be

configured with the Solar Boost 3024i alone within limited ranges. Advanced parameters require the IPN-

ProRemote to access. All parameters are retained if power is lost or the IPN-ProRemote is removed.

Factory Default Settings

Basic Settings Advanced Settings

•Charge mode ................................ 3 stage •Equalize voltage ........................................ 15.2/30.4V

•Acceptance voltage ....................... 14.4/28.8V •Equalize time ............................................. 2.0 hours

•Float voltage .................................. 13.4/26.8V •Auto equalize days .................................... 30 days

•Charge time ................................... 2.0 hours •Maximum voltage setpoint limit ................. 15.5/31.0V

•Equalize ......................................... Disabled •Float Transition Current ............................. 1.5A/100 amp-hours

•IPN Network address .................... 0 (zero) •Temperature compensation factor ............ -5.00mV/°C/cell

•Auxiliary Output mode ................... Aux. bat. charger •Load control ON voltage.......................... . 12.6/25.2V

•All DIP switches ............................. Physically set to OFF •Load control OFF voltage........................ . 11.5/23.0V

Blue Sky Energy - Solar Boost 3024i

9

Basic Settings

These setup options are configured with a single 8 position DIP switch located on the main circuit board as shown in

Figure 3. All parameters are saved by switch position or in non-volatile memory and are retained if power is lost.

PARAMETER

OR FUNCTION

FACTORY

DEFAULT

RANGE WITH

SB3024i ALONE

RANGE WITH

IPN-ProRemote

Acceptance Charge

Voltage (VCHG)

14.4V* 14.0 – 14.8V*

(0.2V steps)*

10.0 – 40.0V

Float Charge

Voltage (VFLOT)

13.4V* 13.2 – 13.8V*

(0.2V steps)*

10.0 – 40.0V

Charge Time

(TCHG)

2.0 Hrs 0.0 – 4.0 Hrs

(1.0 Hr steps)

0.0 – 10.0 Hrs

(0.5 Hr steps)

Auxiliary Output Aux. Battery Charge Aux. Battery Charge

-or- Load Controller

Remote Monitoring

Only

Auto Equalize Enable Disabled Enabled / Disabled

-or- Manual

Remote Monitoring

-and- Manual on/off

IPN Address 0 (zero) 0 – 7 –

*Double for 24V battery

Advanced Settings

Advanced settings are programmed into the Solar Boost 3024i and are suitable for most installations. Advanced

parameters can be changed only with the IPN-ProRemote display. All advanced parameters are saved in non-volatile memory

and are retained if power is lost or IPN-ProRemote is permanently removed.

PARAMETER

OR FUNCTION

FACTORY

DEFAULT

RANGE VIA

IPN-ProRemote

Auto Equalize Days 30 days 10 – 400 days (5 day steps)

-or- Manual

Equalize Voltage 15.2V* 10.0 – 40.0V

(0.1V steps)

Equalize Time 2.0 Hrs 0.5 – 10.0 Hrs (0.5Hr steps)

Load Control Low Voltage Disconnect

ON ≥12.6V* OFF ≤11.5V*

ON/OFF 10.0 – 40.0V -or-

Based on net battery amp-hours (5AH steps)

End Of Charge

Determination

Time at charge voltage

(TCHG)

Time at charge voltage (TCHG) -or- net battery

charge current matched to battery amp-hours

Temperature

Compensation Factor

-5.00mV/°C/cell -0.00 – -8.00mV/°C/cell

(0.05mV/°C/cell steps)

Maximum voltage

setpoint limit

15.5V* 10.0 – 40.0V

(0.1V steps)

*Double for 24V battery

Restoring Factory Default Settings

Factory defaults can be easily restored into the Solar Boost 3024i. If the unit is not received in a factory sealed package, it is

possible that settings may not be set to factory defaults. If there is any doubt about present settings, restoring defaults is highly

recommended. Note that restoring defaults as described here restores all defaults in the Solar Boost 3024i but does not restore

defaults in IPN-ProRemote. See the IPN-ProRemote operators manual regarding it’s restore defaults function.

