Blue Square Labs Q360 Product manual

Page | 1

V14612INSLM

V

Va

al

lv

ve

e

I

In

ns

st

ta

al

ll

la

at

ti

io

on

n

a

an

nd

d

M

Ma

ai

in

nt

te

en

na

an

nc

ce

e

G

Gu

ui

id

de

e

Page | 2

V14612INSLM

IMPORTANT SAFETY INFORMATION

When installing and using this equipment, basic safety precautions should always be

followed.

**READ AND FOLLOW ALL INSTRUCTIONS**

WARNING: To reduce risk of injury, do not permit children to use this product unless they

are closely supervised at all times.

Swimming Pool equipment can generate high pressures capable of causing injury.

Always use caution when manipulating valves associated with the pool equipment and

turn off the pump if pressures exceed manufacturer’s specification. Always turn off the

pool equipment when disassembling or servicing your circulation system.

Swimming Pool equipment can create suction sufficient to entrap even adults. If pool

fittings are broken or missing, turn off your equipment and contact a certified swimming

pool expert to make the needed repairs.

To ensure proper cleaning and to qualify the warranty, fax or email a System Design Form

provided by Blue Square along with a scaled pool plan for a FREE certified In-Floor

Design. (New pool construction only.)

Email: plans@bluesquaremfg.com

Fax: (888) 282-6955

If the pool plan design or dimensions change during excavation, a revised plan must be

submitted to Blue Square in order to maintain warranties.

Install the valve above ground at finished pool water level. Do not bury top of clear lid

and inlet of valve after installation.

Install cleaning heads and nozzles according to the Design Plan.

If pool includes an elevated spa, install a check valve on the line feeding the spa heads

to avoid spa draining. Install other check valves (as normal) to avoid spa return jets and

suction lines from draining. For multiple elevation changes in bodies of water and/or

negative edge water features, please contact our design center. (800) 277-4150.

SAVE THESE INSTRUCTIONS

For customer service or support:

For on-line support: www.bluesquaremfg.com

To contact Blue Square: Customer Service

525 E Baseline Road

Suite 107

Gilbert, AZ 85233

(800) 277-4150

Page | 3

V14612INSLM

INTRODUCTION

The Q360 In-Floor Cleaning system is designed to give years of service. The benefits of

deep circulation are well documented and scientifically proven to give the most

efficient swimming pool circulation available. This superior circulation delivers substantial

chemical, electrical and heat savings to the pool owner while offering outstanding

cleaning benefits as well.

The unique engineering of the Q360 System smoothly transfers power from the turbine to

the ports or outlets with minimal friction loss and back pressure, allowing the maximum

possible flow rate to the in-floor cleaning jets. The open gear design allows for effective

pass-through of debris, greatly minimizing annoying cleaning system disruptions and

lowering maintenance costs even further over other in-floor systems.

The Innovative pressure-safe valve design protects your system by ensuring that one port

is always open. Large 2" inlet and (6) 2" ports maximize flow rate. Reinforced space-age

molded construction weathers the elements and is saltwater/chemical friendly. See-

through lid design allows for inspection of turbine and gears without the need for

disassembly.

Failure to follow recommended installation methods could void warranties and cause

injury.

