Pub 49442

Effective 01/02 3

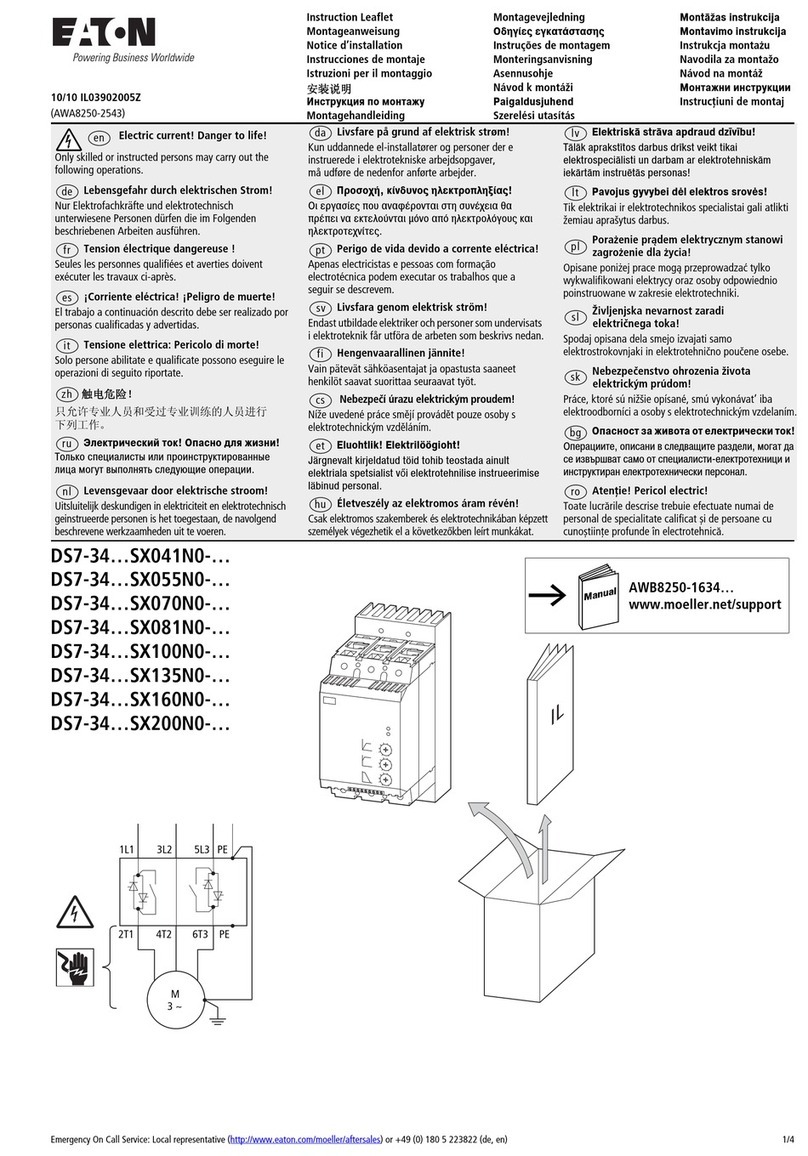

Overload Protection with

Mechanical Starter

Overload protection of the

motor is easil

achieved b

installin

a mechanical starter

on the suppl

side of the soft

start controller.

The overload provides the

necessar

motor protection for

an overload condition.

A short circuit protective

device is required to meet UL

requirements.

*Use UL specified backup

fuse.

Specifications

Table 1. Thermal Specifications

Table 2. Insulation Specifications

Current Deratin

Current Derating in High Temperature Applications

Operation in ambient temperatures exceedin

40°C is possible

if the power dissipation is limited either b

reducin

the stead

-

state current or b

reducin

the dut

c

cle of the soft starter as

shown in Table 3.

Table 3. Temperature Specifications

Table 4. Current Derating by Trip Class

EMC

This compartment meets the requirements of the product stan-

dard EN60947-4-2 and is CE marked accordin

to this standard.