To restore Solar Boost 3024i factory defaults:

1. Remove PV and battery power.

2. Turn ALL 8 DIP switches shown in Figure 3 ON.

3. Restore battery power, wait at least 10 seconds, then remove battery power.

4. Return ALL 8 DIP switches to their default OFF position.

5. The unit is now configured to factory default settings.

Battery and PV Voltage

¾WARNING: Battery and PV voltage are determined automatically. Be certain battery is sufficiently

charged and connected quickly to allow proper battery voltage determination. The battery is determined

to be 12V if voltage when first connected is less than 18V, or 24V if battery voltage is greater. PV voltage

is also determined automatically. PV voltage is determined to be 12V if always less than 28V, or 24V if

ever greater. If PV type is changed from 24V to 12V following installation, battery and PV power must be

momentarily removed and restored so that proper PV voltage can be determined by the controller.

Installation and Operation Manual

10

Charge Mode

Solar Boost 3024i is typically configured for three stage charge. Certain battery types or system configurations may benefit

from two stage constant voltage charge. Two stage charge is selected by setting the Float voltage setting to one step below it’s

minimum voltage setting. “No Float” will then be displayed and the unit will never switch to the Float charge stage.

Acceptance Charge Voltage

The factory Acceptance charge voltage setting of 14.4/28.8V is suitable for most lead-acid batteries. The setting can be

viewed or changed using the charge parameter setup LED’s and operating mode DIP switch shown in Figure 3. To view the

present setting, turn the VCHG switch #8 ON momentarily. If more than one value LED lights, the present setting is in-between these

values. If no value LED’s light, the present setting is outside the range than can be shown. For a 24V battery the actual setpoint is

double that shown on the LED’s.

To change the setting, turn the VCHG switch ON, OFF and then back ON before the LED’s turn OFF. The unit will enter the

setup mode and scan through available settings. Turn the VCHG switch off at the desired setting to store the new value. The LED’s

will blink several times to show the new value was accepted and stored.

Float Charge Voltage

The factory Float charge voltage setting of 13.4/26.8V is suitable for most lead-acid batteries. The setting can be viewed or

changed using the charge parameter setup LED’s and operating mode DIP switch shown in Figure 3. To view the present setting,

turn the VFLOT switch #6 ON momentarily. If more than one value LED lights, the present setting is in-between these values. If no

value LED’s light, the present setting is outside the range than can be shown. For a 24V battery the actual setpoint is double that

shown on the LED’s.

To change the setting, turn the VFLOAT switch ON, OFF and then back ON before the LED’s turn OFF. The unit will enter the

setup mode and scan through available settings. Turn the VFLOT switch off at the desired setting to store the new value. The LED’s

will blink several times to show the new value was accepted and stored.

Acceptance Charge Time

Once the battery recovers sufficient charge to reach the Acceptance charge voltage setpoint, it will remain at this voltage for

the Charge Time period, and then the unit will switch to Float. The default Charge Time setting of 2.0 hours is suitable for most

lead-acid batteries. The setting can be viewed or changed using the charge parameter setup LED’s and operating mode DIP switch

shown in Figure 3. To view the present setting, turn the TCHG switch #7 ON momentarily. If more than one value LED lights, the

present setting is in-between these values. If no value LED’s light, the present setting is outside the range than can be shown.

To change the setting, turn the TCHG switch ON, OFF and then back ON before the LED’s turn OFF. The unit will enter the

setup mode and scan through available settings. Turn the TCHG switch off at the desired setting to store the new value. The LED’s

will blink several times to show the new value was accepted and stored.

IPN Network Address

¾A single controller must have it’s IPN network address set to 0 (zero), which is the factory default. In a

multi-controller system one (and only one) controller must have it’s IPN network address set to 0 (zero) to

serve as the network and charge control master. The other controllers can be any other address (1-7), but

no controller can have the same address.