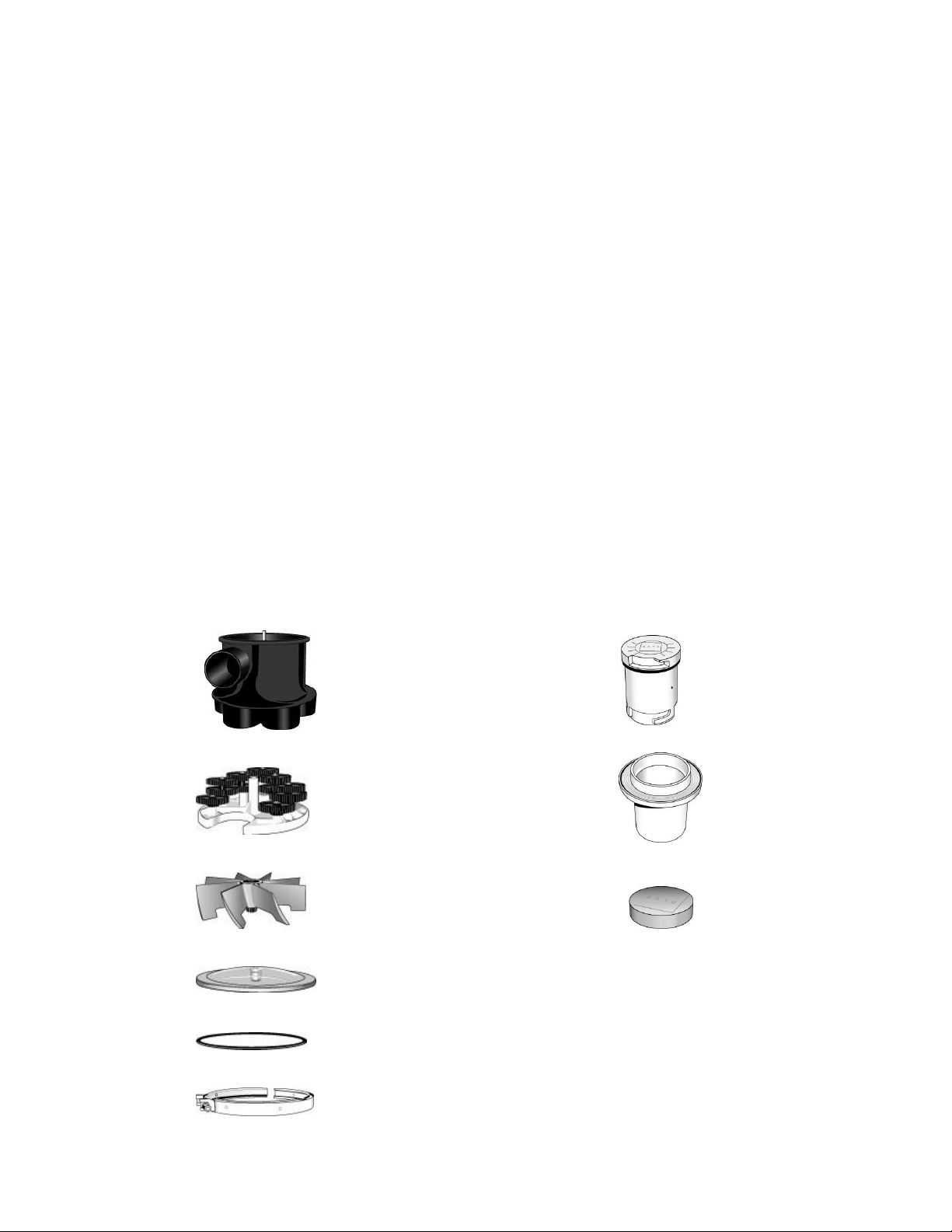

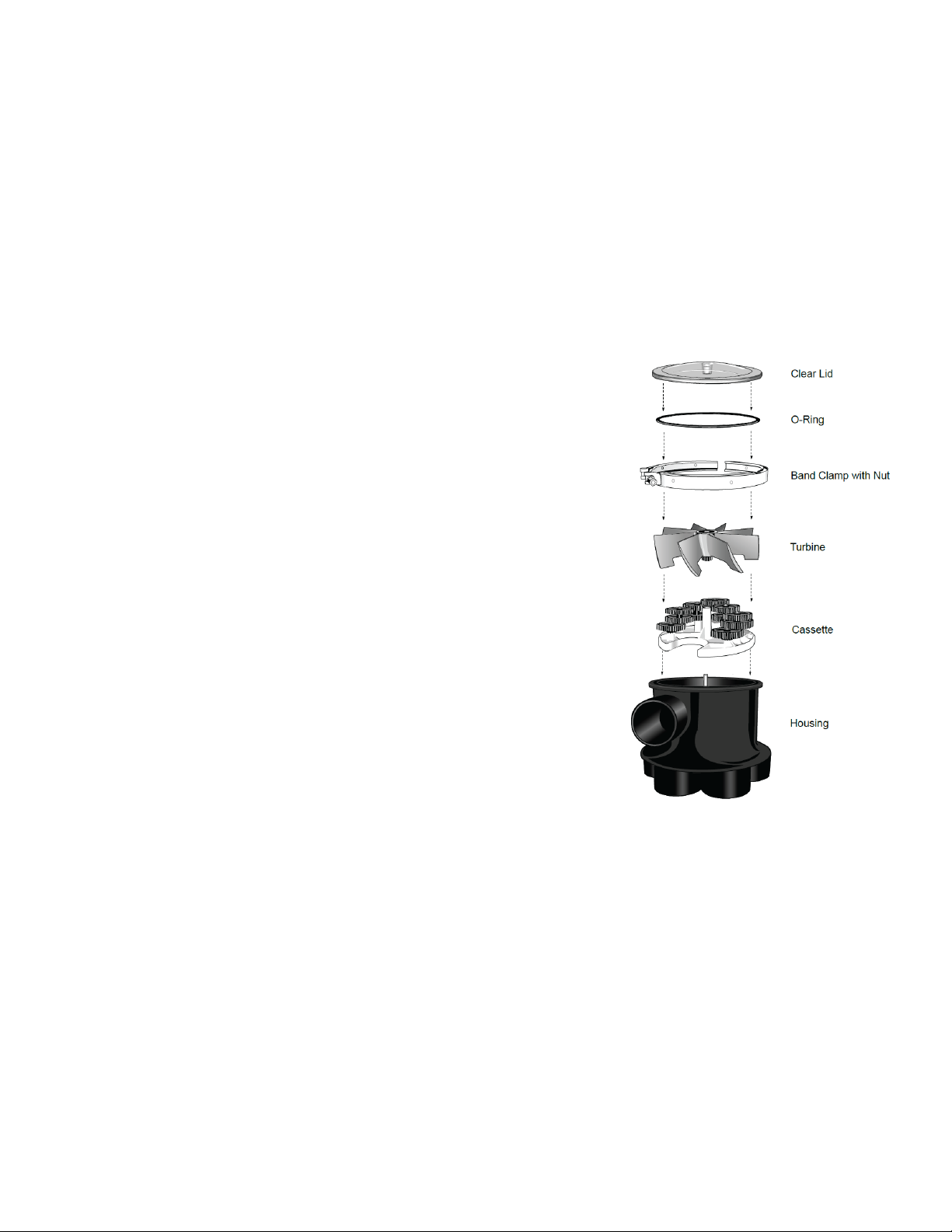

COMPONENTS

The Q360 High Performance Water Valve: The Q360 Jet Complete:

A. Valve Housing or Body A. Jet (High Flow & Low Flow)

A. Cassette B. Collar

B. Turbine C. Protective Cap

B. Clear Lid

C. O-Ring

D. Band Clamp w/ nut

Page | 4

V14612INSLM

INSTALLATION

1. Site Planning

Verify that the excavated pool matches the Blue Square Certified Pool Plan.

Check the break, width, depth and designated step/bench locations. Blue

Square design dimensions are from finished pool edge. They are not taken from

the excavation edge. Allowances will need to be made for the thickness of the

shell according to your pool companies specifications and local codes. If any

aspects of the pool design change during the construction process, please

resubmit an updated plan with the changes for a new Factory Authorized Plan to

ensure proper cleaning and circulation. Failure to follow the FREE factory

authorized design and to ensure that the pool is built to the plan specifications

may void the warranty.

In order to save on plumbing costs, position the valve as close as possible to the

swimming pool or water feature. The valve should be at least five feet away from

the water’s edge. (Check the bonding codes in your area.) The low profile

design, the quiet and smooth operation of the Q360 Water Valve allows for the

valve to be inconspicuously hidden by an irrigation box or landscaping.

Although servicing the valve is very rare, the valve should be placed in a location

where it may be easily accessible.

Install the valve so that the lid and band clamp are above grade and the top of

the valve housing is 2-3” above the water level of the main body of water. If a

below water level installation is necessary, serviceable check valves or manual

valves on all of the inlet and outlet ports will be required to prevent flooding when

servicing the valve.