Table 5. Output Specifications —Main Circuit

Table 6. Control Specifications

Product Selection

Table 7. Product Description and Item Selection

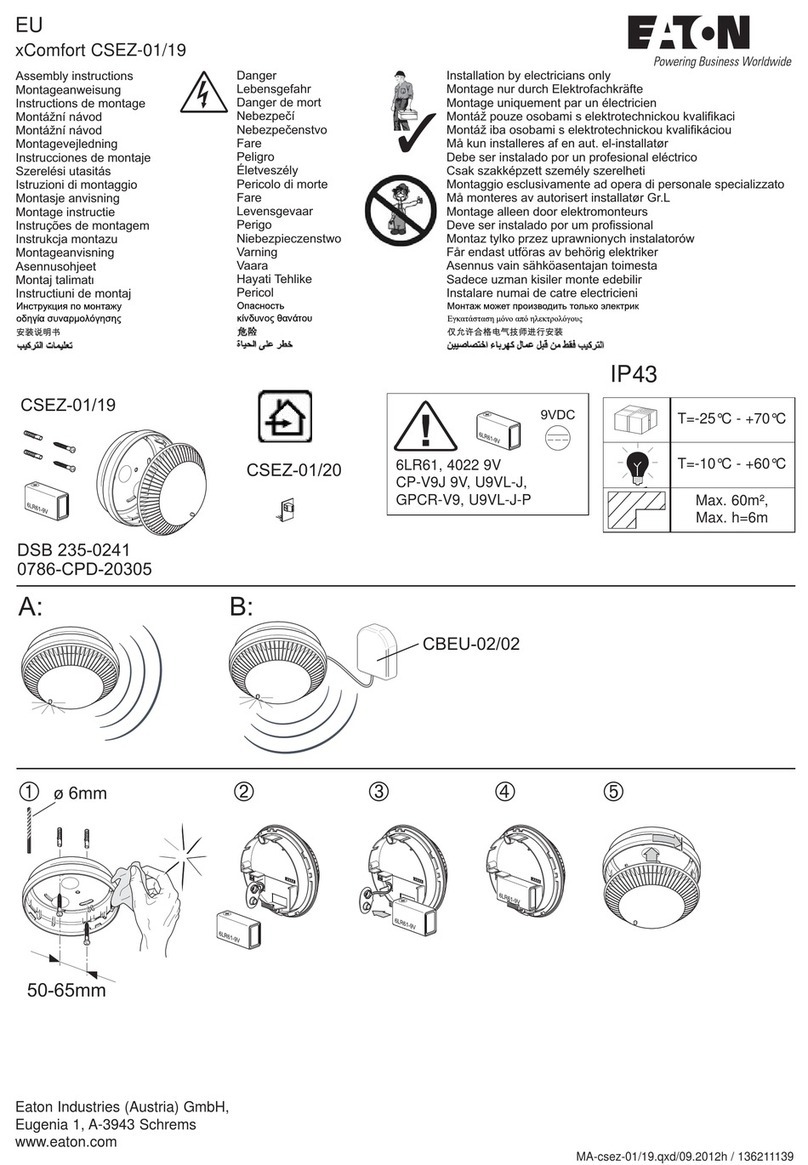

Short Circuit Protection

Two t

pes of short circuit protection can be used:

short circuit protection b

circuit breaker

short circuit protection b

fuses

Short circuit protection is divided into two levels —

T

pe 1 and T

pe 2.

T

pe 1 —protects the installation

T

pe 2 —protects the installation and the

semiconductors inside the motor controller

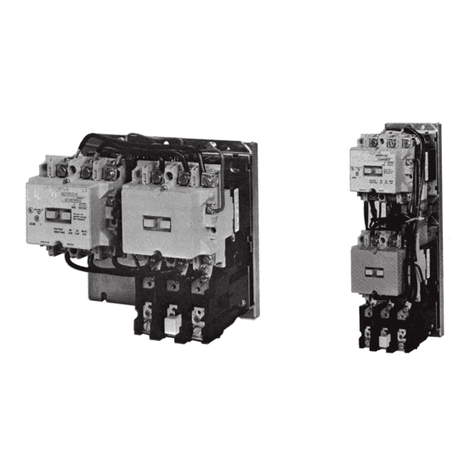

Short Circuit Protection by Circuit Breaker

A 3-phase motor with a correctl

installed and adjusted over-

load rela

will not short-circuit totall

to earth or between the 3

phases. Part of the windin

will normall

limit the short circuit

current to a value that will cause instantaneous ma

netic trip-

pin

of the circuit breaker without dama

e to the soft starter.

The ma

netic trip response current is approximatel

11 times

the maximum adjustable current.

Description Specification

Power dissipation for continuous

operation PD max.

2 W/A

Power dissipation for intermittent

operation PD

2 W/A x duty cycle

Cooling Method Natural convection

Mounting (No Derating) Vertical ±30°

Operating temperature range,

EN60947-4-2 (no derating)

-5°to 40°C*

[23°to 104°F]

* UL Tested.

Storage temperature, EN60947-4-2 -20°to 80°C

[-4°to 176°F]

Max. operating temperature with current

derating according to table

60°C [140°F]

Description Specification

Rated insulation voltage Ui 660 Volt

Rated impulse withstand voltage Uimp 4 kVolt

Installation category III

Ambient Temperature S701X25N3BP

50°C [122°F] 20A continuous

Limited Duty Cycle Rating by 50°C On-time max. 15 min.

Duty cycle max. 0.8

60°C [140°F] 17A continuous

Limited Duty Cycle Rating by 60°C On-time max. 15 min.

Duty cycle max. 0.65

Figure 9. Overload Protection

with Mechanical Starter *

Overload

Trip Class

Without

Bypass

With

Bypass

10A

10

20

30

25A

25A

20A

15A

30A

30A

24A

19.5A

Approvals: UL Std. No. 508

Environment: Degree of Protection / Pollution Degree: IP20 / 3

Description Specification

Short circuit protecting fuse (max.) 80 A gL/gG. No time delay

Operational current (max.) 25A AC-53a, 30A AC-53b

Semiconductor protecting fuse (max.) 6300 A2S

Overload relay trip class 10 or 10A

Description Specification

Control voltage range 24 –300V AC/DC

Control current/power (max.) 15 mA/2 VA

Ramp-Up time Adjustable from 0.5 to 20 sec.

Ramp-Down time Adjustable from 0.5 to 20 sec.

Initial torque Adjustable from 0 to 85% of nominal

torque with optional Kick Start

Output/Current voltage (max.) 0.5A AC14, AC15,

24 –480V AC 50 –60 Hz

Fuse (max.) 10 A gL/gG. l2t max. 72 A2S

Line

Voltage

(V AC)

Motor

Size w/o

Bypass

Motor w/

Bypass

Control

Voltage

Range*

* 24 –480V for CE only.

Controller

Type

Designationhp / kW hp / kW AC/DC

208 –230 10 / 7.5 10 / 7.5 24 –300V S701C25N3BP

400 –480 15 / 11 20 / 15 24 –300V S701E25N3BP

550 –600 20 / 15 25 / 18 24 –300V S701G25N3BP