IPN NETWORK ADDRESS

MASTER SLAVESDIP

SWITCH 0 1234567

# 1 (A2) OFF OFF OFF OFF ON ON ON ON

# 2 (A1) OFF OFF ON ON OFF OFF ON ON

# 3 (A0) OFF ON OFF ON OFF ON OFF ON

Blue Sky Energy - Solar Boost 3024i

11

BATTERY AND PV WIRING

¾WARNING: This unit must be installed and wired in accordance with National Electrical Code,

ANSI/NFPA 70. Over current protection for the battery must be provided externally. To reduce the risk of

fire, connect to a circuit provided with 40 amperes maximum branch-circuit over current protection in

accordance with National Electrical Code, ANSI/NFPA 70. Figures 3, 4 and 5 show generalized wiring

information only and do not include all wiring and safety requirements for a photovoltaic electrical system.

¾CAUTION: Battery and PV compression terminals accept #14−4 AWG wire and are to be tightened to

45 in-lb (5 nm). IPN network compression terminals accept #24−14 AWG wire and are to be tightened to

2.1 in-lb (0.24 nm). Auxiliary Output compression terminals accept #24−12 AWG wire and are to be

tightened to 6 in-lb (0.67 nm).

--------------------------------------------------------------------

¾CAUTION: DO NOT connect Bat– and PV– together outside of the unit or improper operation will

result. Bat– and PV– connect together internally.

Wiring requirements for Solar Boost 3024i are somewhat different than conventional PV controllers. While the performance of

other controllers may be affected somewhat by wiring, wiring and connections used with this unit can have a significant effect on

current boost performance. The effect wiring has on current boost performance is that PV power wasted heating undersized wires

or poor connections becomes unavailable to charge the battery. A desirable installation would produce a total system wiring voltage

drop of 3% or less. Table 2 is meant to serve as a wire size guide which will lead to good boost performance with reasonable wire

sizes. The lengths shown are one way for the wire pair between the PV array and battery. Larger wire sizes will tend to improve

boost performance whereas smaller wire sizes will reduce boost performance.

MAXIMUM CONDUCTOR PAIR LENGTH - 3% VOLTAGE DROP

WIRE GAUGE

AWG

12 VOLT SYSTEM @24AMPS

FEET / METERS

24 VOLT SYSTEM @24AMPS

FEET / METERS

12 AWG 5.3 / 1.6 10.7 / 3.3

10 AWG 8.5 / 2.6 16.9 / 5.2

8 AWG 13.5 / 4.1 26.9 / 8.2

6 AWG 21.4 / 6.5 42.8 / 13.0

4 AWG 34.0 / 10.4 68.1 / 20.7

2 AWG 54.1 / 16.5 108.2 / 33.0

1/0 AWG 86.1 / 26.3 172.2 / 52.5

TABLE 2

24V INPUT / 12V OUTPUT

It is possible to wire the PV array for 24V and charge a 12V battery. In this 12/24V operating mode a minimum PV input

current of approximately 0.3 amp is required for MPPT to operate and PV voltage to rise the desired operating point. When MPPT

operates, output charge current will be approximately 2X or more PV input current. This special operating mode can be quite useful

for 12 volt systems with long PV wiring lengths. Wire length can be four times as long for a given wire size by doubling input voltage

and halving input current. This operating mode can also solve problems associated with very high temperature operation where

conventional controllers cease to deliver current due to temperature induced PV voltage reduction. In this mode input current

should be limited to 12 amps since 12 amps of input current will produce approximately 24 amps of output current.

BATTERY TEMPERATURE SENSOR

Simply connecting the optional battery temperature sensor as shown in Figure 3 will enable temperature compensation of all

charge voltage setpoints, and enable all other battery temperature related functions. While the copper lug containing the sensor

element has no electrical connection it is recommended that the sensor be connected to a negative battery terminal. Sensor

temperature can be displayed directly on the IPN-ProRemote, or sensor voltage can be used confirm operation. With the sensor

connected it’s voltage should read approximately 2.98V at 25°C and change by +10mV/°C. If the sensor open, short, installed

reverse polarity or missing, all temperature related functions will operate as if the sensor was at 25°C.

¾In a multi-controller system only one (1) the temperature sensor is required and must connect to the

master (IPN address zero [0]). The master then shares temperature information with all other devices on

the IPN network.