In order to reduce plumbing costs; layout the system so the feed pipes enter the

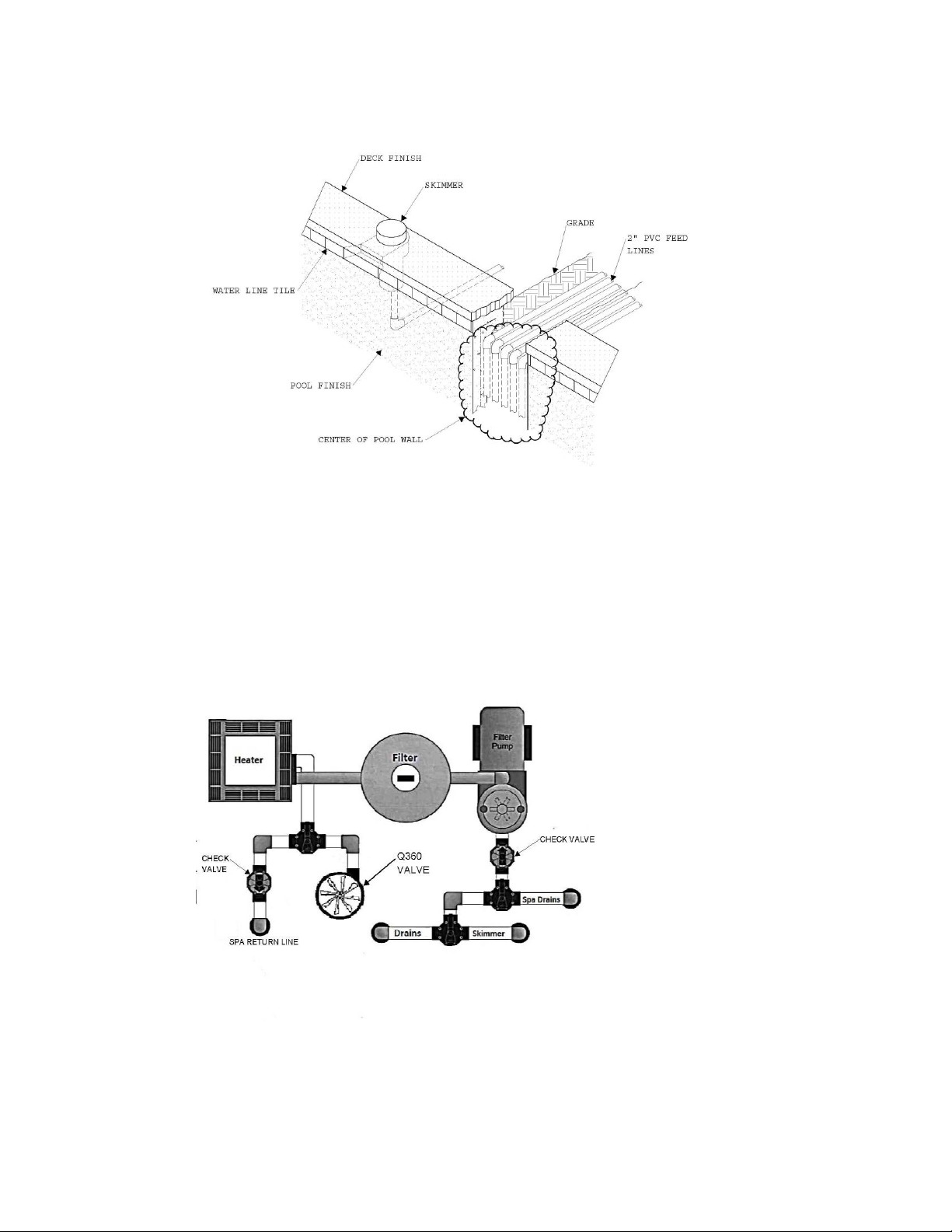

pool close to the center of the pool nearest the pool equipment. See Fig. A 1-1

& Fig. A -1-2

Fig. A 1-1

Page | 5

V14612INSLM

Fig. A 1-2

Just like any other plumbing, a check valve is needed on the feed line running to

an elevated spa or a different elevation body of water to prevent drain-back or

equalization. See Fig. A 1-3

Fig A 1-3

Follow the design plan to position and stake the cleaning head locations. Each

head has a designated nozzle that has a precise cleaning radius. Perimeter

heads have a one foot overlap. Mark the cleaning radius around each stake

Page | 6

V14612INSLM

with a 5’ arch to verify cleaning coverage. Keep in mind that the jets clean

much further. The design allows for overlap to prevent debris accumulation in-

between filter cleaning cycles.

2. Plumbing the System

The Blue Square certified plan indicates which cleaning heads will be plumbed

together to form a bank. Run all feed lines to the top of the bond beam to

facilitate easy valve hookup. Number the lines

according to the design plan. Keep in mind that

the valve cycles counter clockwise from the top

view.

Excavate niche in pool wall, 6 x 24” down to

the pool floor

Make line trench depth sufficient to cover all

pipes

Do not cross lines in floor

Use 2” Schedule 40 pipe

Position so jet feed lines are perpendicular to

the slope of the finished pool floor.

See Fig. A 1-4

Fig. A 1-4

Cleaning Head Risers / Stub-ups

The cleaning head collars require a 2” Schedule 40 riser with no reaming required.

*These stub-ups should be perpendicular to the slope of the pool floor.