Installation and Operation Manual

12

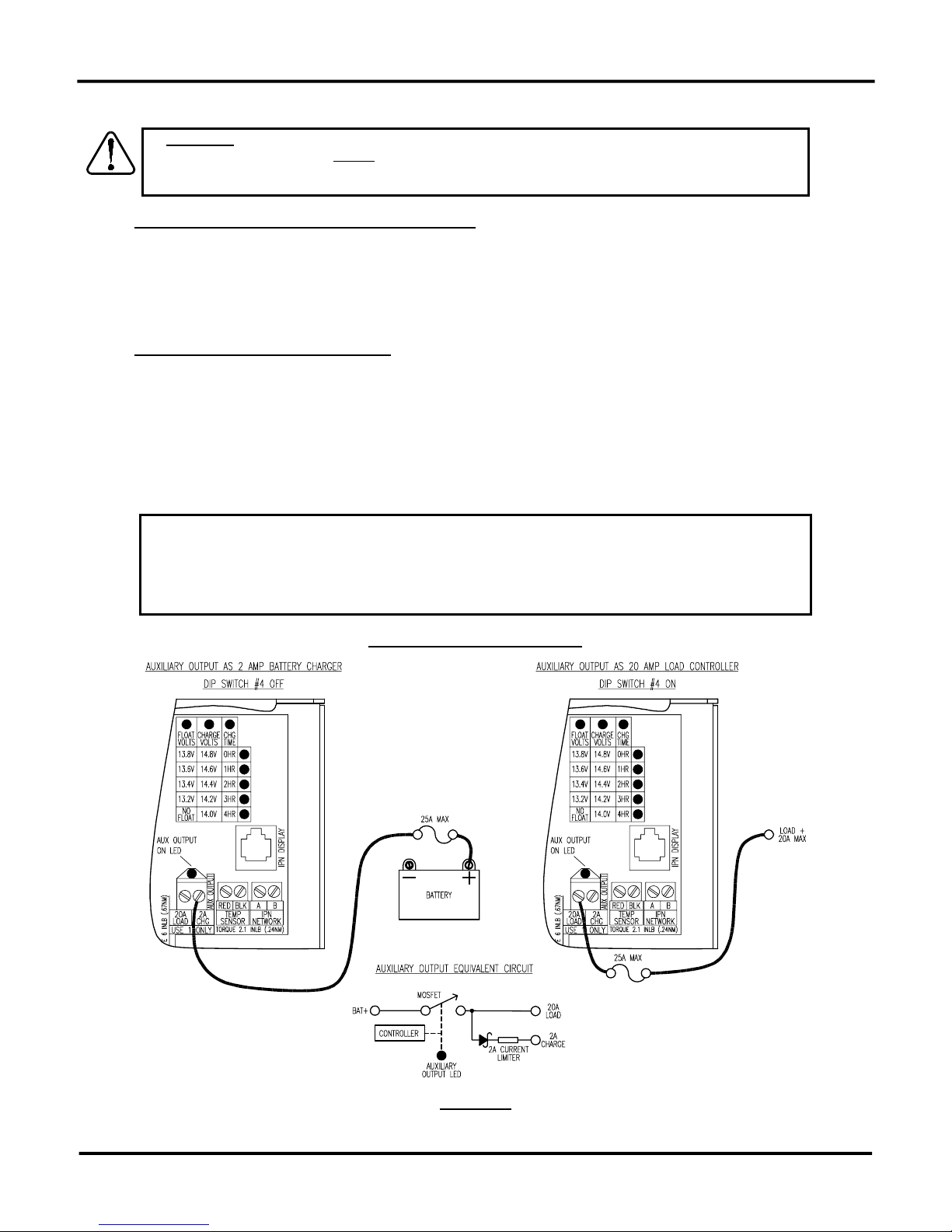

AUXILIARY OUTPUT

¾CAUTION: The auxiliary output can serve one of two functions, either a 2 amp auxiliary battery charger,

or a 20 amp load controller. It cannot perform both auxiliary battery charge and load control functions at the

same time. The function is selected by DIP switch #4 as shown in Figure 3. The auxiliary output LED will

illuminate whenever the auxiliary output is ON.

AUXILIARY BATTERY CHARGE – DIP #4 OFF

The auxiliary charge function is used to charge a separate battery of the same voltage as the primary battery. Control is such

that the primary battery is first priority and the auxiliary battery is second priority. If charge is off or the primary battery is in Bulk, no

power is diverted to the auxiliary battery. If the primary battery is in Acceptance or Float meaning the primary battery does not need

all available power, up to 2 amps is diverted to the auxiliary battery at roughly the same charge voltage as the primary battery.

Auxiliary battery voltage can be displayed on the IPN-ProRemote. Auxiliary battery charge is disabled during equalization.

LOAD CONTROLLER – DIP #4 ON

The load control feature can deliver up to 20 amps and controls ON/OFF based on battery voltage. If the IPN-ProRemote is

used ON/OFF switching can be based on net battery amp-hours. Factory default settings are for Low Voltage Disconnect (LVD)

operation with ON at VBAT ≥12.6/25.2V, and OFF at VBAT ≤11.5/23.0V. These values can be changed using the IPN-ProRemote.

The ON/OFF condition must be valid for 20 seconds before switching will occur. The only constraint is that the ON/OFF values

cannot be set the same. For normal LVD operation the OFF threshold is set to a lower value than the ON threshold. If the

higher/lower values are reversed, the output control logic is inverted. For example a low voltage alarm can be created by setting

ON to ≤11.5V, and OFF to ≥11.6V. The output will turn on to activate an alarm when battery voltage drops to 11.5V or less, and

turn off when battery voltage climbs to 11.6V or more. This output invert capability applies to amp-hour control as well.

¾If load controller output is configured to operate based on net battery amp-hours with the IPN-

ProRemote, it is very important to set ON/OFF voltage thresholds as well. If a valid amp-hour reading is

not available, load control operation will revert to voltage based operation. This will occur if the amp-hour

counter has not been initialized by fully charging the battery, or the IPN-ProRemote is not present.

--------------------------------------------------------------------

¾Voltage or amp-hour ON/OFF thresholds must not be the same values or improper operation will result.

AUXILIARY OUTPUT WIRING

FIGURE 4

Blue Sky Energy - Solar Boost 3024i

13

INSTALLING A MULTI-CONTROLLER SYSTEM

Up to 8 IPN based charge controllers can be connected together in a multi-controller system charging a common battery. In

an IPN based multi-controller system the controllers will setup and operate as a single machine rather than separate charge

controllers. A display or other special communication hardware is not required for a multi-controller IPN network to operate.

The basic control scheme is that device address 0 (zero) is the master and devices 1 – 7 are slaves. The master controls

the charging process and directs power control activities of the slaves. Each controller will be in the same charge mode and the

system as a whole will properly charge the battery based on charge parameter setup in the master. The charge control system

will start whenever one or more devices has input power, but only those devices with input power will have their Charge Status

LED’s on.

MULTI-CONTROLLER WIRING AND SETUP

¾CAUTION: A multi-controller system requires the following specialized installation and setup:

1) Each controller must connect to and charge the same battery.

2) One controller only must be set to IPN address 0 (zero) to serve as the charge control master.

3) All other controllers must be set to addresses 1 – 7, and no two controllers can have the same address.

4) Charge parameters for the system as a whole are setup in the master only. Charge parameters cannot

be set in slaves. Slaves automatically copy the master’s charge parameters.

5) While outputs connect in parallel to a common battery, PV inputs to each controller must be separate

and cannot be connected in parallel. A large PV array must be divided into sub-arrays with each sub-

array connecting to it’s charge controller with separate PV+ and PV– wiring. Sub-arrays do not need

to be of the same PV voltage or type.

6) All controllers must be connected to the IPN network as described below and shown in Figure 5.

IPN NETWORK

An RS-485 communication link is established between controllers by daisy chaining a twisted pair cable from the IPN Network

terminal block, controller to controller (A-to-A, B-to-B) as shown in Figure 5. A display or other special communication hardware is

not required for the IPN network to operate.