Plumbing the Valve (see Plumbing the System Diagram)

Remove the Cassette / Gears during pressure testing to allow for equal

distribution of pressure down all 6 ports or zones. Store the Cassette with the jets

for reinstallation at start-up. Position the O-ring on the valve housing in the O-ring

groove. Align the center hole on the clear lid with the guide pin in the lid and use

the band clamp to secure the clear lid to the valve housing. If the lid does not sit

firmly on the O-ring the cassette is not in the full down position. Replace (re-drop)

the cassette into the vavle to make sure the outer gears engage with the gear

train on the interior perimeter of the valve housing.

When plumbing the valve housing use heavy bodied PVC glue with a compatible

primer. It is best to prime the housing heavily to ensure a good glue joint.

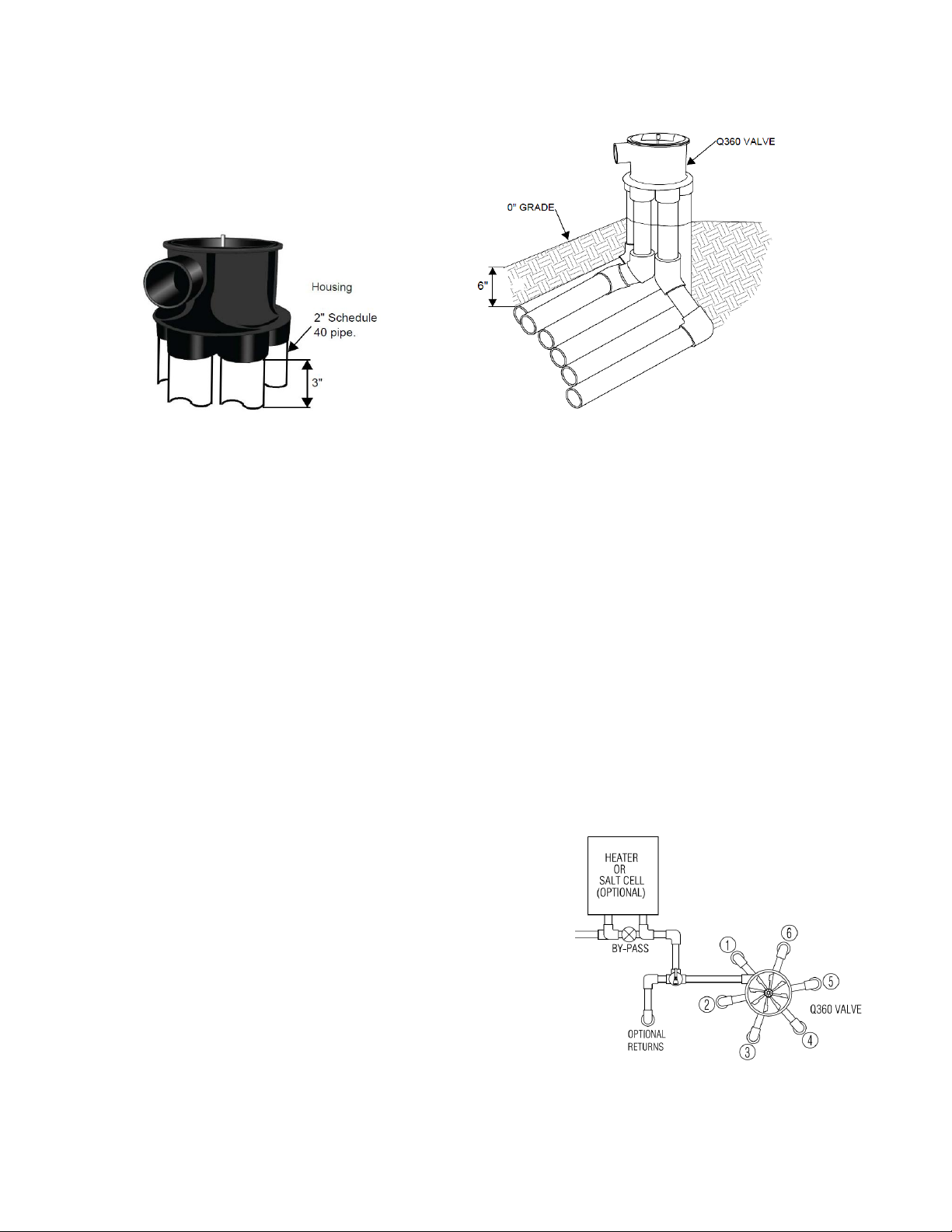

Discharge or Feed Lines

The Q360 valve uses 2” Schedule 40 pipe. Use a 3” stagger when cutting pipes

to provide enough clearance. See detail. See Fig. A 1-5

Page | 7

V14612INSLM

Fig. A 1-5 Fig. A 1-6

Install the discharge lines from the valve in a stacked or flat configuration.