IPN NETWORK WIRING

FIGURE 5

AUXILIARY OUTPUT IN MULTI-CONTROLLER SYSTEMS

Auxiliary outputs in a multi-controller system will function as normal, but only the auxiliary output in the master can be

configured or monitored using the IPN-ProRemote. If the auxiliary output setup of a slave needs to be modified or have its factory

defaults restored, that unit can be removed from the system, temporarily configured to be master (IPN address zero [0]) and then

configured using the IPN-ProRemote. Auxiliary output setup will be retained when power is removed.

Installation and Operation Manual

14

MOUNTING

¾CAUTION: Mount the unit with heatsink fins oriented vertically and do not enclose in a confined space. If

not mounted vertically, average output power may be reduced to prevent damage due to over temperature.

The unit is not watertight and must be protected from rain, snow and excessive moisture.

DETAILED DIMENSIONAL DRAWING

FIGURE 6

Blue Sky Energy - Solar Boost 3024i

15

TROUBLESHOOTING GUIDE

SYMPTOM PROBABLE CAUSE ITEMS TO EXAMINE OR CORRECT

Completely dead,

no display

No battery power Battery disconnected, overly discharged, or connected reverse

polarity. Battery powers the system, not PV.

Unit will not turn

on (charge status

LED off), Display

if attached is OK

PV disconnected

PV reverse polarity

PV- connected to BAT- external to

controller

IPN network address set wrong

Unit did not properly recognize

battery voltage

PV must supply at least 0.25A at 2V more than battery voltage to

begin charge.

Reverse polarity PV will cause heat sink to heat.

PV- & BAT- must be separate for proper operation. PV- must

receive earth ground via shunts inside the SB3024i which internally

connect PV- to BAT-. External connection prevents proper operation

of internal shunts and current measurement system.

A single unit must be set to IPN network address 0 (zero). One unit

of a multi-unit network must be set to IPN network address 0 (zero),

AND all other units must be set to different addresses.

Battery voltage is determined automatically when the unit first

receives power. Voltage must be less than 18V for 12V battery, or

greater than 18V for 24V battery. Apply battery quickly and crisply.

Charge status

LED on., but no

output charge

current

Battery voltage greater than

charge voltage setpoint

Battery voltage too low

This is normal operation. Output is off due to high battery voltage

which may be caused by other charging systems.

Battery voltage must be at least 9V for the unit to operate.

Charge status

LED blinks

rapidly

System in equalize mode Disable equalize via IPN-ProRemote, or by turning DIP switch #5

off.

Charge current is

lower than

expected, PV

current may be

low as well

Battery is highly charged

Worn out PV modules

Low insolation

PV- connected to BAT-

Nominal PV voltage has changed

from 24V to 12V

Normal operation, current is reduced if battery voltage is at setpoint.

Replace, or use as is.

Atmospheric haze, PV’s dirty, sun low on horizon, etc.

PV- & BAT- must be separate for proper operation. PV- must

receive earth ground via shunts inside the SB3024i which internally

connect PV- to BAT-. External connection prevents proper operation

of internal shunts and current measurement system.

If PV voltage is changed from 24V to 12V, battery and PV power

must be removed momentarily to reboot unit and load initial 12V PV

control values.Unit considers PV’s to 24V if PV voltage ever goes

above 28V.

MPPT Current

boost is less than

expected

PV maximum power voltage (VMP)

is not much higher than battery

voltage, leaving little extra power

to be extracted

PV’s hot

Nominal PV voltage has changed

from 24V to 12V

PV’s with low VMP.PV’s with higher VMP produce greater power and

current boost potential. PV’s with VMP ≥17V work best, PV’s with

<36 cells tend to work poorly.

Excessive PV wiring voltage drop due to undersize wiring, poor

connections etc.

Battery is nearly charged and battery voltage is high. Output during

MPPT operation is “constant power”, higher battery voltage reduces

charge current increase.

VMP and available power decrease with increasing PV cell

temperature. Cooler PV’s will produce greater boost. It is normal for

boost to decrease as temperature rises.

If PV voltage is changed from 24V to 12V, battery and PV power

must be removed momentarily to reboot unit and load initial 12V PV

control values.Unit considers PV’s to 24V if PV voltage ever goes

above 28V.

Installation and Operation Manual

16

SYMPTOM PROBABLE CAUSE ITEMS TO EXAMINE OR CORRECT

Auxiliary battery

not charging

Auxiliary output not configured for

auxiliary battery charge

Primary battery not highly charged

Load on Auxiliary battery too high

Confirm dip switch #4 is OFF.

Auxiliary battery will not receive charge unless primary battery is

highly charged in Acceptance or Float.

Maximum auxiliary charge current is roughly 2 amps. Load may

need to be reduced.

Charge OFF at

high ambient

temperature

System temporarily shuts down

due to high heat sink temperature

Improve ventilation or reduce PV power. Sufficient ventilation to

prevent over temperature shut down will improve reliability. See

Technical Bulletin #100206.

System appears

OK, but will not

correctly switch

between Bulk,

Acceptance &

Float

Not set for 3 stage charge

System will not switch out of Bulk

and into Acceptance or Float

System will not switch from Float

to Bulk or Acceptance

System will not switch from

Acceptance to Float

Double check Float voltage setpoint.

Battery is so discharged that net charge current cannot bring battery

voltage up to the desired charge voltage setpoint. PV power may be

too low or loads too high.

Battery is fully charged. System will stay in Float and not switch to

Bulk or Acceptance until it is unable to hold the battery at the Float

voltage setpoint.

Battery not fully charged. Unit will not switch to Float until battery

voltage remains at the Acceptance voltage setpoint continuously for

the Charge Time period (or net battery current drops to the Float

Transition Current setpoint if using IPN-ProRemote).

Load control not

working

Auxiliary output not set for load

control

Output may have shut off due to

low battery charge

ON/OFF thresholds set to

inappropriate values

Confirm dip switch #4 is ON.

Load will shut off if battery voltage drops below OFF threshold

(default 11.5/23.0V). Once shut off, the load will not come back on

until battery voltage is above ON threshold (default 12.6/25.2V).

Correct settings (or perhaps restore defaults).

Networked units

do not seem to

coordinate action

or slaves do not

turn on

IPN network address set wrong

Network wiring problem

A single unit must be set to IPN network address 0 (zero).

One unit of a multi-unit network must be set to IPN network address

0 (zero), AND all other units must be set to different addresses.

Confirm wiring correctly in place. Use IPN-ProRemote to view

charge unit status and confirm communication.

Temperature

related functions

do not work.

Temperature sensor missing

Temperature sensor not installed

on master

Temperature sensor failed or

installed reverse polarity

Install temperature sensor.

Temperature sensor must be installed on the master in a multi-

controller system. Temperature sensor inputs on slaves are

disabled.

If sensor is open, short, reverse polarity or missing system will

operate as if sensor was at 25°C. Sensor temperature can be read

directly on the IPN-ProRemote. Sensor voltage when connected

should be 2.98V at 25°C, changing at +10mV/°C.

Blue Sky Energy - Solar Boost 3024i

17

SPECIFICATIONS

SPECIFICATIONS Solar Boost 3024i

Output Current Rating 30 Amp maximum, automatic 30 Amp current limit

Nominal Battery Voltage 12 / 24VDC

PV Input Voltage 57VDC maximum

Power Consumption 0.35W Typical standby •1.0W Typical charge on

Charge Algorithm 3-stage Bulk/Acceptance/Float (Can be tied to net charge current matched to battery AH➁)

Acceptance Voltage 14.4VDC➀(range 14.0 – 14.8VDC➀, 10.0 – 40.0VDC➁)

Float Voltage 13.4VDC➀(range 13.2 – 13.8VDC➀, 10.0 – 40.0VDC➁)

Equalization Voltage 15.2VDC➀(range 10.0 – 40.0VDC➁) •automatic or manual

Voltage Setpoint Limit 15.5VDC➀(range 10.0 – 40.0VDC➁)

Single output configurable as either: 20 Amp load controller –or– 2 Amp aux. battery charger

2 Amp typical, same charge voltage as primary battery

Auxiliary Output Funct.