See Fig. A 1-6

Use heavy bodied PVC glue to connect PVC fittings to the valve housing. Do

not get glue inside the housing as it will void the warranty.

Install lines a minimum of 6” below grade or in accordance with local codes.

The distribution system is usually designed to rotate from shallow to deep,

following your factory design. Looking down on the valve, it rotates counter-

clockwise. If a spa is included in the application, it will require a dedicated

line from the valve and a check valve if it is a raised spa.

If all outlet ports on the valve are not needed, use the Y-Pipe as noted in the

plan to aid in efficiency and reduce plumbing costs. *Note: Surface returns

can be applied to the unused port.

Never tie a raised spa bank with any plumbing from a lower body of water

and drain down.

Consult the design plan for proper connections.

Auxiliary Equipment

Heaters

To compensate for heater system pressure

drops, plumb heaters in a bypass line before the

water valve. The heater bypass valve should be

adjusted to ¾ open. See Fig. A 1-7

Chlorinators

In-floor systems can be used with erosion

feeders, ozone generators and in-line salt

converters. Consult manufactures instructions

for proper installation to protect water valve

and other pool equipment. Any chlorinator with

a venturi or restrictive channels should be

plumed with a bypass. See Fig. A 1-7 Fig. A 1-7

Page | 8

V14612INSLM

Pressure Testing

Pressure-test the system at a minimum of 35 psi or follow local code requirements.

Keep the water valve secure and under pressure throughout the construction

process. Remember to remove the cassette and turbine in order to allow for

equal distribution of pressure down all 6 lines and store the cassette and turbine

for reinstallation at startup.

3. Preparing the System

Cut cleaning Jet Stub-ups and Clear Debris from System

After inspection, clear the system lines of debris using a combination of air and

water. (see inspection steps below)

1. Verify that the system is holding pressure (minimum of 35 psi), then relieve

system pressure at filter gauge.

2. Cut each stub-up ensuring collars sit at a height to accommodate

approximately ½” of final finish material. Clean off all burs and debris.

3. Insert test plug in each stub up.

4. Attach a blower assembly unit (blower, check valve, air/water supply and

connectors; call Blue Square for assembly instructions) to the blower plate or

directly to the valve.

5. Turn on blower and water supply to fill the lines.

6. Starting at the cleaning head farthest from the valve, remove test plug and

flush the pipe, blocking and releasing pressure several times to ensure a clear

line.

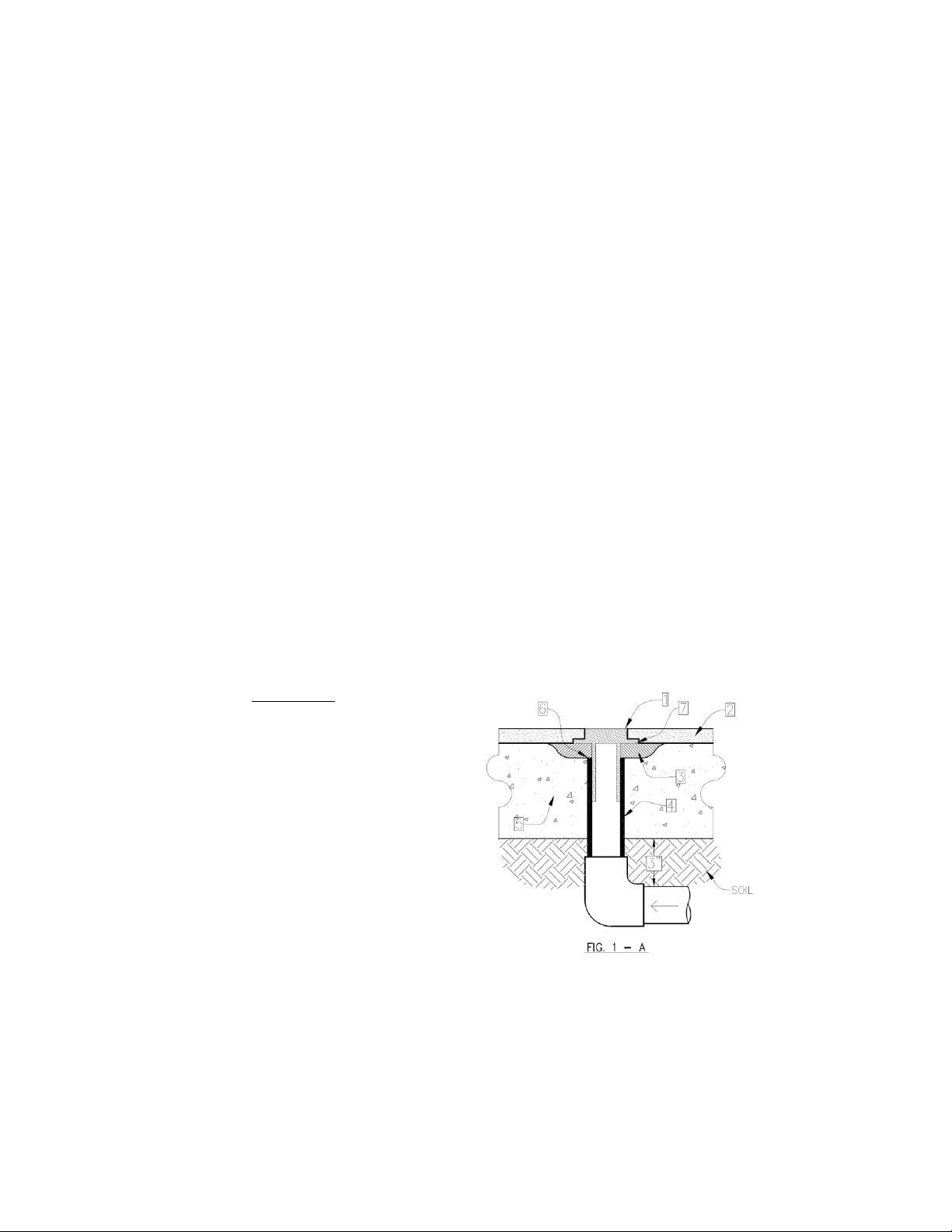

Install Cleaning Collars and Heads

Use inside pipe cutter to cut pipe 1/2" below pool concrete floor.

use Hydraulic cement over and around pipe and up to bottom of flange

(See Fig, 1-A)

Reference:

1. In floor collar

2. Interior pool finish

3. Hydraulic cement

4. 2" P.V.C. Pipe

5. Pool Shotcrete / Gunite

6. Top of Supply pipe 1/2"

below flange

7. Bottom of flange

Page | 9

V14612INSLM

Install Working Valve for Startup (after the pool is filled)

1. Turn pump off at the pool pump.

2. Loosen the bolt on band clamp and remove the band clamp and clear lid.

3. Clean any construction debris from the interior and top edge of the valve

housing.

4. Install the cassette (Gear Train) by sliding it onto the center shaft. Spin the

gears and make sure the cassette drops all the way down and the lower gear

engages with the gear train on the housing perimeter.

5. Place the turbine on the center shaft gear side down. Make sure the gear on

the turbine engages the upper gear on the cassette. Spin the turbine several

times and observe that the white bottom plate is slowly turning. If it does not

the cassette is not in the full “down” position and the lower gear is above the

gear train on the housing perimeter. Push the

cassette down into the gear train if necessary.

6. Check the positioning of large 0-ring and make

sure it is in the groove on the top of the valve

housing. Remove any debris.

7. Align the center shaft on the guide pin hole in the

center of the clear lid and gently push the lid

down. The lid should sit firmly on the top of the

valve housing with no wobble. If it does not sit

firmly remove the turbine and press the cassette

down into the gear train.

8. Replace the band clamp and tighten the bolt

firmly. Do not over tighten.

9. Turn on the system and allow it to cycle until all of

the protective caps are blown free from the collar

and to allow any additional construction debris to

be blown out of the pipes.

10. After the interior finish has properly cured (see the

interior finish manufacturer’s specifications) install

the jets in the collars. Make sure to follow the

design plan for proper locations of High Flow Jets

½ opening, and Low Flow Jets 3/16” nozzle.

Improper nozzle sizes in the wrong location can

cause high pressures and water to be forced out

of the pool onto the deck.

OPERATION AND ROUTINE MAINTENANCE

The Blue Square Q360 cleaning heads are designed to operate at a specific flow rate

and pressure. To ensure proper circulation and or cleaning, run the system whenever the

pump is on.