•Aux. Battery Charge

•Load Control 20 Amp max., ON ≥12.6VDC➀/ OFF ≤11.5VDC➀(Range 10.0 – 40.0VDC➁, or net battery AH➁)

Temperature

Compensation

Optional temperature sensor adjusts charge voltage setpoints based on battery temperature,

-5.00 mV/°C/cell correction factor (Range -0.00 – -8.00 mV/°C/cell➁) •sensor range -60 – +80°C

Power Conversion Effcy. 96% typical @ 28 Volt 24 Amp Output

Cabinet Dimensions 6⅞”H x 6⅝”W x 3⅜”D (17.4cm x 16.8cm x 8.59cm)

Volt/Amp

Accuracy/Range

Battery & Aux-bat voltmeters 40.0VDC±0.50% FS •PV voltmeter 60.0VDC±0.50% FS

Ammeters 35.0A±0.50% FS

Communication Blue Sky Energy’s proprietary IPN Network interface.

Environmental -40 – +40°C, 10 – 90% RH non-condensing

As a part of our continuous improvement process ➀SB3024i alone, voltages double for 24V battery

specifications are subject to change without prior notice ➁With IPN-ProRemote

Installation and Operation Manual

18

TWO YEAR LIMITED WARRANTY

Blue Sky Energy, Inc. (hereinafter BSE), hereby warrants to the original consumer purchaser, that the product or any

part thereof will be free from defects due to defective workmanship or materials for a period of two (2) years subject to the

conditions set fourth below. If within the coverage of this limited warranty, BSE will repair or replace the product at BSE’s

discretion. The original consumer purchaser is responsible for all transportation costs and insurance related to returning the product

to BSE. BSE will cover standard ground transportation costs and insurance to return the product to the original consumer within the

continental US.

1. This limited warranty is extended to the original consumer purchaser of the product, and is not extended to any other

party.

2. The limited warranty period commences on the date the product is sold to original consumer purchaser.

3. This limited warranty does not apply to any product or part thereof damaged by; a) alteration or disassembly, b) repair

or service not rendered by a BSE authorized repair facility, c) accident or abuse, d) corrosion, e) lighting or other act of

God, or f) operation or installation contrary to instructions pertaining to the product.

4. BSE’s liability for any defective product or any part thereof shall be limited to the repair or replacement of the product,

at BSE’s discretion. BSE will not be liable for any loss or damage to person or property, or any other damages, whether

incidental, consequential or otherwise, caused by any defect in the product or any part thereof. Some states do not

allow exclusions or limitations of incidental or consequential damages, so the above limitation may not apply to you.

5. Any implied warranty for merchantability or fitness for a particular purpose is limited in duration to the length of this

warranty. Some states do not allow exclusions or limitations on how long an implied warranty lasts, so the above

limitation may not apply to you.

6. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

7. To obtain warranty repairs, contact BSE at 800-493-7877 or 760-597-1642 to obtain a Returned Goods Authorization

(RGA) number. Mark the outside of the package with the RGA number and return the product, postage prepaid and

insured to the address below. A copy of the purchase receipt identifying original consumer purchaser and date

purchased must accompany the product to obtain warranty repairs.

Blue Sky Energy, Inc.

2598 Fortune Way, Suite K

Vista, CA, 92081, USA

800-493-7877 •

••

•760-597-1642 •

••

•Fax 760-597-1731 •

••

•www.blueskyenergyinc.com

Other manuals for SOLAR BOOST 3024i

1

Table of contents

Other Blue Sky Energy Controllers manuals

Blue Sky Energy

Blue Sky Energy IPN Remote User manual

Blue Sky Energy

Blue Sky Energy SOLAR BOOST 3024iL User manual

Blue Sky Energy

Blue Sky Energy SOLAR BOOST 3024i Installation and operating instructions

Blue Sky Energy

Blue Sky Energy SOLAR BOOST 3048 User manual

Blue Sky Energy

Blue Sky Energy SOLAR BOOST 1524iX User manual

Blue Sky Energy

Blue Sky Energy SOLAR BOOST 3024DiL User manual