Cleaning times will vary according to application and environment. To determine the

optimum cleaning time, run the system 24 hours a day after initial startup. Reduce run

times by four hours every two days until minimum cleaning time is determined. Six hours a

day is recommended as a minimum, but pools with high debris conditions often need

longer cleaning cycles.

Page | 10

V14612INSLM

CLEANING THE FILTRATION SYSTEM

For optimum cleaning efficiency, routinely clean the

pump basket, skimmer and filter screens. Backwash or

clean the pool filter whenever pressure increases 5-10 psi

above normal clean-filter operating pressure or if you

notice dirty spots between the jets.

CHANGING CLEANING HEADS

The cleaning jets must be in the full down position before

removal.

1. Attach the Jet Removal Tool to the pool pole

2. Snap tool into the jet

3. Turn counter-clockwise to release head from

collar

4. Pull and lift the jet out of the collar

To reinstall, simply insert head into collar and turn

clockwise to lock into position.

TROUBLESHOOTING

If the Blue Square Q360 cleaning system displays the following actions, adjustments may

be necessary to restore performance. Refer to exploded parts diagram for part

references.

Action: Dirty Spots appear

Solution: Clean the pool filter, pump basket and skimmer baskets.

Make sure all auxiliary valves (surface returns, waterfall, spa overflow, etc.) are closed.

If you have a variable speed pump, check to make sure the pump is running at a

sufficient RPM as recommended by your pool builder.

Action: Dirt is trapped between heads

Solution: Verify that the water flows from the jet nozzle on each side of dirty spot are not

apposing one another. To change the cleaning jet flow direction, press the jet down 5-6

times while it is in the up position and the water is flowing out of the nozzle.

Actions: Cleaning jet advances, but is not cleaning, (dirt remains near the jet.)

Solution: Remove the cleaning jet with the jet removal tool. Check for debris lodged in

the nozzle. Make sure the jet freely travels up and down and ratchets slightly each time.

If the jet does not, hold the jet in the up position and rinse with water to dislodge internal

debris. Run the pump, while the jet is removed, a full cycle until you see water flow out of

the opening on the problem bank. Let the system run without the jet until you are certain

that all of the debris is blown out of the pipe. Re-insert the cleaning jet with the jet

removal tool.

Action: Cleaning jet will not go down

Solution: Try to gently touch the jet with the pool pole to see if it will retract, if the jet

retract let the system run and see the problem is solved. If the problem recurs, remove

the jet with the jet removal tool. Inspect the cleaning head and collar for or debris. Run

the pump, while the jet is removed, a full cycle through the problem bank, to blow out

any debris. Re-insert the cleaning jet. On variable speed pump applications, you may

need to increase RPM’s to ensure jet fully ratchets to next position.

Page | 11

V14612INSLM

To replace the Cassette in the water valve:

1. Turn pump off

2. Loosen the bolt on band clamp and remove the band clamp and clear lid.

3. Remove the turbine and old cassette by sliding them off of the center shaft.

4. Install the new cassette by sliding it onto the center shaft. Spin the gears and make

sure the cassette drops all the way down and the lower gears engage with the gear

train on the housing perimeter.

5. Place the turbine on the center shaft gear side down. Make sure the gear on the

turbine engages the upper gear on the cassette. Spin the turbine several times and

observe the white bottom plate is slowly turning. If it does not the cassette is not in

the full “down” position and the lower gear is above the gear train on the housing

perimeter.

6. Check positioning of large 0-ring on the clear lid.

7. Align the center shaft on the guide pin hole in the center of the clear lid and gently

push the lid down. The lid should seat firmly seat on the top of the valve housing with

no wobble.

8. Replace the band clamp and tighten the bolt firmly. Do not over tighten.

Thank you for purchasing a Blue Square Q360 In-Floor Cleaning System! With over 20

years of pool building and in-floor knowledge, this system was designed with you and the

homeowner in mind. This cost effective and efficient system is truly innovative with a very

simple approach to installation and repair; making it easy for the homeowner to keep

their pool clean and, should there be a problem to arise, easy to fix. We are here to

answer questions, resolve issues and provide exceptional customer service.

Blue Square Manufacturing, LLC

525 East Baseline Road

Suite 107

Gilbert, AZ 85233

Office 480.612.6880 Toll Free 800.277.4150

sales@bluesquaremfg.com

Other manuals for Q360

1

Table of contents